Week 10: Molding and Casting

Group Assignment

Individual Assignment

Group Assignment

This week's group assignment is to review the datasheets of the materials we are using in making molding and casting. Initially we reviewed datasheets of materials we used while molding and casting. Some considerable points are given below.

Mold Max 60 Safety DataSheet Review:

Product/Chemical Name: Mold Max® 60 Part A:

- Hazards Identification -Not hazardous according to United States Occupational Safety and Health Administration (OSHA)

- Inhalation - Remove source(s) of contamination and move victim to fresh air.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact -In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

- Ingestion -Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point -300 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment -Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Eye Effects:Irritation

- Skin Effects:Irritation

- Carcinogenicity:not Determined

- Mutagenicity: Not Determined

Product/Chemical Name: Mold Max® 60 Part B:

- Harmful if swallowed.

- Irritating to eyes, respiratory system and skin.

- Harmful to aquatic organisms may cause long term adverse effects in the aquatic environment.

- Inhalation -Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- Eye Contact -Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact -In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

- Ingestion -Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Handling Precautions -Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

- Flash Point - 150 °F

- Storage Requirements -Store in cool dry, well-ventilated area Protective Clothing/Equipment - Wear chemically protective gloves and aprons to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Eye Effects:Irritation

- Skin Effects:Irritation

- Carcinogenicity:not Determined

- Mutagenicity: Not Determined

Smooth-Cast 300 Series Safety DataSheet Review:

Product/Chemical Name: Smooth-Cast 305 Part A:

- Hazards Identification

- Harmful : by inhalation.

- Irritating to eyes, respiratory system and skin.

- Limited evidence of a carcinogenic effect

- Harmful; danger of serious damage to health by prolonged exposure through inhalation environment.

- Inhalation -Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- Eye Contact -Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact -In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

- Ingestion -Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Handling Precautions -Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

- Flash Point - 262 °F

- Storage Requirements -Store in cool dry, well-ventilated area Protective Clothing/Equipment - Wear chemically protective gloves and aprons to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Hazardous Component: 4,4’ Methylene, bis(phenylisocyanate)

Product/Chemical Name: Smooth-Cast 305 Part B:

- Inhalation - Remove source(s) of contamination and move victim to fresh air.

- Eye Contact -Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 262 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

- Storage Requirements -Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Acute Inhalation Effects: None Established

- Reproductive Toxicity:None Established

- Mutagenicity:None Established

- Teratogenicity:None Established

- Sensitization:None Established

Individual Assignment

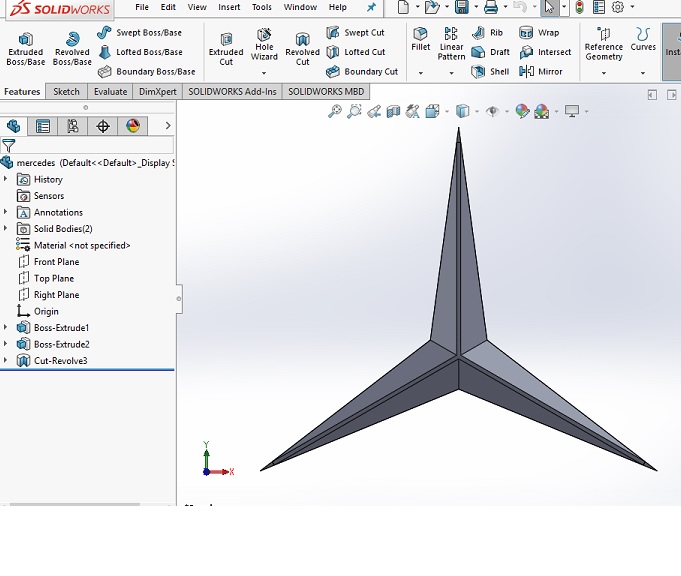

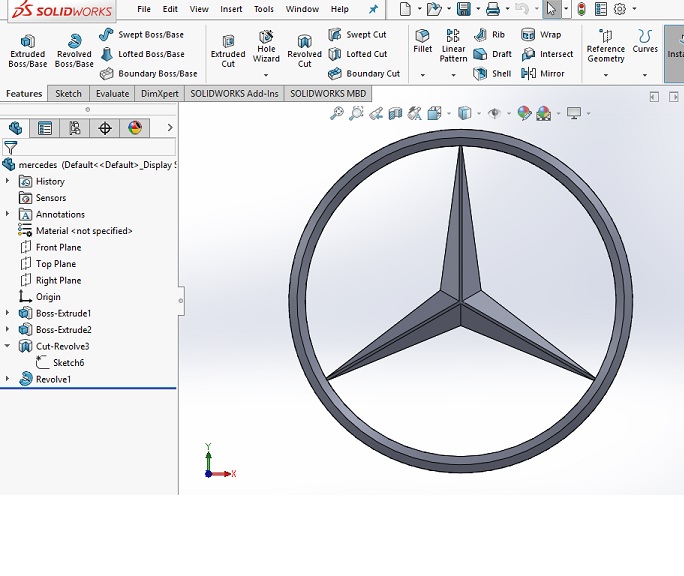

A major requirement of this weeks assignment was to design any 3d part which must be subtractive and shall not be broken. Initially i searched alot related to soft electronics, pneuamtics and soft sensors. I found much stuff, but I was unable to design them in solidworks. So I tried to something different like I designed a 3d heart which can be seen below. Unfortunately it has larger depth so I left this one I tried to design something resaonble. I design mercedees logo in 3d which is really cool idea.

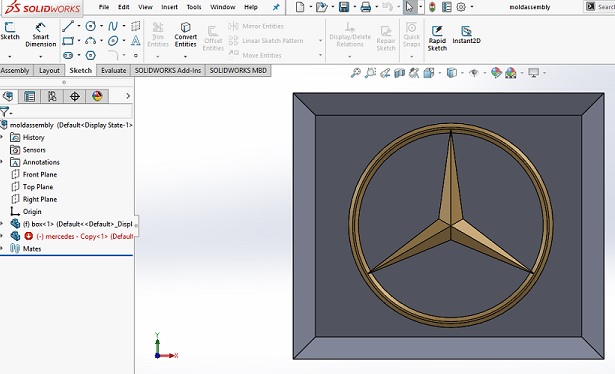

I designed the mercedees logo in solidworks 2016 which can be seen below. First I designed the inner part of merceedes logo shown in figure(a) later I designed outer part of mercedees logo shown in figure(b). After designing this I tried to do the rendering in solidowrks which is shown in figure(c). To give it perfect look I tried my level best by giving it sufficient depth to the center part and outer part of logo. the center part has maximum deoth of 15mm however outer part has max depth of 5mm.

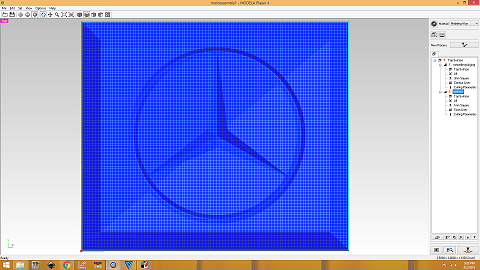

Secondary step is to design the molding box which shall hold the material so I started to design that box. The size of that box is essentially critical. You need to check the size of molding wax available at your lab. Keeping in view I designed that box of 3x3.5x20mm^3 and attached the designed logo as shown in figure. After attaching this I had to make it's stl file in order to check the size of designed model in cura software. I checked it and took my file for milling. At milling site There are two software which are used one is modella and other is srms vapanel.

Again I used srm 20 machine for milling the designed model. I have used machinable wax to get the desired output such that casting should be fine. Rolland Player 4 has been used to generate the (.prn) files required for the milling. Follwoing steps are required to generate the (.prn) files in model player 4.

- Open the Rolland Player 4 software.

- Open the stl file that you have generated.

- Select the material as molding wax.

- Open the model in the top view.

- Set the orientation , origin for the model.

- Now, click on New process and select roughing and set the milling size , for roughing as "3mm".

- Set the speed to "26m/s".

- Click on partial and set the boundary lines.

- After checking the preview of milling, it was verified that it has been done properly.

- I followed the same steps for finishing, except setting the tool size to "1mm" and speed to "14m/s" and scan direction to X+Y.