Concept

My new final project for this year is a robot that has been presented with support from the Fab Labs Kids network.

This project is developed in order to improve it so that it can be replicated in the different laboratories that

work with the fabkids network.

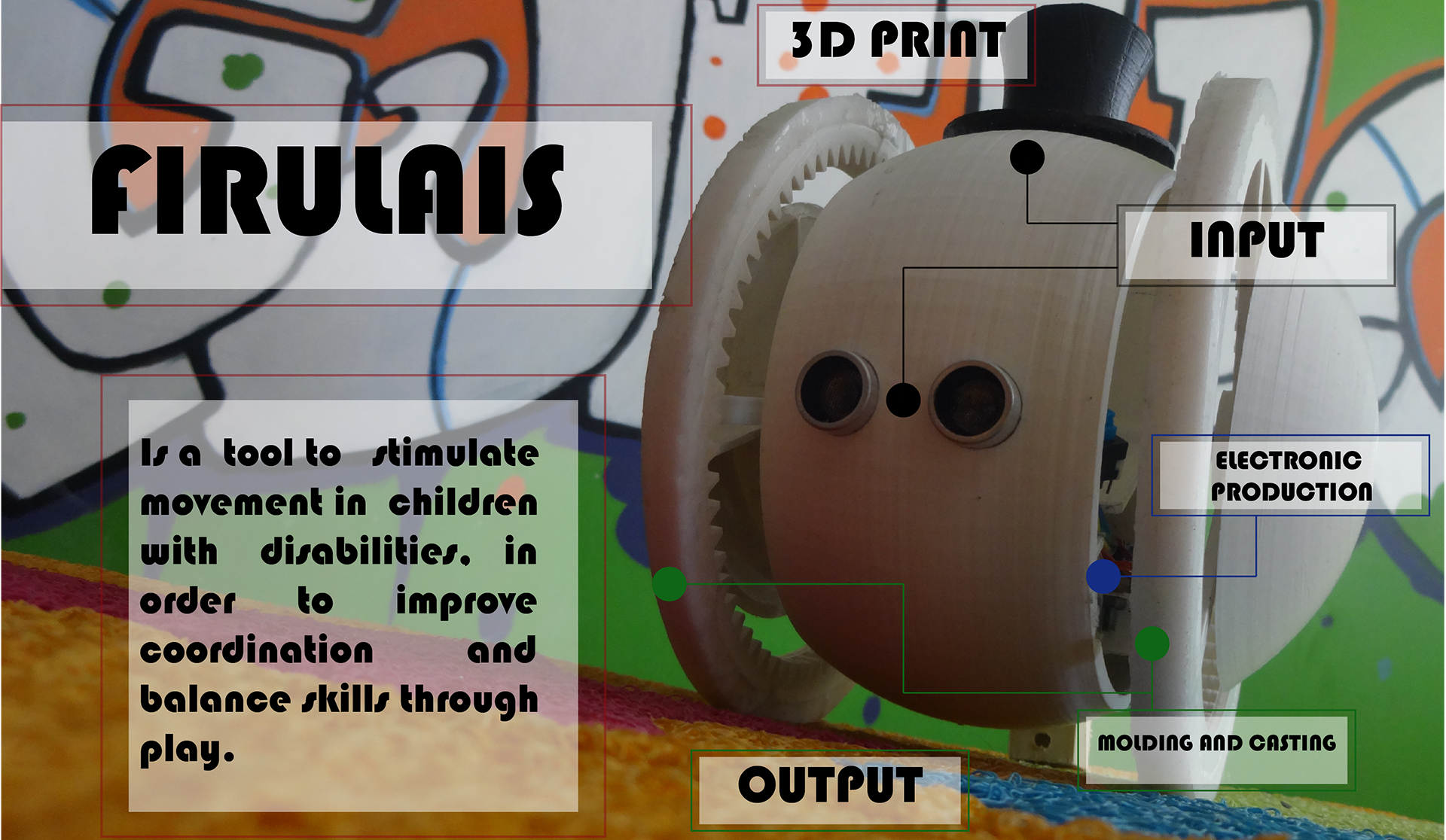

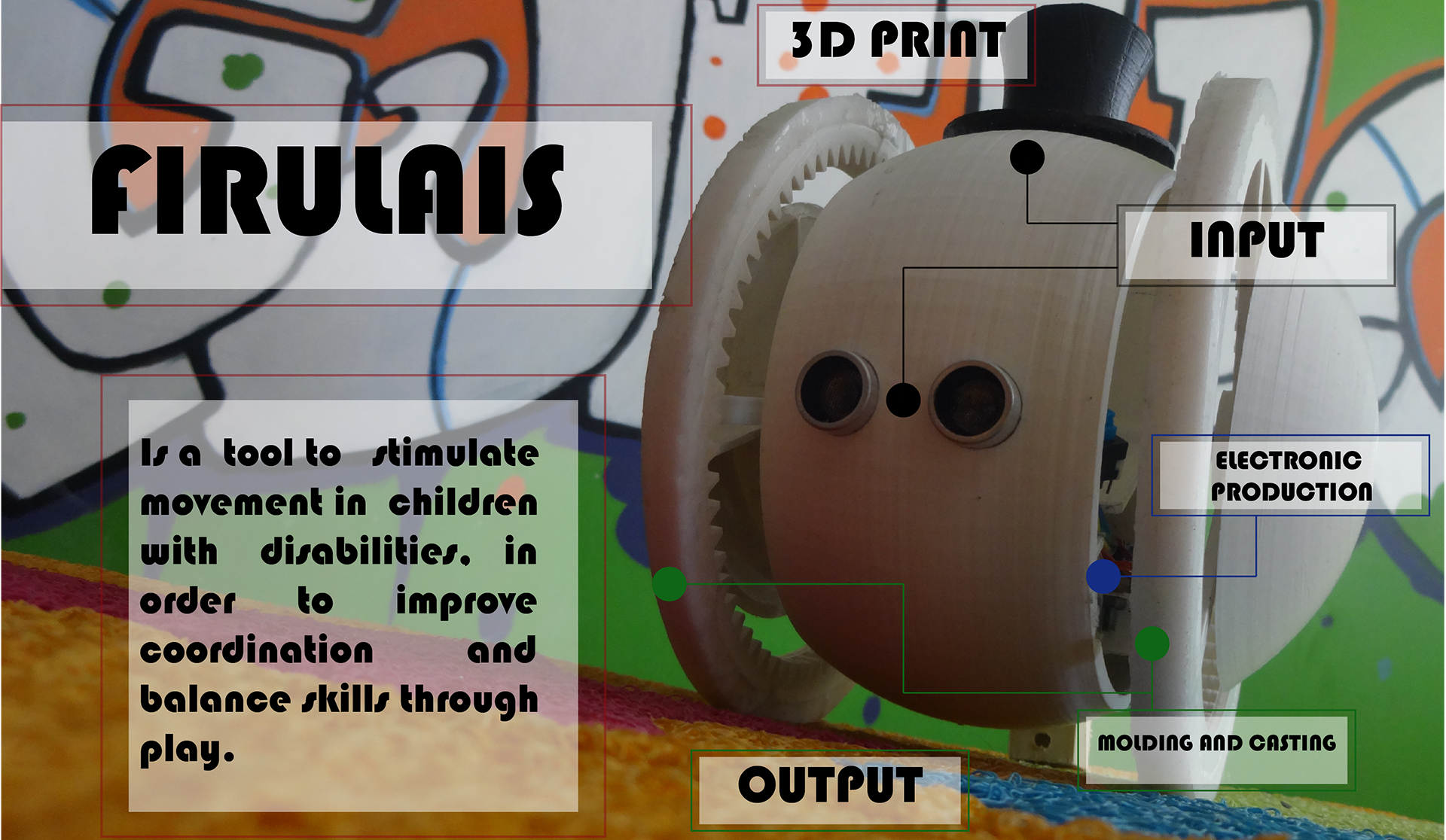

Firulais, is a tool to stimulate movement in children with disabilities, in order to improve coordination and balance

skills through play.

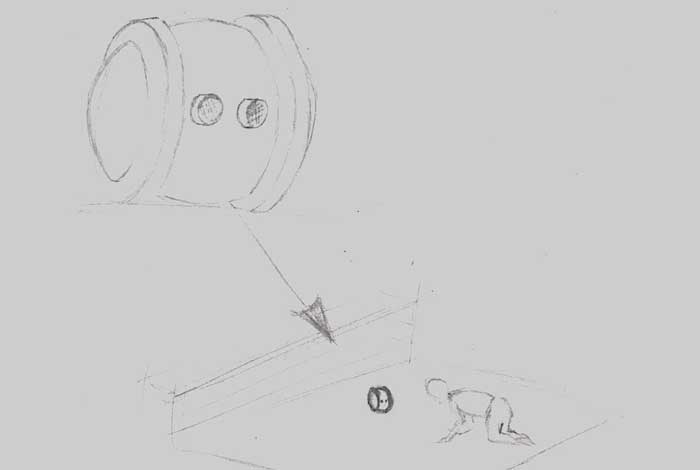

The operation of Firulais is based on creating a stimulus, to try to catch it while it flees, it is an automaton robot,

which aims to be a complement for the therapy of children with motor disabilities.

Stimulation is a factor which gives a different nuance to the development of each child, "specific stimuli can induce

greater development in different areas".

"LEARN PLAYING"

For the proper development the friendly design and that calls the attention of the children should be a priority so investigate

in some of the best toys and how is their behavior in order to be able to add firulais the best features.

BB8 Star wars

The BB-8 droid was a physical support developed by Disney Research, created by the special effects artist Neal Scanlan and operated

´live on the set with the actors. To take pictures, several BB-8 models were built. The highlight was a puppet controlled by the puppeteers

Dave Chapman and Brian Herring. In addition, there were several units controlled by radio and some versions of static support. At full

operation, an autonomous robotic unit was not practical for filming, so most of the scenes in which it appeared "walking" were achieved

by the puppet, with threads that were removed in post-production. However, over time a remote control unit was built and used in promotional

events.

COZMO

Meet Cozmo, a gifted little guy with a mind of his own. He’s a real-life robot like you’ve only seen in movies, with a one-of-a-kind personality

that evolves the more you hang out. He’ll nudge you to play and keep you constantly surprised. Cozmo’s your accomplice in a crazy amount of fun.

Problematic

For the best development of the team, the problem to be solved from the main axes was analyzed, understanding this problem better in children.

Physical activity in children is a fundamental need for a healthy life, so that disability is a factor that acts against. However, nowadays, it

can be counteracted with therapies and equipment that improve the quality of life.

In children with disabilities, the development of physical activity is a challenge that engineering has faced with technological aids.

From the medical point of view, there are several reasons why there is a disability in the motor skills of a child. It can have several origins

either progressively due to the bad training of the person or who has suffered a stroke.

The gross motor is the ability to move the muscles of the body in a coordinated manner and maintain balance. It is the agility, strength and speed

needed to perform all the movements that encompasses our body such as control of the head, mobility of the upper and lower extremities, in order to

perform the following movements such as crawling, jumping, turning, being standing, walking, catching objects, etc.

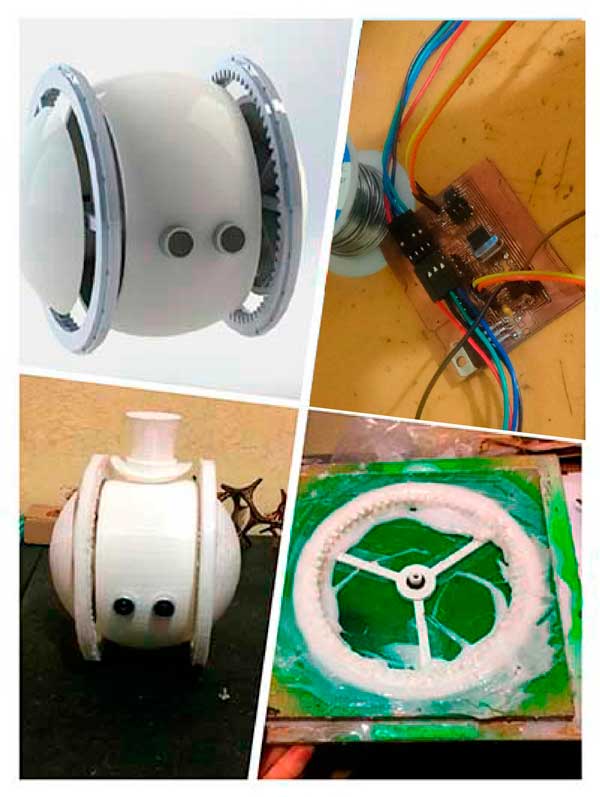

Processes

For the creation of Firulais, several proposals were developed in digital manufacturing until reaching all the basic digital

manufacturing processes in a Fab Lab.

Principles and Practices

For this process practice in the following week where you can observe the development processes of each of the processes in greater detail in the following link.

Fab inventory

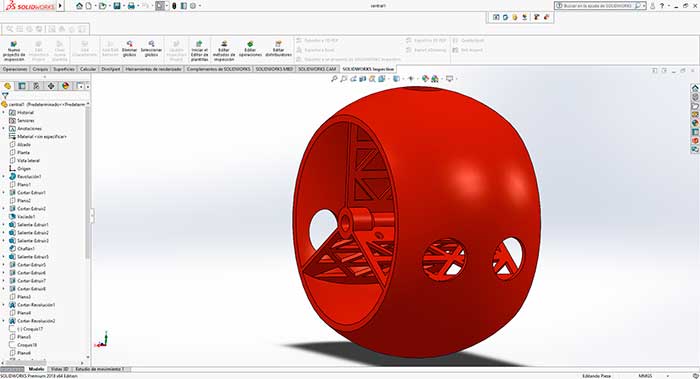

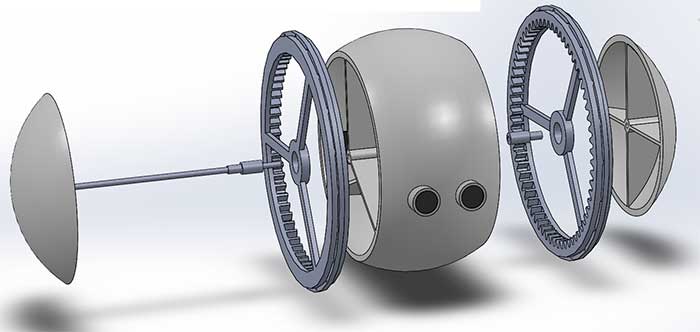

Computer aidded design

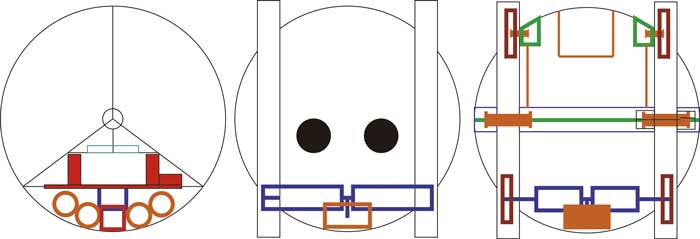

Mechanical design

Electronic production

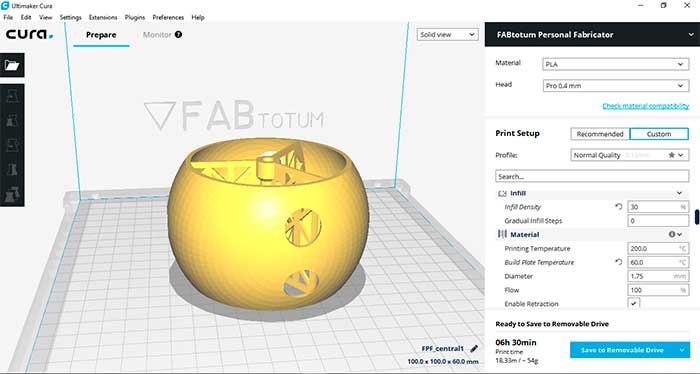

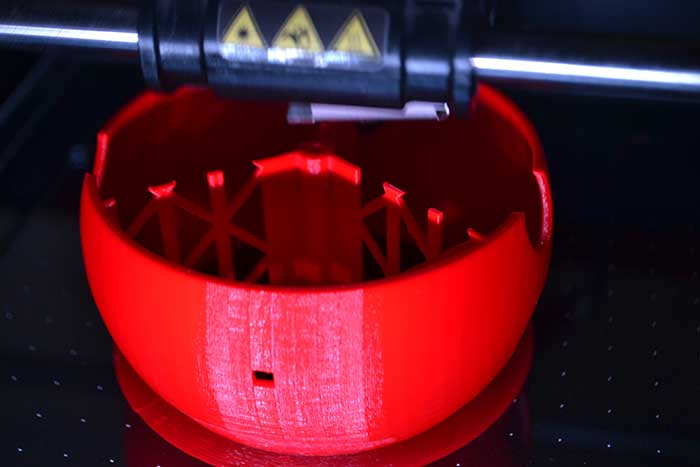

3D printing

Embedded programming

Molding casting and composites

Input

For this process practice in the following week where you can observe the development processes of each of the processes in greater detail in the following link.

Output

For this process practice in the following week where you can observe the development processes of each of the processes in greater detail in the following link.

Molding and casting

CNC machining

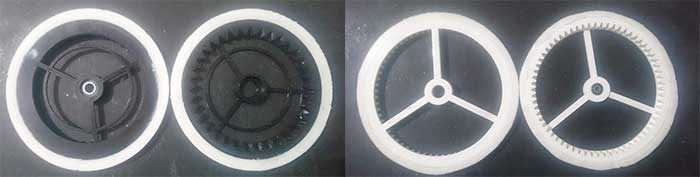

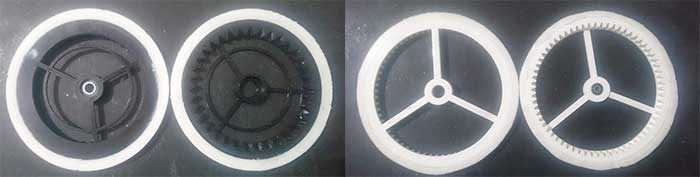

for the development of the tires we use silicone rubber to be able to have more traction in them.

for this we use the same Fabtotum machine, nothing more than changing to the milling head to create the mold.

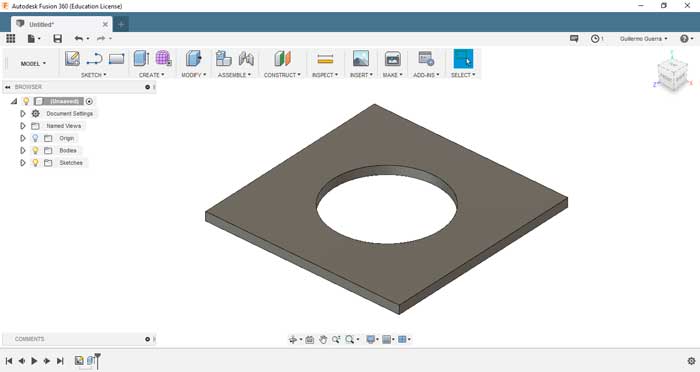

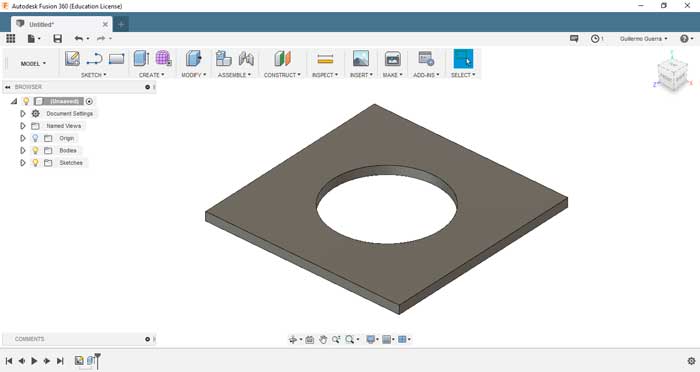

In this process we use cnc machining and composite materials, as a first step in fusion 360 design the mold in MDF.

Then for the modeling process we create a square to which a circle of diameter of the tire is cut and the thickness

of the tire is extruded from the dimensions 0.9 mm and from this design we perform the machining in the CAD process

as explained below.

CAM PROCESS

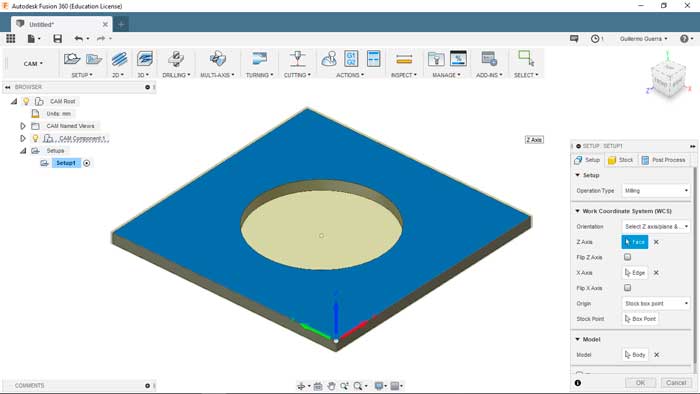

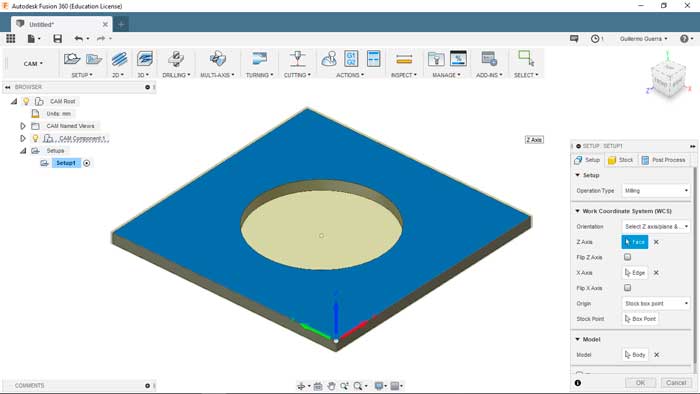

Within the software allows us to directly generate the gcode with the calibration of the machine to which it is going to be used. For this,

the following processes were generated.

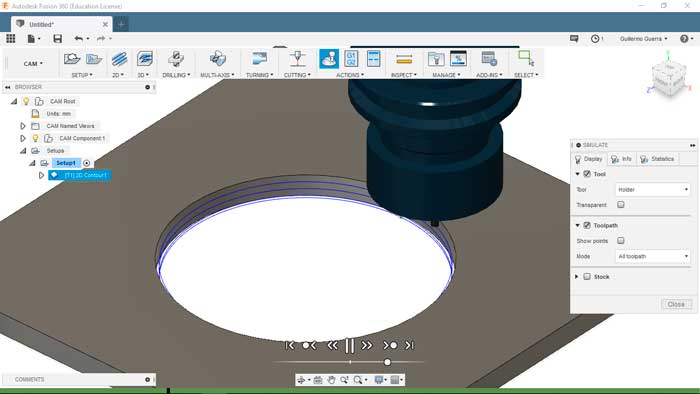

We chose the CAM process followed by creating a new configuration in SETUP in which we modified the frames of the pieces to be machined, choosing

the correct orientation of the axes according to the point of origin selected and that of the machine. To achieve this in the configuration, we

modify in the first two sales of the Setup menu orientations, axes and Stock in which the limits of the area to be machined are established.

As a next step we choose the process or the appropriate processes to be able to generate the form.

For the development of these pieces, two processes were used, each of which is detailed.

2D CONTOUR

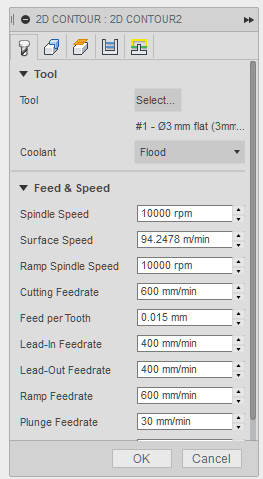

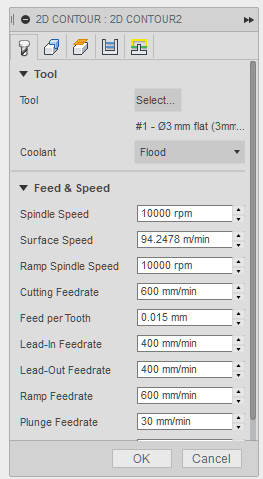

Based on the design of the piece we chose the right tools for this the contour tool was chosen. In this process we also modify milling parameters

based on the characteristics of the milling cutter and the material.

Tool._ in this window is configured and the mill is chosen according to the material for this process was chosen a 3mm titanium STRAWBERRY

with four blades, followed by this in the same window are set the speeds of step, rise, fall, etc.

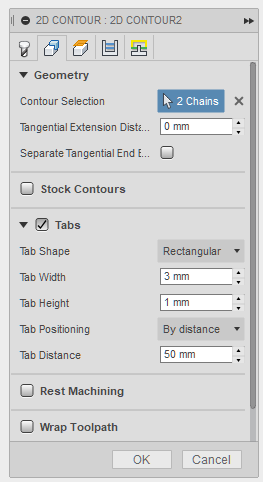

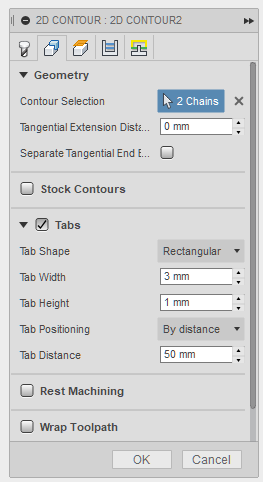

Geometry._ with this tool we select the contours of the pieces and add some couplings with which will hold the pieces so that they do not move

at the moment of finishing the cutting process to which they are attached at a prudent distance for this piece every 50mm.

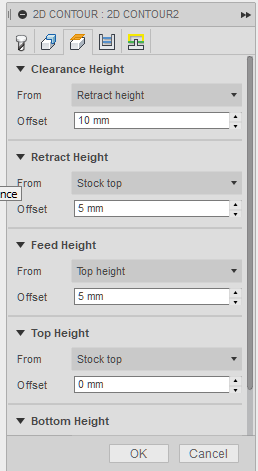

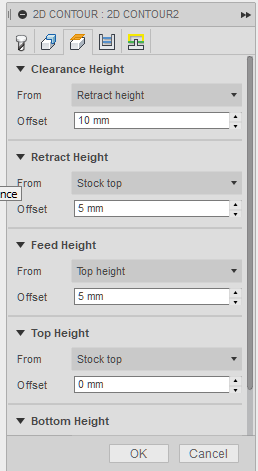

Heights._ No changes were made in this window.

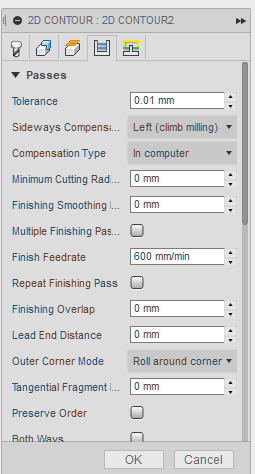

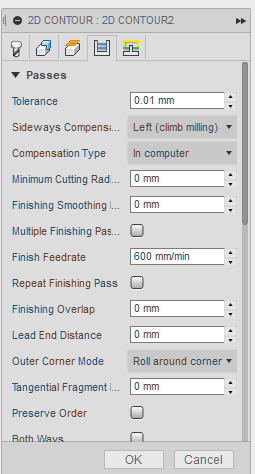

Passes._ With this tool we define the distance between the steps of descent, this will also depend on the type of STRAWBER that will be used

and the configuration of the speeds mentioned above for this process was determined a value of 3 mm.

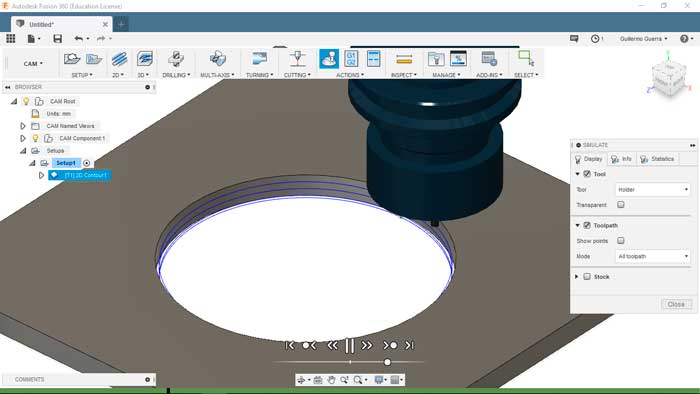

Once with all the loaded values, we can click on the "ACTIONS" window and choose the option of "SIMULATE" to check that all the processes are

correctly established.

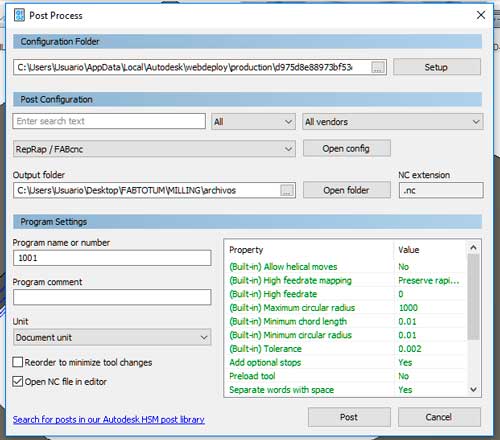

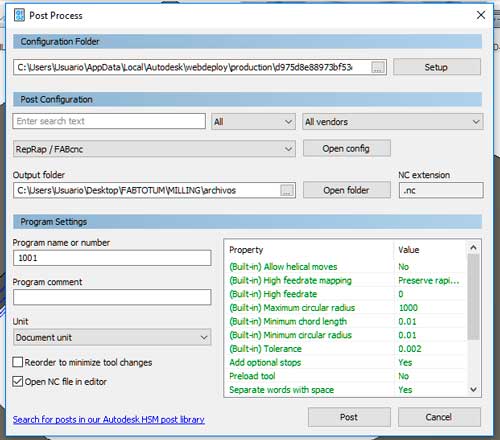

To finish the process in Fuision 360 we generate the G code to load the program into the machine. For this we click on the tool "POST PROCESS".

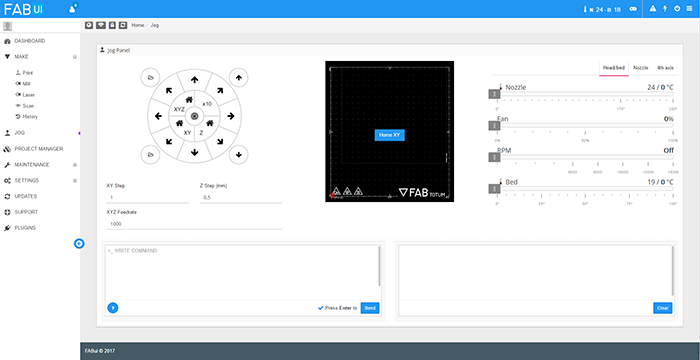

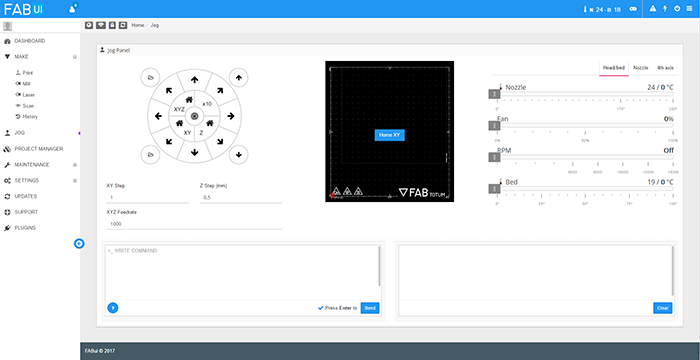

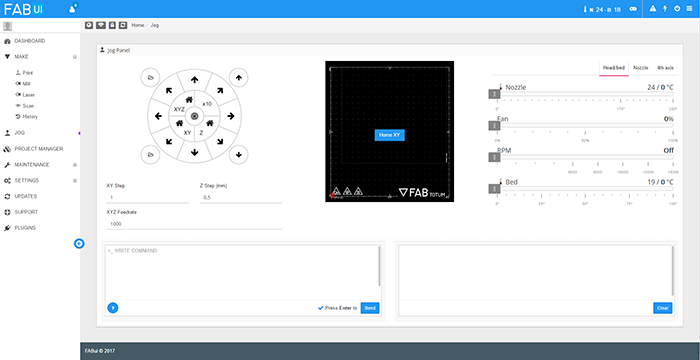

As to next step we proceed to add the file in the machine to machine. we use Fabtotum which uses Fab ui as a driver software, a very simple

program to which you only load the file and calibrate the machine to machine.

Below you can see images of the machining and the process of emptying rubber.

Finally we hope that the rubber will dry, we extract the tire from the mold and we obtain the final product

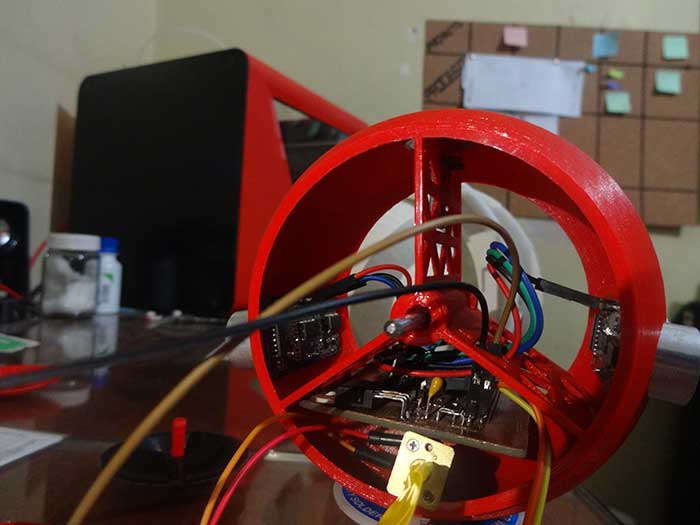

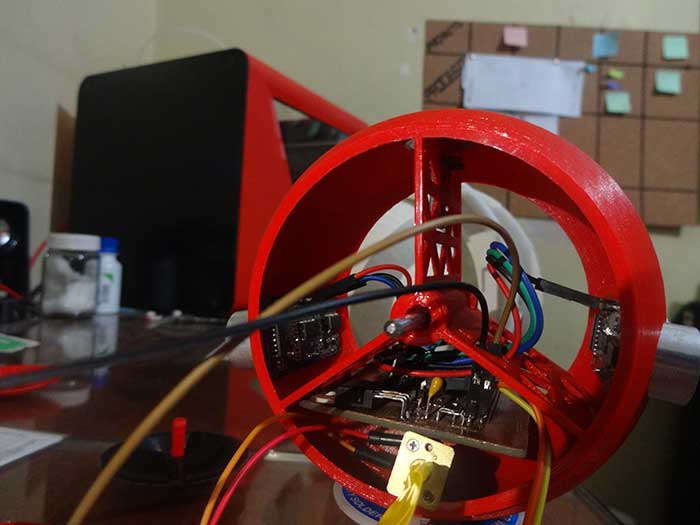

Electronic Prodction

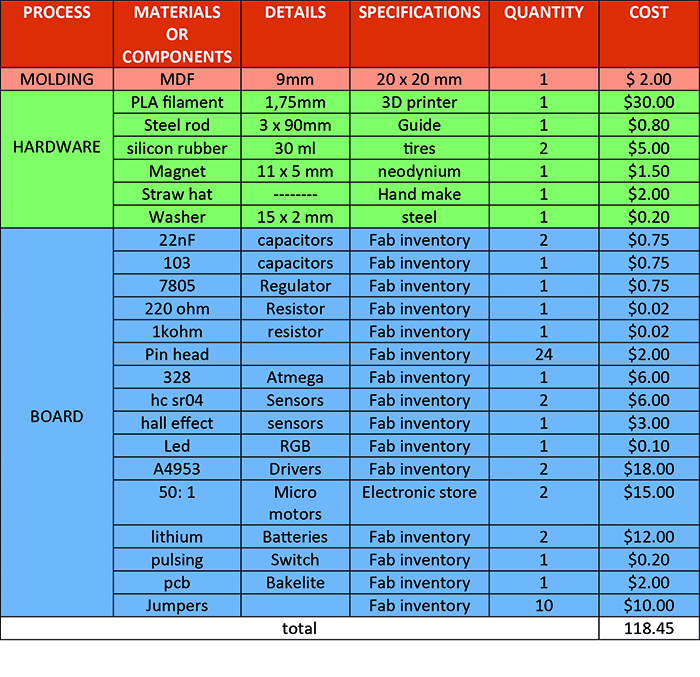

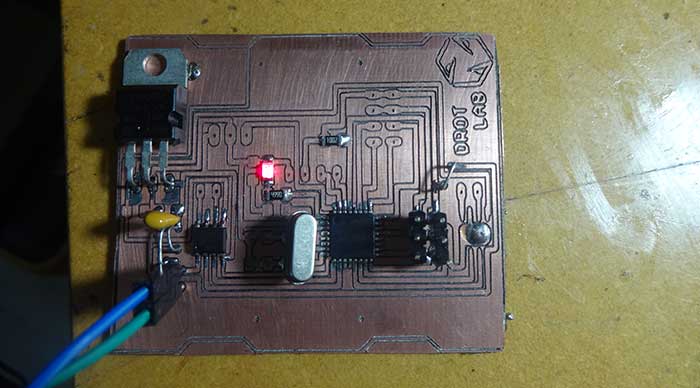

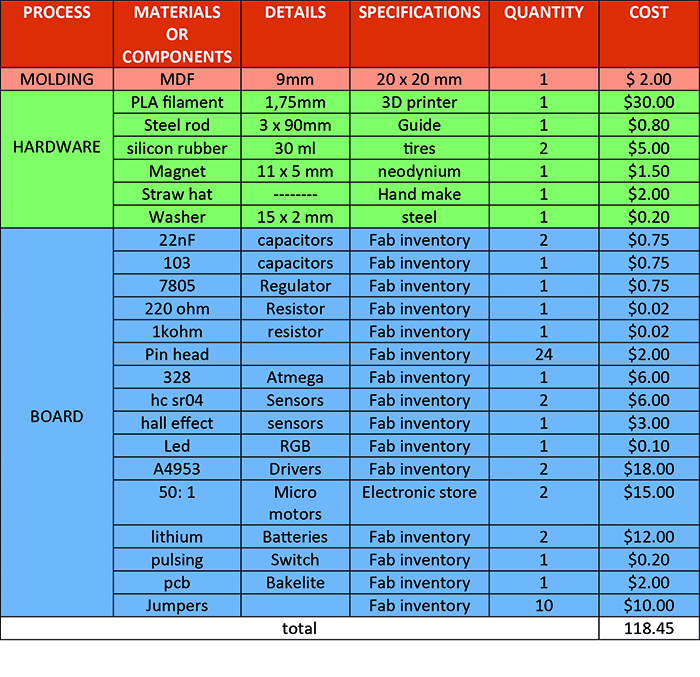

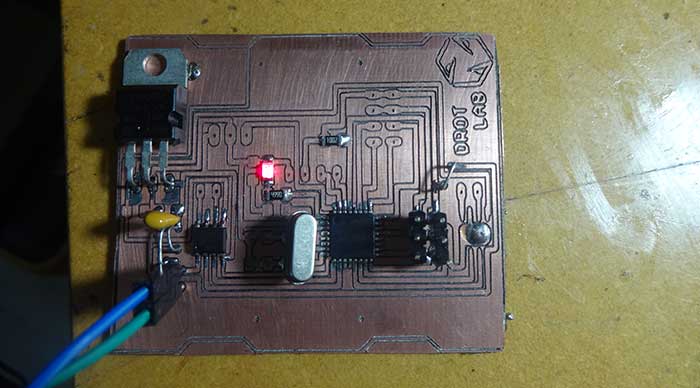

Components

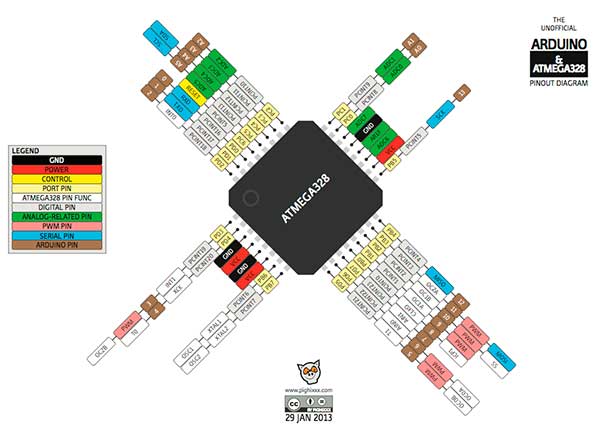

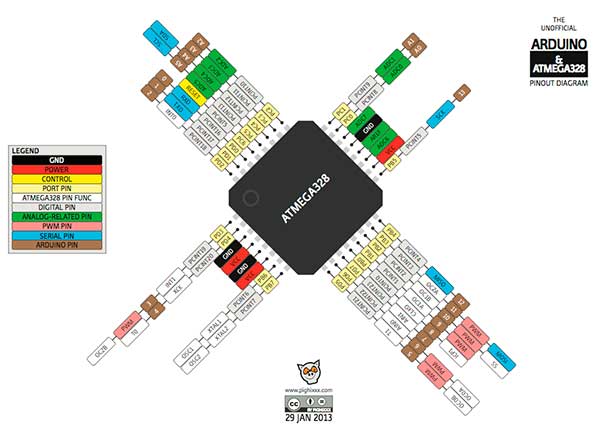

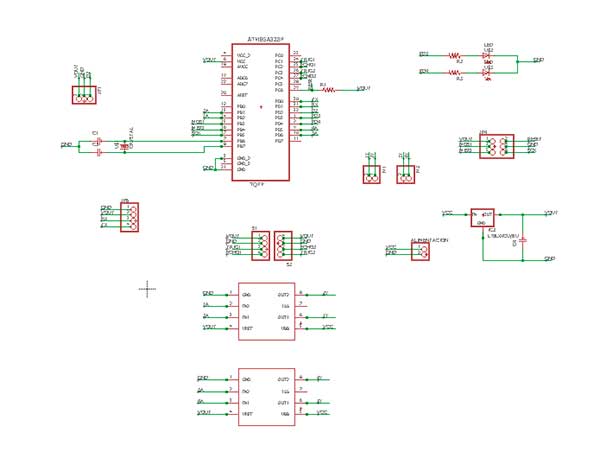

For the board we use an atmega 328 processor, resistors, LEDs, capacitors, A4953 drivers, hc sr04 sensors, hall effect sensor, regulator.

Datasheet interpretation

The atmega328 microprocessor we use for its large number of pins that has compared to an attiny44 or attiny45, for its operation we use a voltage regulator

to obtain the desired input to the micro, this regulator uses a ceramic condenser 103 to filter the noise and have a better signal, we use resistors to

limit the current directed to the LEDs, to the micro an external crystal of 16 MHz is connected for its operation.

Atmega 328 Datasheet

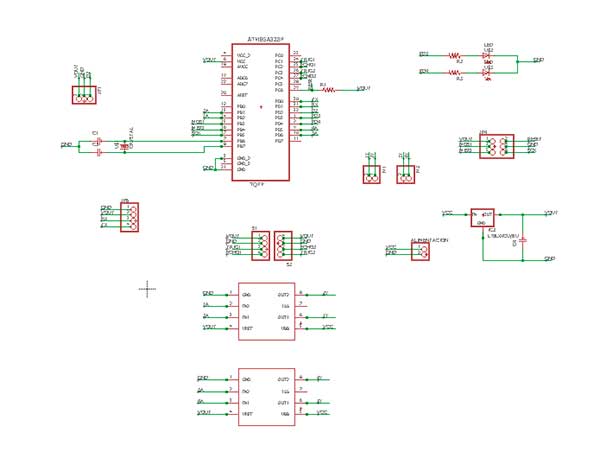

Design

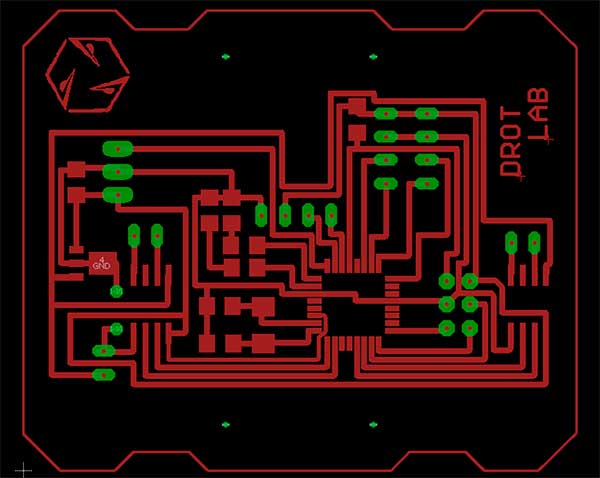

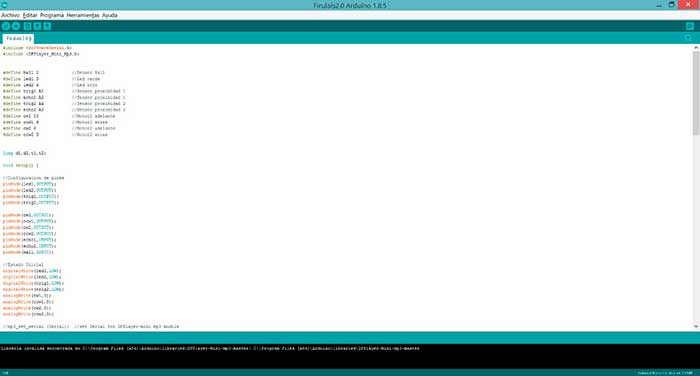

In the design of this plate we use Eagle for the creation of the scheme by selecting all the components mentioned above.

Once the scheme is finished we can generate the clues to obtain the plate.

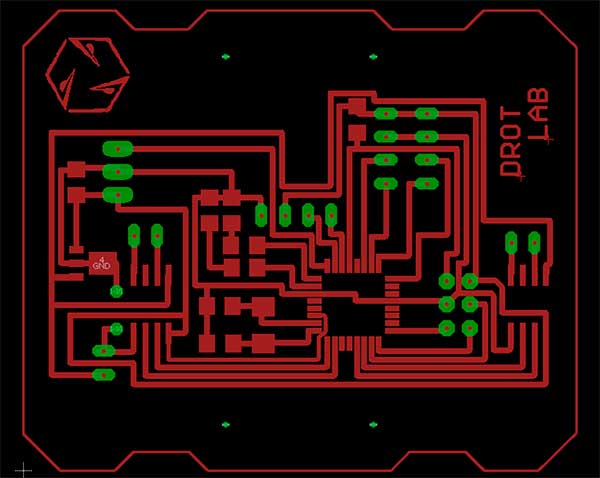

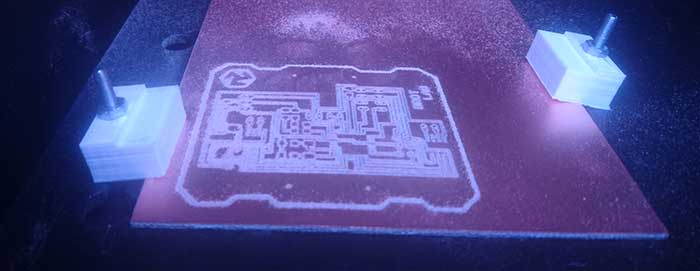

Fabrication

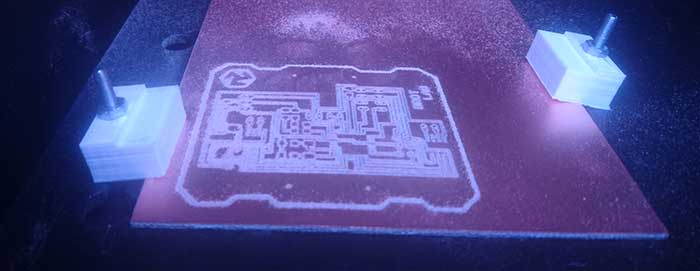

In this process we use the same machine from the previous one the Fab totum with its head for CNC machining.

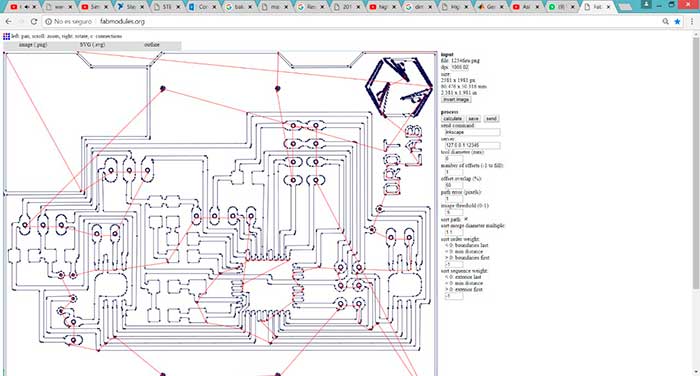

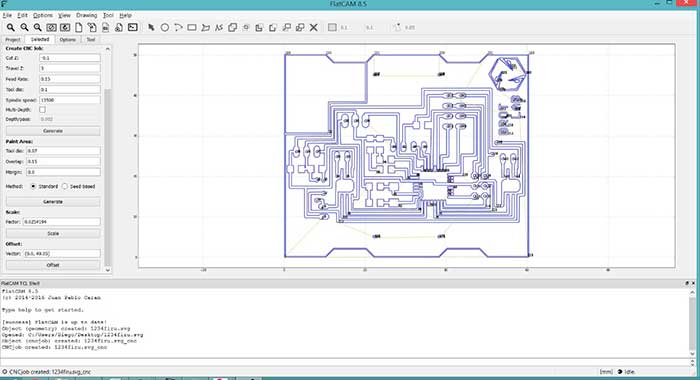

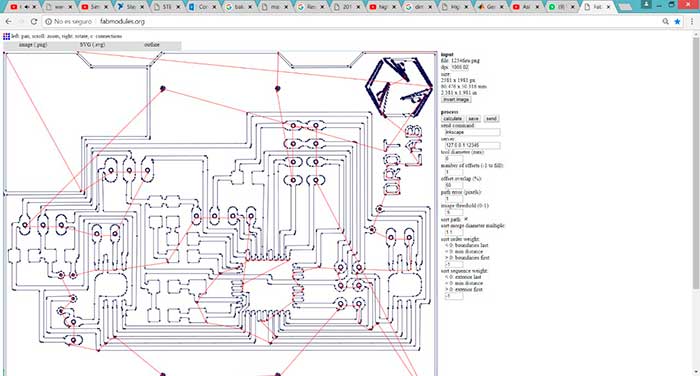

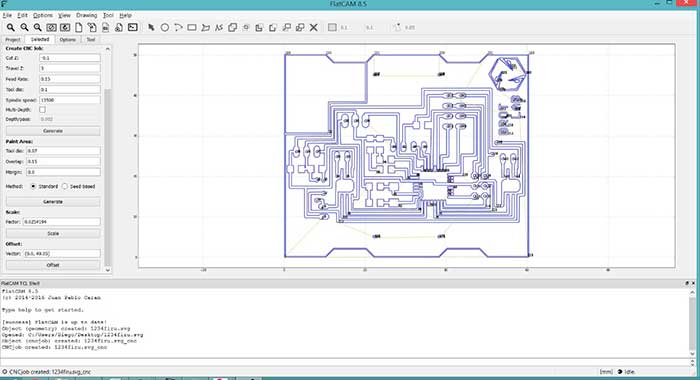

To generate the files we use a program called flatcam which receives the files in SVG or GERBER formats so we save it in eagle

as a PNG format and in the FAB MODULES we transform it to SVG and in the software it transforms them into NC, format

that supports the machine before mentioned.

Once we obtain the .NC files we import into the machine software for machining, to accomplish this process we use a ten-degree tool.

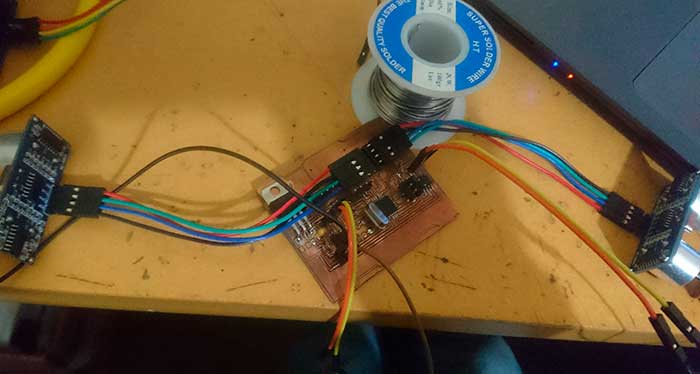

We check that the tracks have been made properly and solder the components.

As a next step we proceed to add the file in the machine to machine. we use Fabtotum which uses Fab ui as a driver software, a very

simple program to which you only load the file and calibrate the machine to machine.

As next step we proceed to solder the components on the electronic board.

Final Board

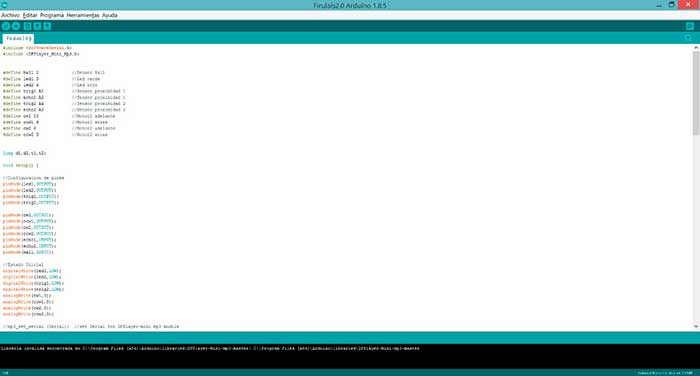

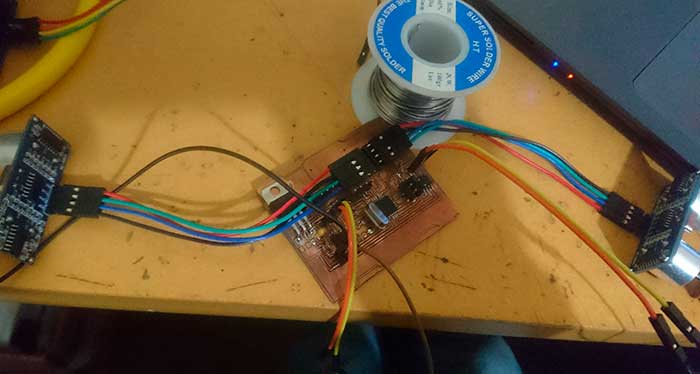

programming

Within the schedule, Firulais will once the shading starts and can avoid obstacles by changing the rotation of the engines either for the left

or right depending on the space in which it is located. Continue in this same way until the child manages to remove the hat and it stops.

Input

Hc sr04 sensors we will use to measure the distance in the front and back, these sensors will send a signal when an object or obstacle is near or to

a certain extent that can vary depending on how we program, this signal is connected with the movement of the motors which will cause the toy to avoid

the obstacle or change direction.

I use the hall effect sensor as a stop, since the toy will have a magnet in its hat, this will be the objective of it, the signal created by the sensor

when the magnet approaches will be the one that allows the movement, the child will have to remove it so that he can finish the game.

Output

The driver drivers that we use are those recommended in academy, this driver can be used for stepper motors, but two of them are needed, in case it is

only used as driver for a dc motor, these drivers are recommended because, in their datasheet, it tells us that it can withstand 2 A current and voltages

up to 40v.

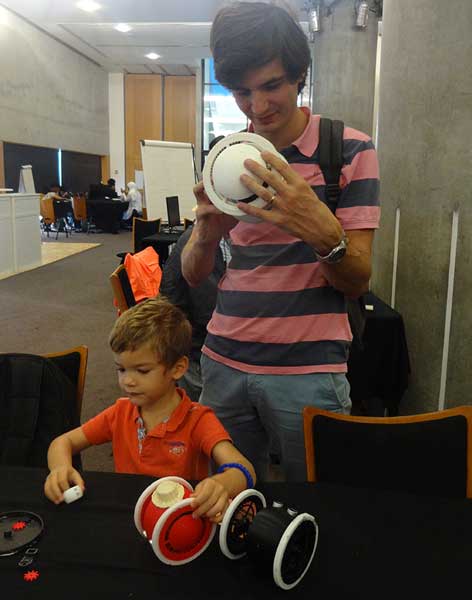

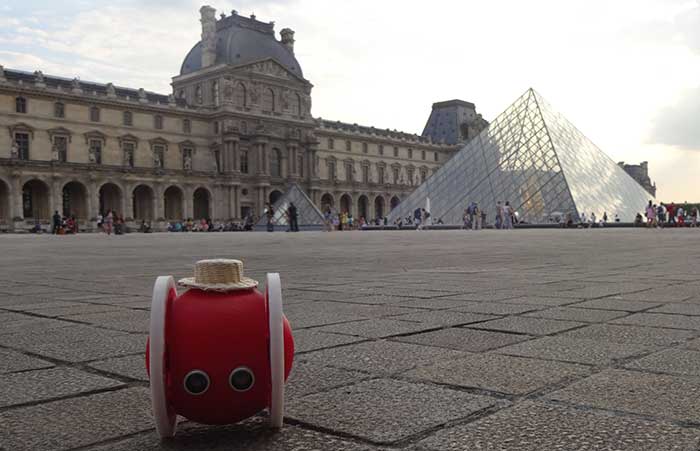

FAB 14

In the event FAB 14, Firulais was present at a workshop in which we made it available to all the children and their parents who came to visit and learn

about the different projects, and attached some images of examples of Firulais during his visit to France.