INDIVIDUAL ASSIGNMENT network

OBJETIVES: The objective of this assignment is to communicate two boards through a network protocol.

In my case, a board with an LCD sensor must send a signal to a board that will be responsible for moving a servo depending on the light detected

input ldr network

because the board made in the assignement input does not have the proper connections it is not prepared to communicate with another, so I design and manufacture another

The board with the light sensor will work as a master and send a signal to the servo control board (slave) so that it moves under the conditions indicated by the software

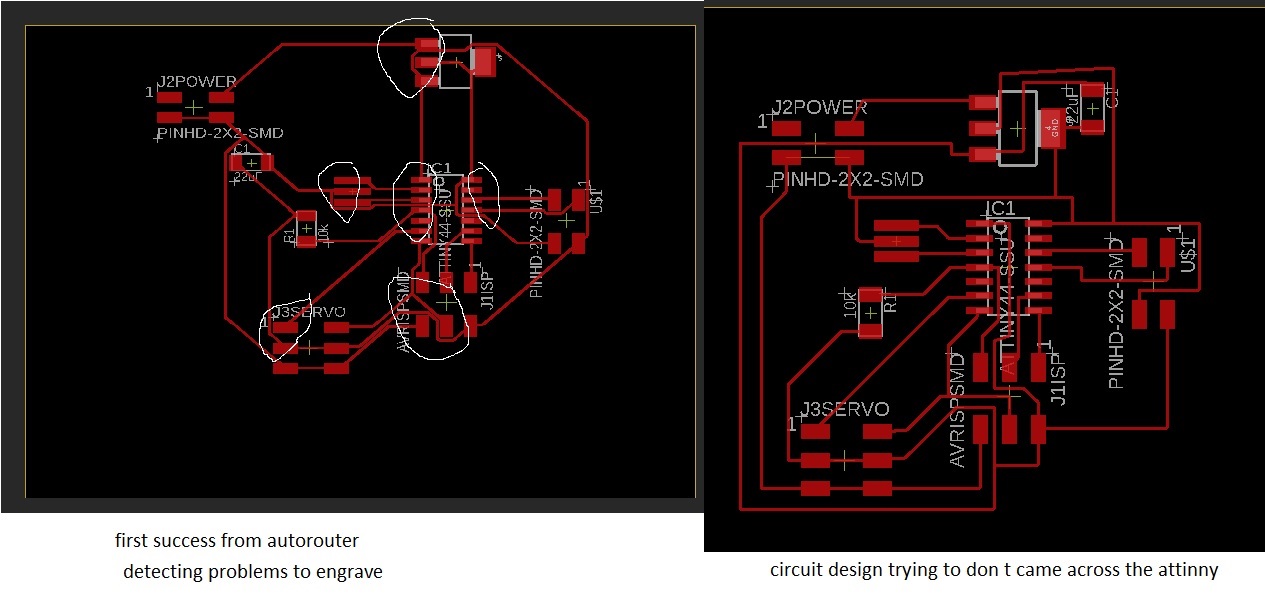

STEP 1 : FABRICATION PROCESS OF MASTER

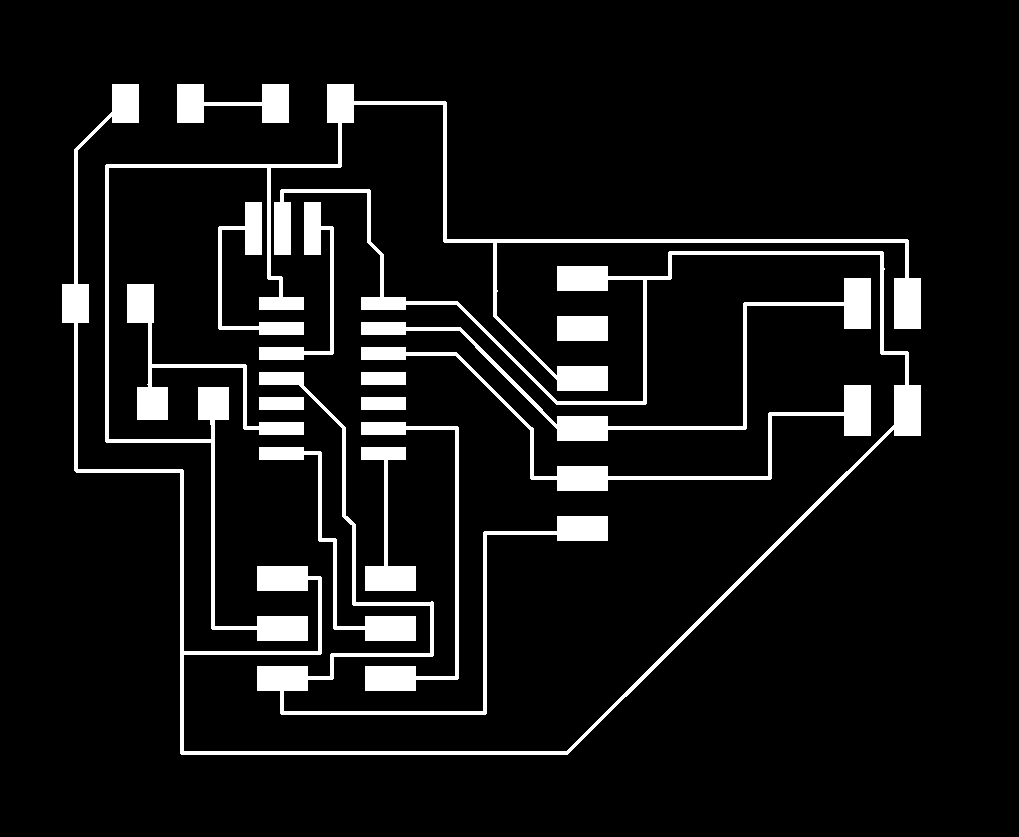

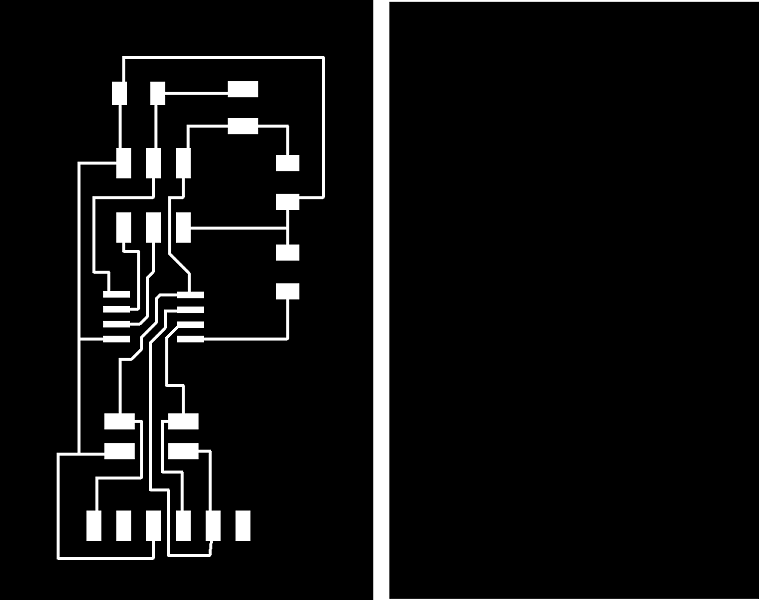

this is the final png for milling

ERC TOOL:ERC is an eagle tool to detect possible connection errors and consistency on the board. Its use is very advisable to have a final idea of possible errors

as always I first use fabModules with a single path, because that way we can better appreciate the possible defects in the trajectory of the drill.

dangerous trajectorys are not appreciated that accidentally connect roads, but if some details of nearby trajectorys where attention should be paid.

so I decide to modify small details just for prevention, to have this final path for milling

STEP 2 : design and fabrication of servo network board

For the same reasons explained above, the board designed in previous assignments to control a servo (assignment output) is not valid, so design and mill a new one.

components in schematic

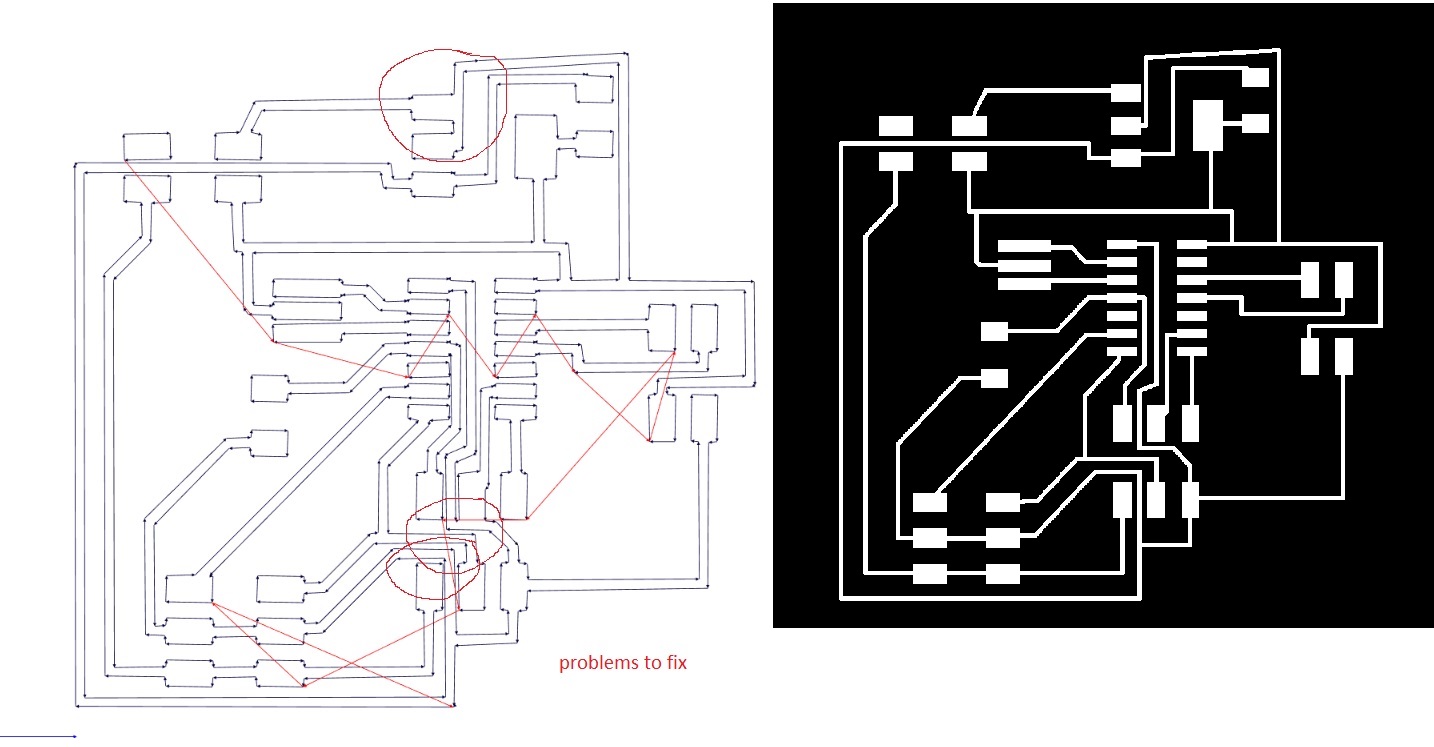

first design with lots of problems

In this first attempt you can easily see how there are some lines very close to the footprints of some components, once the line widths and the separation of these are adjusted. Thus, it is necessary to correct positions and the layout of some of these lines by hand. The most serious of all, of course, is the bridge marked in blue, it would be required to establish the connection on the back of the board..

Second design with a line crossing under the attinny44 wich allways gave me problems

I have tried to solve it on other occasions by passing the line between the tracks of the attiny44, but I have almost always had errors in the layout and it has been necessary to repeat the board. So I decide to reserve this solution and opt for it only in the case of not finding another solution

This seems to be the solution,although there would be several tweaks on hand to do. Try to avoid the footprint of the connections, make the line paths as straight as possible, access the component footprints perpendicularly, and separate the lines from the footprints whenever possible.

checking all using ERC tool

Hand made tweacks example :I modify some lines for the milling process taking care of distances to footprints

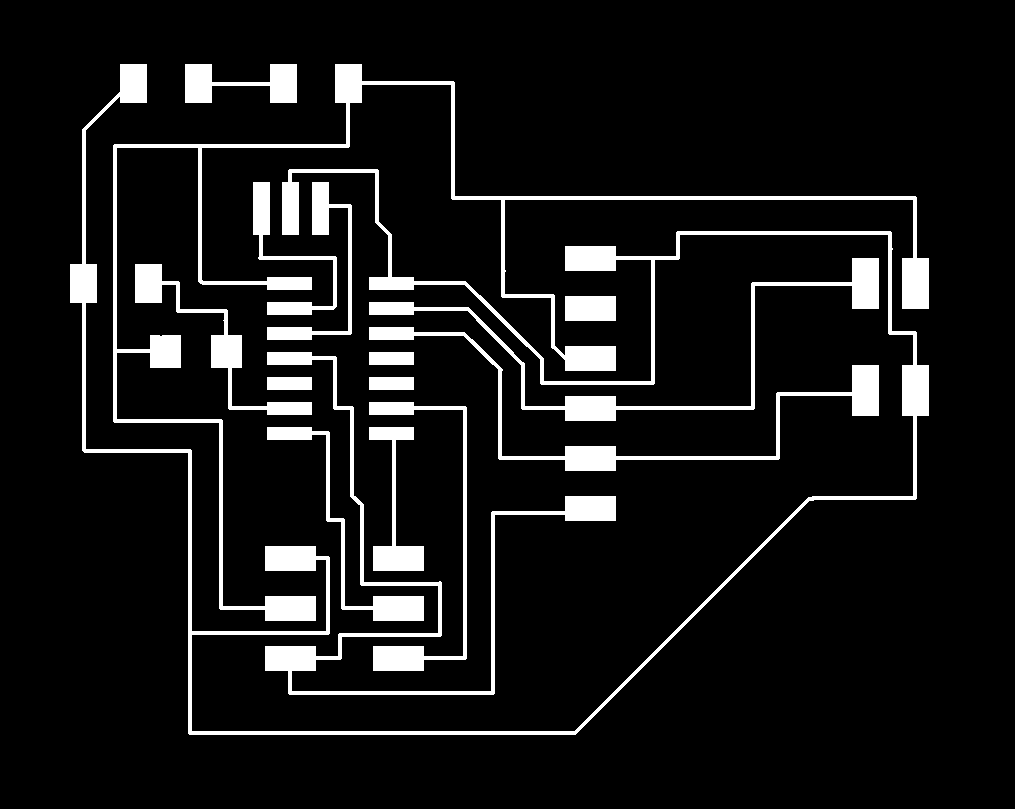

this seems to be good for milling

check in fabmodules with just one ofsset to see clearly any problems

result in fab modules for milling

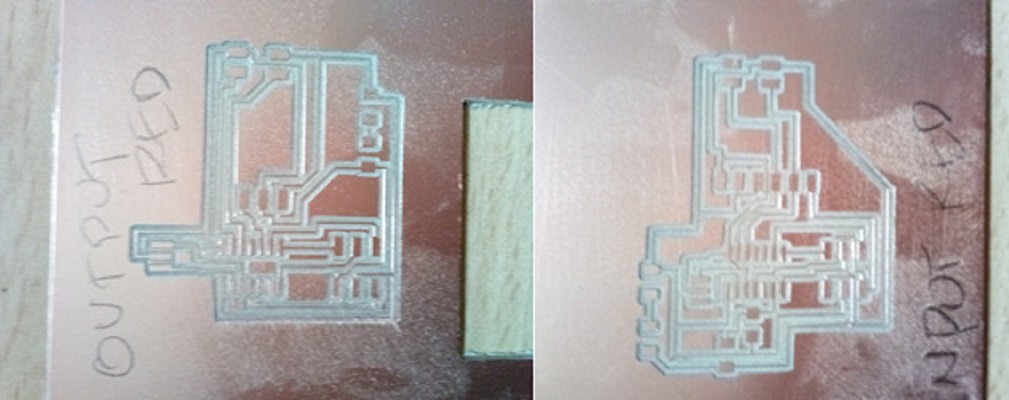

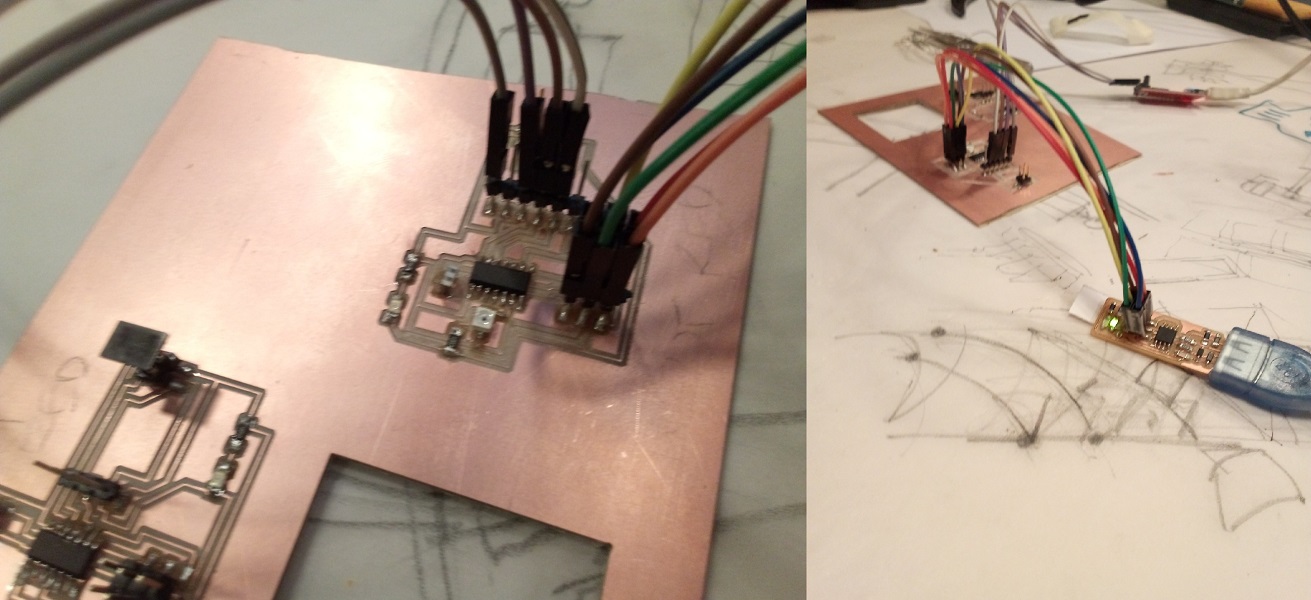

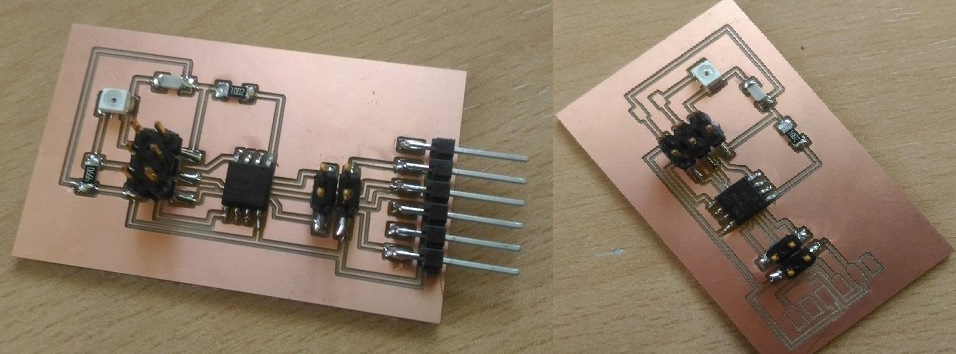

STEP 3 : MILLING BOARDS

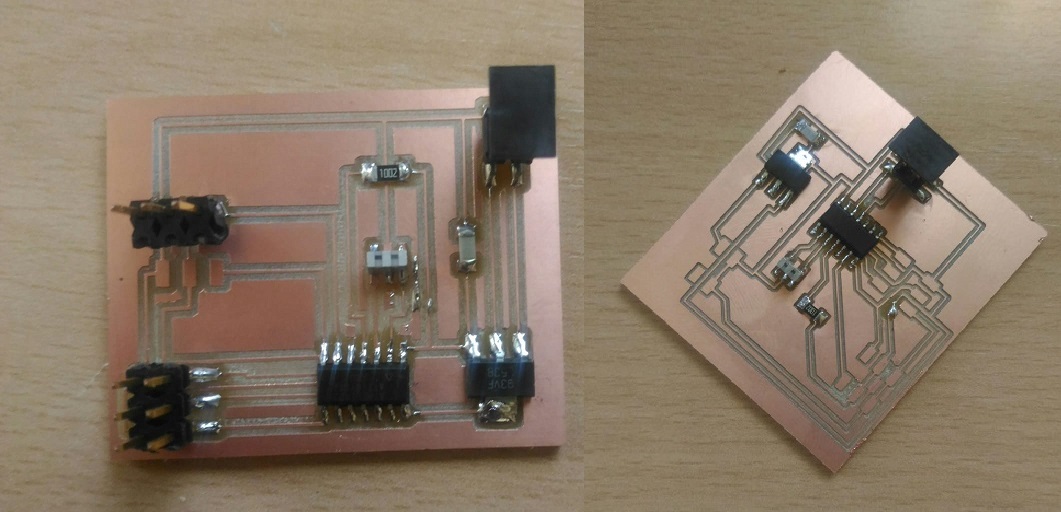

board engraving result

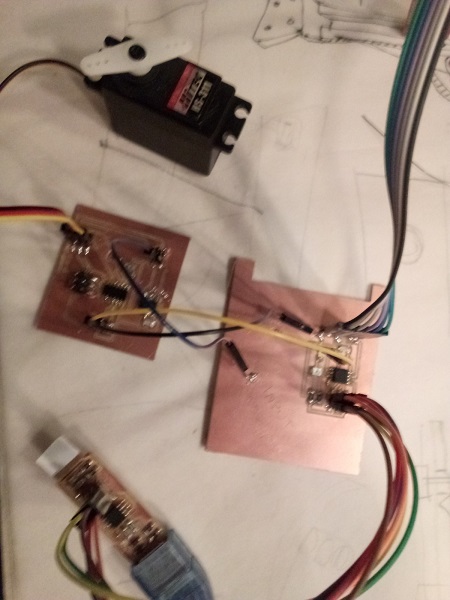

STEP 3 : COMPONETS SOLDERING AND CONNECTIONS

STEP 3 :PROGRAMMING BOARDS

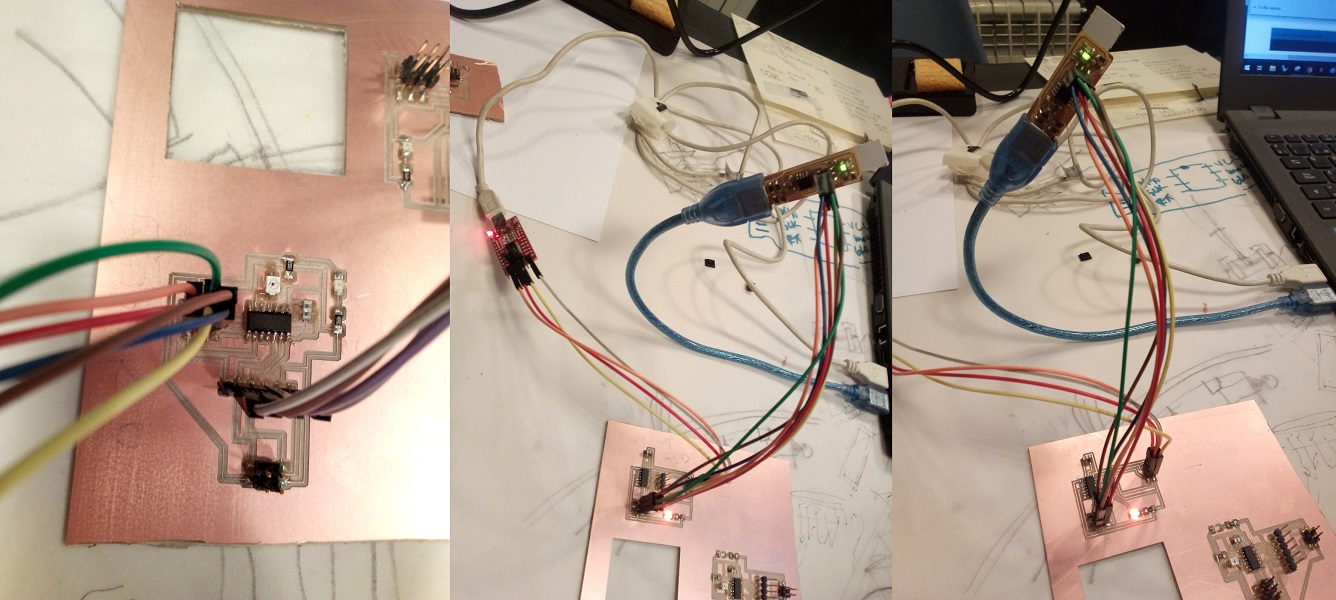

different attempts of programming of the two boards.

The problems were:

Arduino IDE does not recognize the board.

error search protocol

--revision of the arduino IDE configuration. correct

--USB connection review (fails many times). The computer does not detect the boards.

--methodical review of connections between boards and with the

programmer.

Since this did not work: complete disconnection of the boards and check line by line with the polymeter.

No works

so I deduced that there was some error in the design of the plates.

As a solution I intend to design the boards from scratch again by going to different examples of my colleagues at fab academy in this and other years, trying to find new ways of such a design and adapt them to mine

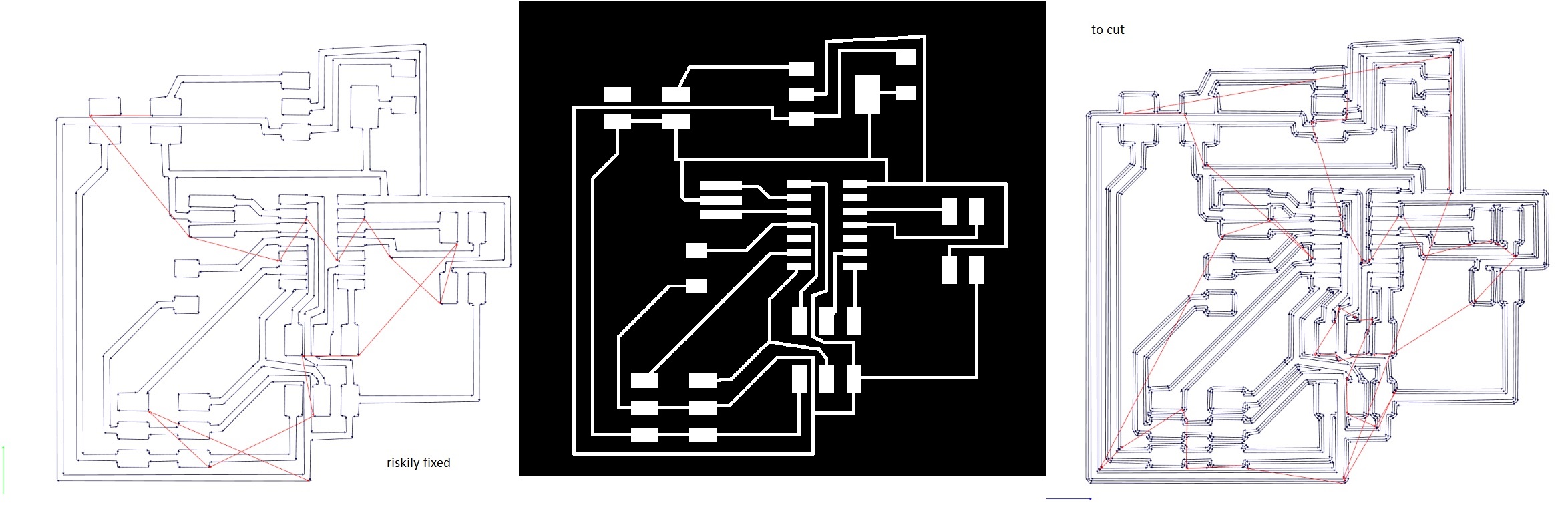

STEP 4 : NEW BOARDS FROM SCRATCH

so same process for design and fabrication

the input one

png traces ready for fab modules

fab modules files for milling withs single offset check

solderng components and final result

the output one

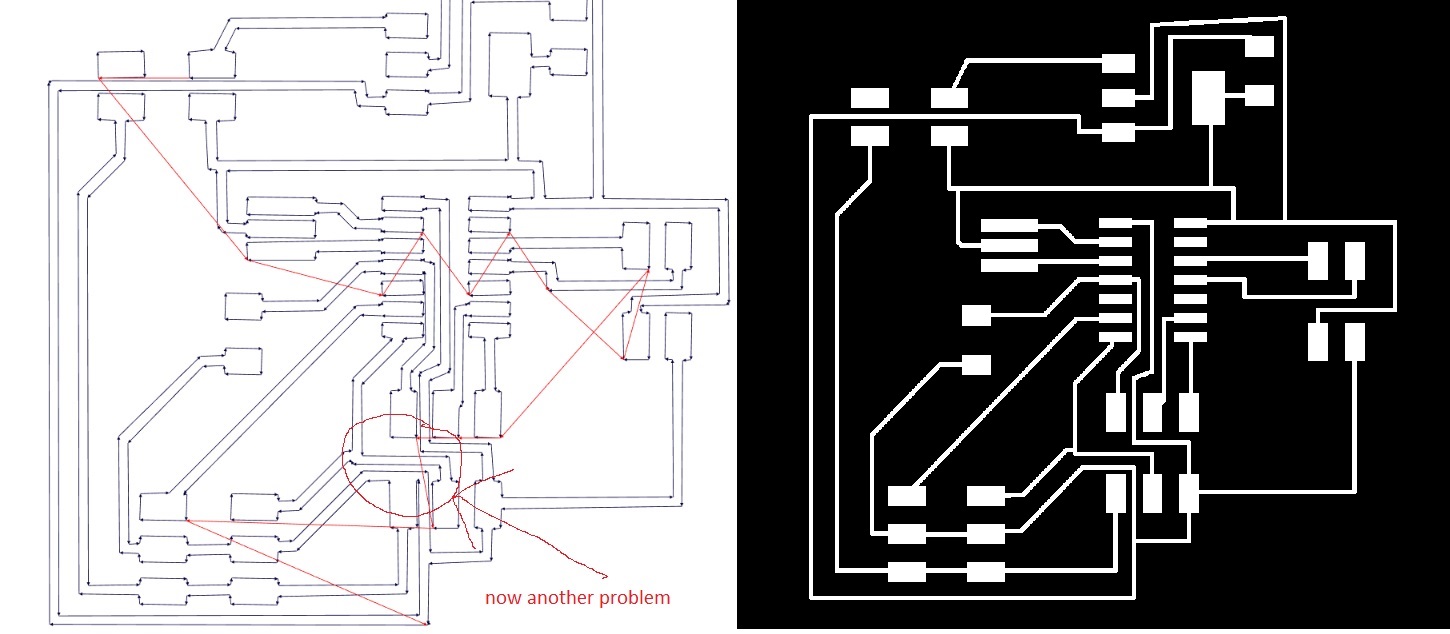

Now works in differents solutions with autorouter

In this process I find different solutions, although again and again I find the problem of passing lines between the fingerprints of the processor

finally I find a solution and check in fab modules with a single offset, because given the proximity of some lines I'm afraid of a problem

and indeed, although in the plot PNG everything seems correct fab modules detects that there will be problems in milling

after some manual corrections a new check detects another possible problem due to the proximity of the lines

It seems that in this solution the problem is solved. It is a risky solution due to the poor condition of the bits, but I decide to continue

fab modules files to cut the board

solderng components and final result

STEP 5 (UPDATE): UNDERSTANDING THE SERVO CODE AS DEEP AS I CAN

Following the instructions of my global instructor about the code to be developed, I revisit the neil code to move a servo, in order to understand how it behaves

//

// Neil Gershenfeld

// 4/8/12

#include 'avr/io.h'

#include 'util/delay.h'

// What this macro does is apply an OR (|) function between directions and pin. This is used to set a pin to 1.

// This is done because the

directions register address that indicates the digital status of the pins.

// So if the record says 00000000 and you want to put pin 3 high, you have to make a door

// OR with the value 00100000. To know what is the value to use, in

the datasheet you have to

// look for the description of that record.

#define output(directions,pin) (directions |= pin) // set port direction for output

// Do the same as the previous one

#define set(port,pin) (port |= pin)

// set port pin

// This macro does the opposite, if the register indicates that this pin is at a high level, making a door

// AND (&) with the opposite of the pin value, with a NOT (~) operation, so if pin 3 is

// 00001000, when

NOT is applied 11110111. And then the AND function is applied: 00001000 & 11110111 = 00000000

#define clear(port,pin) (port &= (~pin)) // clear port pin

// What this macro does is detect if pins and pin have the same value, if so it

stays the same, if not

// the result is 0

#define pin_test(pins,pin) (pins & pin) // test for port pin

// same idea as the previous one

#define bit_test(byte,bit) (byte & (1

<< bit)) // test for bit set

// wait one second

#define position_delay() _delay_ms(1000)

// To use a pin you always have to turn on the port first and then the address,

// This is because inside the hardware the pins are separated by ports.

// // PORTA

- this is the Port A Data Register

// PORTA7|PORTA6|PORTA5|PORTA4|PORTA3|PORTA2|PORTA1|PORTA0

// initial value: 00000000

#define PWM_port PORTA

// To have a 1 in the position where you need, in this case use the 1 that

in binary is 00000001

// As PA3 = 00000011 = 3, whereby the operator

<< moves the bits of the value on the left so many

// times as indicated by the value on the right. In this case it would be 00000001

<< 3=0 0001000

#define PWM_pin (1

<< PA3)

// PORTA - is the Port A Data Direction Register

// DDA7|DDA6|DDA5|DDA4|DDA3|DDA2|DDA1|DDA0

// initial value: 00000000

#define PWM_direction DDRA

... and the main code allready commented in the output assignement

STEP 6 : UNDERSTANDING WHAT NETWORK IS

In the search for information and in the data provided by Neil you can realize that there are many network communication protocols. So I go to several sources to know what it is, different types and rules, advantages and disadvantages of each, and their fields of application

tech target some definitionswikipedia protocols

interserver protocols and applications

lifewire protocols explained

science direct network protocols

after some reviews I decided to go deep in two protocol possibilities I2C and SPI

REVIEWING i2c PROTOCOL

based in this instructions and information...

CIRCUIT BASICSI realize that this protocol is quite suitable when communicating a microcontroller with many others considered slaves.

I2C is a serial communication protocol therefore the data is transferred BIT A BIT along a single cable.

I also note

that the same as SPI I2C is synchronous so that the output information is synchronized with the processor clock. clock is controlled by the BOARD MASTER.

As I see in this analysis

BUS I2C ARDUINOthere is some advantages and disadvantages for this protocol

ADVANTAGES

It requires few cables

It has mechanisms to verify that the signal has arrived

DISADVANTAGES

Its speed is medium-low

It is not full duplex

There is no verification that the content of the message is correct

The I2C protocol is used through the Wire library, which is implemented as "#include

This library contains a few basic functions for data transmission.

--- for transmission (master)

Wire.begin (); // join i2c bus (address optional for master)

Wire.beginTransmission (4); // transmit to device # 4

Wire.write (x);

// sends one byte

Wire.endTransmission (); // stop transmitting

---- for reciving (slave)

Wire.begin (4); // join i2c bus with address # 4

Wire.onReceive (receiveEvent); // register event

Wire.available ()

Wire.read ()

that would be exactly what I need to transmit my data

but looking for some application examples I found

USING I2C ON ATTINNY85where I can read "The standard Arduino library cannot be used for I2C on the Attiny because it does a call to 'Wire.h' and that one is not compatible with the Attiny" literally

so I need to check SPI protocol

REVIEWING SPI PROTOCOL

Serial Peripheral Interface (SPI) is a very similar protocol developed by motorola

with similar functions like

#include

SPISettings settingsA(x, x, x); // setting the communication

SPI.begin(); // inicialization

SPI.beginTransaction(settingsx);

SPI.transfer();

SPI.endTransaction(); //recommended not to interfere with other libraries

But, as I can read in

ARDUINO SPI LIBRARY"this library supports only master mode"

so I cant use it in my proyect

USING UART Based Networking for Microcontrollers

After weighing the advantages and disadvantages of the different network protocols reviewed, I consult similar examples carried out in fab academy to get an idea of how to use a protocol, the advantages and disadvantages of each in the different projects and results and find the best way to adjust it to my project

eduardo segovia jose fuenzalidafablabegypt

nikita-kovalchuk

gustavo deabreu

anton-pchelkin

ivan-avado

mayra-lopez

The solution came discovering the UART network for microcontrollers used by the SoftwareSerial.h library, much lighter, which also allows me to label devices in a propper network.

so I decided to learn about and use this to operate

from wikipedia :

A universal asynchronous receiver-transmitter (UART ) is a computer hardware device for asynchronous serial communication

in which the data format and transmission speeds are configurable.

The electric signaling

levels and methods are handled by a driver circuit external to the UART.

A UART is usually an individual (or part of an) integrated circuit (IC) used for serial communications

over a computer or peripheral device serial port.

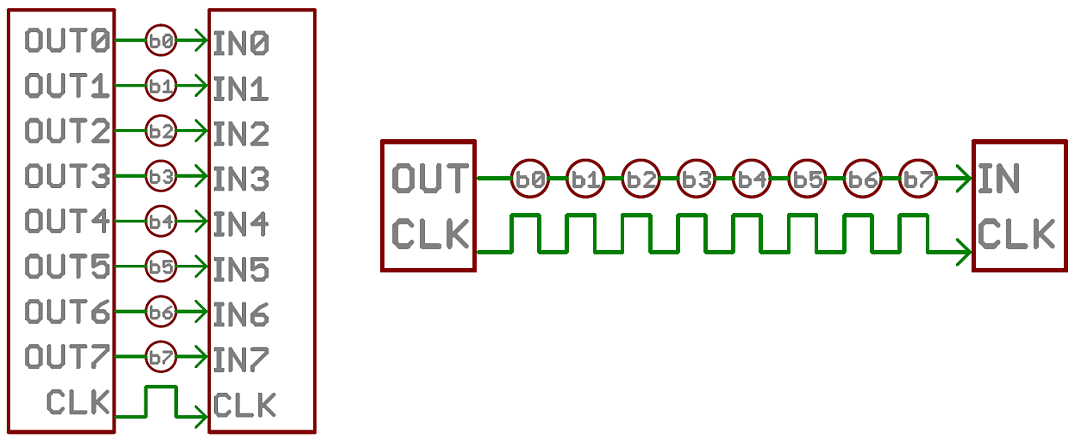

The first question to understand, since it appears on all the websites consulted, is the difference between serial communication and parallel communication.

in this example as parallel An 8-bit data bus, controlled by a clock, transmitting a byte every clock pulse. 9 wires are used.

meanwhile in an example of a serial interface, transmitting one bit every clock pulse. Just 2 wires required!

from MIKROESo serial communication is the process of sending data one bit at a time, sequentially

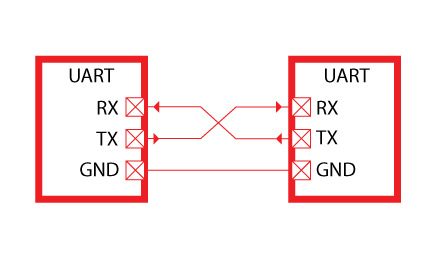

The communication goes through the two independent lines : TX (transmission) and RX (reception).

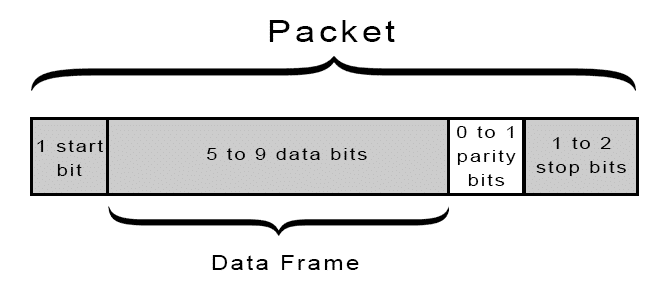

UART transmitted data is organized into packets. Each packet contains 1 start bit, 5 to 9 data bits (depending on the UART), an optional parity bit, and 1 or 2 stop bits:

from circuit basicssee more in webs

sparkfunelectric imp

geekytheory

aprendiendoarduino

So I use the softwareSerial library for my network using the code included in the arduino web as an application example and some other examples from fab academy

software serial examplecode commented . complete code included in download files

ldr sensor code

#include "SoftwareSerial.h"#define address_1 1 // label

const int analogInPin = A2;

int sensorValue = 0;

int outputValue = 0;

const int Rx = 1; // this is pin 7

const int Tx = 2; // this is pin 6

SoftwareSerial mySerial(Rx, Tx);

void setup()

{

// pin configuration

pinMode(3, OUTPUT);

pinMode(Rx, INPUT);

pinMode(Tx, OUTPUT);

mySerial.begin(9600); // send serial data at 9600 bits/sec

}

void loop()

{

// read the sens

sensorValue = analogRead(analogInPin);

// map it

outputValue = map(sensorValue, 0, 1023, 0, 255);

//mySerial.print("sensorValue = ");

mySerial.print(outputValue);

mySerial.write(address_1);

// sensor conditions to send a signal

if(outputValue > 240)

{

digitalWrite(3, LOW);

}

else

{

digitalWrite(3, HIGH);

}

delay(15);

}

servo code

#include "Servo.h"#include "SoftwareSerial.h" //load serial library

const int Rx = 1; // this is pin 7 input

const int Tx = 2; // this is pin 6 output

SoftwareSerial mySerial(Rx, Tx);

#define servo 3 // the PWM pin the servo is attached to

#define address_1 1 // label

int bytein = 0; // for incoming serial data

//variables

int pinServo = 3; //revisar para ver el pin

Servo motor; //Servo as an object

int sensor; // sensor values

void setup (){

mySerial.begin(9600); //comunicación entre el puerto serial y el arduino

motor.attach(pinServo); //vinculamos el servo al pin

}

void loop (){

if(mySerial.available()>=1)

{

int addressbyte = mySerial.read();

if (addressByte == address_1)

{

motor.write (sensor); // servo moving with sensor values

Serial.println (motor.read()); //servo position

delay (2000); // intervalo de 2 seg

}

}

}

console program testing one servo

the make -f hello servo

the program usb tinny fuses

the writting flash

and this this is the console program testing two servos

p> the make -f hello servothe program usb tinny fuses

network connexions