3D Scanning and Printing

3D Scanning and Printing

Test the design rules for your 3D printer

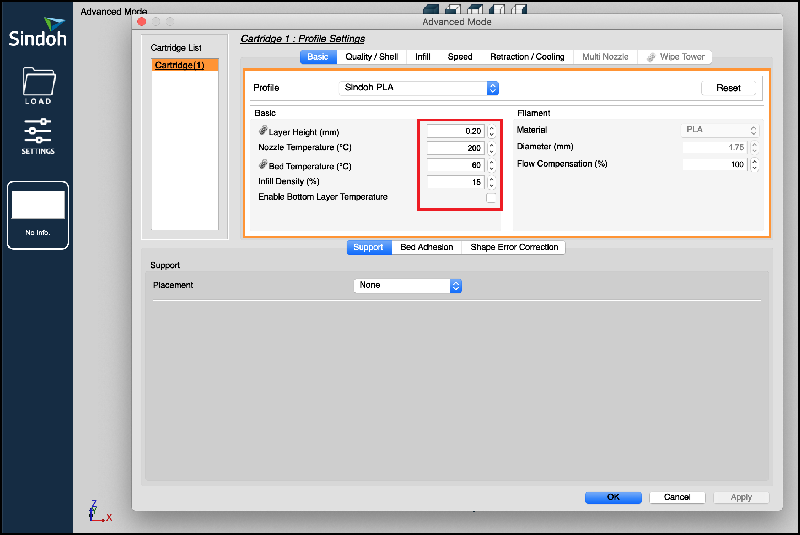

The 3D printer we used is a SindohP200 DP200 specification

We tested with default setting of DP200

Materials are white PLA

I changed the stl file to g code using 3DWorks

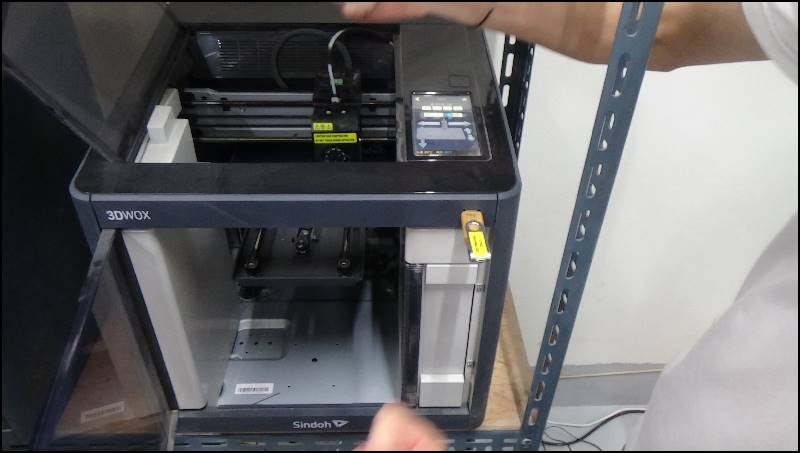

Appearance of DP200

I printed out the design file on USB

Appearance of DP200

I printed out the design file on USB

After everything is done, wait until the bed cools and remove it using tools

After everything is done, wait until the bed cools and remove it using tools

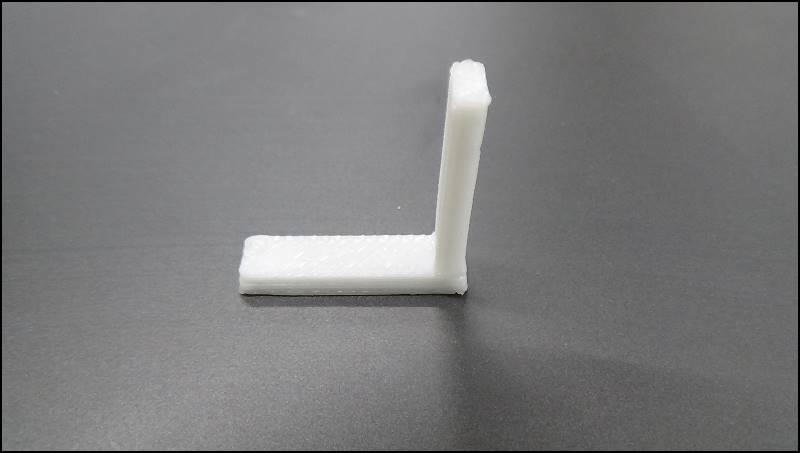

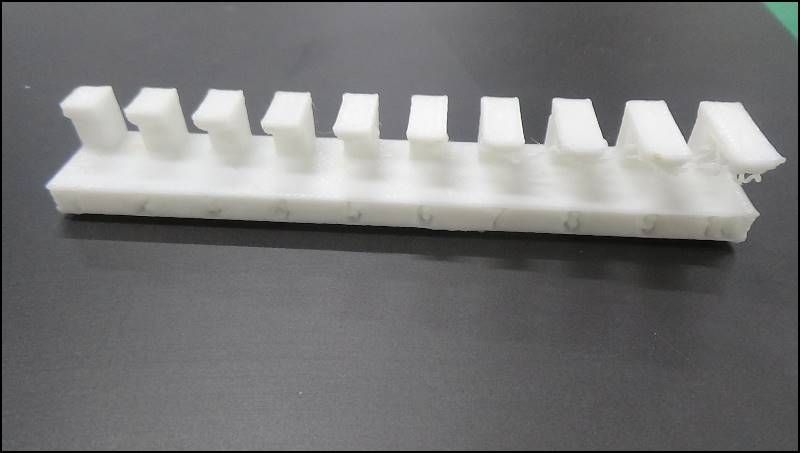

Strength test

We’ve found that for thin, long pieces of work, it’s very strong to print on a bed

Strength test

We’ve found that for thin, long pieces of work, it’s very strong to print on a bed

Support Test

If there is space between the output and the floor, we have confirmed that a supporter is required

Support Test

If there is space between the output and the floor, we have confirmed that a supporter is required

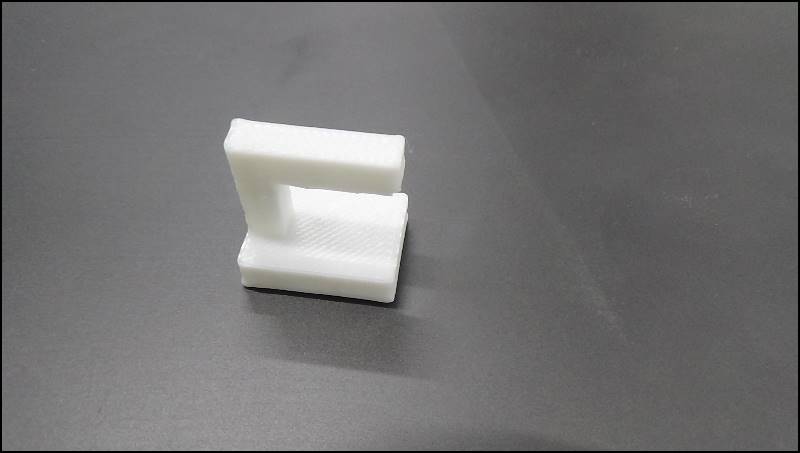

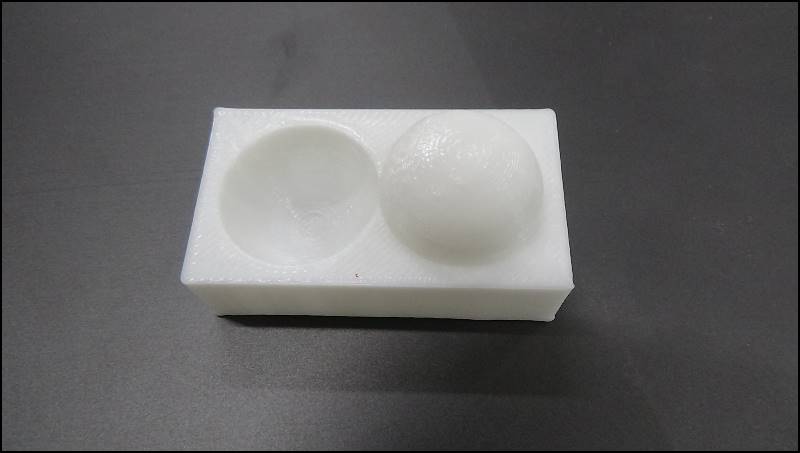

Surface test

Depending on the state of the filament, the bumpy side can occur

To get a smoother surface, you have to lower the height of the layer

Surface test

Depending on the state of the filament, the bumpy side can occur

To get a smoother surface, you have to lower the height of the layer

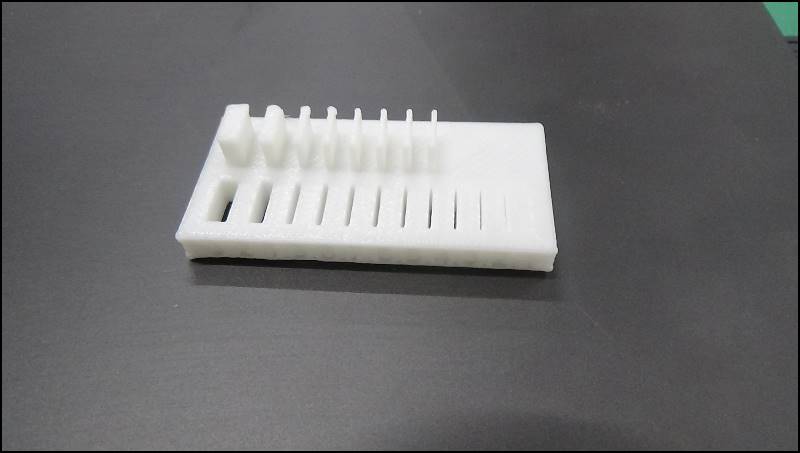

Thickness test

Our printer could be implemented from 0.5mm

The gap could be implemented from 0.3mm

Thickness test

Our printer could be implemented from 0.5mm

The gap could be implemented from 0.3mm

Bridge test

At 8mm, the middle of the bridge began to droop

Bridge test

At 8mm, the middle of the bridge began to droop

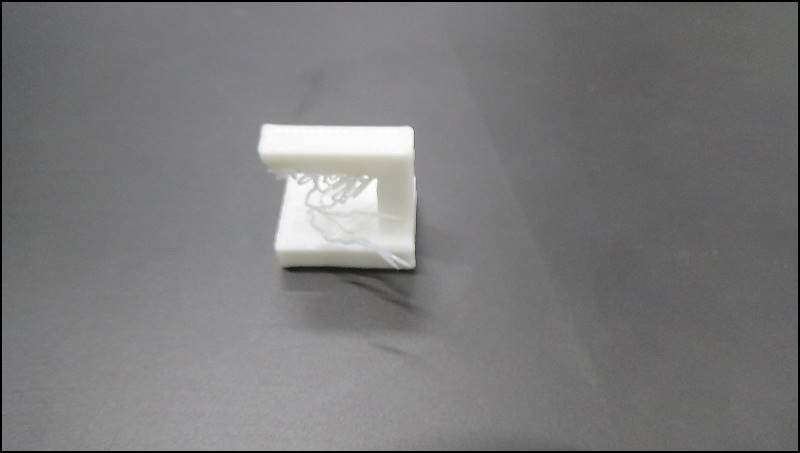

Overhang distance test

Overhang failed from 4mm

Overhang distance test

Overhang failed from 4mm

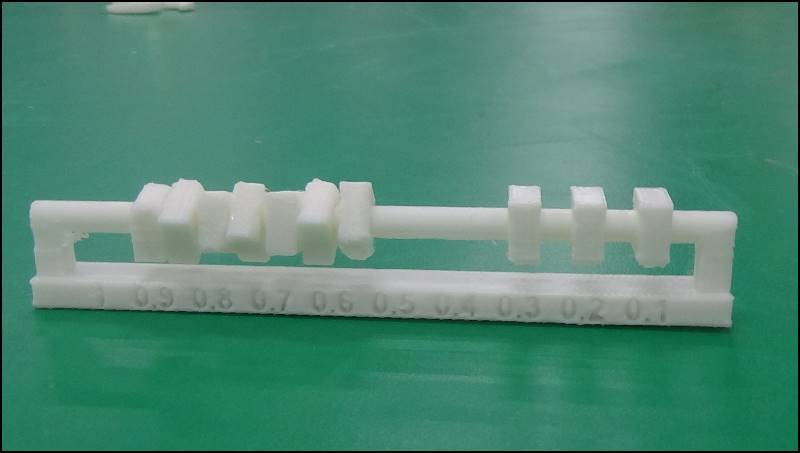

Tolerance test

The fit was right up to 0.3mm

Tolerance test

The fit was right up to 0.3mm

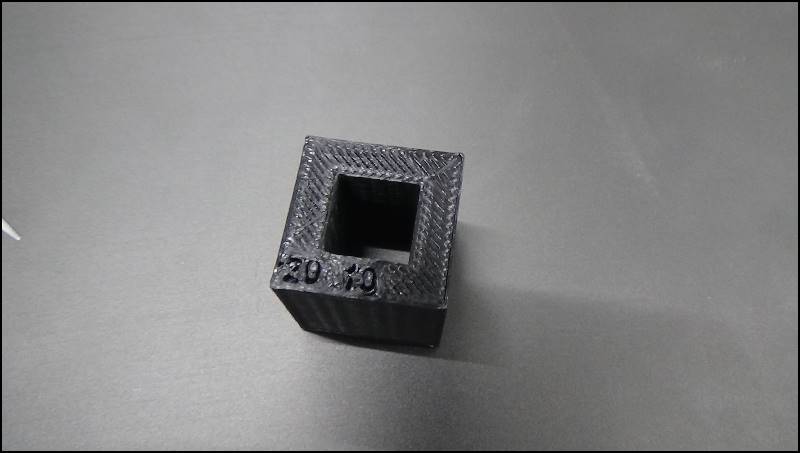

Dimension test

Internal and external errors of 0.05 mm

Dimension test

Internal and external errors of 0.05 mm

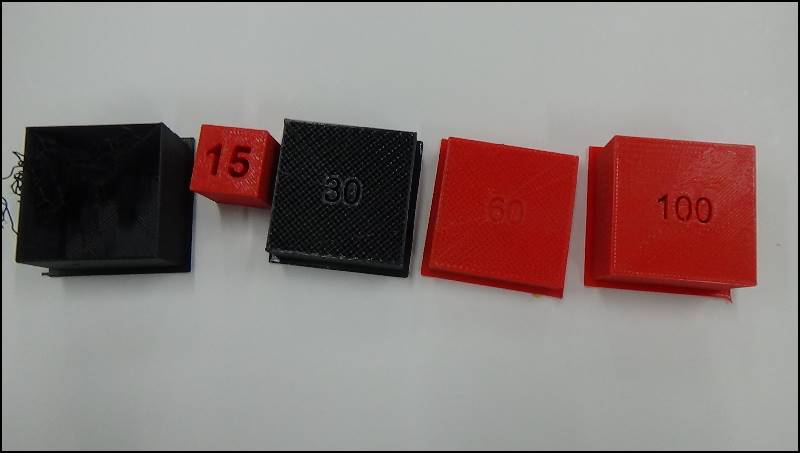

Infil test

Between 15 and 30 percent was enough

Infil test

Between 15 and 30 percent was enough