Week 16 – Applications and Implications – Shmulik Bilgoray – Douglas Anderson

The project we are proposing is a flying hexocopter with a spray can and trigger mechanism mounted so that it can paint ˜graffiti art” on high walls. The final and ultimate goal is for this copter to fly automated on pre-defined draw-paths.

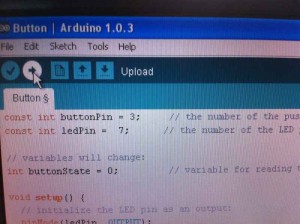

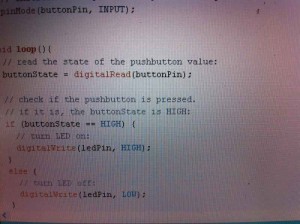

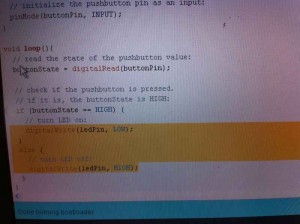

A preliminary goal for the project, particularly on the time-frame of the FabAcademy is to design, construct and test the spray and trigger mechanism. This includes the physical trigger mechanism with its motors, the control/driver chips (could be the hello bridge) and an input device. The input device may range from something as simple as a button or button on a radio transmitter (similar to a controller for the hexacopter) or to such things as proximity sensors, light sensors etc.

A further sub-goal is to construct the shop-bought Y6 hexacopter, mount the spray mechanism and conduct test flights.

Potentially, but not necessarily within the time frame, we may also be able to program flight paths initially with GPS waypoint plotting and then further develop a fine-resolution system for positioning and feedback adjustment.

Whos done what beforehand?

-Similar projects in existence:

While there have been projects developed dealing with automated graffiti art and numerous projects that deal with automated flying machines, no evidence has been found of projects that combine the two fields as is intended here. The success of this project has many implications for further projects that may utilise the technology for other purposes. Documented graffiti art projects include the Tag Bot

-Experience of group members

Group member Shmulik has had some experience with constructing and operating flying vehicles. Aside from this, this project is being approached with only the skills gained from the FabAcademy 2013 course.

What materials and components will be required?/Where will it come from?/How much will it cost?

What parts and systems will be made?

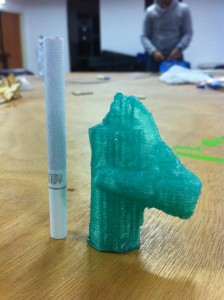

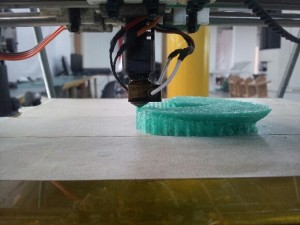

The Trigger Mechanism

The trigger mechanism will be made and will include a number of sub-systems:

The Mechanical trigger mechanism includes an aluminium structure, levers, pulleys and steel cable. The motors with be 12V DC motor with gear head ratio 100:1. The motors will be mounted onto the trigger support arm and will need to be driven by H-bridge boards (to be made). The H-bridge board/s may require additional control in the form of a Fabduino or similar that will interpret the input signal (sensor, button etc.) and transfer the output signal to the driver boards. We may choose to employ a signal transmitter and receiver board/s to remotely transfer this trigger input for the initial testing. This would allow a greater understanding of the final arrangement to be made.

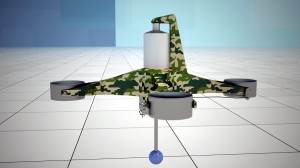

Constructing the hexacopter

The shop-bought hexacopter will arrive in kit form and will need to be assembled. This process will allow assessment as to which parts may ultimately be replaced by custom-made parts

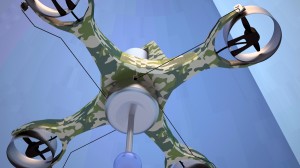

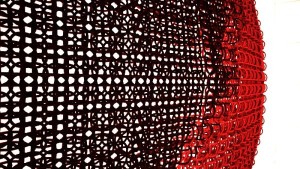

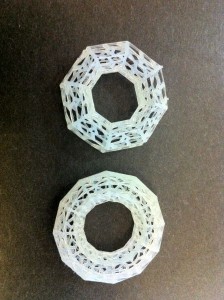

Propellor Guards

Propeller guards will be needed for flying in close proximity to walls or other objects and will be constructed during the following weeks.

Navigation System

A navigation system will ultimately be made for the flight path and spray trigger. This will be developed and potential methods explored over the coming weeks. This will undoubtedly include sensors and emitters providing input for a feedback responsive system, that will be capable of navigating with a precision sufficient to write legibly over reasonably small areas.

What processes will be used?

Numerous processes will be used during the construction and testing of the hexacopter. These may include but are not limited to the following:

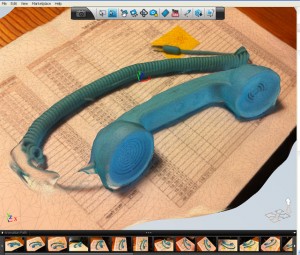

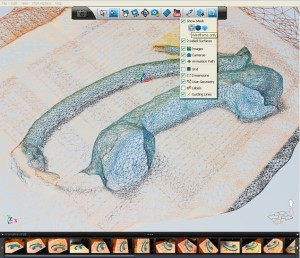

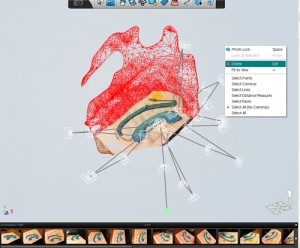

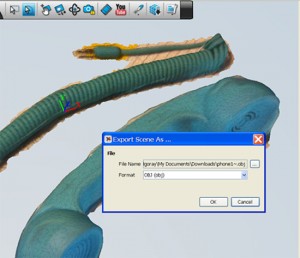

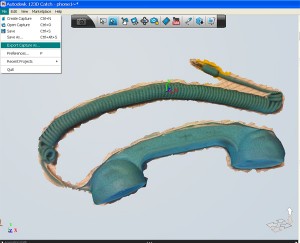

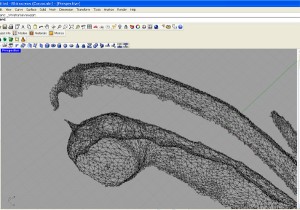

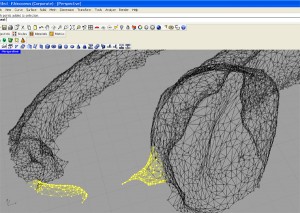

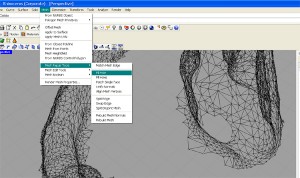

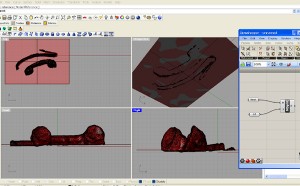

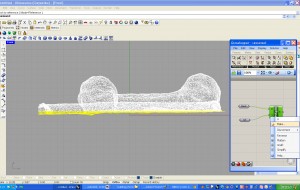

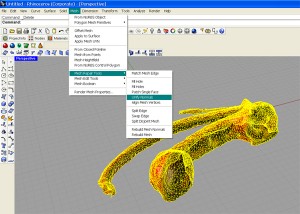

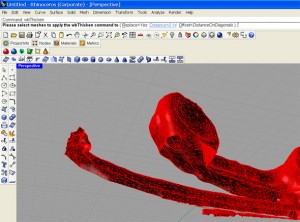

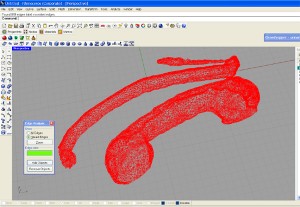

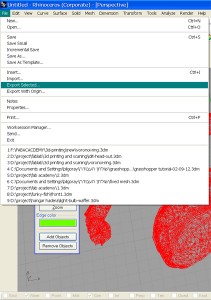

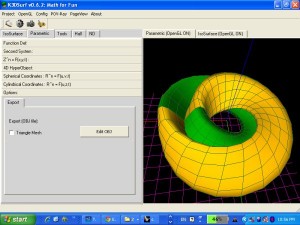

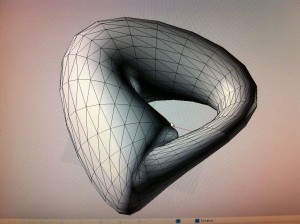

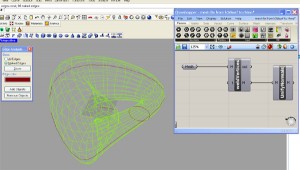

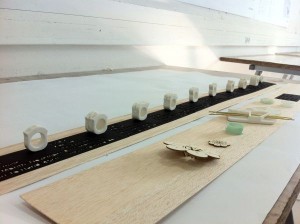

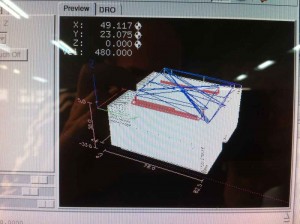

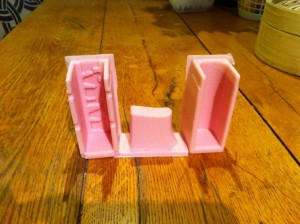

Computer Aided Design

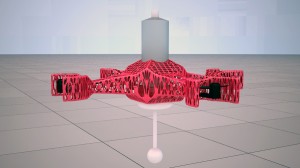

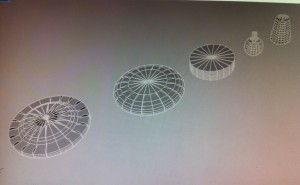

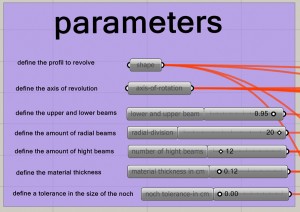

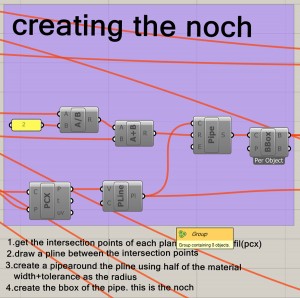

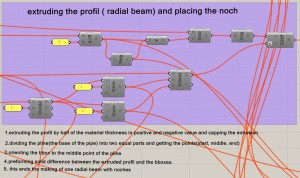

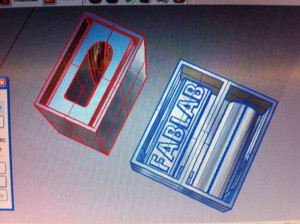

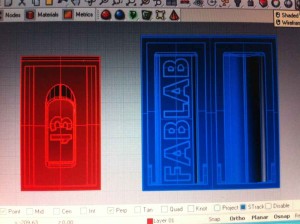

The trigger mechanism will be designed and modelled in both Rhino and eventually Solidworks for animation. The CAD files will be used to test various styles and sized eccentric arms that will provide the lever for the spraying of the paint can. The entire Copter will also be modelled and sliced in order to make a lazer-cut layered model for testing and visualisation.

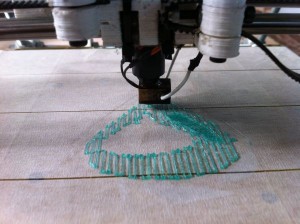

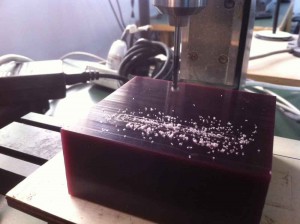

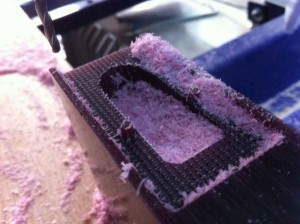

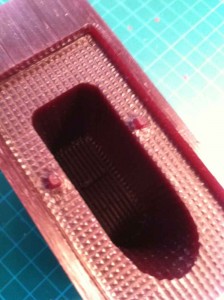

CNC-Milling

The Aluminium components used in the trigger mechanism and structure will be milled from stock aluminium sheet and/or square tubing. This may be conducted on the shopbot and/or the Sherline CNC.

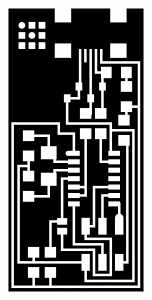

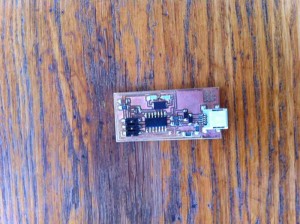

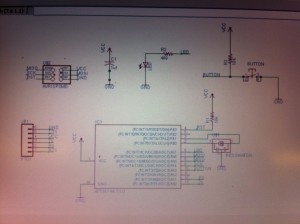

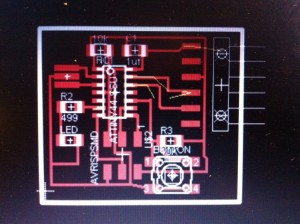

Electronics Design -

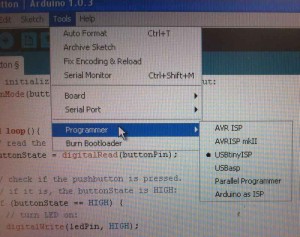

May be required in order to design and construct a signal transmitter and receiver board for initial set-up of the trigger mechanism.

Electronics Production

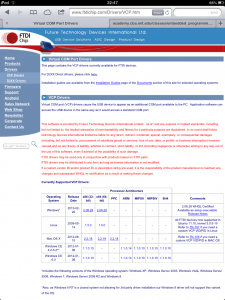

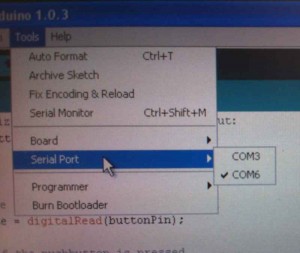

Initially, there will be the requirement for electronics to drive the trigger mechanism motors, send and receive signals and potentially more to process the complex messages. The construction of the hexacopter will include electronics however this will rely on the shop-bought control chips for simplicity.

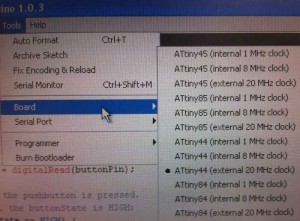

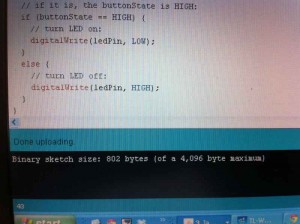

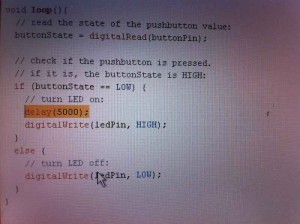

Embedded Programming –

Will drive the DC motors as a response to input signal/s.

What tasks need to be completed?

Assembling the Hexacopter kit

Test flight

Finalising design of the trigger mechanism and control system

Constructing the trigger mechanism and control system

Programming the control system

Designing and investigating the navigation system

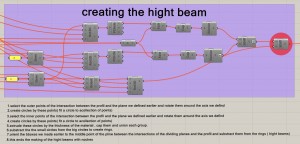

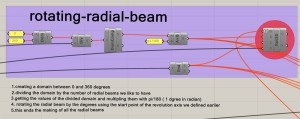

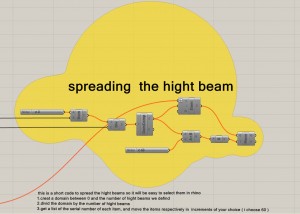

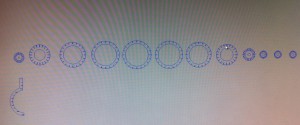

Developing a method for transferring a vectorial 2D design into a flight path

What questions need to be answered?

What profile and dimensions of the trigger eccentric arm will minimise force required (motor torque) and maximise effectiveness.

Will the hexacopter carry the weight of the trigger mechanism

Will carrying the trigger mechanism affect manoeuvrability and function

How will the navigation system be designed and function

How can a 2D vectorial design be transferred into a useable flight path

What is the schedule?

Week 1 -

Assemble Hexacopter

Test Flight

Finalise Design of trigger mechanism

Construct trigger mechanism and control boards

Week 2 -

Programming the control system

Develop communication system and test input devices to trigger spray

Devise an electronics Packaging system for Hexacopter

Test mountig system for Trigger system on Copter

Test flight + test spraying during flight

Week 3 -

Development in positioning system

Deveolp/research mecthod for transferring design into flight path

Test flights with lED and camera to capture path

How will the schedule be evaluated?

Sub-weekly meetings and assessment of the completion/success/failure of assigned tasks.