♦ Molding and Casting ♦

This week is all about molding and casting .On wednesday's lecture Neil gave brief about different material of molding and casting and also processes used for molding and casting.After Neil's lecture on next day our instructor komal ma'am and aditi told about how to make design and which parameter should be used for molding and casting.Aditi introduced us about different material.

Please refer group assignment here:

Group Assignment:Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Individual Assignment:design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

Molding:

Molding or moulding is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix.This itself may have been made using a pattern or model of the final object.A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or sets inside the mold, adopting its shape. A mold is the counterpart to a cast.The very common bi-valve molding process uses two molds, one for each half of the object.

Casting:

Casting is a manufacturing process in which a liquid material is usually poured into a mold,which contains a hollow cavity of the desired shape, and then allowed to solidify.The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.Casting materials are usually metals or various time setting materials that cure after mixing two or more components together;examples are epoxy, concrete, plaster and clay.

Group Assignment:

In group assignment task is to read material safety datasheet.In Vigyan Ashram we have different material like Hydrostone,Instamold,Epoxy,machine wax,Moldsil for molding and casting.So we decided to study all materials in group and everyone will share their study material with other.Its not possible to study all material by one person.I got Instamold .

Available material:

Machining Wax

Hydrostone

Epoxy

Silicon rubber

Instamold

Flexwax

It is a Casting Compound,Non-Toxic & Safe to use it can be use for Craft or fine art.It can be used for Preserving,Body Casting,Historical Reproductions,Antique Molding,Repair Hobby Castings,Jewelry Making,Ice Sculptures

Individual Assignment:

For individual assignment I decided to make two positive molds on wax then I will pour silicon rubber .For final product I will use different material like epoxy,bismuth ,hydrostone.So I decided to make stamp design using fusion 360.

|

|

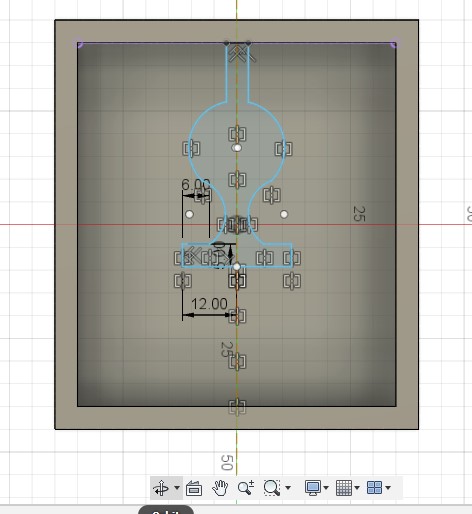

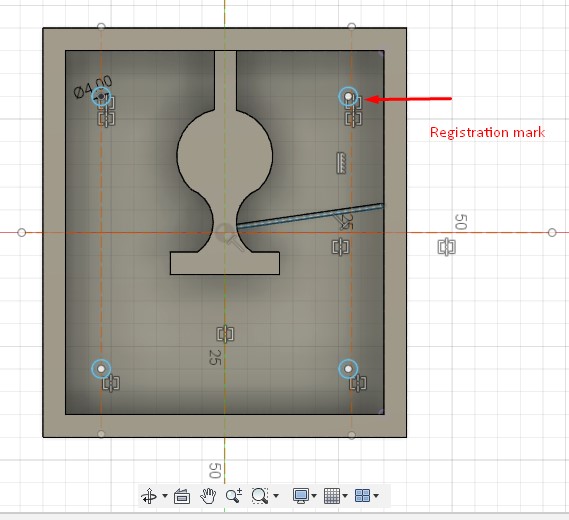

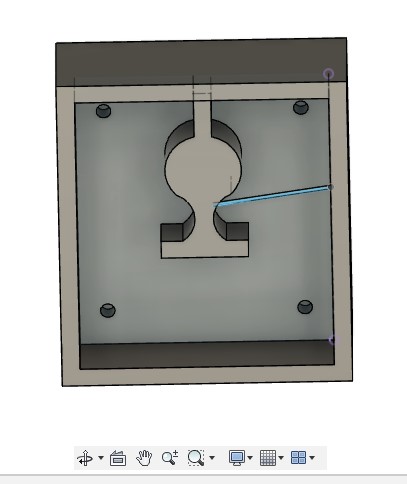

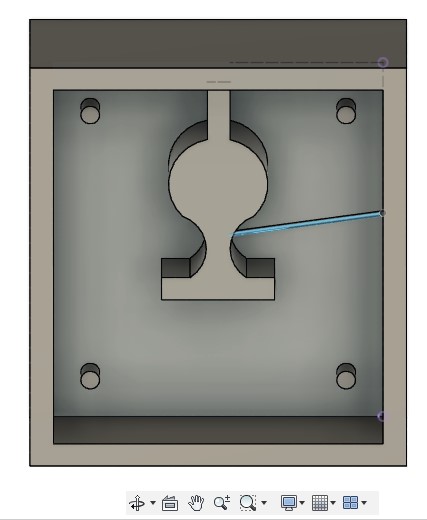

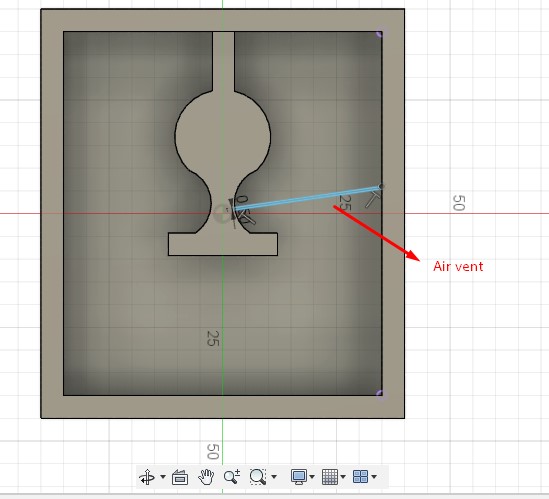

I have made this design using fusion 360. During making of design our instructor told us some tips required for design.As per that instructions I made my design.I have added registration marks and air vent in my design.

|

|

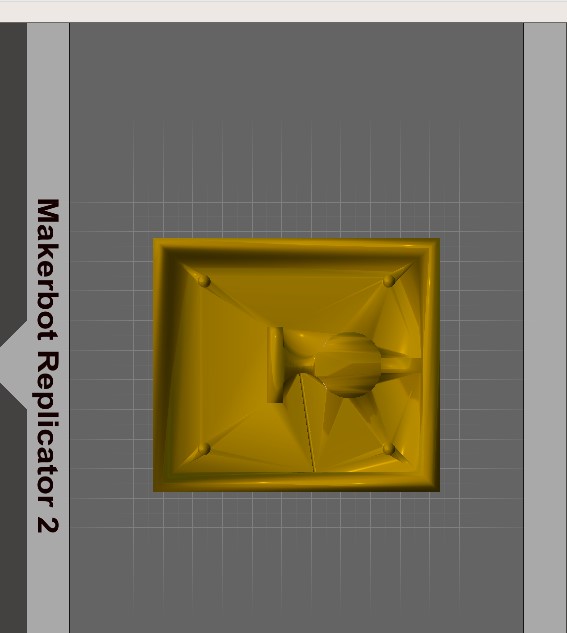

After completion of design I saved design in .stl format.Because for SRM-20 I required .stl file format.Also I chekced my file using meshmixer.

|

|

Machining:

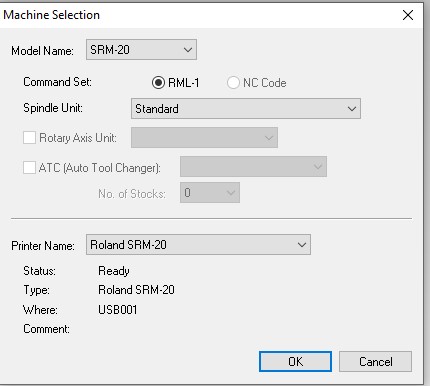

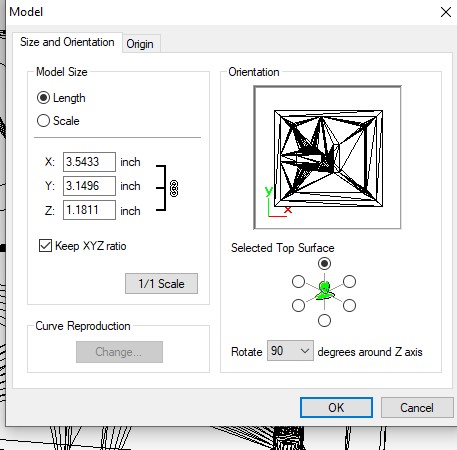

For mold making I have used machinable wax. We have used SRM-20 machine for molding. For mold making we required another software which is modella player and v-panel.Open modella player software.Go to machine selection and select machine as SRM-20.Then go to file,open your file which is in .stl format.

|

|

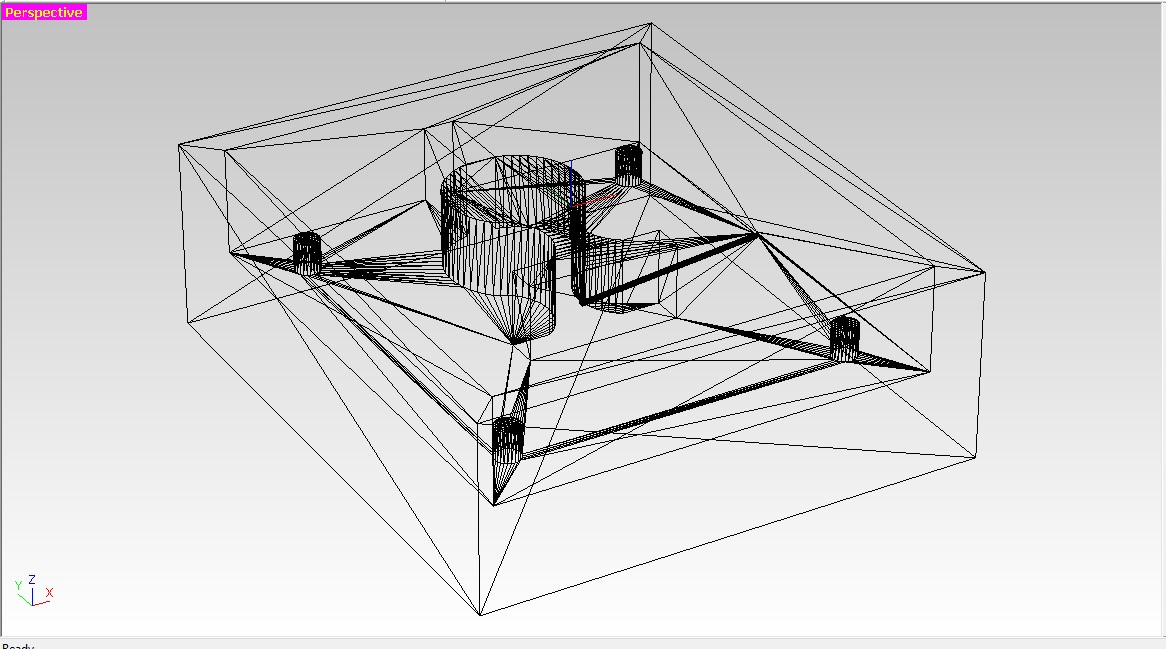

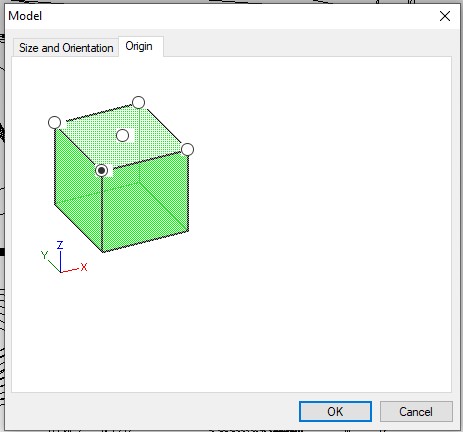

Go to model window and change the orientation.Then select the origin from where you want to start milling.

|

|

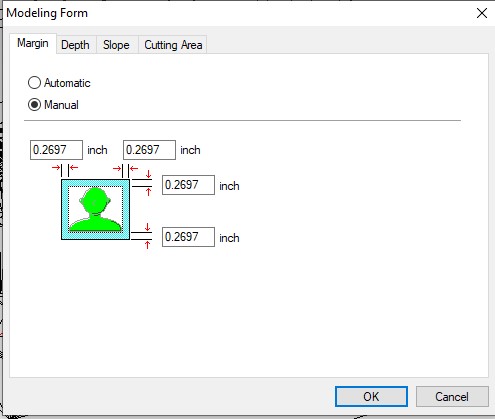

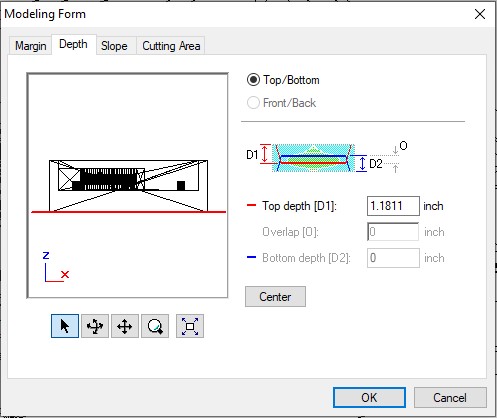

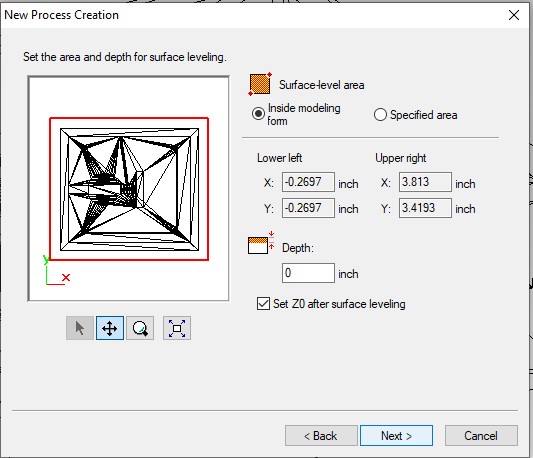

Select modelling form ,go to margin and select manual option.Select depth option and select top/bottom option.

|

|

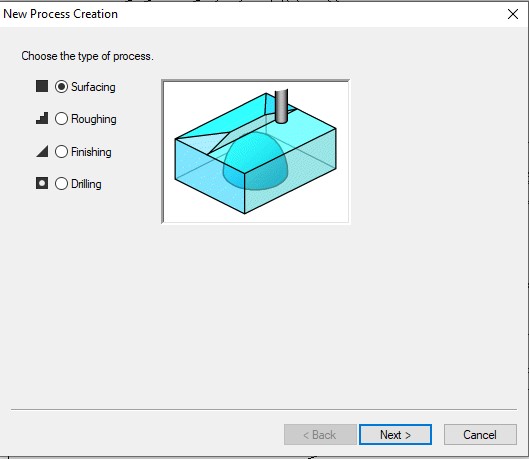

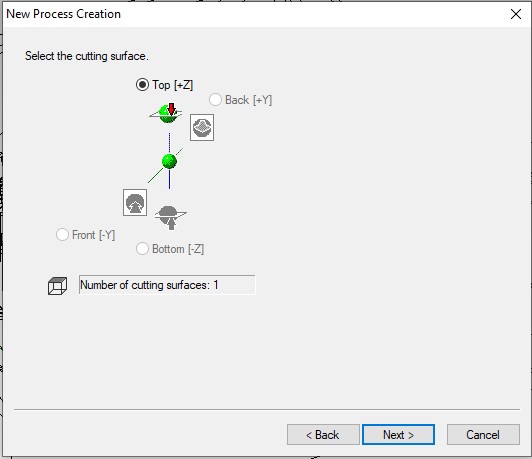

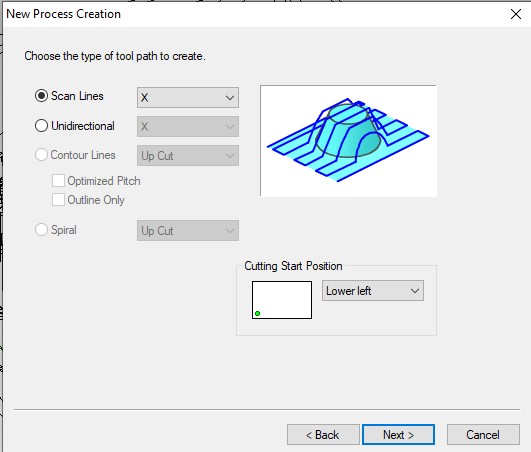

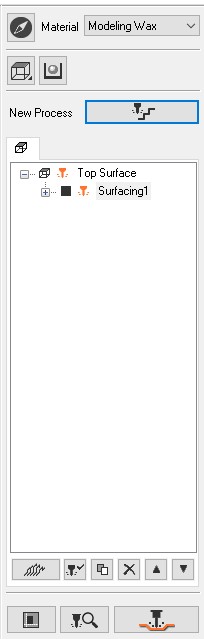

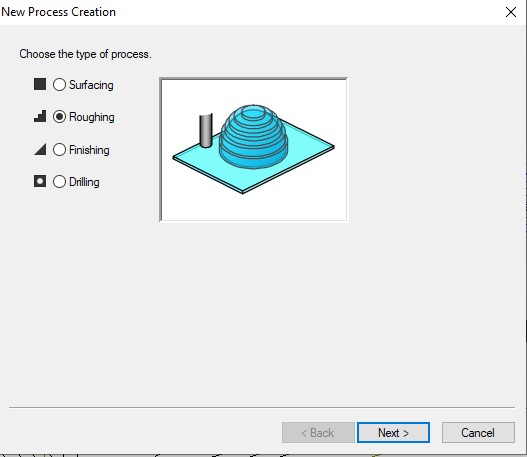

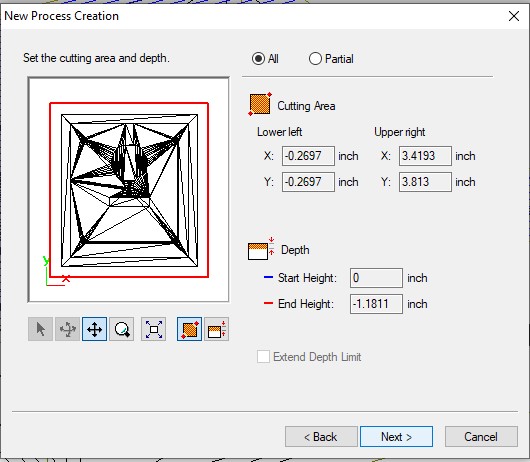

There are three different processes like surfacing,roughing and finishing.First select surfacing option.Then select the cutting surface.I selected it as top surface.

|

|

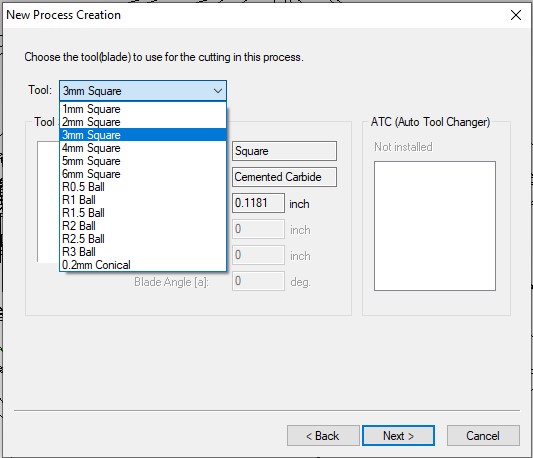

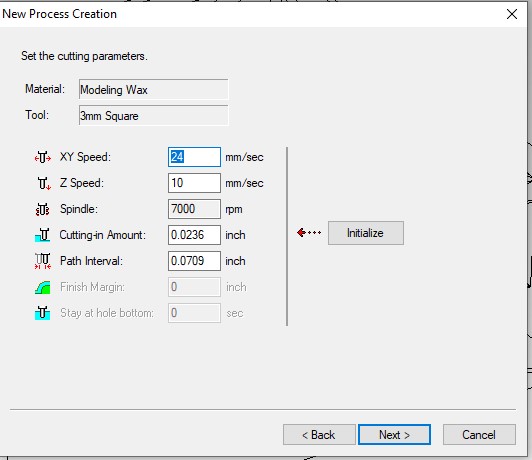

Select tool as 3mm square and click on next second window will come .Again click on next.

|

|

Choose the tool path as scan lines and also set the cutting parameter.

|

|

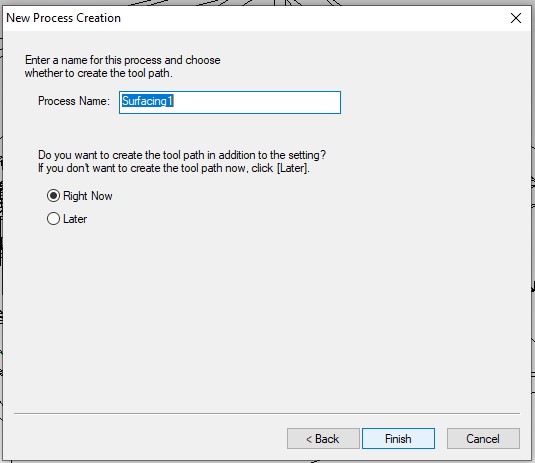

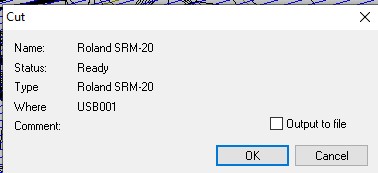

New process will create and click on finish.After that click on cut process option.

|

|

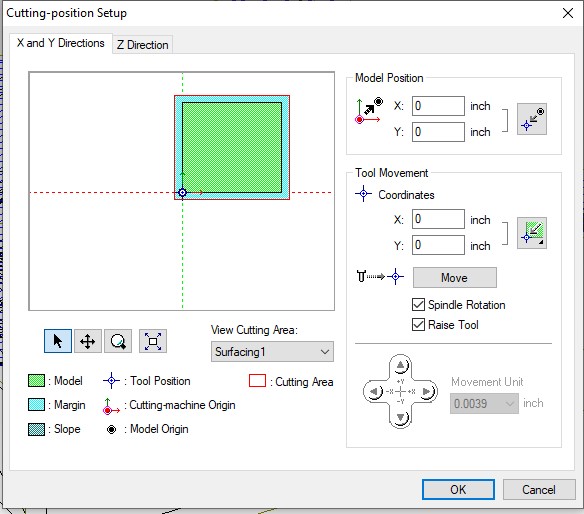

After all these setting this window will come and from this window we will get idea of our object ,from where that will start surfacing or roughing.

|

|

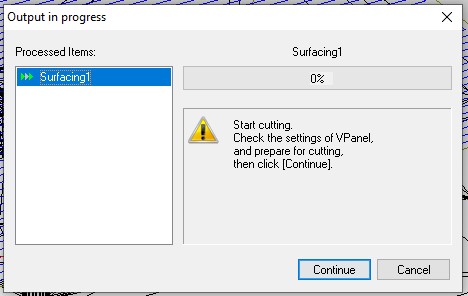

click on continue and it will start molding,before that set the origin using v-panel.

|

|

Repeat the same procedure for roughing and finishing process.

|

|

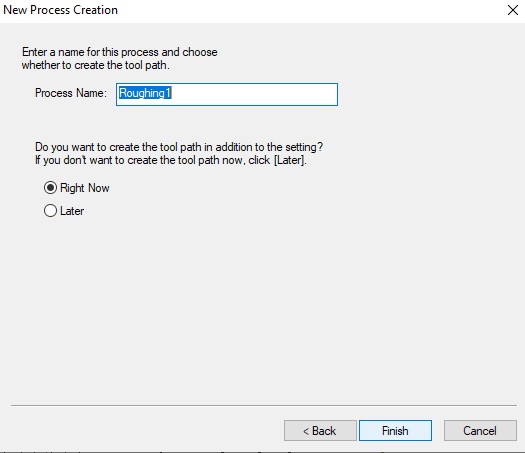

Milling process on SRM-20 machine.

This is the final mold of my design .Now I will do casting .

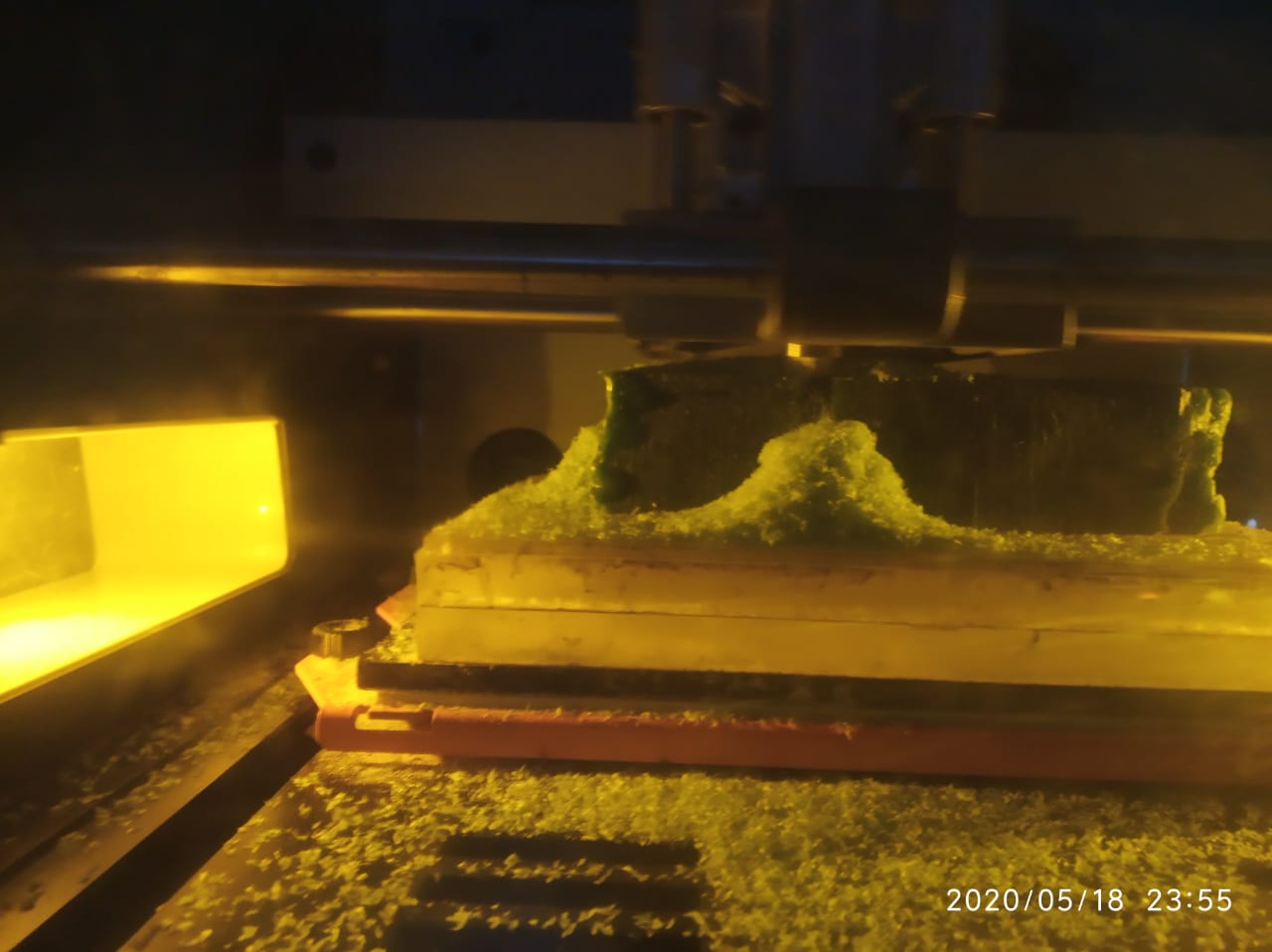

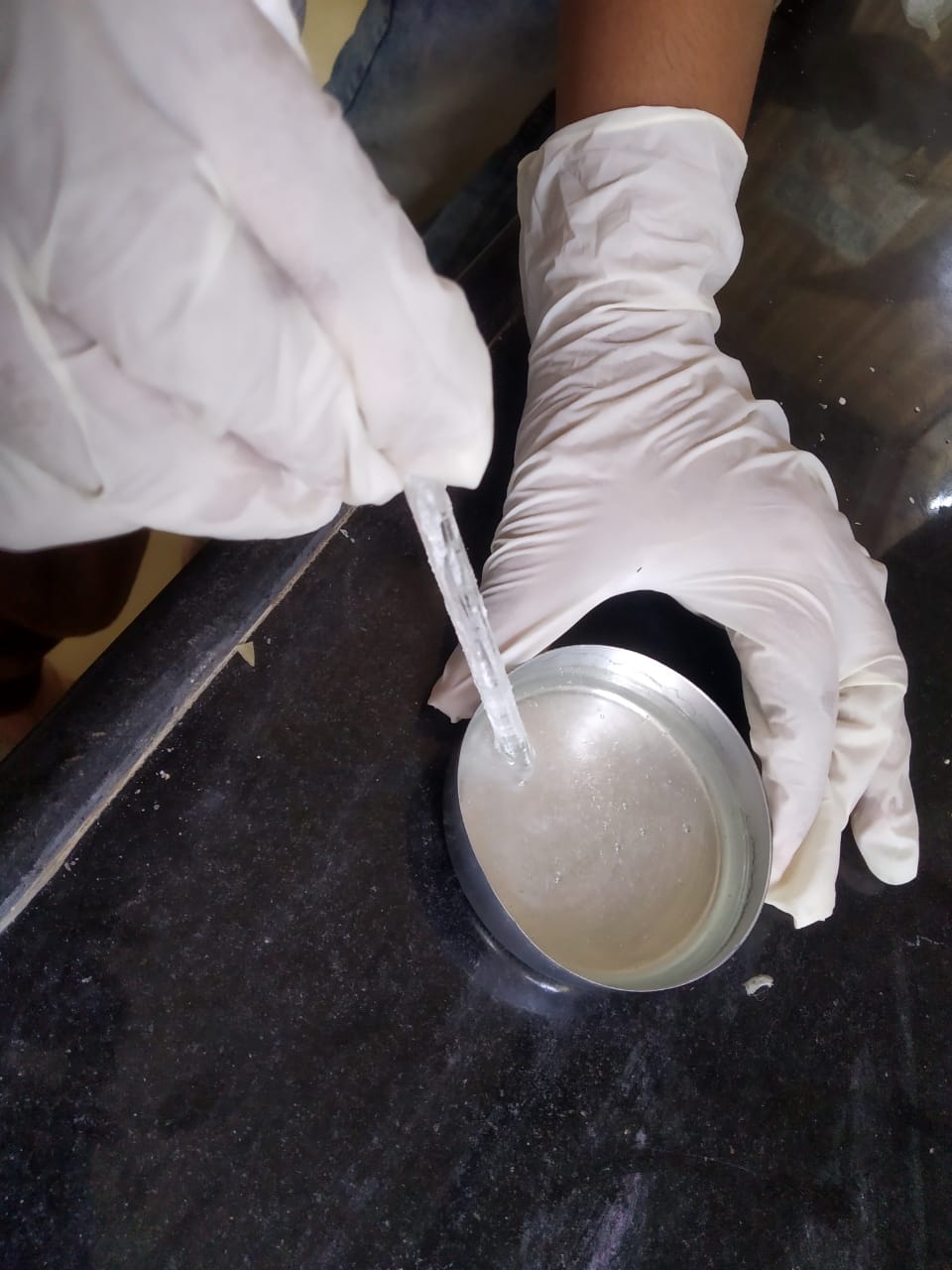

For casting we required silicon rubber flexible mold.So for that we required silicon rubber and hardner.We need to add hardner in silicon rubber by calculation.Take 55% of silicon rubber and 45% of hardner.first take water in your mold and measure how much it is and take 55% of that amout of silicon rubber and 45% of hardner .Add hardner in silicon rubber and mix it in one direction only.Pour it in mold.Remove air bubble.

Mixing of hardner and silicon rubber should be proper.

This is flexible silicon rubber mold.We will add another material for casting

Casting process

For casting I have used hydrostone and epoxy material.For hydrostone it will take less time to set.For epoxy it will take 24 hrs to set.First I have taken hydrostone

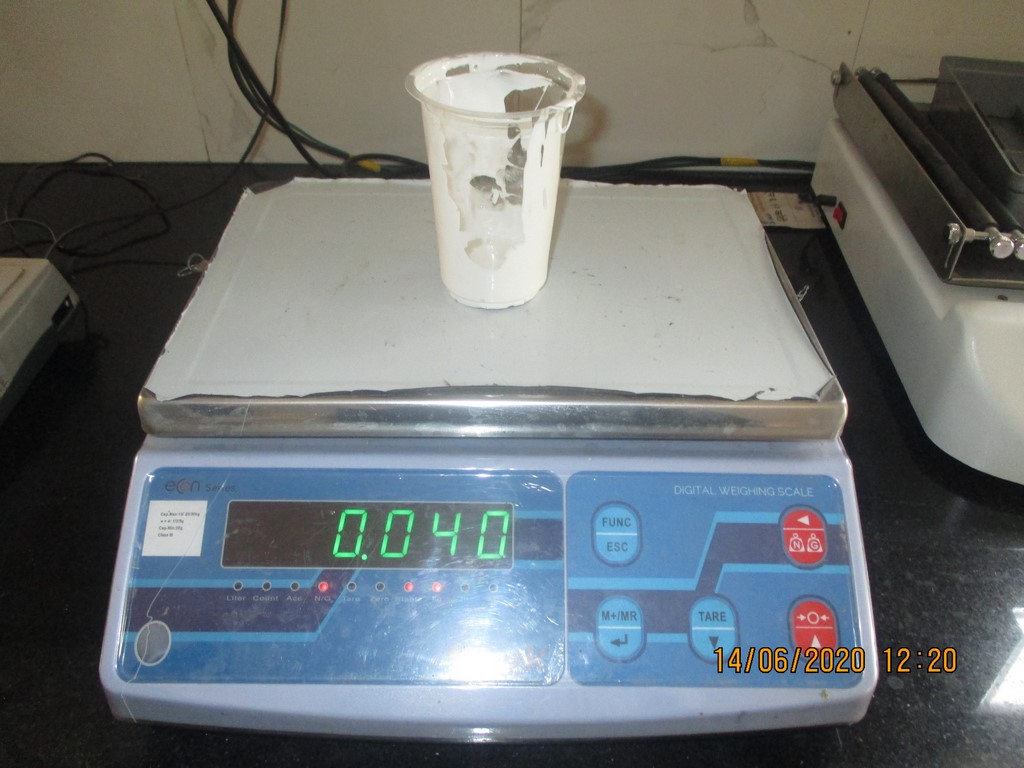

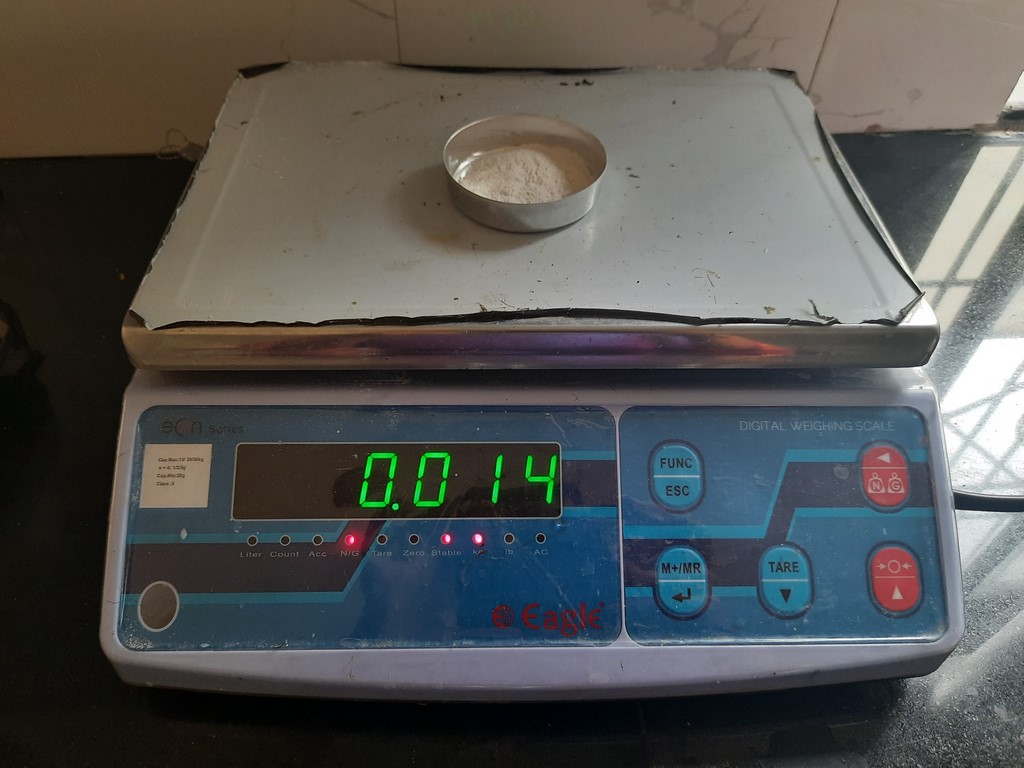

In hydrostone we dont need any hardner,you just need water.For 100gm of powder take 65gm of water.Important thing is add powder to water,dont make it reverse.Mix it properly.

Before pouring material into mold check that mold is sealed properly.Fix the mold in C-vice.Pour the material in mold and keep it for 3-4 hrs.

This is the final object which is cast in hydrostone.

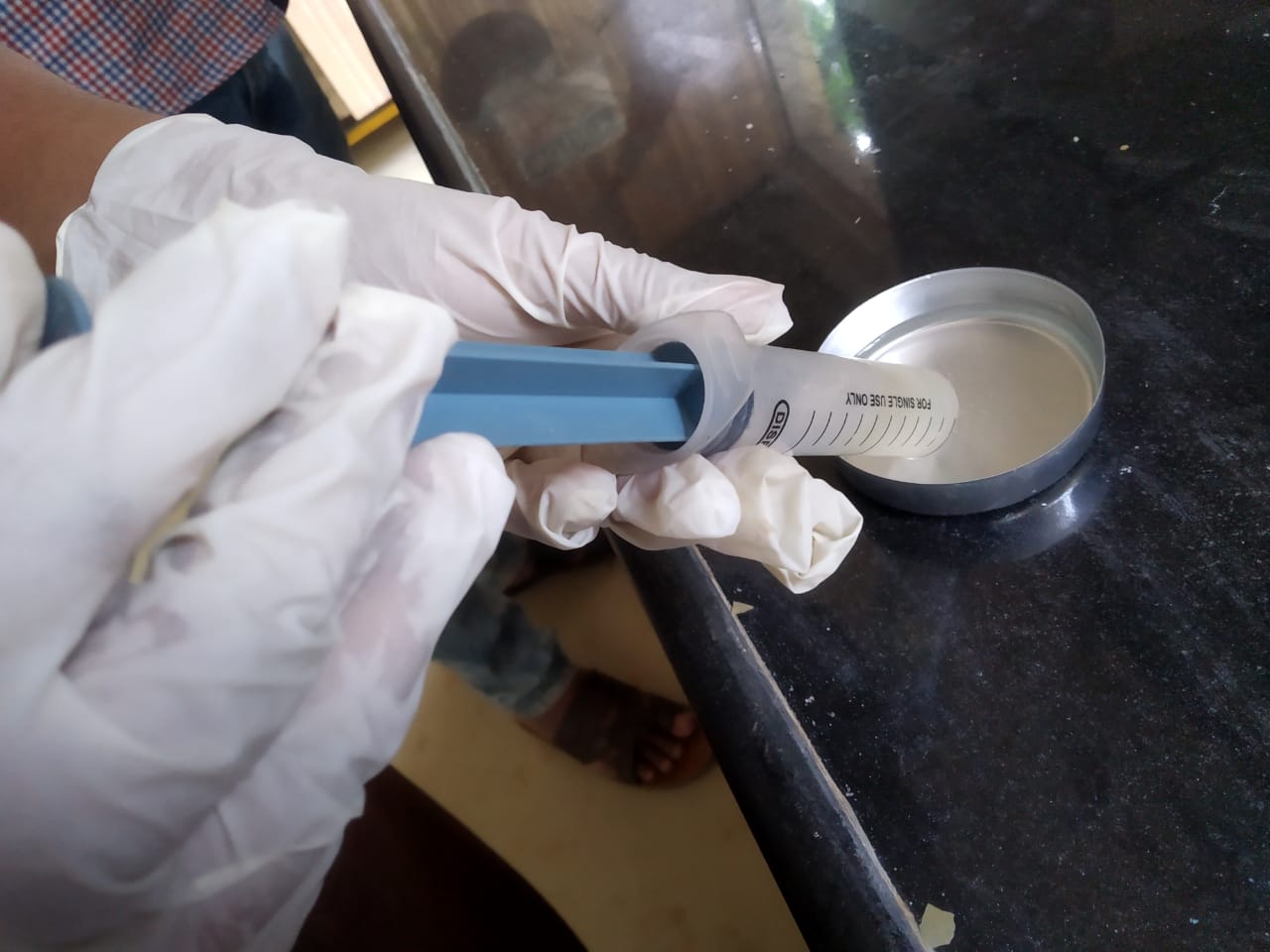

Second material I used is epoxy.For epoxy we required hardner.Take 1:2 propertion of hardner and epoxy.Mix it properly.

To pour the material into mold ,take the syringe.

Pour the material into mold with the help of syringe.

It looks very pretty.It looks transparent.