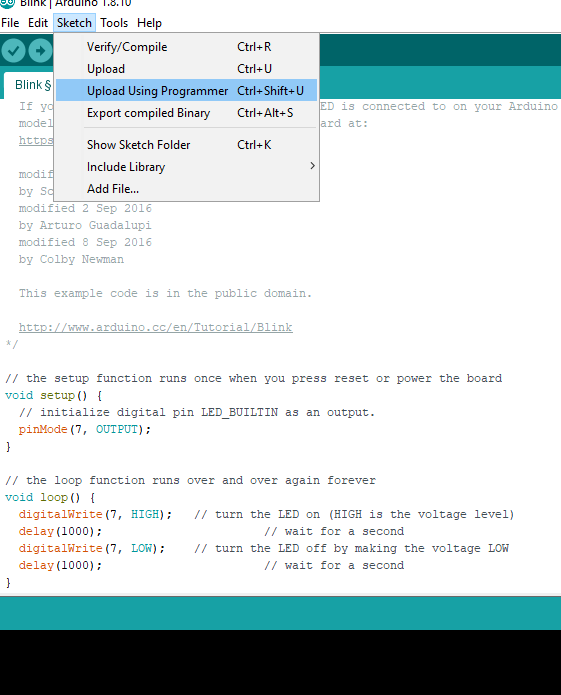

void setup() {

// initialize digital pin LED_BUILTIN as an output.

pinMode(7, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(7, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(7, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

}