Wildcard Week

Tasks of the week

Individual Assignment.

Group Assignment

Individual Task

In this week we have many options to work on that, for example: Composites, Textiles, Biotechnology, Robotics, and Cooking. I choose the first one that is Composites. In composites, the individual task is to Read the safety data sheet and technical data sheet for the resin which we are intending to use. And, also this task includes designing and fabriicating a 3D mold and produce a fiber composite part in, with resin infusion and compaction.

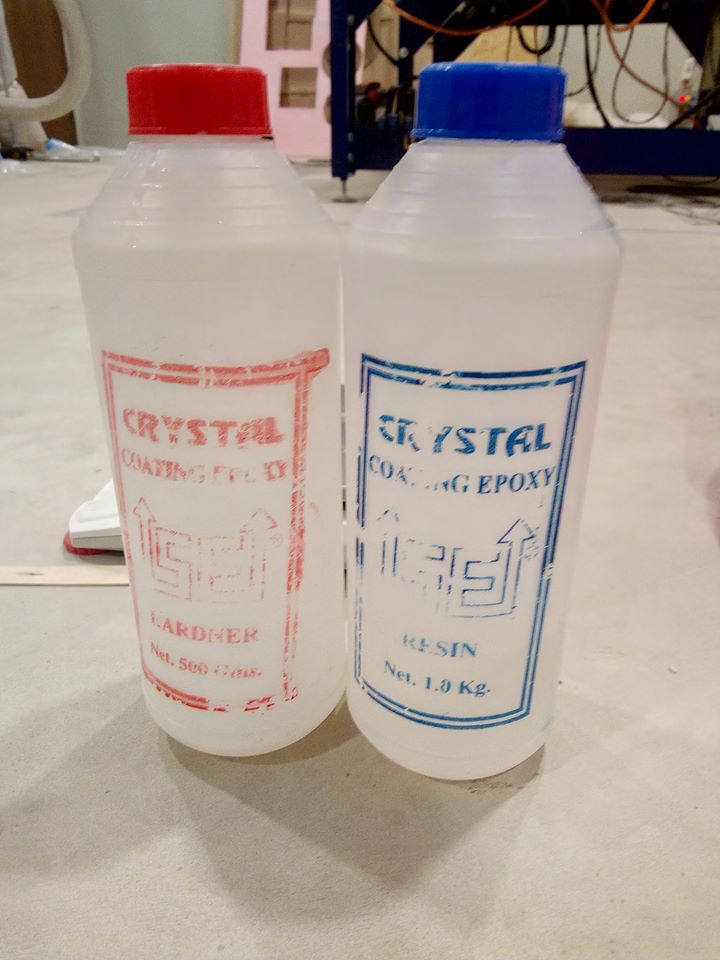

The theme of this assignment is to be aware about the basics of composites.Composites, as its name suggests that its the combination of two or more things/materials which makes something new by combining/joining them. In this case, the output material is strong material. The epoxy resin which I used in my this assignment, was bought locally from the market. The epoxy which we are using in our lab is:

| Hazards Identifications: | Category/Scale | Comments | Precautions |

|---|---|---|---|

| Skin Irritation | Moderate | May cause skin irritation | Use gloves in hands, and try to wear tight clothes |

| Eye Irritation | Ver High | Causes serious eye irritation | Use safety transparent glasses |

| Other Precautions |

|---|

| Avoid breathing its dust, gas or spray |

| Avoid smelling it |

| Wash hands thoroughly after using it |

| Dispose the container in which two parts mixed |

| If skin irritation occurs: Get medical advice |

| Specifications: | Values |

|---|---|

| Mixing Ratio | 1:2 |

| Life after Mixing | 20 minutes |

| Drying Time | 12 to 18 hours |

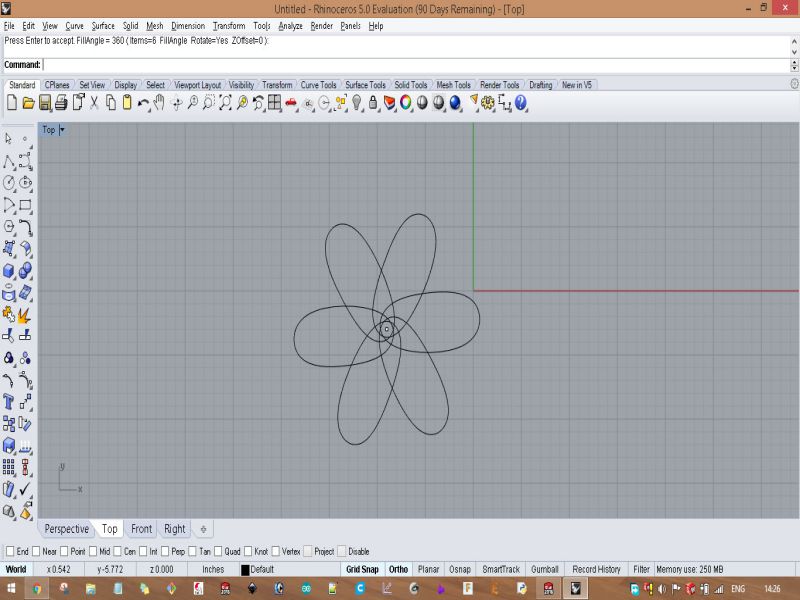

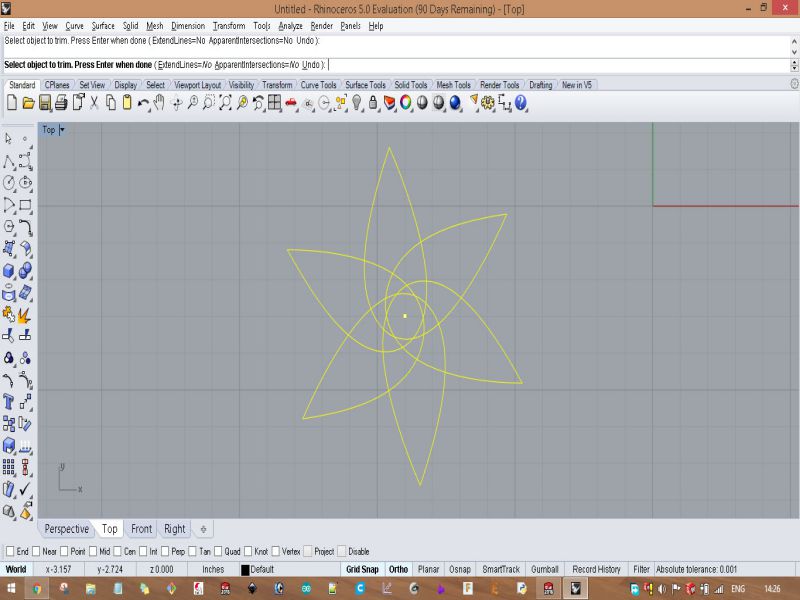

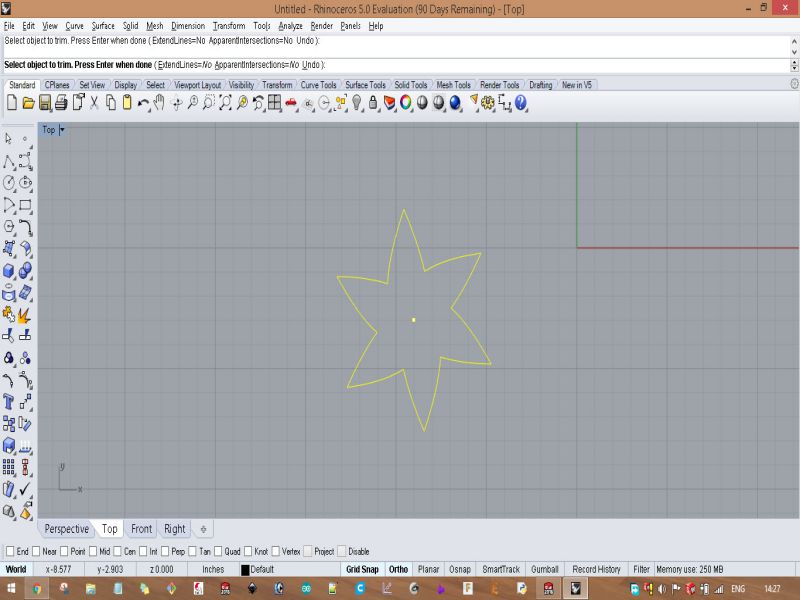

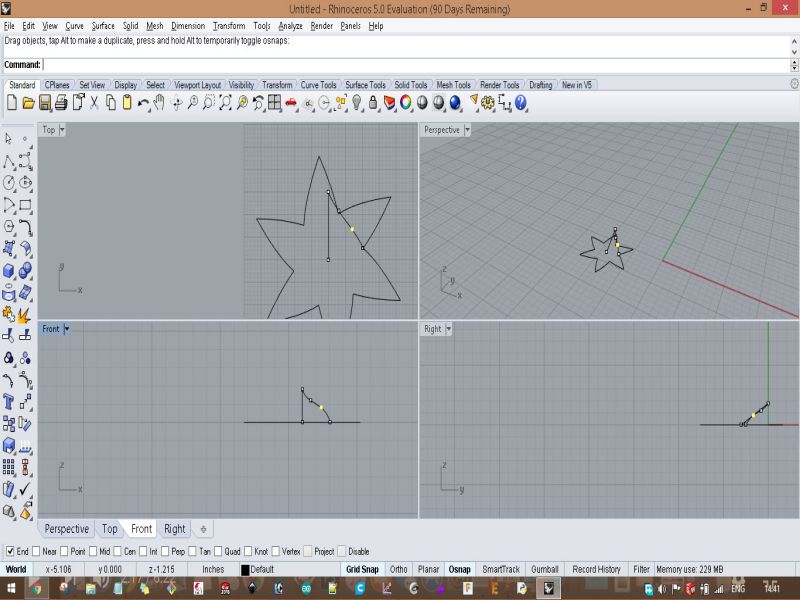

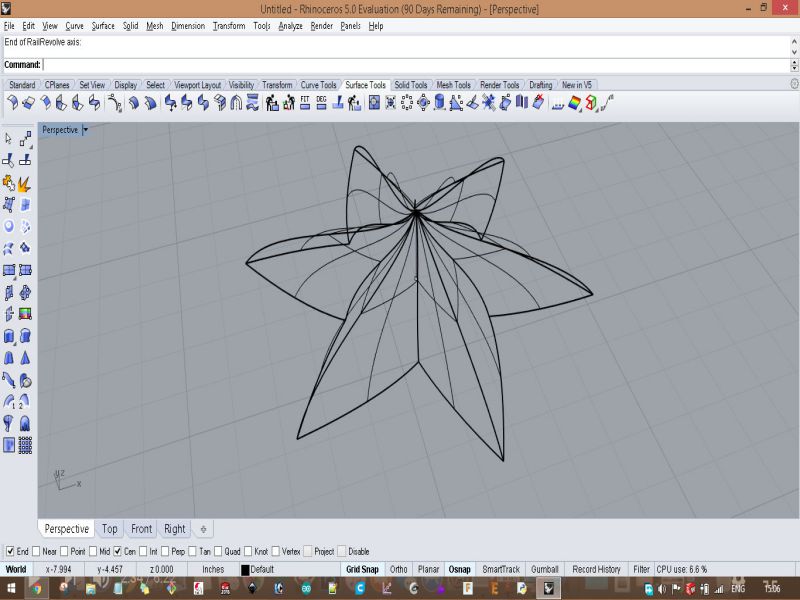

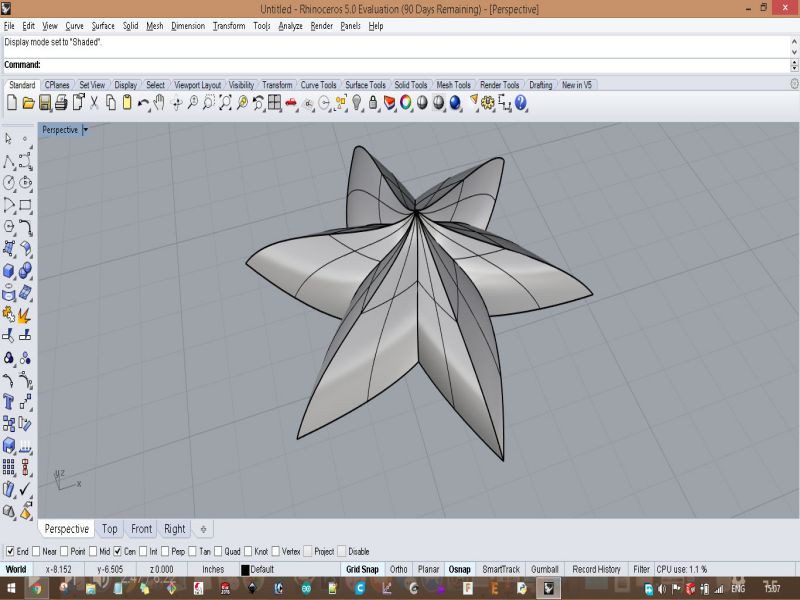

3D designing of the mold:

Composite making process started with the designing of 3D model. I decided to design a star fish for this task, so by using Rhino 3D, I prepared its 3D model.

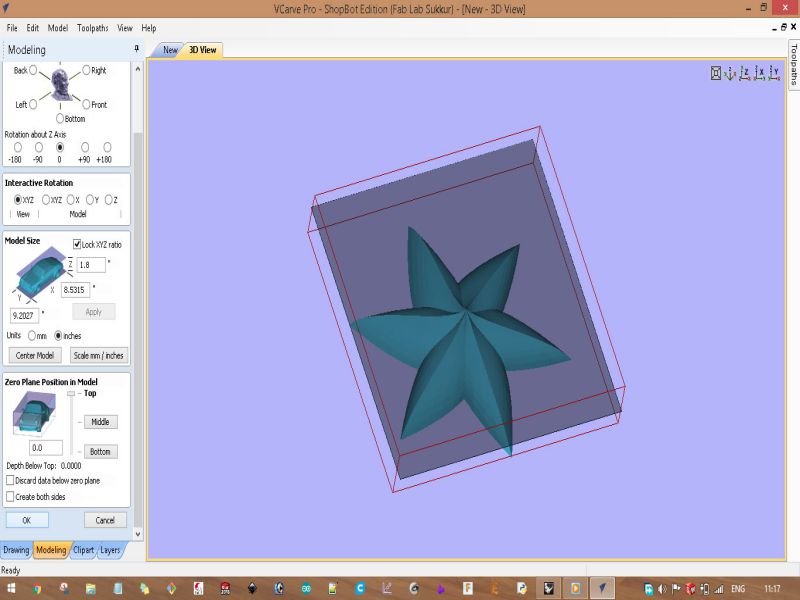

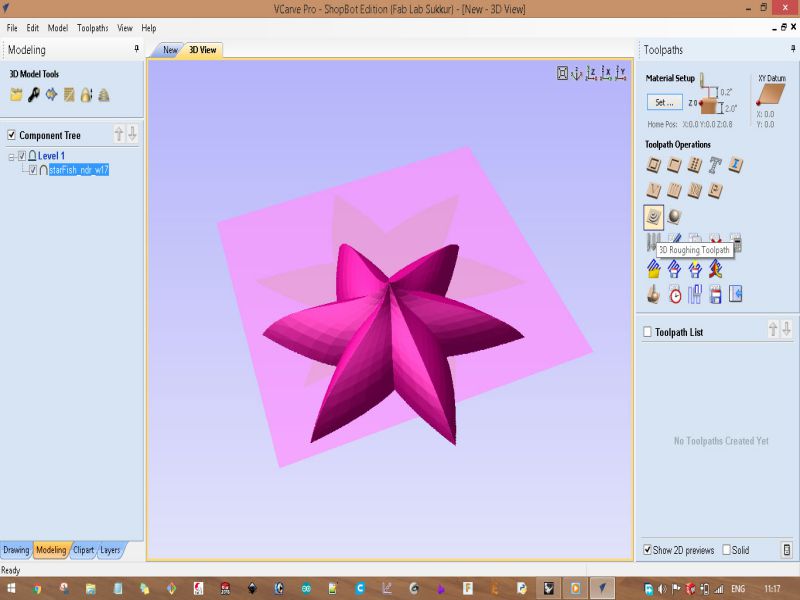

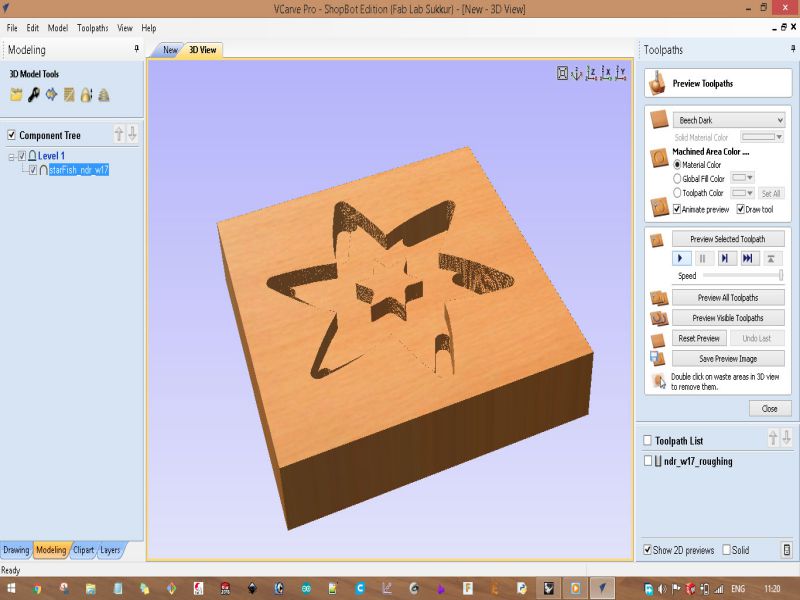

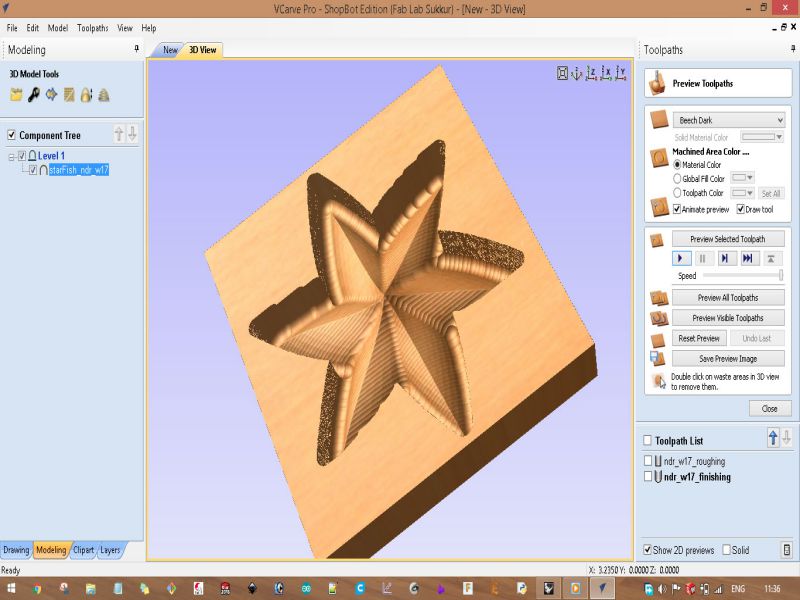

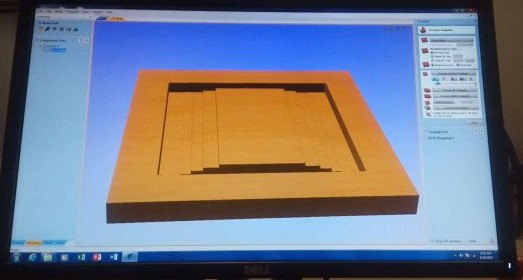

Now, It is the time to generate toolpaths in Vcarve for files for shopbot machine. I Generated two files, one for 'roughing' and one for 'finishing'.

Making Composite:

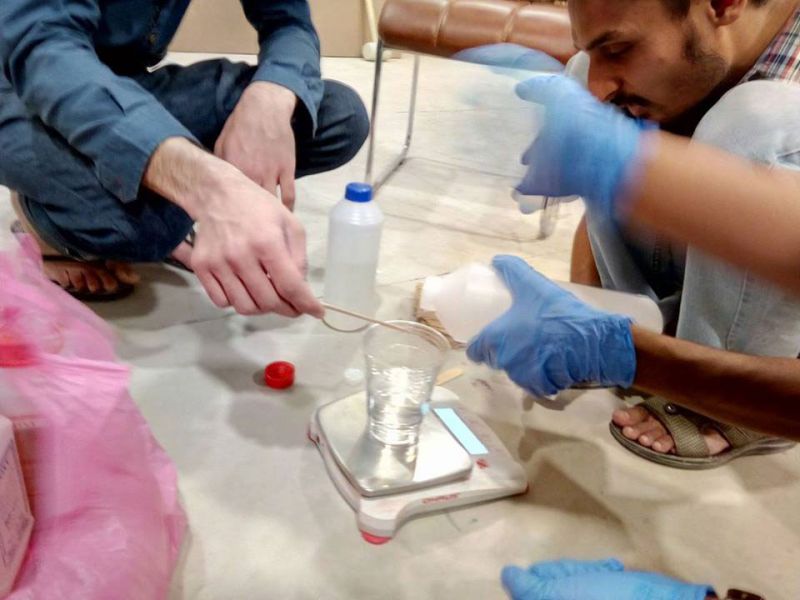

- Make mixture of the material using the ratio of 1:2 of hardner and epoxy

- Stir the material about 8 to 10 minutes

- Apply the mixture of material to the two layers of fabric

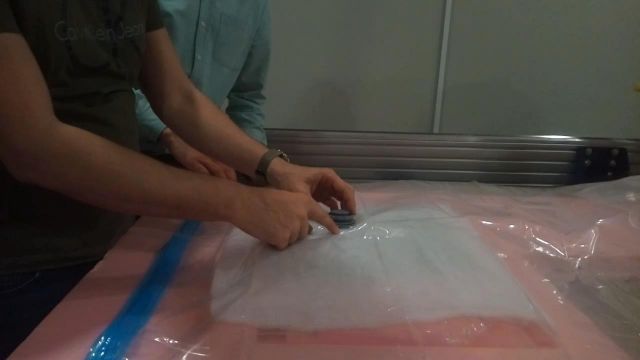

- Layer1Food wrapping plastic

- Layer2Mold of foam covered with wrapping plastic

- Layer32 pieces of jute fiber mixed in resin

- Layer4Wrapping plastic

- Layer5Breather for vacuum

- Best evacuation system generates best final result through vacume machine and plastic bag.

- These composites are lighter, durable and made from cheap material.

- Learnt that how to make different light weight objects using this process.

- be carefull to use the plastic layer on mold so that you can easily remove fabric from the mold.

Total measurement of the mixture: If the weight of fabric is "A" then total mixture weight should be "3A", means three times of the original weight of two layers of fabric. Here, in my case the weight of fabric was near about to 40 grams, so my totla mixture of epoxy and hardner was 120 grams. I applied 1:2 ratio in weight, 40 grams of hardner and 80 grams of epoxy. And, it gave me satisfactory rsults with very hard and very light 3D shape of star fish.

Final Result: After about 18 hours of full pressing through vacume, I found the result as very hard, strong and light weight.

Group Task

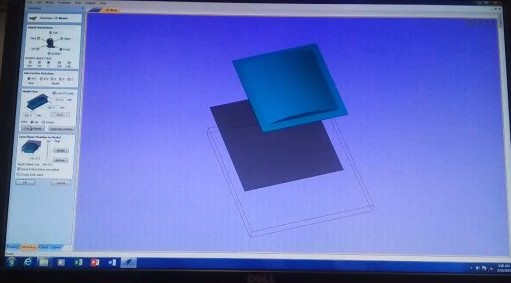

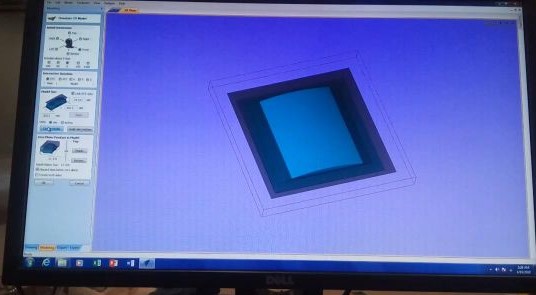

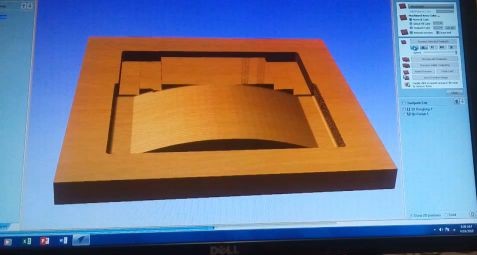

For making a test design we made a simple curvy shape in SolidWorks.The Curve was saved as .stl file and the tool path was generated in Vcarve. All the steps for making the composite are given below and also illustrated through pics. Initially, a new Vcare file was opened and the dimensions were set according to the size of the model (370 by 370mm).Then by importing the Component/ 3D model , the model is imported. Here we make some settings as described in the video attachd for individual assignment section.

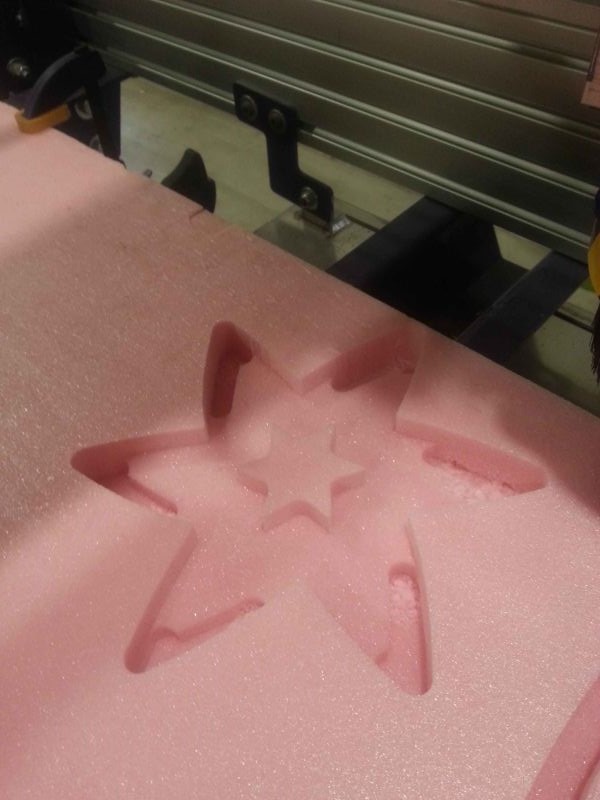

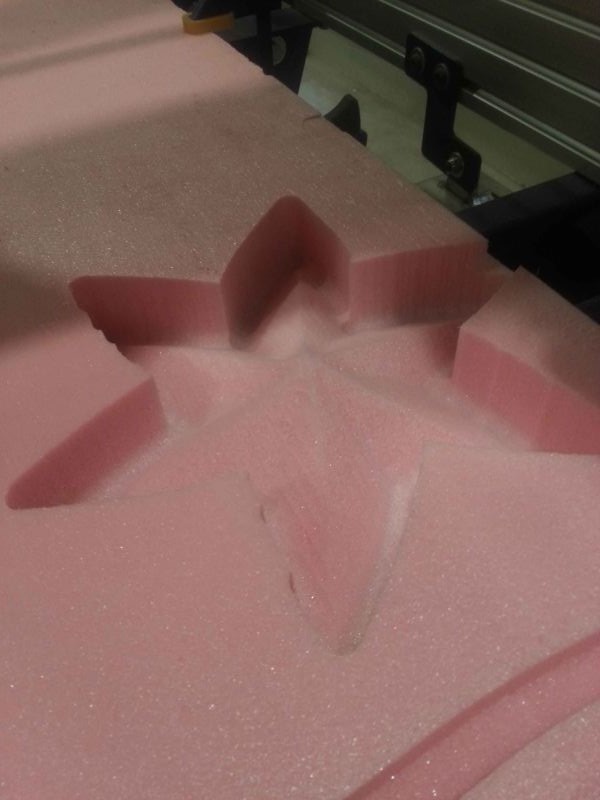

The next step was to cut the model on the 50mm foam, the toolpaths were generated and then used in cutting on shopBot.

We are using Jute as the fiber, we already cut the two pices on Laser cutter. The arrangement of the composite is shown below:

Learning Outcomes

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.