Machine Design

After we finished the first part is the design of the mechanical part now comes the role of machine design so that electronic machining. After working as a team with both Mohammed and Yousef, we managed to finish the mechanical part. To complement the project, Mohamed worked on the design of the electronic circuit and ordered me to solder it. And Yousef worked on programming sensors and DC Motor and I should design the base for the DC Motor.

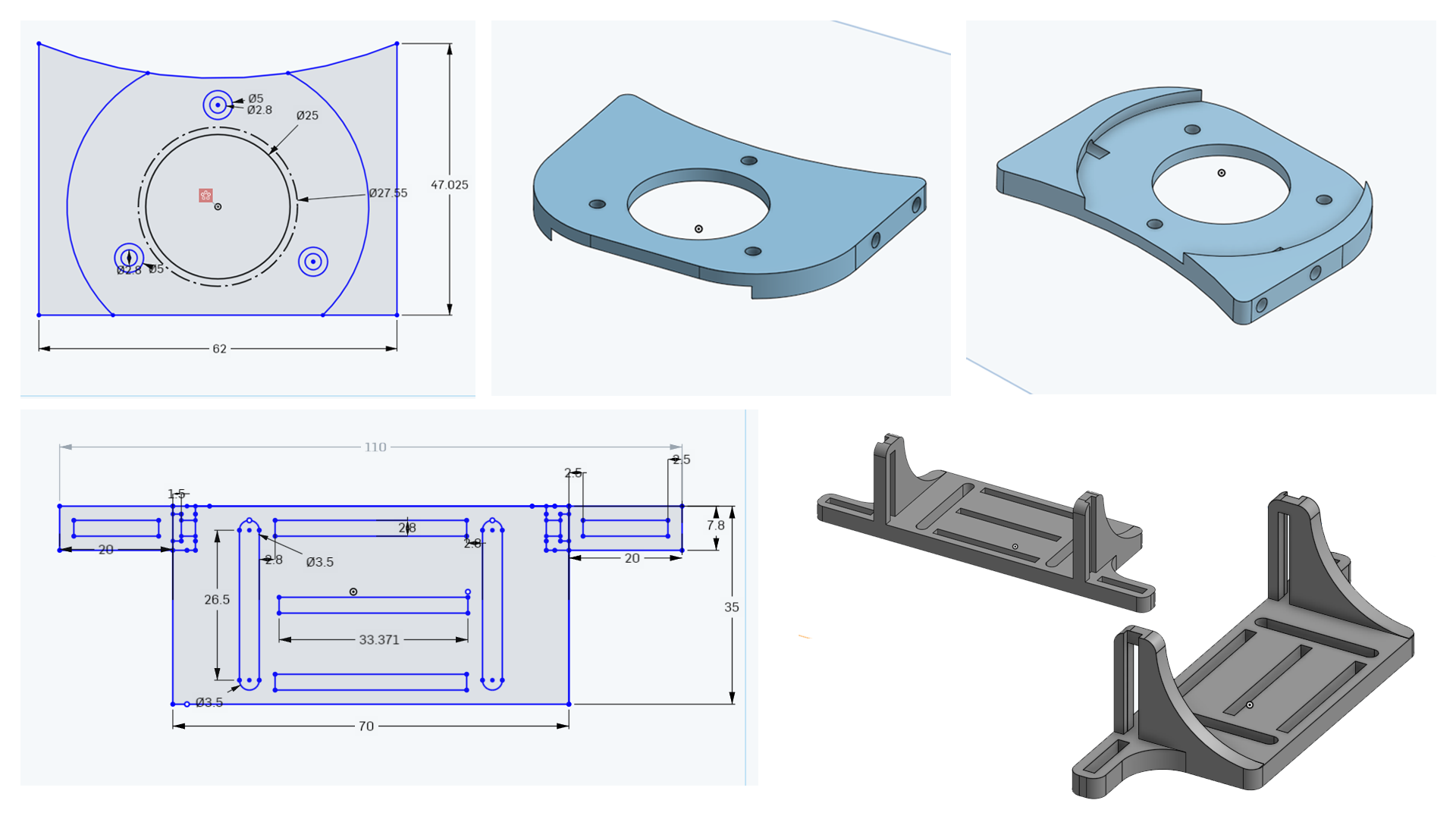

Before starting design the base of DC Motor, it was important to consider three things:

1 - Install the DC motor correctly and non-compliance

2. The DC motor shall be parallel to the axis of shaft rotation

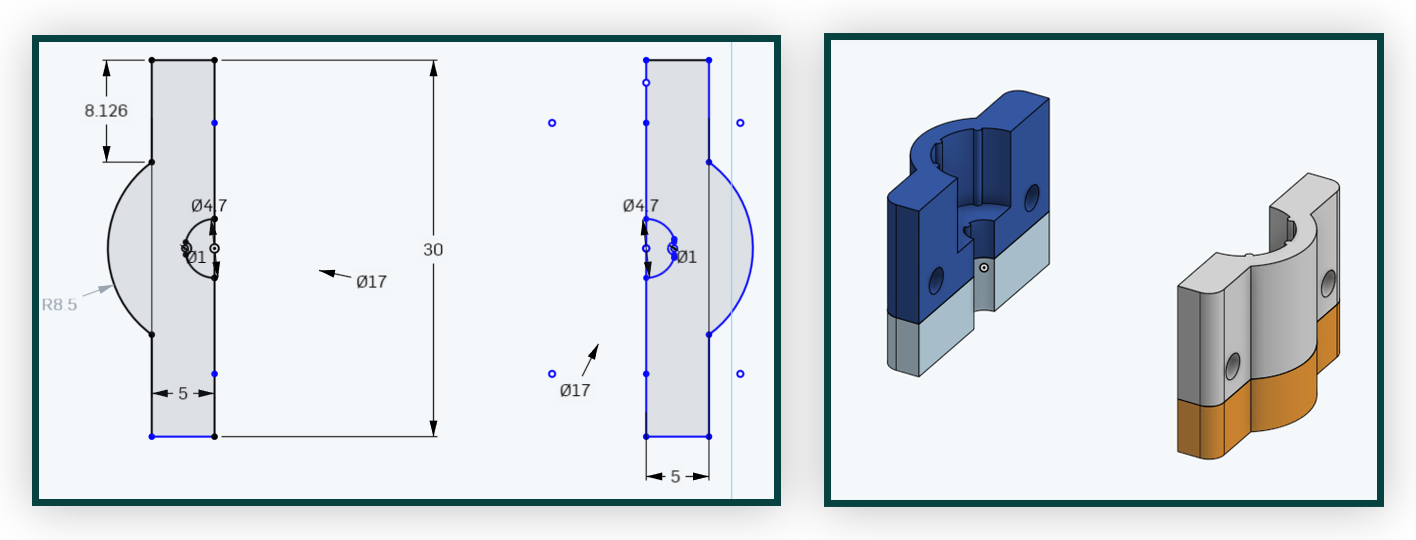

3 - Design a coubler to hold up between shaft and the DC motor

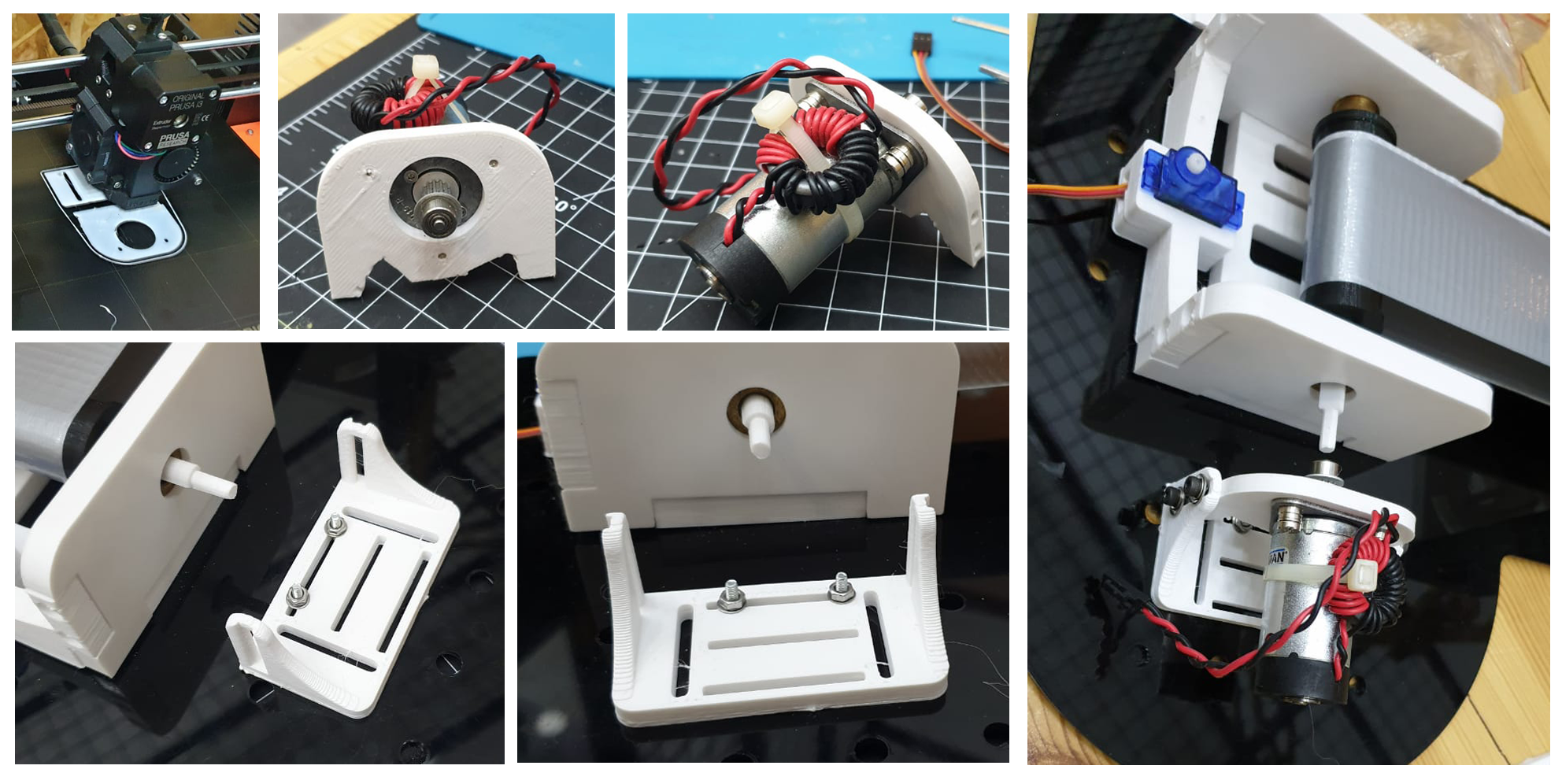

I started working design on the DC motor base then design the base that will installed between the base of project and the DC motor base as shown in the above image

I printed the 3D design then installed all the part together with 3mm screws

then design the coubler that will hold between shaft and the DC Motor

first test was great that the conveyor is working

and tetsted to running the belt and move the things like box

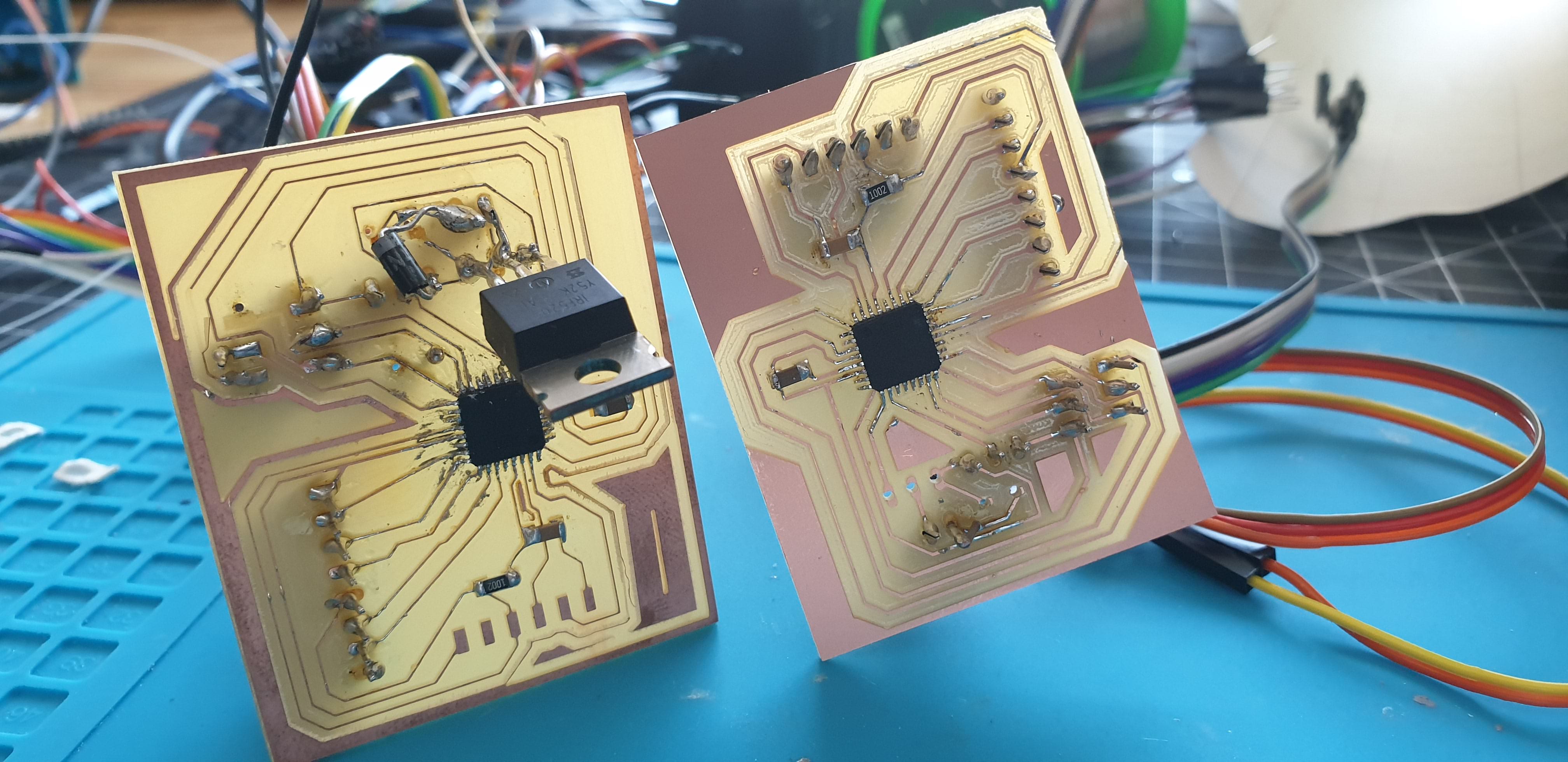

Then I moved to the electronic circuit soldring phase as viewed in the video

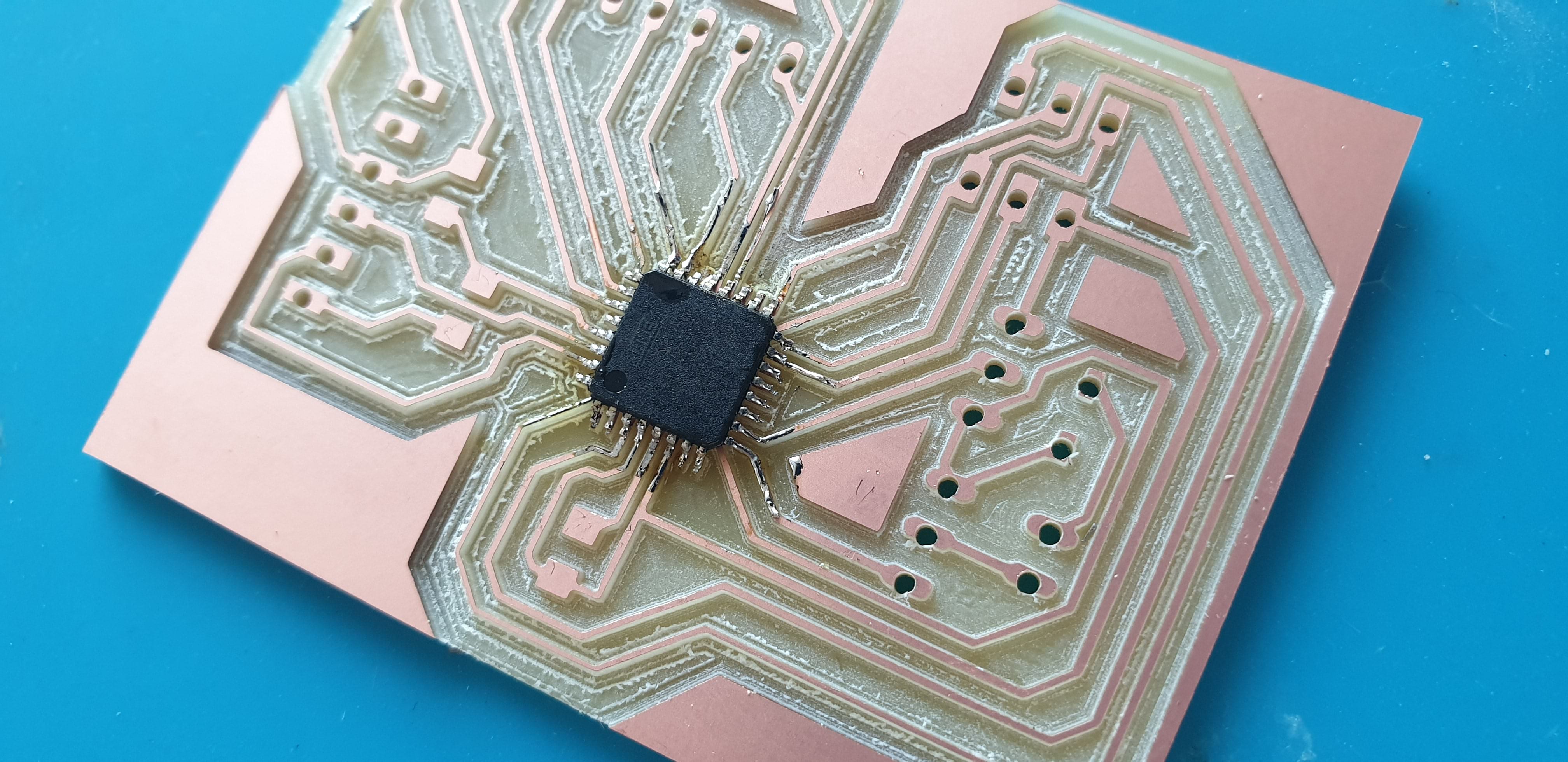

soldred the difficult part which is the ATMEGA 328 P-AU

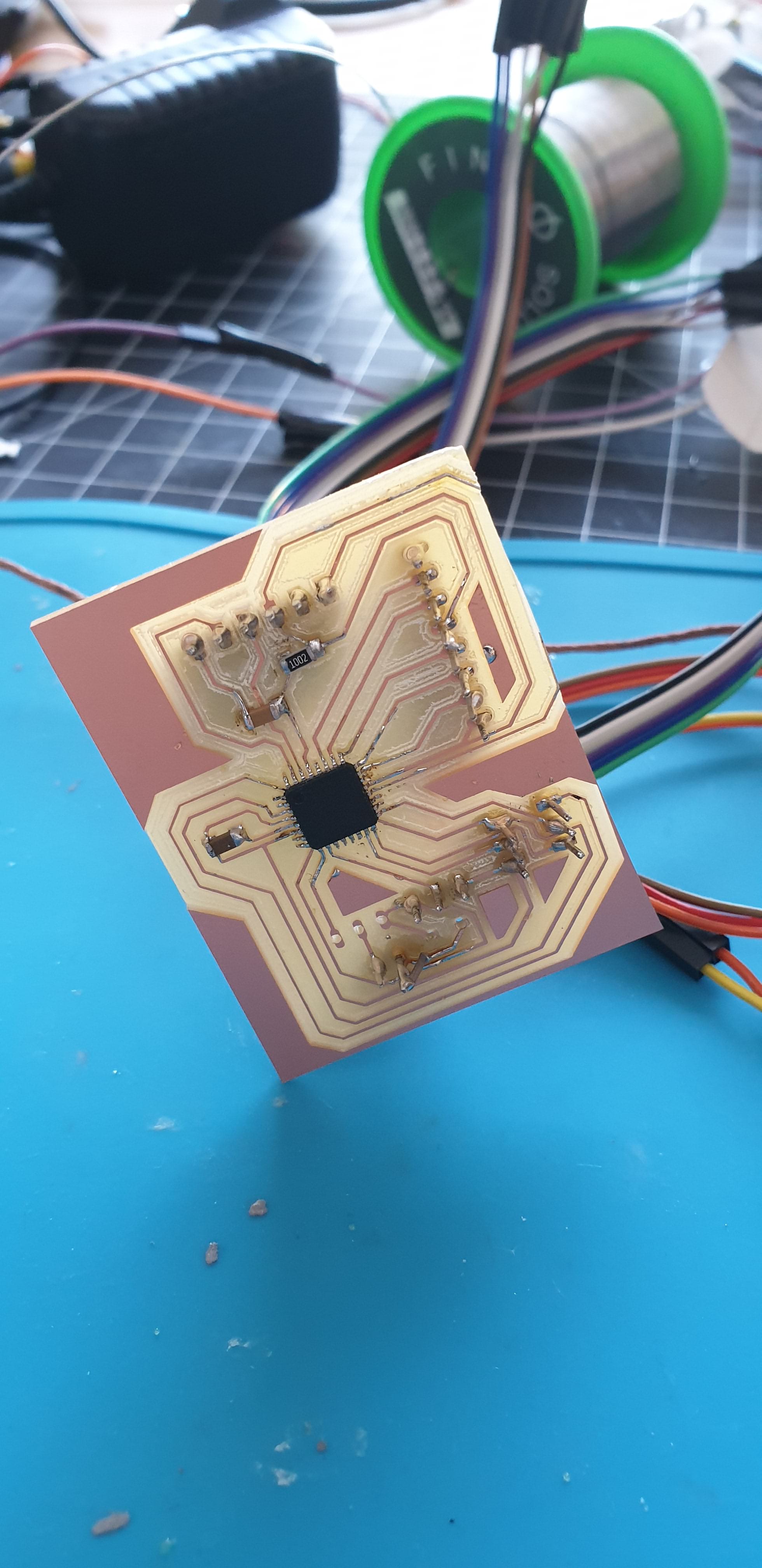

then the capsitor, resitors, pins, and all the components

I finished soldering to PCBs just in case one of them is broken or damaged during working

To download files

ConveyorSTEP files: Click Here!