Week 13. Applications and implications.

What does it do?

For my final project, I'm planning to make an antenna measurement system which can measure the radiation pattern of an antenna according to different angles of measurements.

who has done what beforehand?

Although I could not find any previous Fab Academy student who did their final project on Antenna measurement, I found out some similar projects on the 2011 IEEE Antennas and Propagation Society Student Design Challenge. I liked thefirst and third place winners' projects since it is feasible for me to make an Antenna measurement system using Fablab Hardware with some improvements to it. The finishing of these projects was not quite good and I could improve the control system using Computer interface as well as a mobile application if possible.

What will you design?

I will design the PCB for the control system, 3D print the rotation mechanism and laser cut the cover for the project.

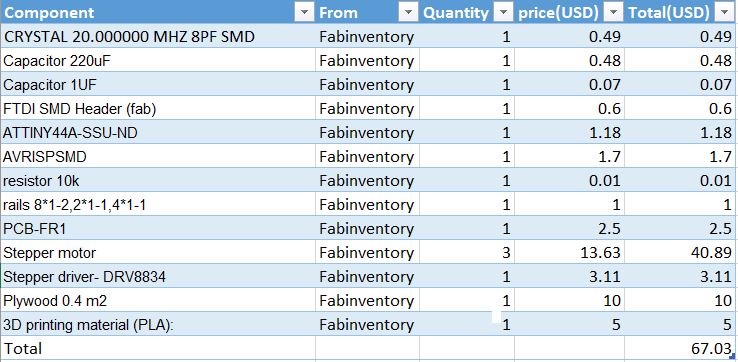

what materials and components will be used? where will they come from? how much will it cost?

what parts and systems will be made? what processes will be used?

Outer enclosure structure will be made with laser-cutting. The rotating mechanism will be made with 3D printing. The control board will be made by milling and soldering. In addition to that processes includes 2D, 3D design, machine design and automation as well as electonics design.

what questions need to be answered?

The rotating mechanism has to be decided in order to optimize the power consumption and smooth control of the system. Moreover, the coding of the control board has to be done parallel with the application development for controlling the rotation of the system.

how will it be evaluated?

From the ability to change the elevation angle as well as azimuth angle of the mounted antenna from use of smartphone/PC, the success of the project can be evaluated. An angle error of 2-3 degrees can be considered as acceptable whereas there's no time constraints.