this weeks assignment is to use composite materials. I want to use fiber glass and epoxy resin to make wall tiles.

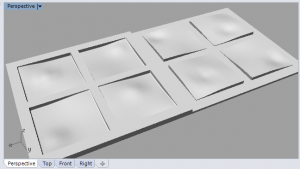

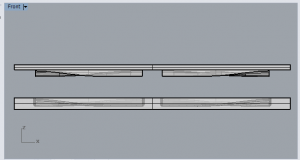

i want to mile a mold from MDF with the shopbot. I designed a mold in rhino. It is for four tiles and made of two parts so i can press the fiberglass with the resin.

it is important to make the part that press smaller so their will be enough space for the fiberglass. i offset it in 3 millimeters.

I made .stl file to run on the shopbot and started milling.

Before adding the fiber glass, i applied wax so i can take the cast out.

i cut the fiber glass sheet to the size of the mold and applied 4 layers with epoxy resin between each layer.

Then i cut the part that came out of the mold.

I applied nylon sheet on top of the fibers and close the mold with some vise.

Afer 24 hours i opened the vise and the upper side of the mold and took out the cast( something like 20 minutes work…)

Then i painted it white with spray to have a better look of the quality of the cast.

Some thoughts for the next mold:

1. use a more compressed M.D.F., like colored M.D.F. to get a smoother surface

2. apply another layer of smoothing material like Epogel or Gelcote and sand it with a very delicate sand paper before casting.

.