I was in the second group, You will find my hands in implmentation pictures xD

Parametric design

I made my design in the fisrt on Iluustratot jus to make a quick idea for my Kit, then i went through Fusion360 to make it parametric.

Here the tutorial to start in fusion to create a parametric design. VIDEO And for starting in Ilustrator if you interested.

VIDEO

Let's start ....

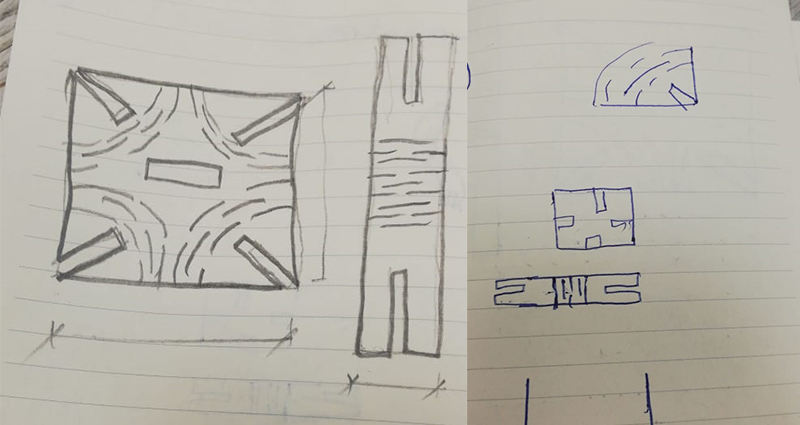

A sketch for the idea, I was trying to add some flexable sides, So i made those dotted lines

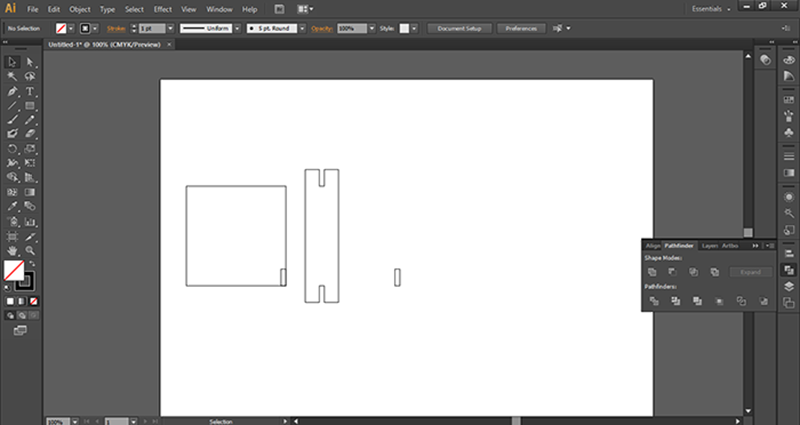

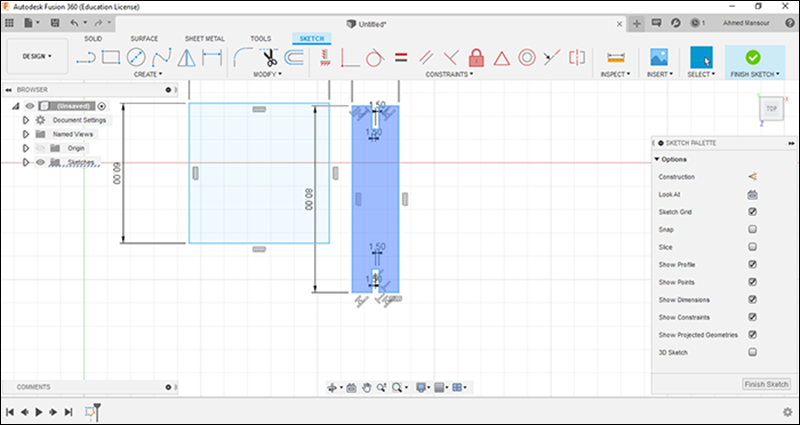

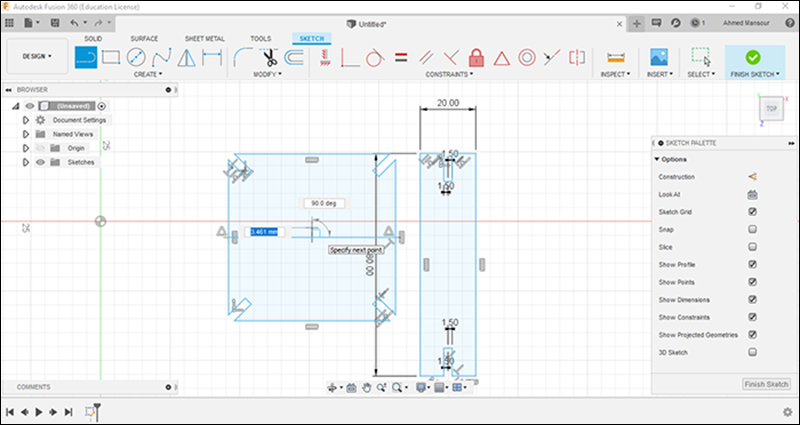

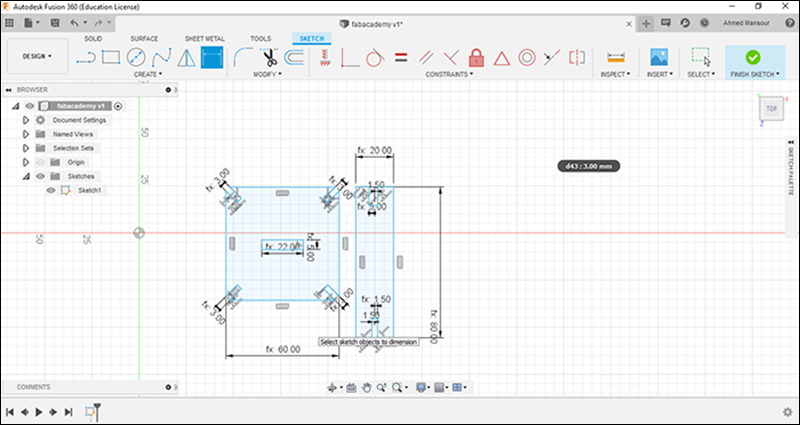

Start with the basic shapes with it's dimenstions

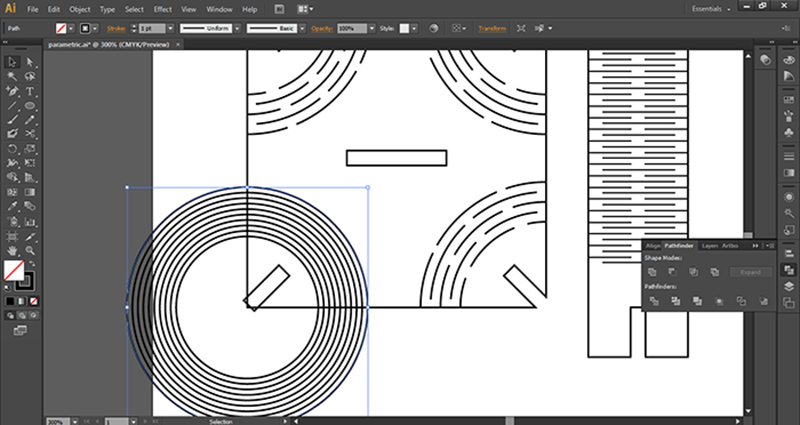

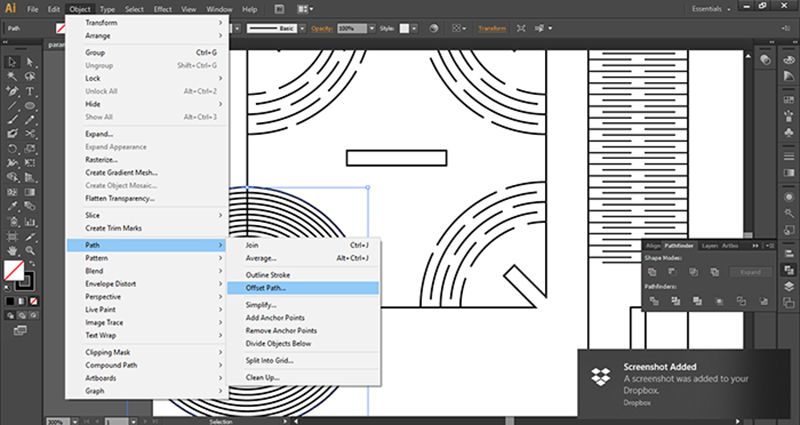

Adding flexable lines in the straight shape was easy, But in the cercular wasn't, So i made it with cicles.

Offset order was very helpfull in this, around 2 mm betweeneach circle and 2mm cut between dotted lines.

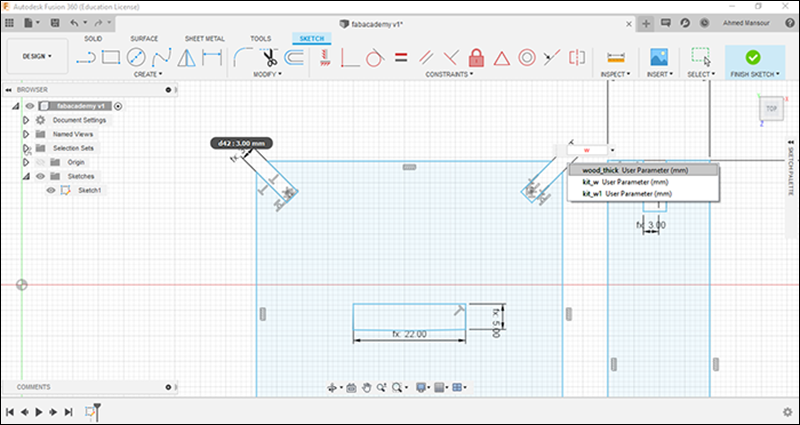

Let's make it parametric and start with the basic shapes sides

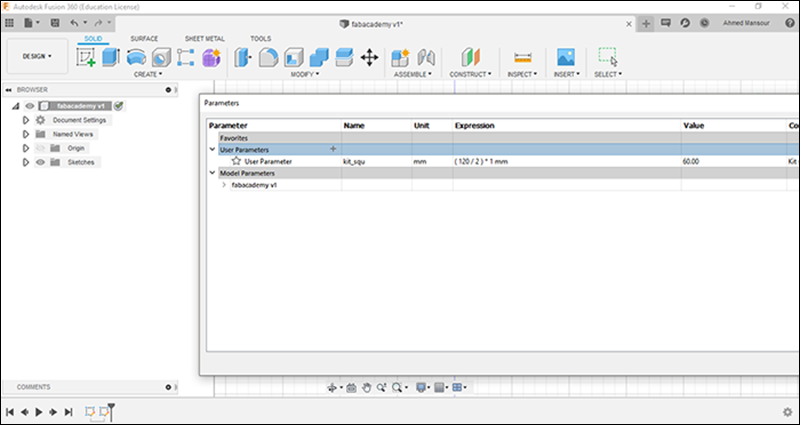

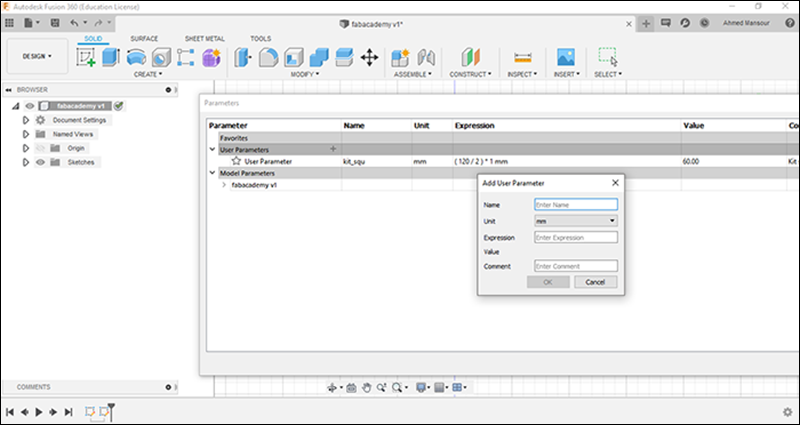

Adding parameters for each side

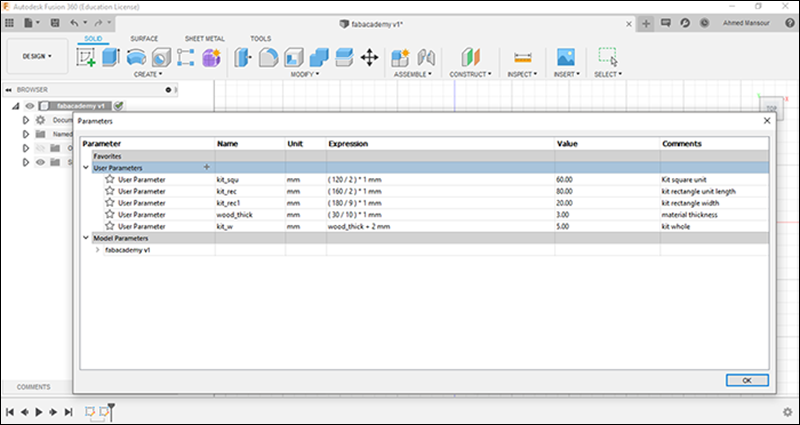

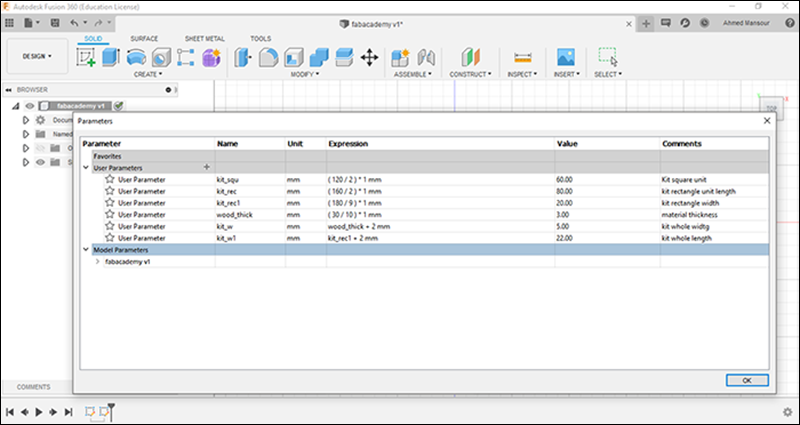

Preparing the parameters ,

Here we can add parameter name and connect it with a specific dimension or other sides dimesion

Modify menu, edit parameters then add the parameters you're going to need

Now the list is ready

Just connecting some details

<

Then we need to Export the file into DXF extension, You can make this in both Fusion360, Illustrator or any other CAD software

DXF file

Fusion360 file

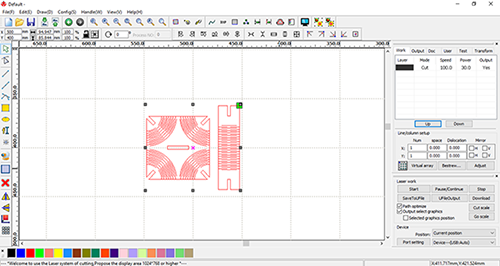

Laser cut

Vinyl cutter

Vinyle was the most interesting task let me show you the journey and explain more in that.

Videos for the whole process on the machine

CutStudio tutorial or Follow my instractor explaining May Eldardery VIDEO

How to Start with the machine.

VIDEO

Measuring material befor processing

VIDEO

Processing.

VIDEO

Finished.

VIDEO

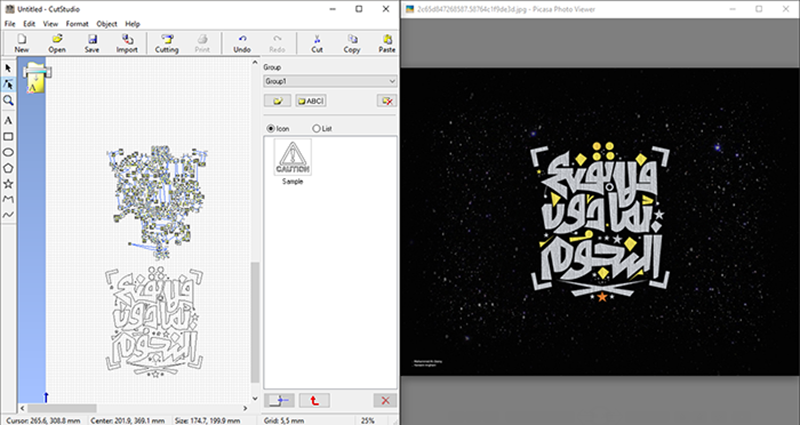

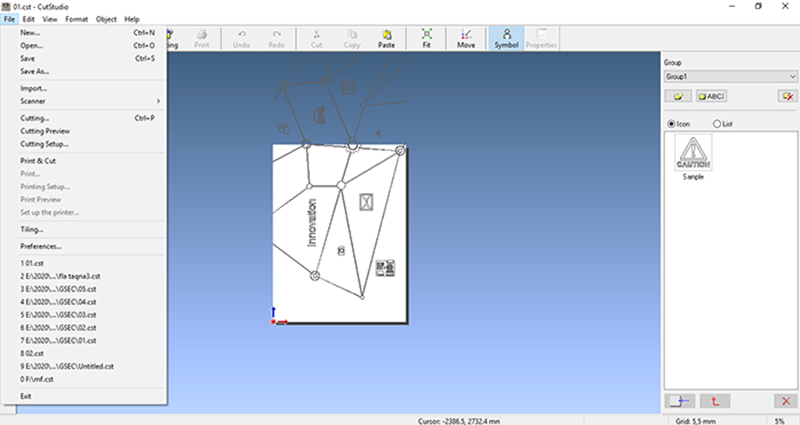

Cut studio steps

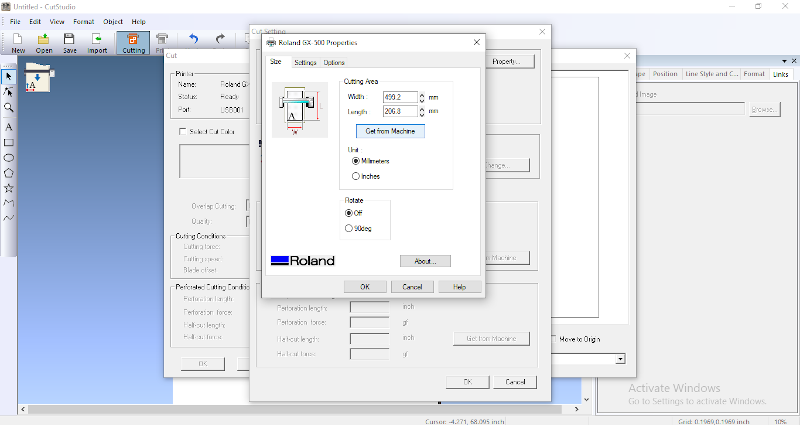

Selecting our machine "Roland GX-500", Getting the sheet dimensions from the machine.

sheet dimenstions will appear

File>import to import the image (extensions jpg, PNG, BMP )

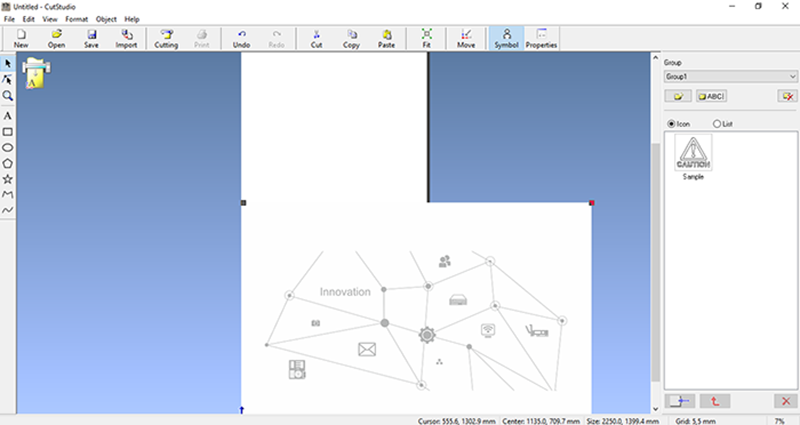

Here where i've impoted another design

Right click> outline image and slect how much details you want the delet the source image and the lines will remain for cutting

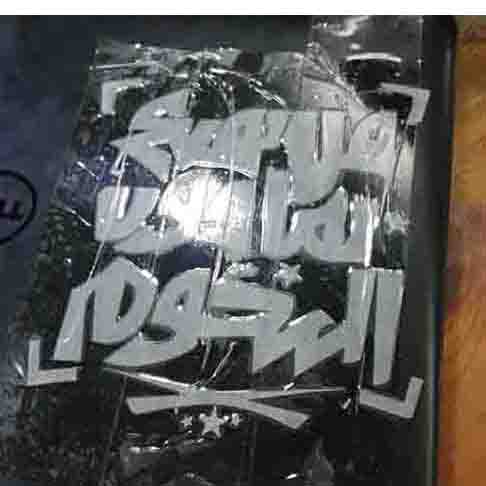

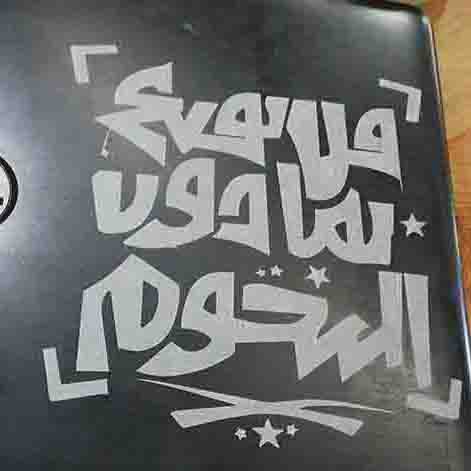

After the cutting shown in the videos cover get with with the design and cover it with the tape and add it on the surface you want to put on

Slowly and with this angle (parallel to the surface) remove the tape.

The result, The dots and the rest of the design in the next photos

I made the same thing with the rest of the design

Put and remove slowly

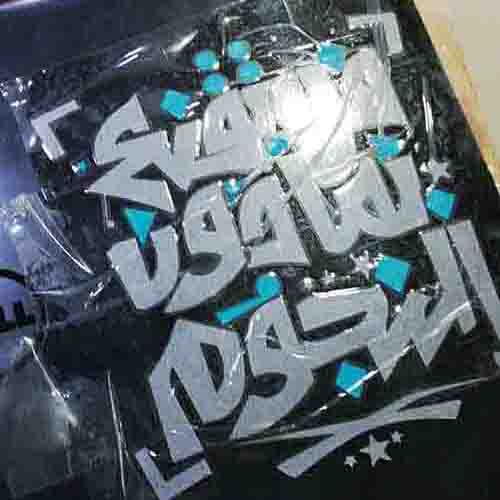

This is other design i've made for the company to cover the glass offices walls

With the same technique, But without tape just add all the design and remove the unwanted parts and leave the details you want

CutStudio file

Done

Creating a construction kit design.

Create a parametric design

Laser cut

Vinyle cut

New Learned

Creating a parametric design.

Make a two colored sticker.

Document with videos.

Enjoyed with

Creating a very enjoyable parametric design and make the parameters connected!

Dealing with the stickers and fixing technics.

Playing with my flexable construction kit.