Design and 3d print an object that could not be made subtractively

3D Scan an object and optionally print it

.

This week's task was to design and 3D print an object that could not be made subtractively along with 3D scanning an object and printing it optionally. This was the most interesting week as i think that 3D printing is the heart of fablab and i was so eager to undertsand the same. Since i had no previous experience with 3d modelling and designing ( even thoough i had done some 2D designs) i started with Autocad fusion 360 on the first week itself. My friend Jogin francis (fablab instructor) helped me a lot with the basics of deisgning. Since i started it from first week onwards i tried to design my final project in fusion 360. My final project was to built a VTOL Plane (Vertical take off and landing plane), i had a design in my mind and even though i knew it was a complicated project i decided to move along with it. I have an altenative project in my mind ie, to build a personal assistant in the shape of an owl.

The thought of an owl came to my mind when a 'silver owl' flew into my office. Anyway the owl was handed over to forest department. So i started searching on the matter in internet, i found the following matters very interesting.

.

.

.

.

.

.

.

.

So i decided to build a personal assistant/assistants with the shape of an owl in fusion 360

First step was to design something that could not be made subtractively

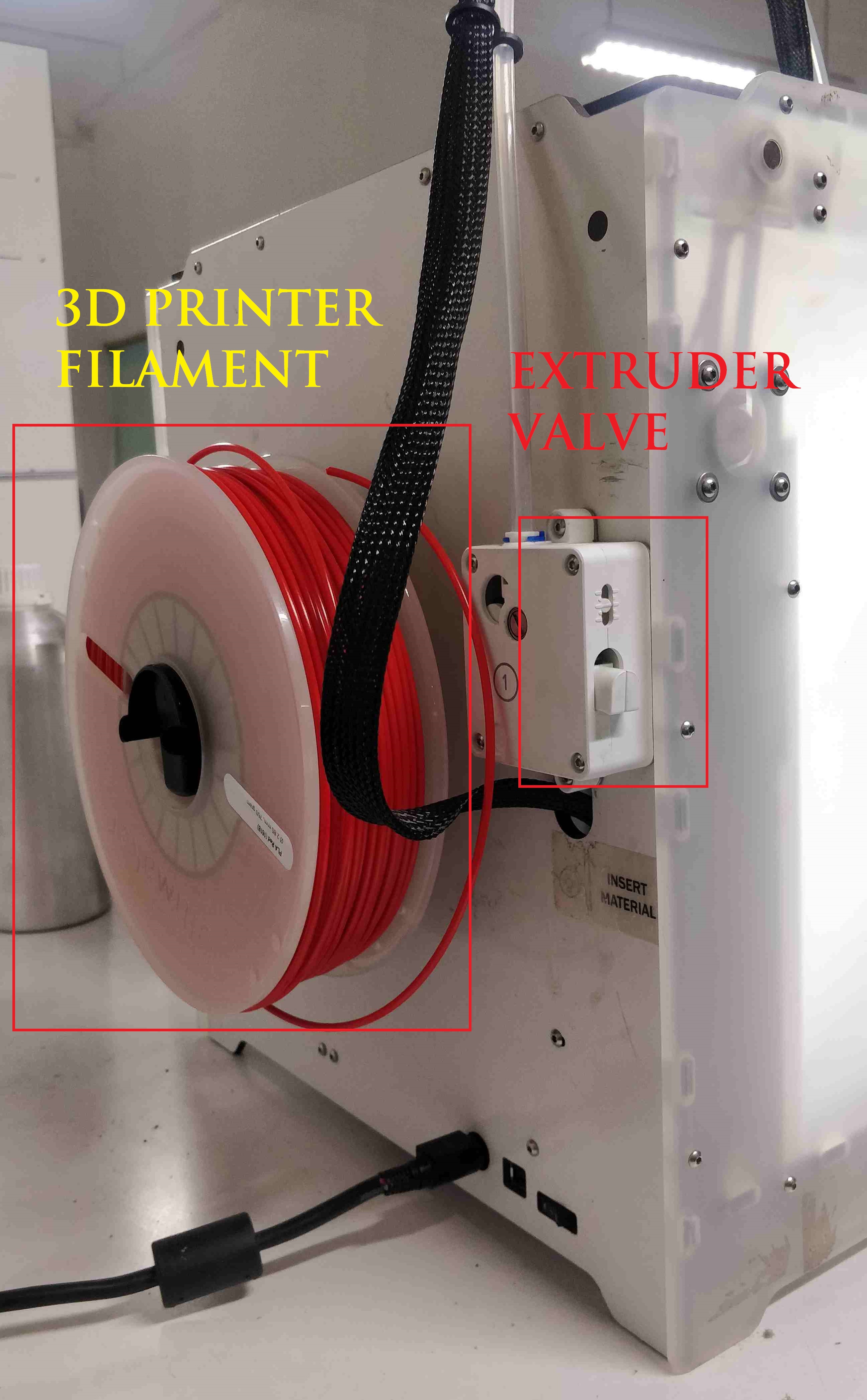

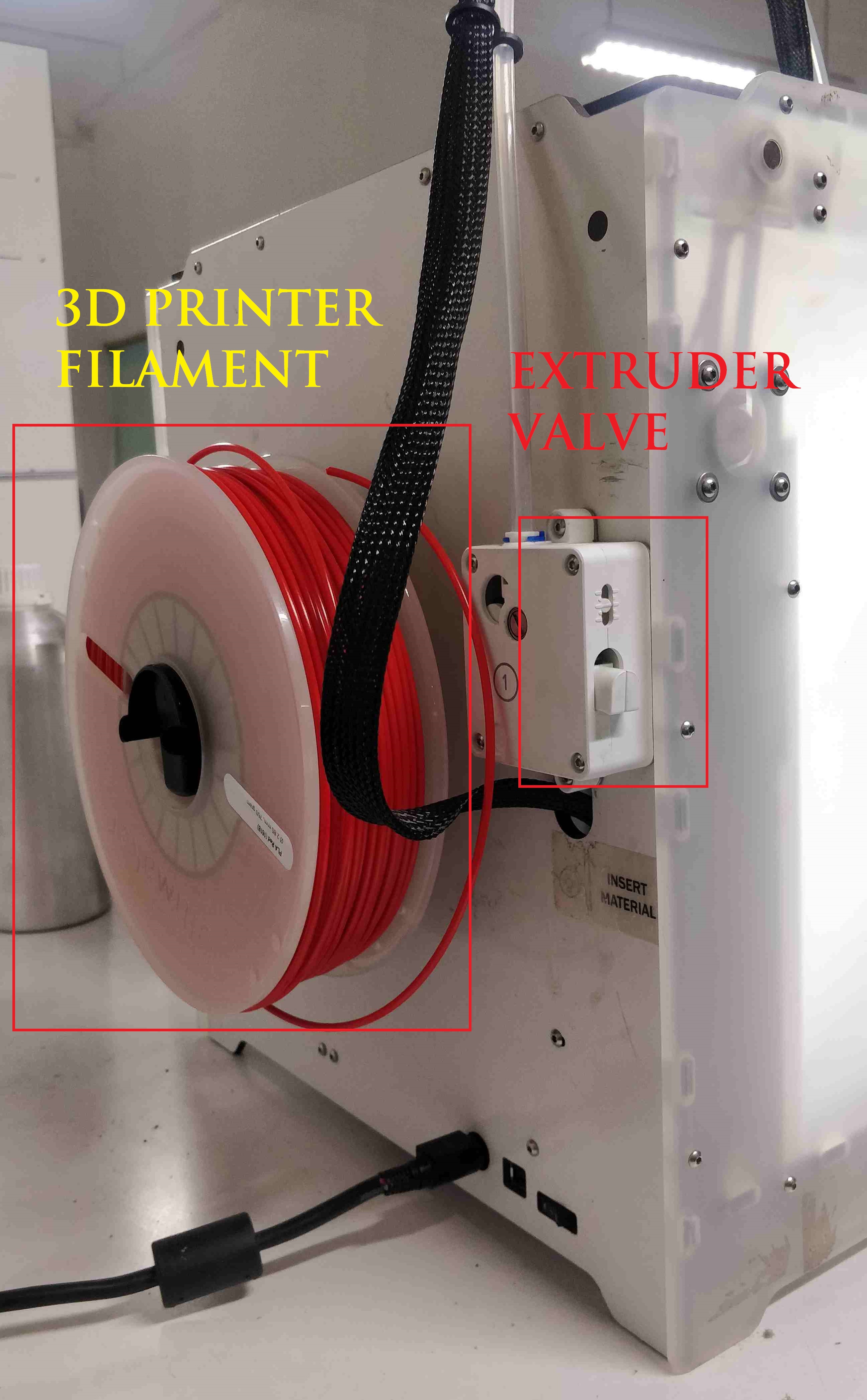

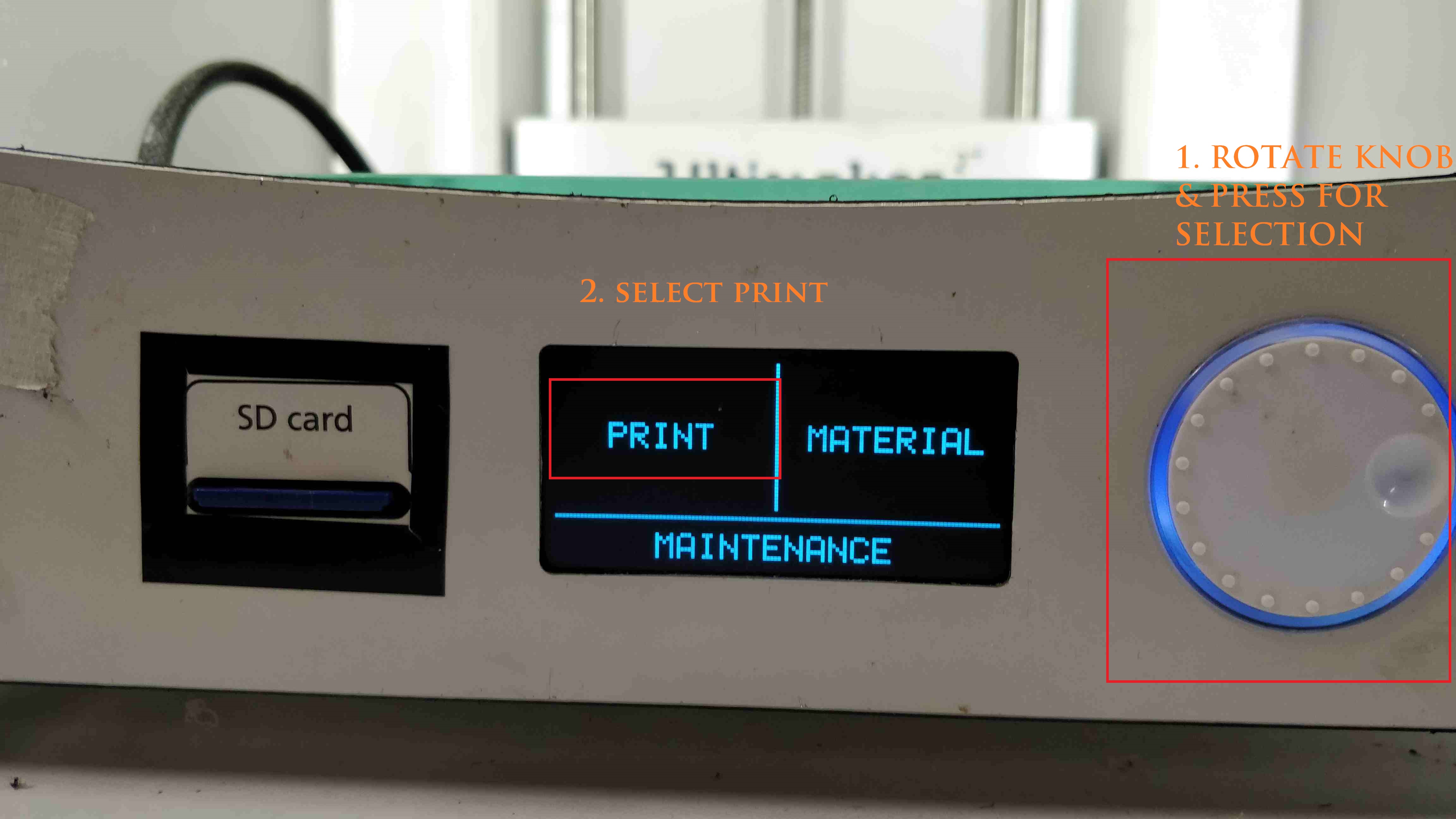

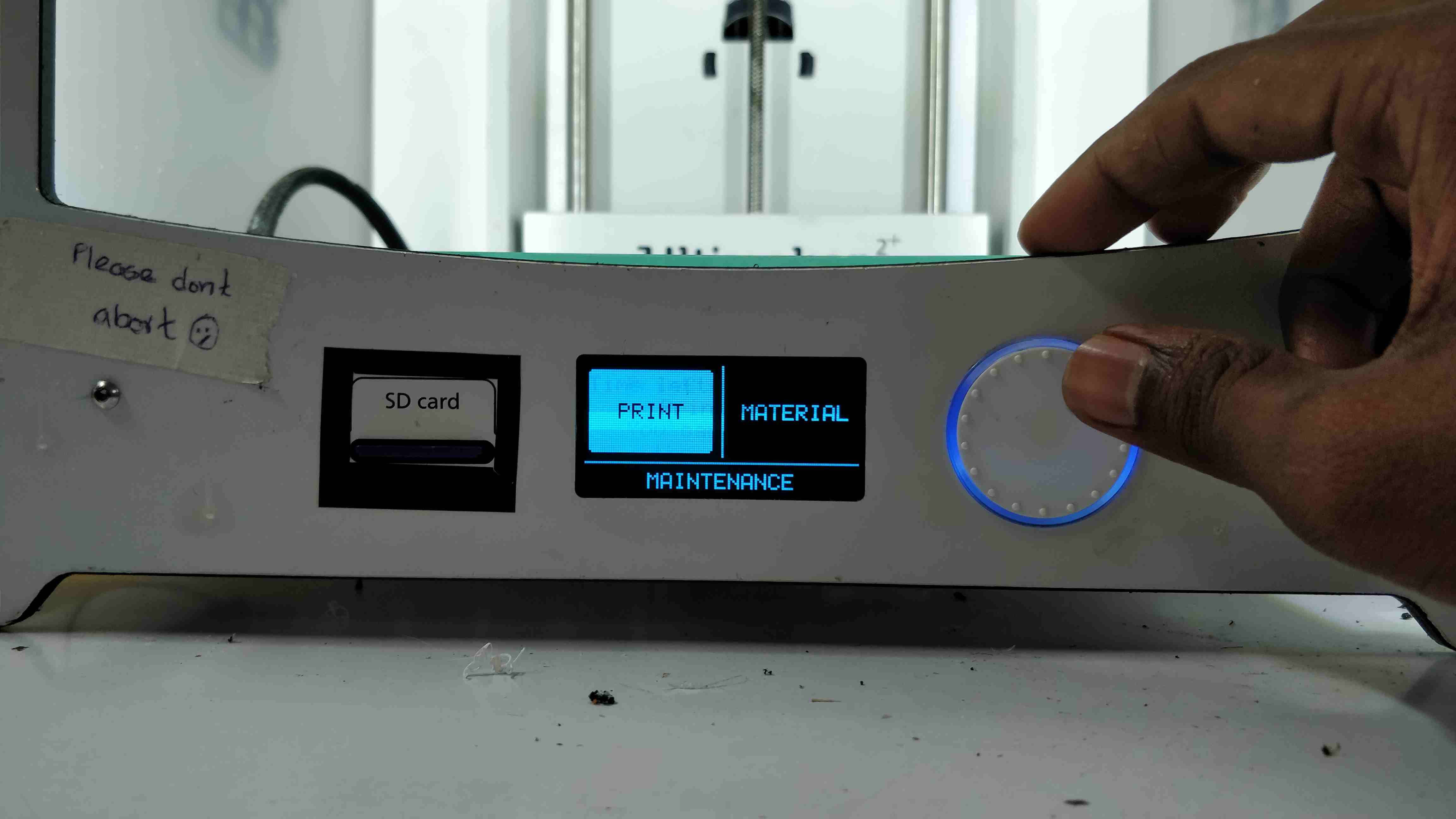

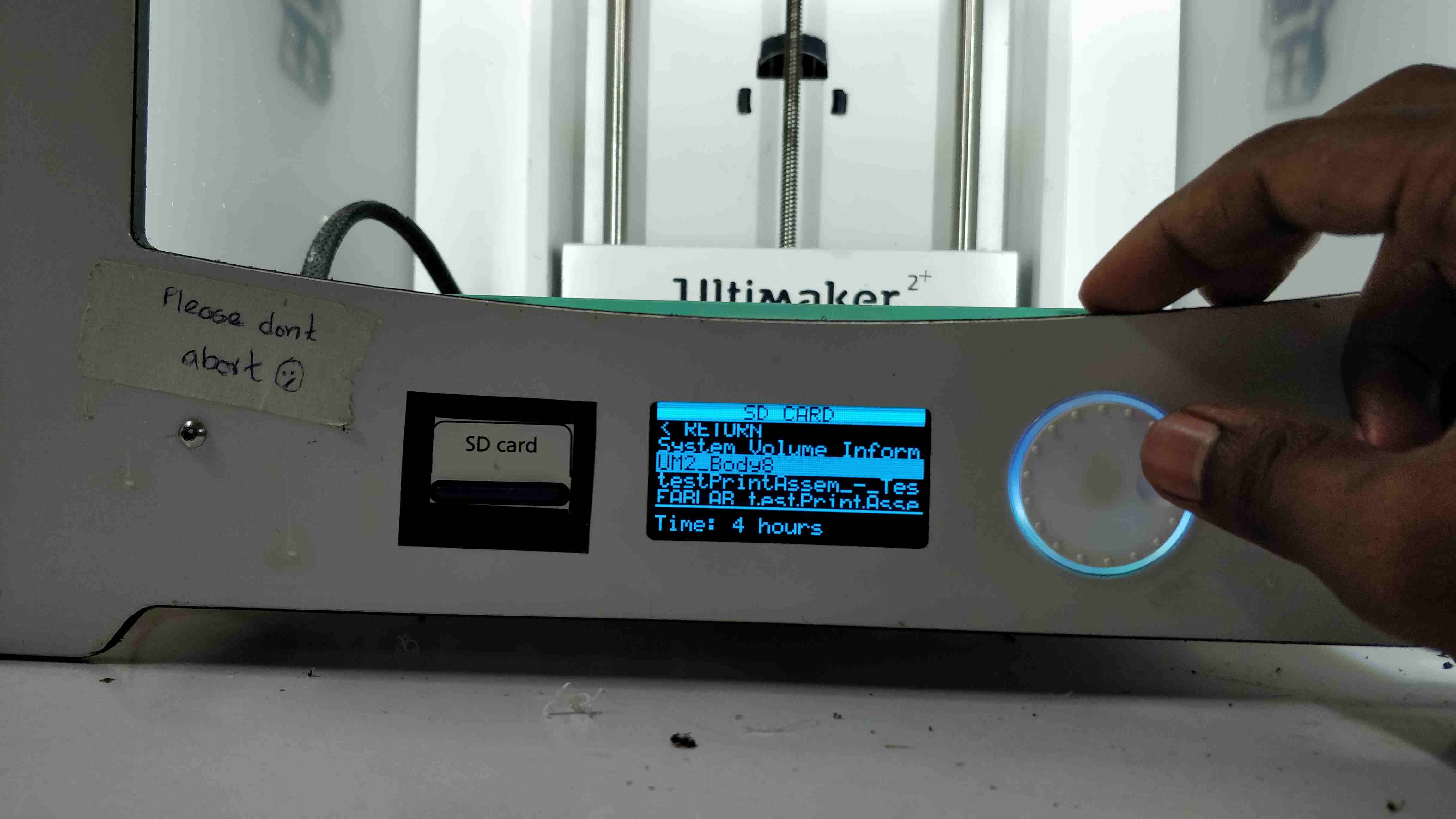

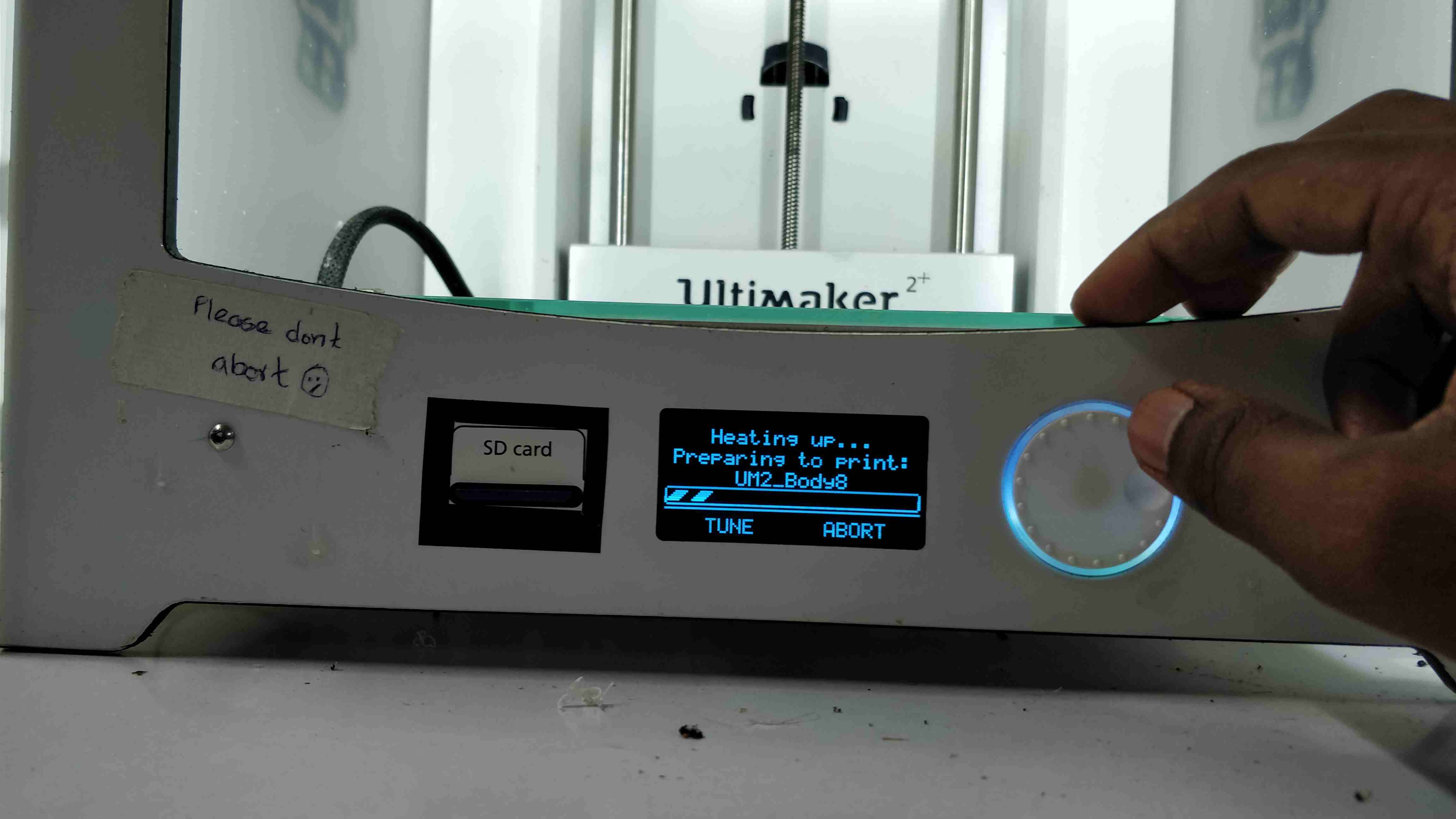

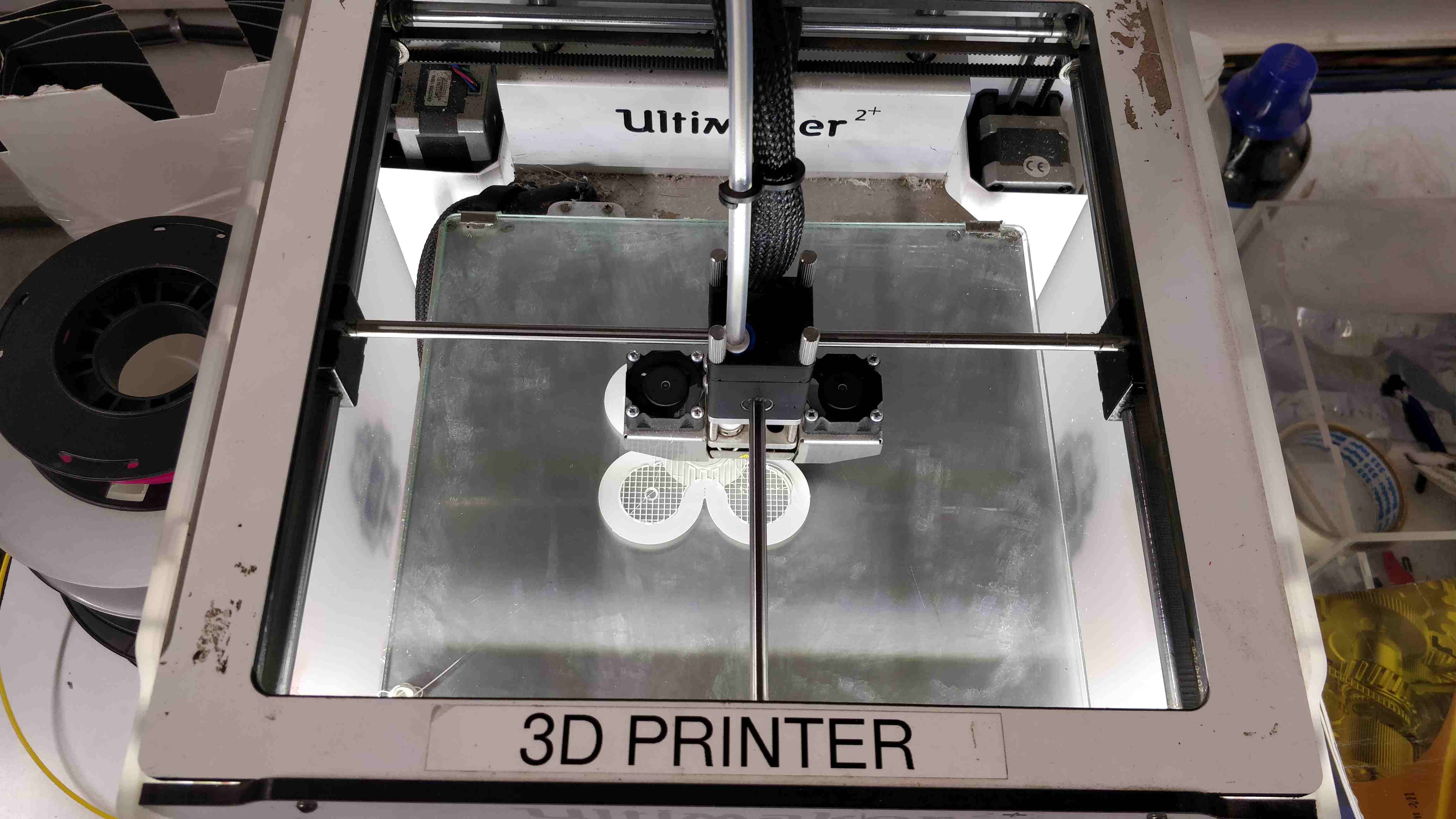

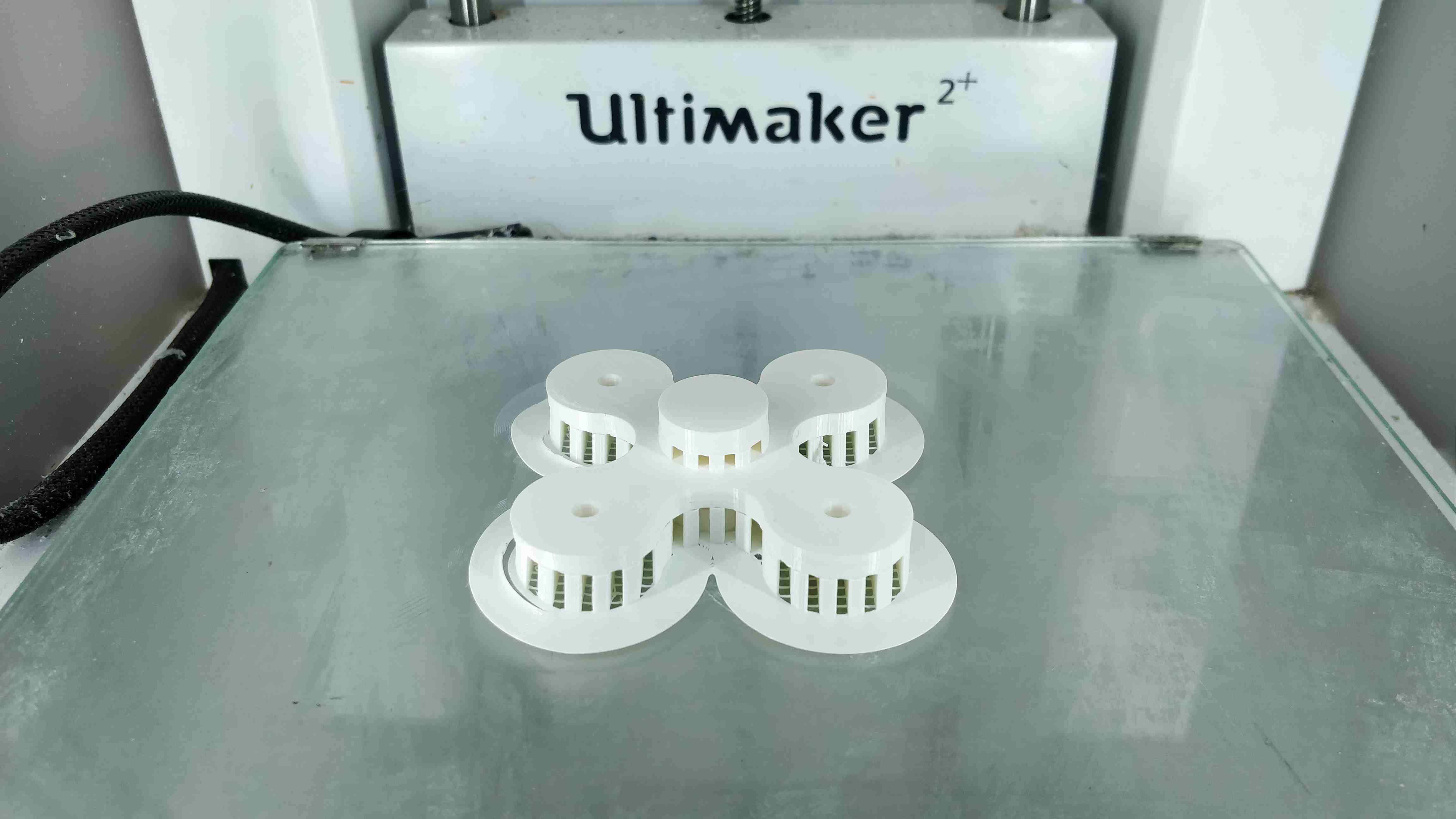

In our fablab we have Ultimaker 2+, Stratasys Dimension 1200es, Divided by zero (indian model)

.

.

.

.

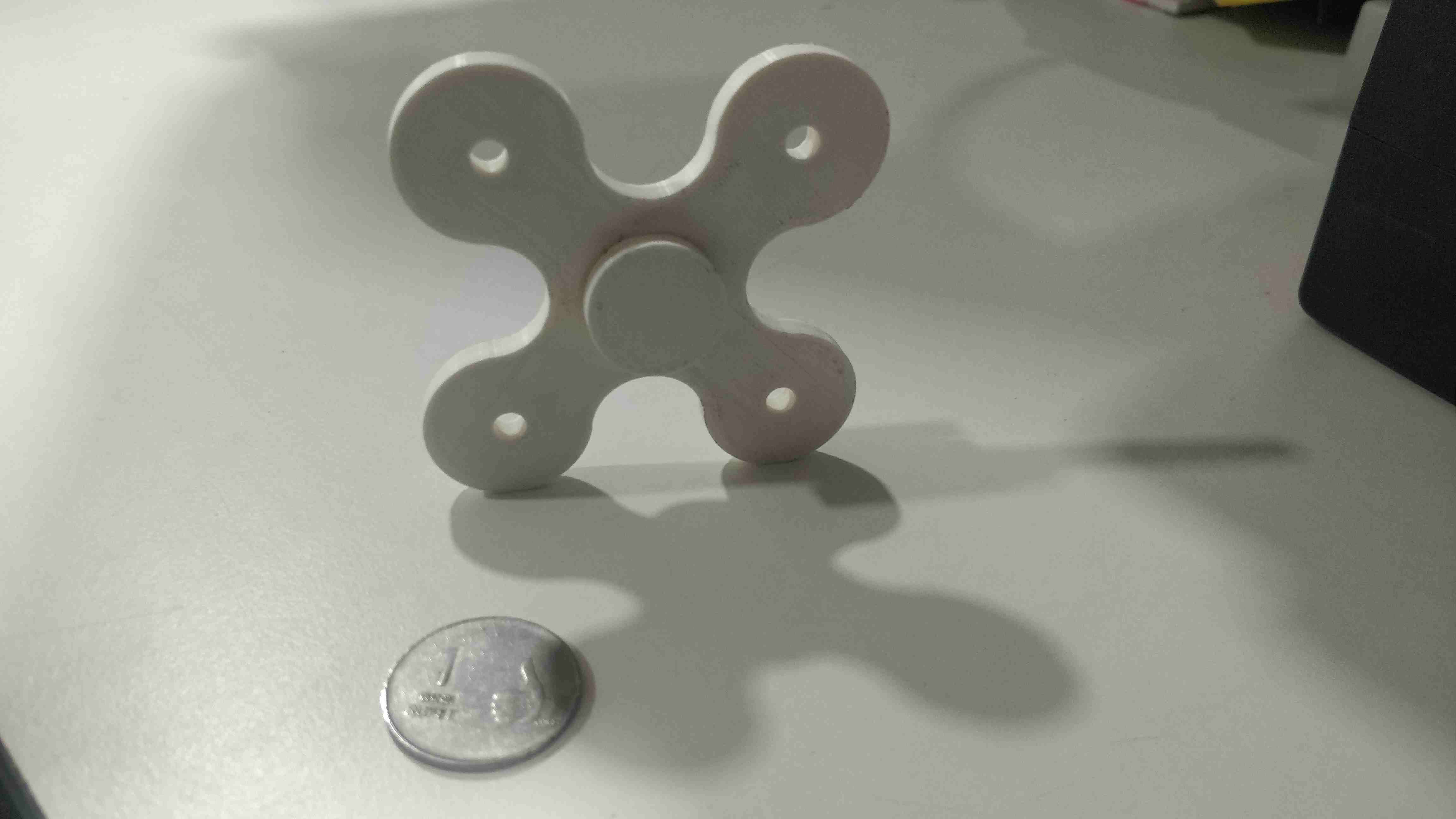

I thought of printing a fidget spinner which would be sufficient for this week's assignment as it would be a non subtractive design

So i started from scratch, sketched circles and joined them ,extruded them as below

.jpg)

.

.

.jpg)

.

.

.jpg)

.

.

.jpg)

.

After completing the design the different bodies were combined to a single body by selecting every body and selecting 'combine'

.

.jpg)

.

.

.jpg)

.

After combining bodies two bodies exists as below since they have no connection between them. Draw a sketch inorder to connect the two bodies as below and repeat 'combine' command.

.

.png)

.

The body was then saved as .stl file inorder to print in 3D printer

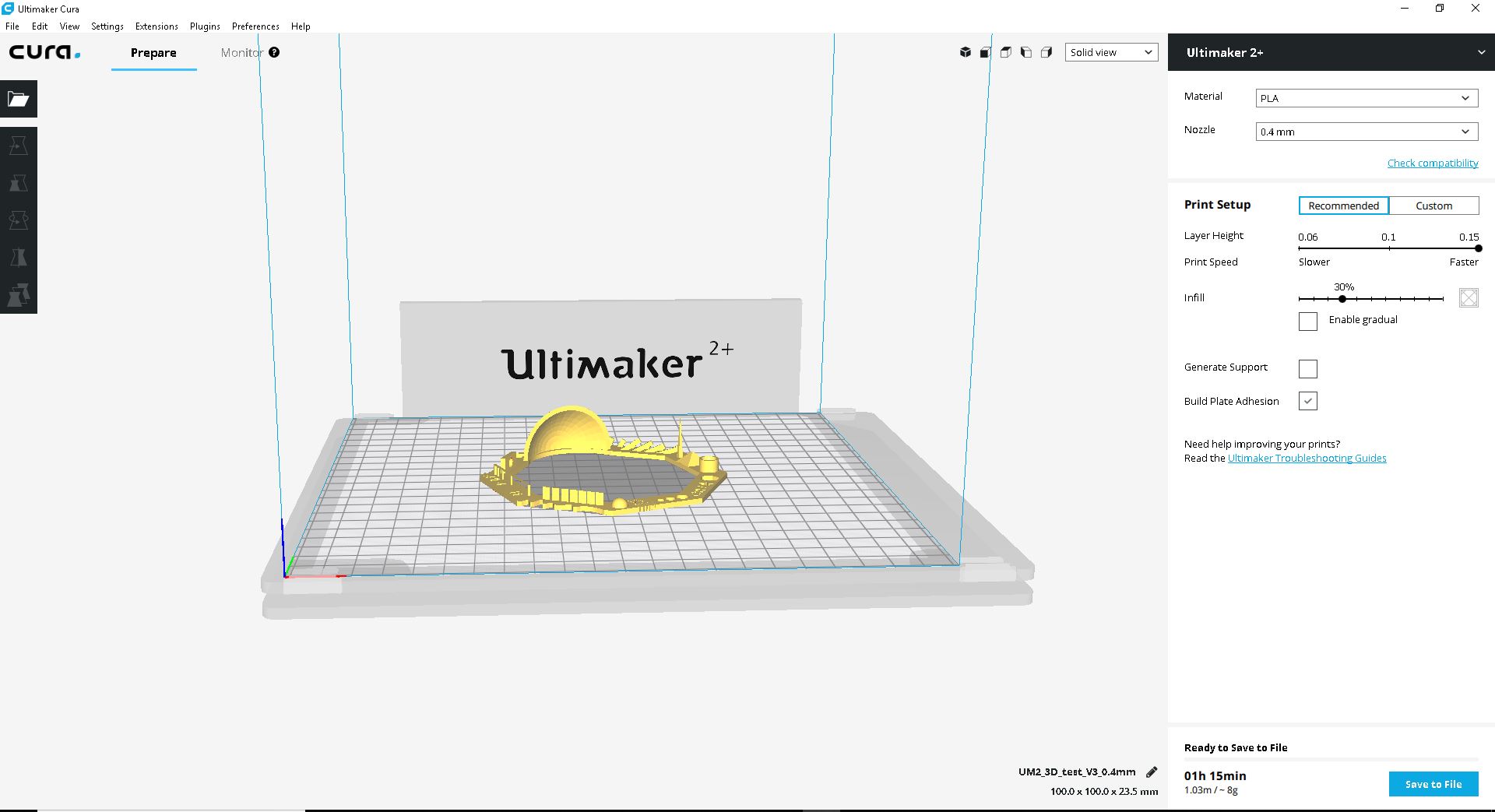

The Software 'Cura' for 3D printing was downloaded from here

Next step is to load the .stl file in cura

.jpg)

.

Following settings needs to be set before printing

.

.png)

.

.png)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

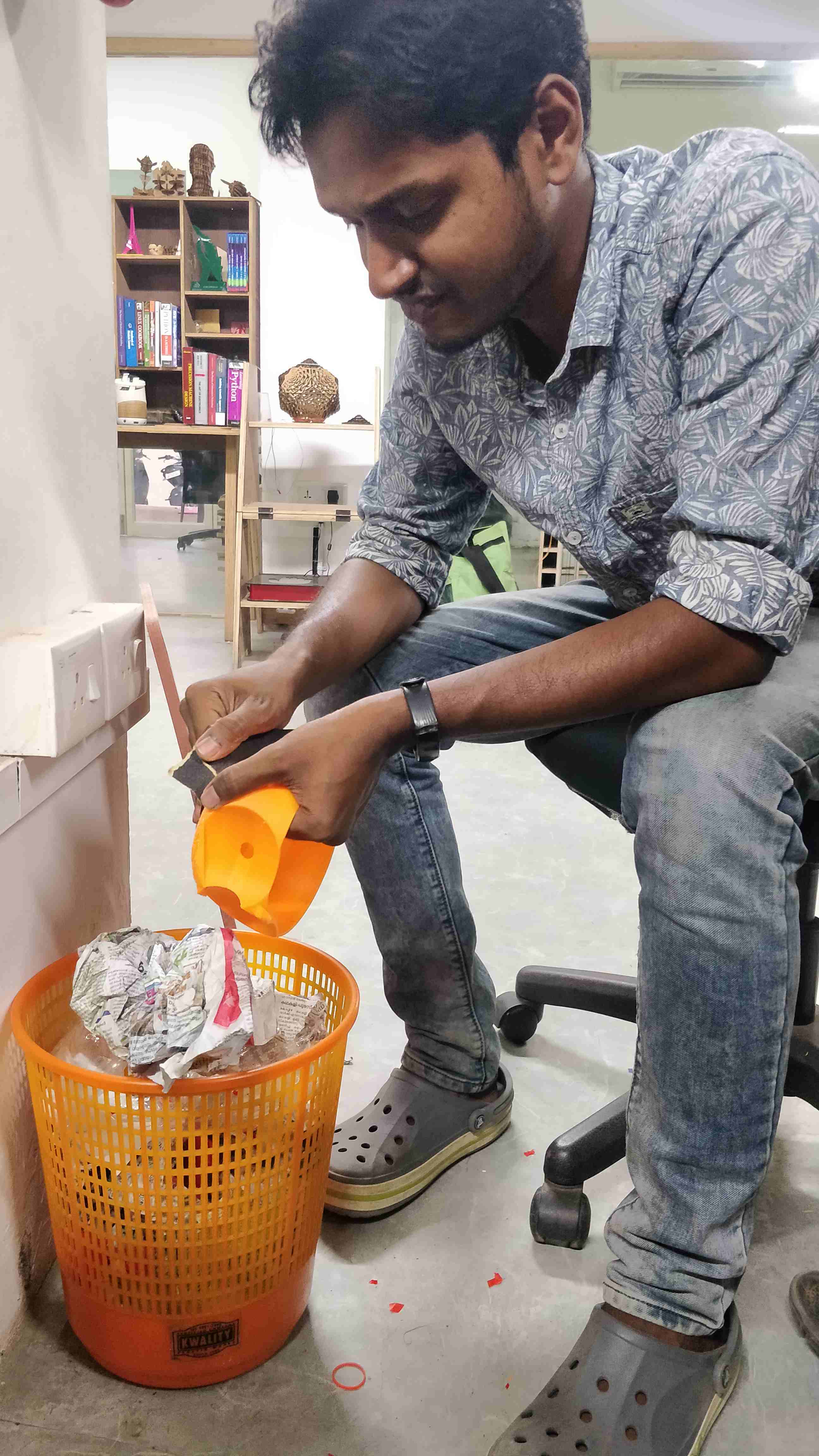

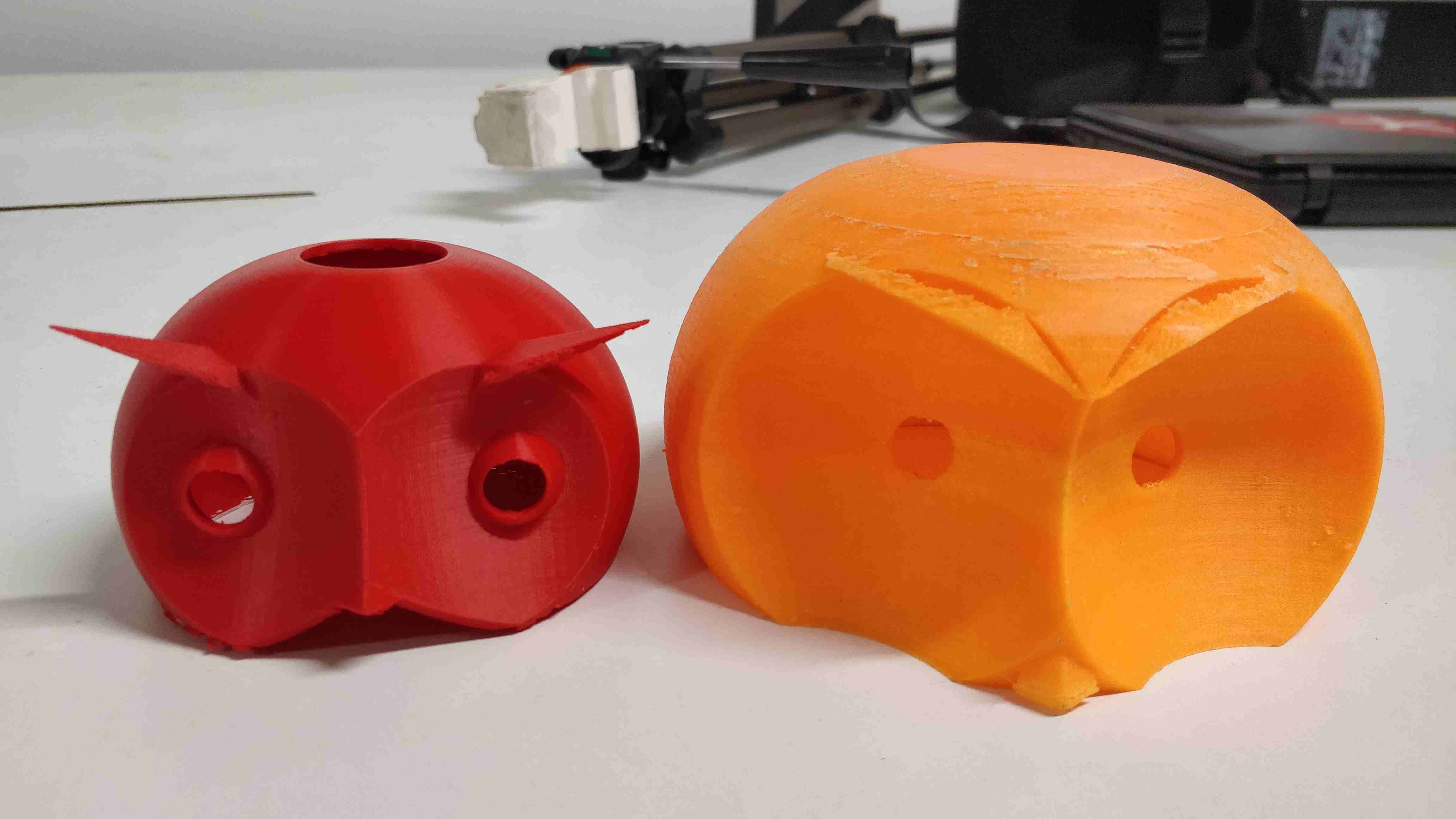

As mentioned earlier my alternative project was to have owl/owls with google assistant which will communicate with each other as my personal assistant

I started with designing the head of the owl in fusion 360

.

.

.png)

.

.

.png)

.

.

.png)

.

.

.png)

.

.

.png)

.

.

.png)

.

.

.png)

.

.

.png)

.

.

.png)

.

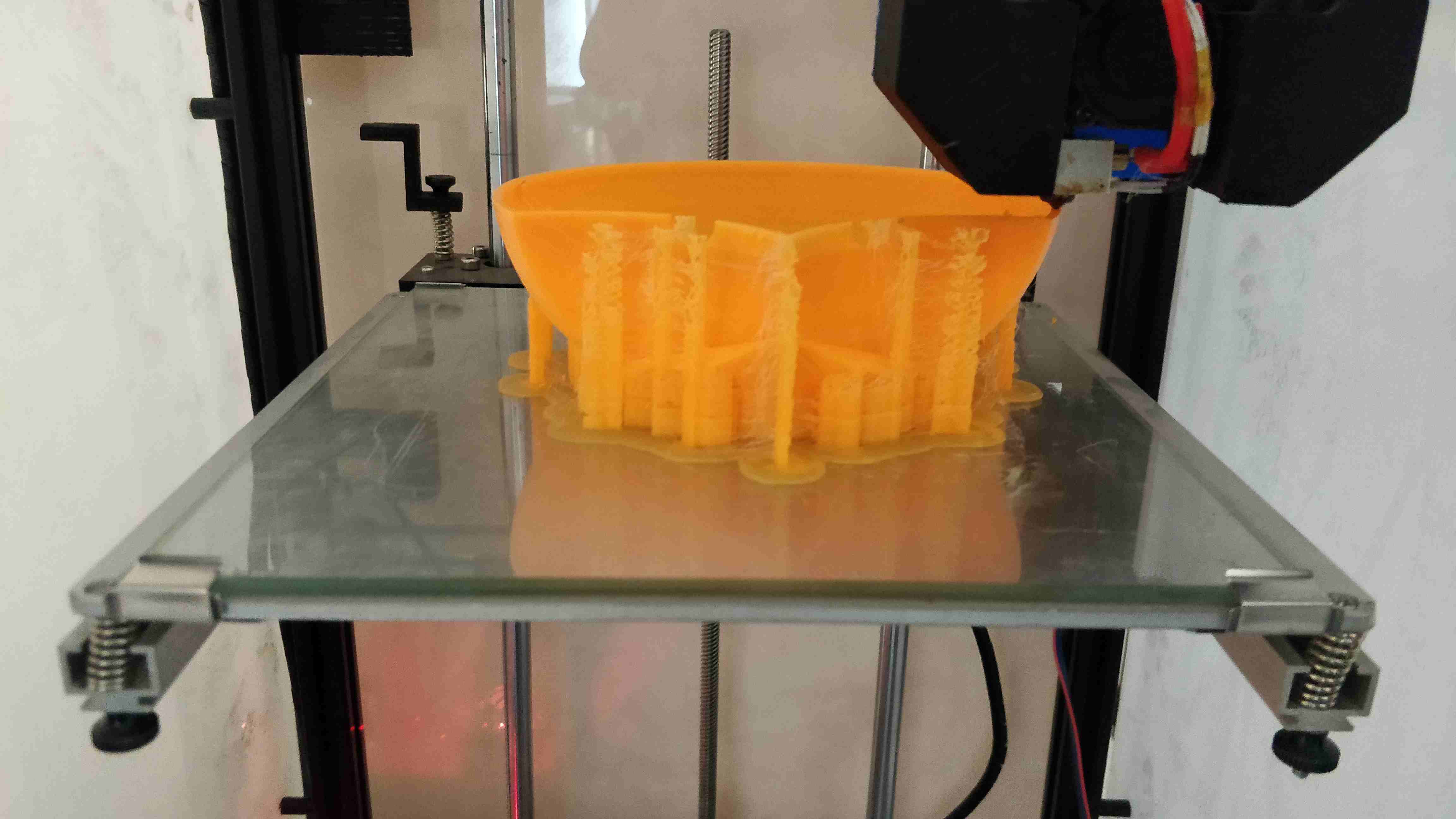

Since i was using a custom made printer by akhil joseph one of by fab colleague, he had set the specifications of the printer similar to Prusa i3. This printer was chosen with custom settings as shown below

.

.png)

.

.

.png)

.

.

.png)

.

.

.

.

.

.

.

.

.

.

.

.

.

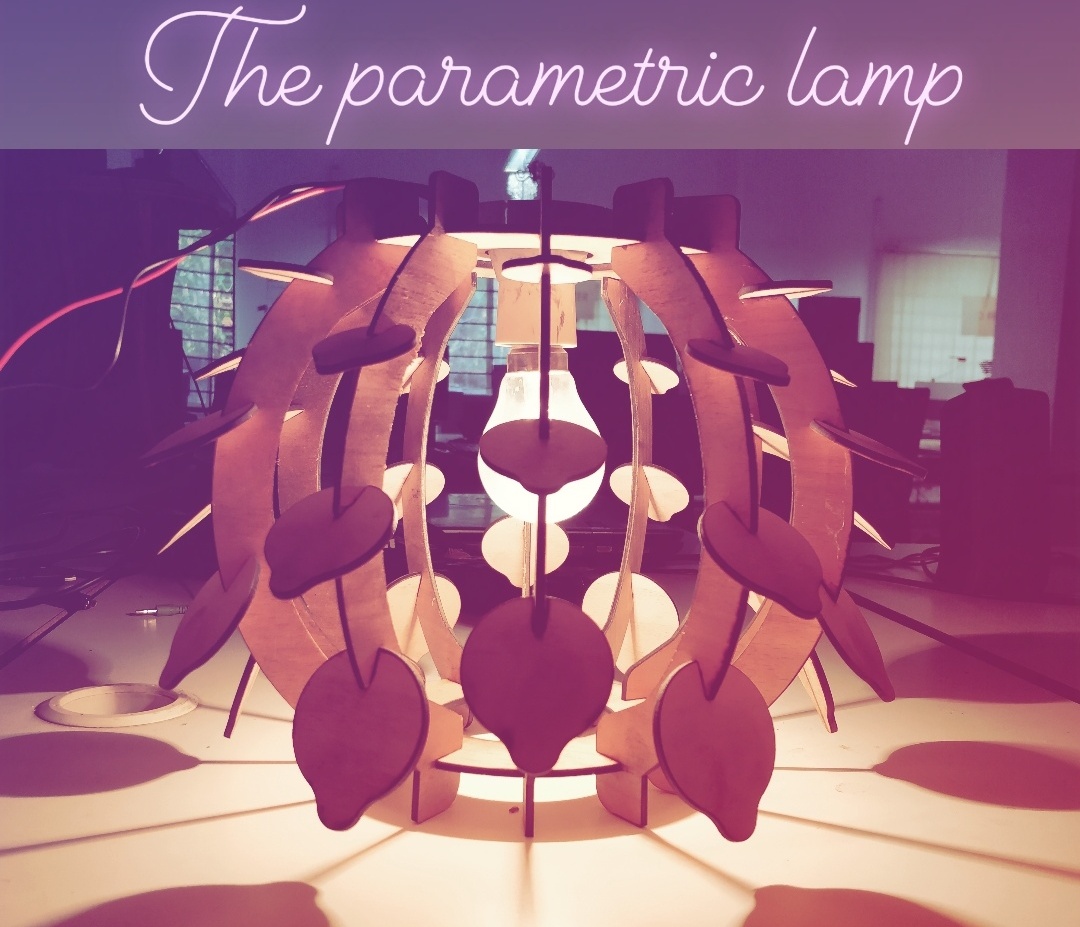

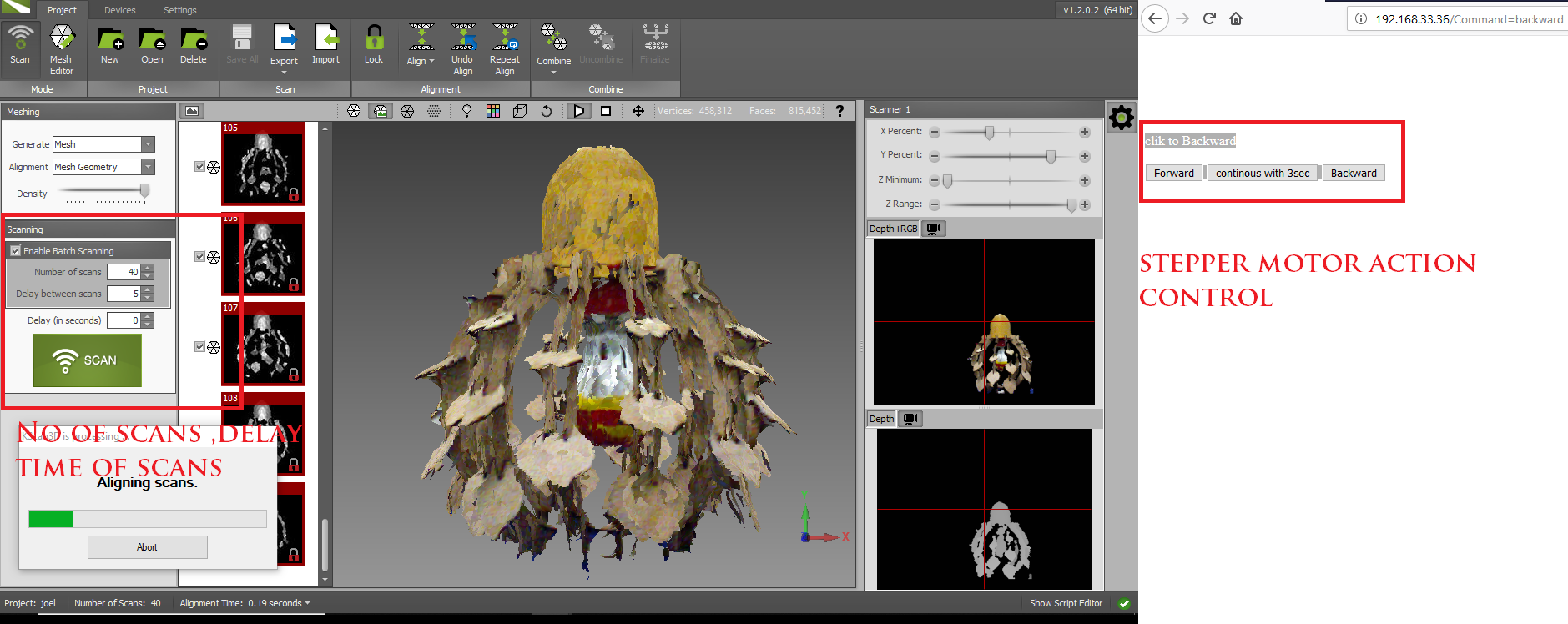

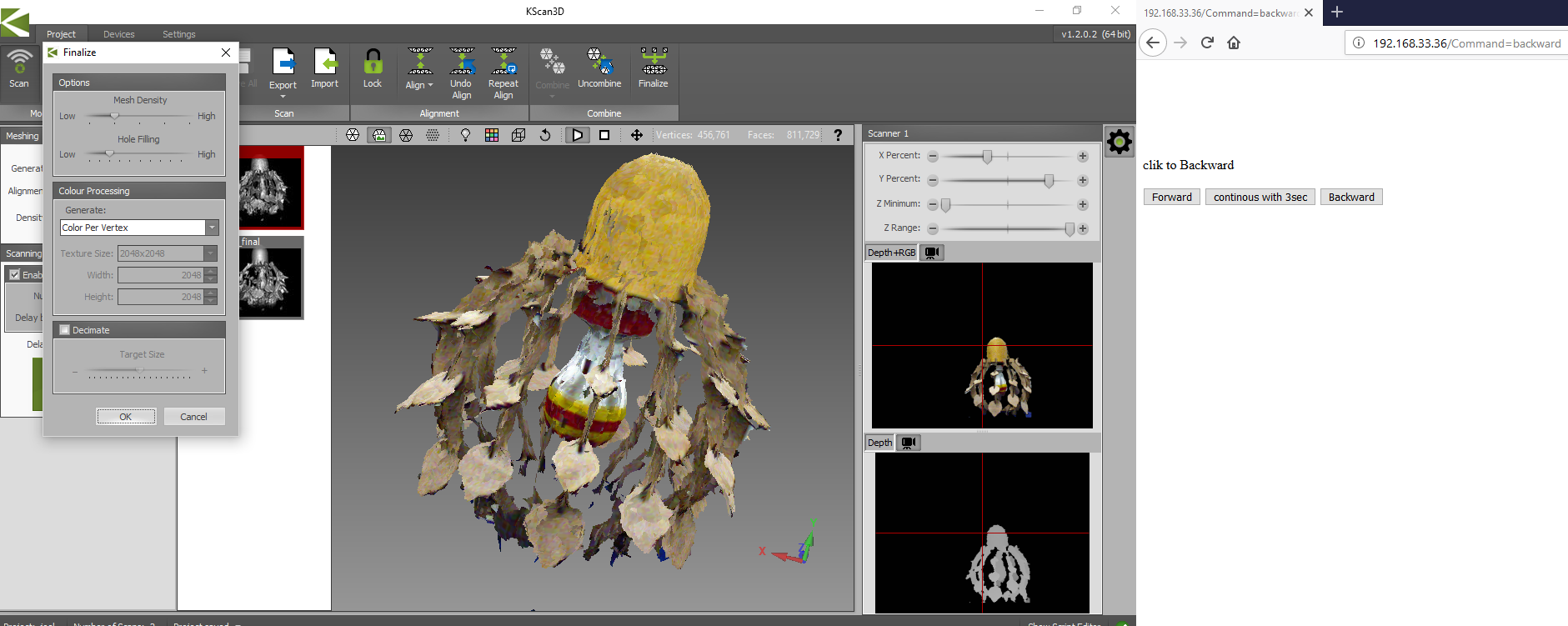

In Week 4, i had designed a parametric lamp and cut it using laser printer, i thought i would 3D scan the same for this assignment

.

.

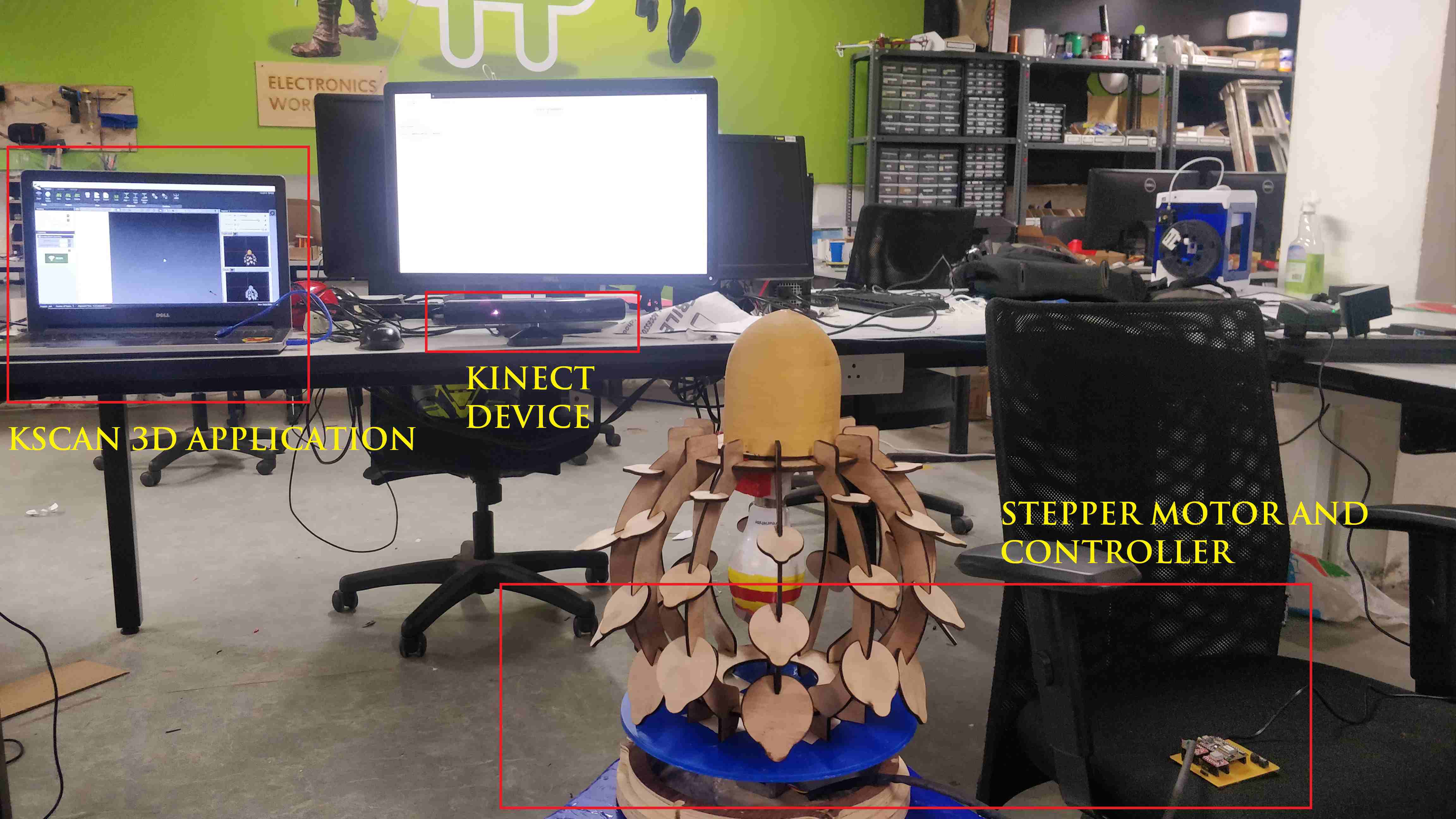

For the purpose, a kinect, KScan software, a 360 degree rotationg diaz ( made by akhil joseph) was setup.So using the software we could move th stepper motor arrangement at different angles for scanning the object

.

.

.

.

.

.

The no of steps can be combined and an stl file can be exported.

.

.

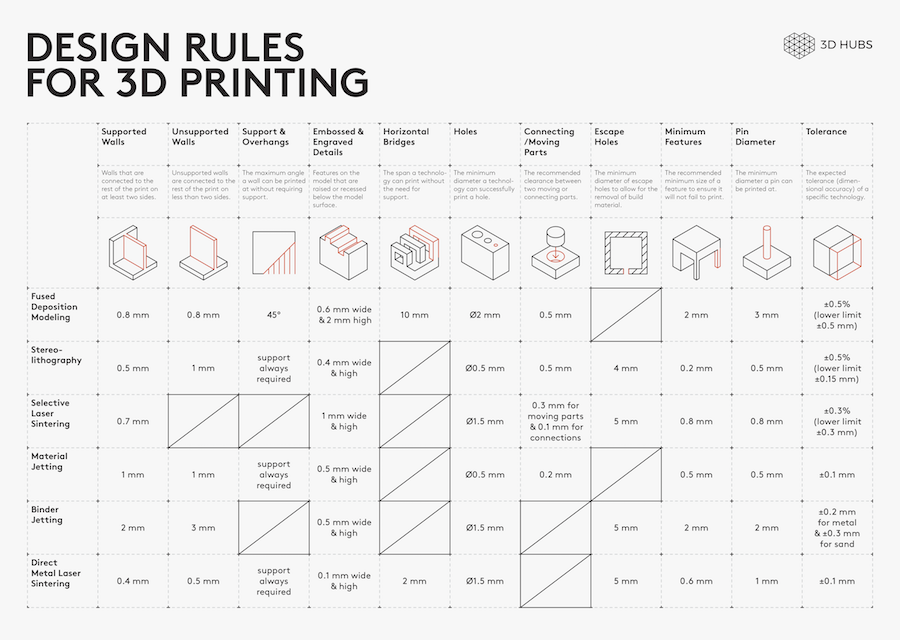

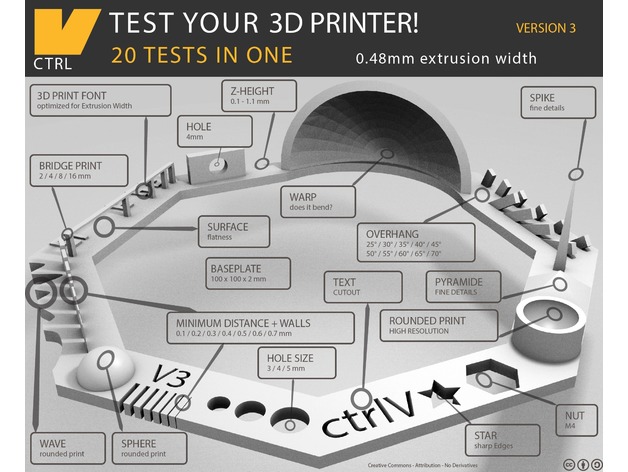

In this group assignemt we will take into account the design capabilities and restrictions.

.

.

.

The print settings files were obtained from the site as below:

.

.

.

.

.

Parameters that needs to be checked for printing: