Week 16 Applications and Implications

Propose a final project masterpiece that integrates the range of units covered, answering:

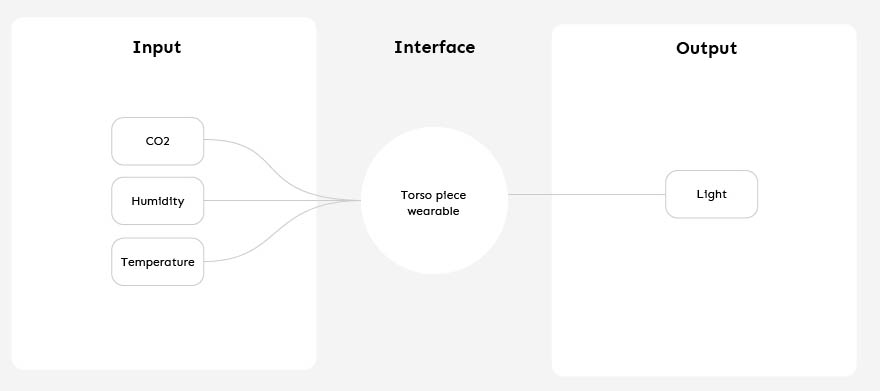

What will it do?

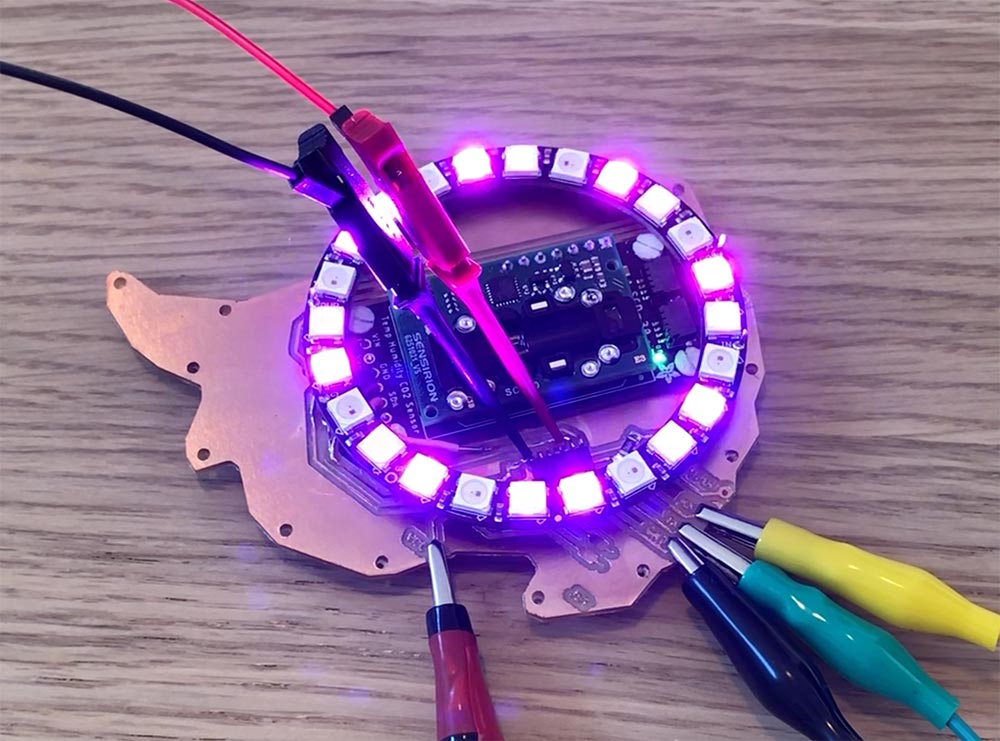

In one sentence: a wearable that visualizes CO2-levels with color. This Fab Academy final project is a wearable sensing device to alert you when you enter a room with high levels of atmospheric carbon dioxide, so you can act upon it.

Why? Sufficient building ventilation and low CO2 levels are important for our health and productivity. In recent studies, CO2 monitoring is also proposed as an assessment tool for determining the COVID-19 infection risk proxy in indoor environments. This project aims to create awareness about the impact of increasing carbon dioxide emissions and stimulates to improve air quality. On the short term, by opening a window, and on the long run by inspiring people to create systemic change towards a post-fossil economy by using and creating renewable energy sources and circular materials.

Who’s done what beforehand?

- Building façade in São Paulo with LEDs visualizing noise and pollution

- Urban Sun, Studio Roosegaarde

- Traditional Frisian costume design and embroidery

- Room CO2 RGB LED matrix portal monitor

- Research paper (2009) on a Wearable sensing application- carbon dioxide monitoring for emergency personnel using wearable sensors

What will you design?

A wearable with an integrated CO2, humidity and temperature sensor and LED output.

What materials and components will be used? Where will come from? And how much will they cost?

| Material | Amount | Vendor | Costs |

|---|---|---|---|

| CO2 sensor module SCD30 | 1x | Sensirion, Switzerland | €44.66 |

| NeoPixel ring 24 RGB LED | 100 x 100 mm | AdaFruit, Brooklyn (NY) | €19.95 |

| Sewable NeoPixels | 1 sheet of 20 | AdaFruit, Brooklyn (NY) | $34.95 |

| Conductive thread 3 ply | 1x | AdaFruit, Brooklyn (NY) | $9.95 |

| Pearl White PLA filament | 1x | Ultimaker, The Netherlands | € 33,00 |

| Biomaterials: glycerine, gelatine, food coloring | 1x | The Netherlands | €15,00 |

| Small electronics components: ATtiny1416, UPDI, FTDI, etc. | 1x | DigiKey ordered by Waag, The Netherlands | €15,00 |

| Copper sheet 100 x 100 mm | 1x | Waag | ? |

Not used and/or for prototyping purposes:

| Material | Amount | Vendor | Costs |

| Shinyei Model PPD42NS Dust Sensor | 1 | Seeed Studio | Second-hand, new prize €15 |

| Arduino Uno | 1 | Arduino | Second-hand, €20 before tax |

The CO2 sensor is the most expensive component of the system. For the final project, I will make a small Life Cycle Analysis of all components and materials used.

What parts and systems will be made?

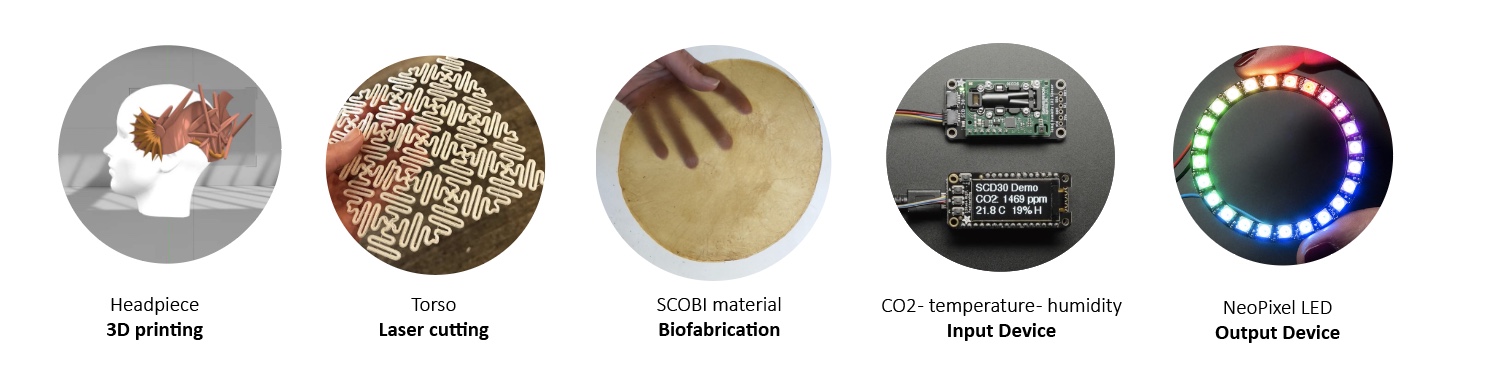

The pattern. The circuit board. The materials. Basically everything except for the sensor and LED ring.

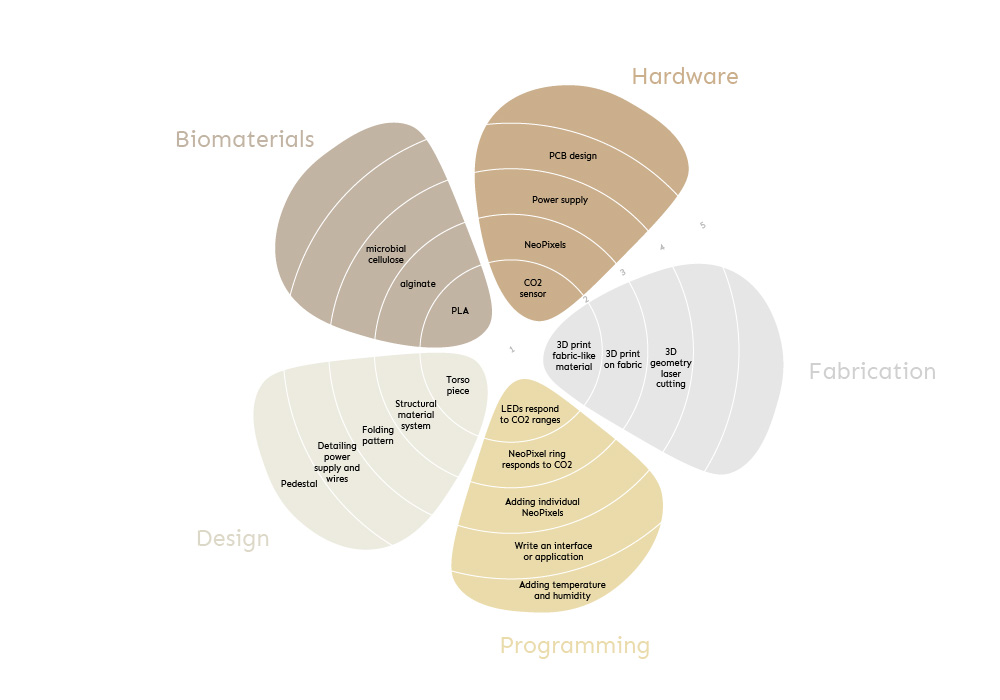

I designed the Five Spiral Flower Diagram to provide guidance in working through the separate components of the final project. This is divided in Design, Hardware, Fabrication, Programming and Biomaterials. In the center, you can see the first spiral. Moving outward, more functionalities are added.

The power supply of the wearable will be organized in two ways: a demo mode (approximately 2 hours) and action mode (full day - 8+ hours). Electronics and wiring is integrated as much as possible. The conductive thread will be visible however, so I’ll design this in a way to make it look interesting.

What processes will be used?

Computer Aided Design, laser cutting, biomaterial fabrication, casting, 3D printing, electronics production, PCB milling with Roland Modela, embedded programming.

What questions need to be answered?

I already finished the programming of the CO2 and NeoPixels during output devices. During wildcard week I experimented with various (bio)materials and materials systems. This informs the overall design of the wearable. Two questions are remaining:

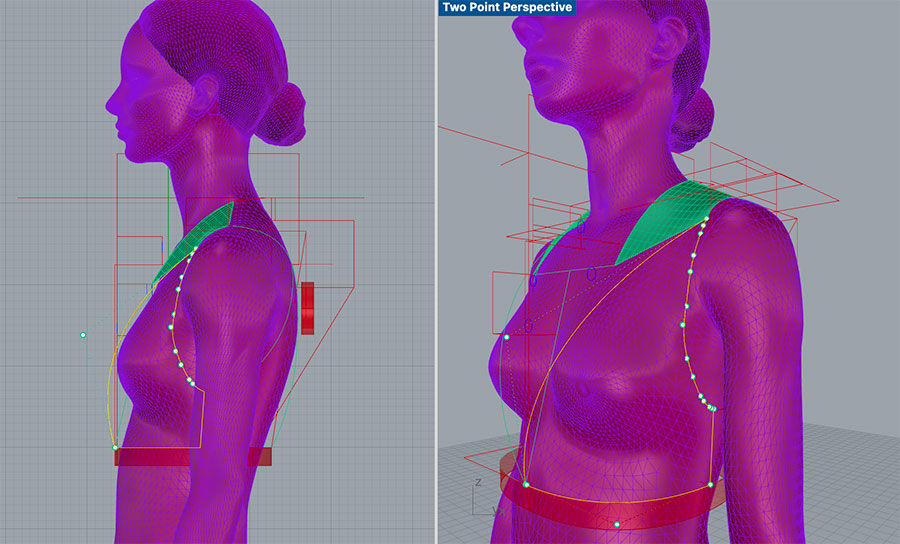

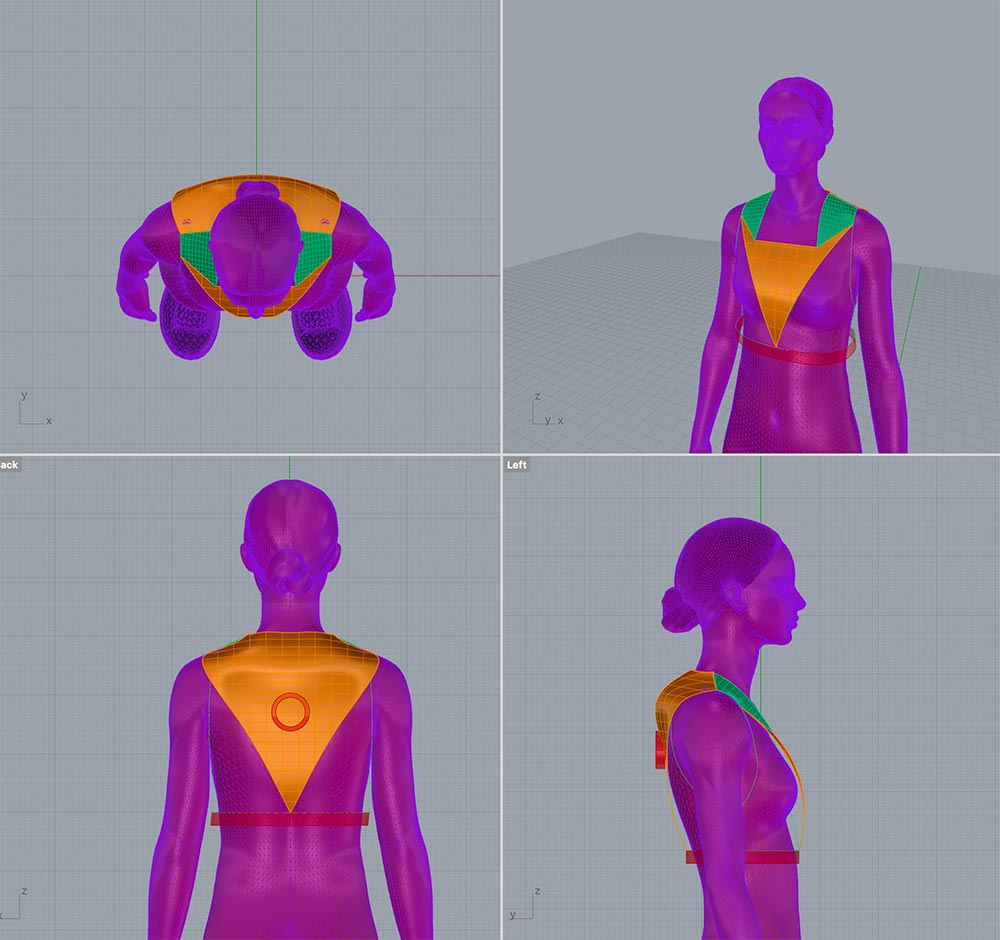

1) Design: how to design a good pattern? There were some limitations in Rhino, so Michelle recommended to work with Clo instead. I’m totally new to fashion design and it’s quite a steep learning curve to design in a new software application.

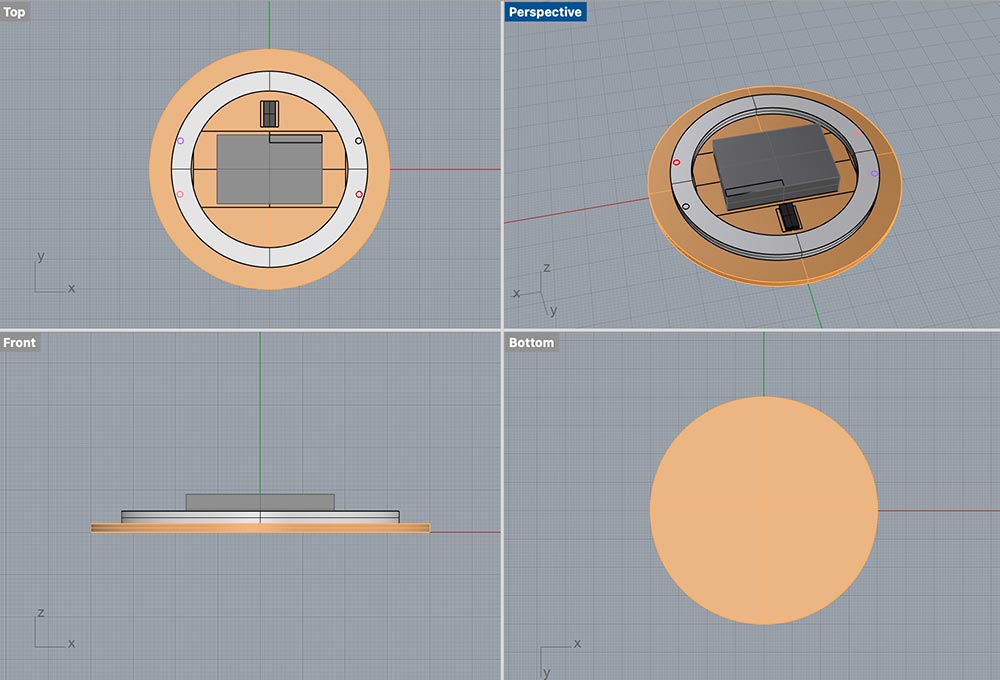

2) System integration: how to make the core PCB as small as possible? What components can I leave out? Is it still robust enough?

How should your project be evaluated? How to know if it succeeds or fails?

The electronics can be evaluated by its technical functionality: if the sensor works and if the NeoPixels respond accordingly to changing indoor CO2 levels. The same applies to the evaluation of the pattern design and the fabrics production. Is it finished and does it fit?

Regarding the wearable’s aesthetics, it is not intended to be a product that will be mass-produced, rather it is an artistic expression to create awareness. How do you evaluate art? That’s an intuitive process based on subjective impressions. But of course I want to make something that looks good!

Project requirements

Your project should incorporate:

- 2D and 3D design

- additive and subtractive fabrication processes

- electronics design and production

- embedded microcontroller interfacing and programming

- system integration and packaging = about hiding wires :)

Other requirements: where possible, you should make rather than buy the parts of your project. Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.