Computer-Controlled Cutting

The assignments for this week were:

- Characterize your laser cutter, making test part(s) that vary cutting settings and dimensions.

- Cut something on the vinyl cutter.

- Design, make, and document a parametric press-fit construction kit, accounting for the laser cutter kerf, which can be assembled

in multiple ways.

Characterize Your Laser Cutter, Making Test Part(s)

1) The first step is to draw the 2D model using Inkscape.

2) Then you have to save the 2D model in (.dxf) and save it on a pen drive.

3) After that open the model in the CutStudio (the machine software).

4) Then you need to unite the lines. I did this step by using “Tools(O)> Unite lines”.

5) Then you need to use the Corel Draw to

realign and change the squares colors. I used the Corel Draw for this

step

because, it was linked to the computer that the machine was hooked up to.

6)

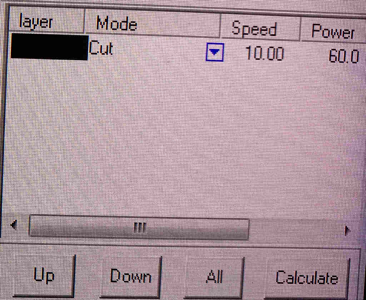

After that you need insert the parameters that you want to test in the

box on the right side. See final image to see

all parameters that were inserted.

7) Once you finished inserting the parameters click on DownLoad.

8) After that you need to turn on the laser

cutter machine. I recommend running a test first to verify the area you

are going to use.

9) Finally cut the 2D model. Video here:

https://youtu.be/KVU-Q8FnXtg .

Please take a look at the final image below, you can see that I used MDF material at 3 different thicknesses: 3mm, 6mm and 9mm.

Paulo did the math about Kerf to show the machine parameters

Below there is a demonstration. Also click on the link to his

webpage to see more details.

Kerf:

Kerf=With

Kerf is defined as the width of material that is removed by a cutting process.

When cutting parts with the CNC laser machine

(which is what I used) or any other kinds of CNC cutting machines you

want to produce cut parts with dimensions as close as possible to your

programmed shape. Example if you program a 6" by 6" square and the

laser removes 0.25" of material as it cuts, then the resulting

part is going to be 5.75" by 5.75". So the actual tool path has

to be compensated by half of the tool kerf. In this case it will

be compensated 0.125".

Kerf offset is usually adjusted by who ever is

using the machine. Before running a program, the operator must enter

the kerf width so that the CNC can calculate the actual tool path

required to cut the part to the correct dimensions.

Final comments:

I Learned that the power parameter determines how deep the laser will

go through the material. As you can see in our fab lab we have 3

different thickness of MDF material ranging 3mm-9mm. I chose to use the

same laser cutter speed for all three thicknesses and start the power

of the laser cutter from 18.5-60.

The Vinyl Cutter Machine

The vinyl cutter machine is Roland Camm-1 CX-24.

Below are the pictures of the front view, rear view and operation panel of the machine:

File Preparation

The vinyl cutter files must contain only vectors; the vectors must be

lines only, with no fill; the vinyl cutter drivers can only interpret

cut lines. All vectors must be contained within the bounds of the

document canvas.You will need to size your page in your drawing program appropriately for the width of vinyl that you

are using. Vinyl comes in two widths, 24" and 15".You can change

the width and the height using Inkscape. The vinyl is on a roll

so, the max height could be as long as the length of vinyl on the roll.

Changing the with and hight using ink skape:

1) File > Document Properties.

2) Modify the width for 23 in and the height for 24 in.

Vinyl Cutter

I decided to make four butterflies to stick on my bedroom wall.I used

Inkscape to do it. First I needed to rasterize the JPG image on

Inkscape by doing:

Path>Trace Bitmap

After this process,

I will have a vector above my image, so I can delete the image and keep

just the vector. Then I saved as “.svg” and I realized that I

should save as “.eps” to use the vinyl cutter. I read a tutorial how to

do this whole process using Inkscape.

Click the link:

https://inkscape.org/en/doc/tutorials/tracing/tutorial-tracing.en.html.

Here are the images of my Inkskape during this process:

The next step is to

go to theCutStudio software and choose "File>Print". A window will

open so you need to choose the Vinyl cutter and click as Printer and

then click Print

Now you can load the Vinyl fallow the following steps:

1) Select a roll of vinyl and place it on the rollers behind the machine.

2) On the back right of the machine you will

see a lever; place it in the "down" position so you can load the vinyl.

3) You need to make sure the vinyl side is

facing up as you feed it through the rollers into the vinyl cutter.

4) Under the rubber wheels there is a white sticker indicator.

o Ensure that the vinyl is aligned

properly under the rubber wheels.

o The left wheel must always be

under the wide white sticker on the left.

o The right rubber wheel must be

under any one of the three white stickers on the right, depending on

the width of your vinyl.

o Make sure your vinyl is straight

and about 2-3 inches past the rubber wheels.

5) After inserting the vinyl into the

machine, pull up the lever at the back of the machine to ensure that

the vinyl is securely loaded.

Now you can turn on the Vinyl cutter:

On the left side of

the vinyl cutter is the power button, which you need to turn on. Now

you need to select press “select roll” on the screen.The vinyl cutter

will measure the width of the roll (in

mm).Set the origin by pressing the "Origin" button on the control

panel. After completing this step and material is placed correctly in

the machine, check if it cuts your material properly using the button

"Test". If not, adjust the force and the speed, or check if the blade

is still good to use or if you need to change it. I chose to use a roll

of black vynil material with the force of 100gF and speed of 10 cm/s to

cut my image.

After that you can start to print:

To print the file, go to File > Print > select the "vinyl cuter"

driver from the print menu.Hit the "print" button to send the file to the vinyl cutter.

You can watch a video here:

https://www.youtube.com/watch?v=yRo0vUNnpQ8

After the vinyl cutter is done you need to cut your file, use scissors

to cut off the section with your cut design, you also need to weed the

vinyl, which is process of removing the unwanted areas from the final

cut design.

The tools I used were:

• Transfer Tape

• Scissors

• X-Acto knife

• Tweezers

Then after cutting, trim area you want to keep with scissors. After

that remove the unwanted parts of vinyl with an X-Axcto knife and or

tweezers. See the images below:

Once those steps

are finished, you are ready to transfer your vynal image to the desired

surface. Carefully apply transfer tape to the surface of the weeded

vinyl. Rub the transfer tape onto the vinyl to form a strong bond

between the tape and the top surface of the vinyl design. Then after

rubbing, carefully pull the transfer tape (with the vinyl adhering to

it) away from the vinyl paper backing. After you have removed the vinyl

from the paper backing and it is attached to the transfer tape, apply

it to the desired surface. Rub the surface of the transfer tape to

ensure that the vinyl will adhere to the new surface. Then carefully

pull the transfer tape away from the vinyl, leaving the vinyl attached

to the desired surface.

Here below you can see the vinyl butterfly and the butterfly on my closet:

Paramitizing Design and Laser Cutter

Parmaitizing Design:

What does it mean to parametrize (parametric measures) a model?

Use parameters in Design Studies and link them to variables that can be

changed with each iteration of an evaluation or optimization design

scenario. You can parameterize model dimensions, global variables, and

features from Simulation and Motion studies.Link parameters to input

fields to let the parameters drive the numeric value of the associated

feature. For example, if you define Force1 as a force parameter, you

can link it to a force input field instead of entering a numeric force

value. Changing the value of the parameter Force1, automatically

changes the force input linked to it.

I decided to

designed my Extractor’s support legs using the SolidWorks

software. I came up with this idea when I first designed my Extractor

and then I realized that I should make a support for it because the

solution entrance is on the bottom of the Extractor. The new leg

supporters would not only make my extractor more stable but would also

add more height from the bottom of the Extractor to any surface

allowing more space bellow the solution entrance.

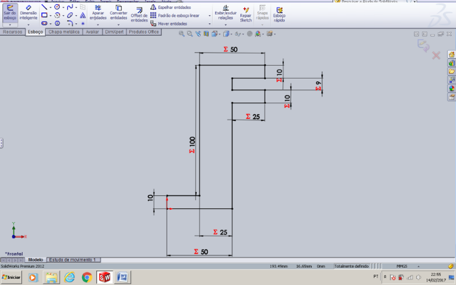

Below is an image from Solid Works of my support design.

Please note

that for this specific assignment I only cut the legs and the support

table. The conical vase was printed at a later date.

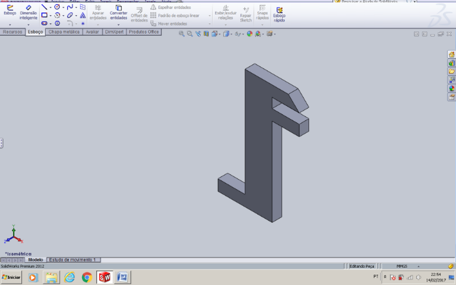

The legs:

Below are two pictures of one leg. The first picture is sketched with a

parametric measure and the second is the solid 3D design. When your

parametric measure is complete click File> Save as> Choose the

“.dxf”.

(Sketch with Parametric Measures)

(Solid 3D Design)

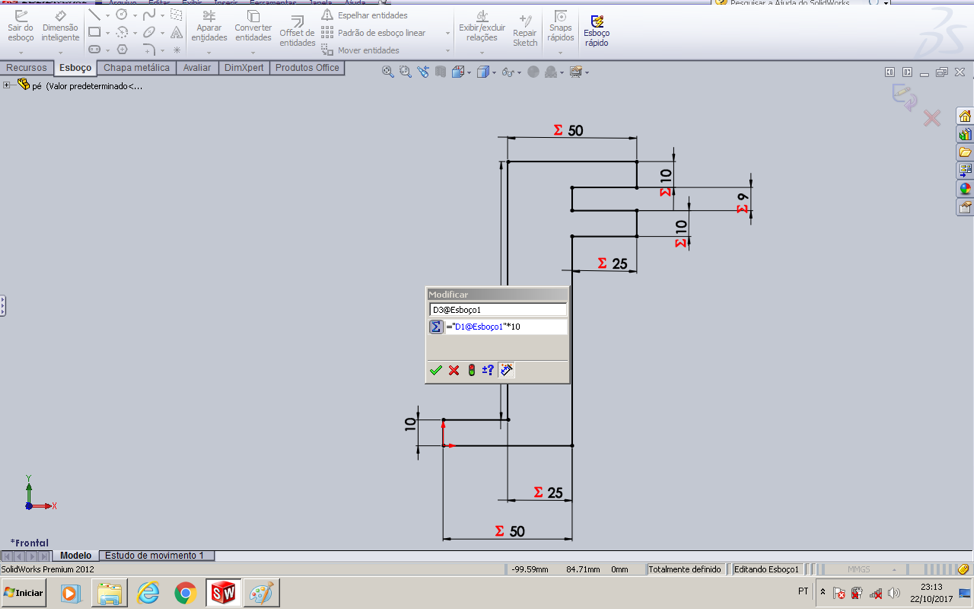

Here below is how I

got my leg parametrized. It’s not so hard to do and you can fallow

these steps on how to design an image using a parametric measure

including a picture of my measurements:

1) Insert your sketch

2) Click one of the lines of your sketch and

then you click smart dimension tool at the top left of the window.

3) A small window will appear and Insert the line dimension you prefer in (mm)

4) Create a global variable by clicking the tool next to the red x button

5) Type an = then type in your name for the variable then accept the variable by clicking on the

symbol

6) Click on another sketch line and repeat

steps except for this time insert an equation as you can see in the

image bellow and

click accept.

7) Continue these steps where you see fit to parametrize the dimensions of your sketch.

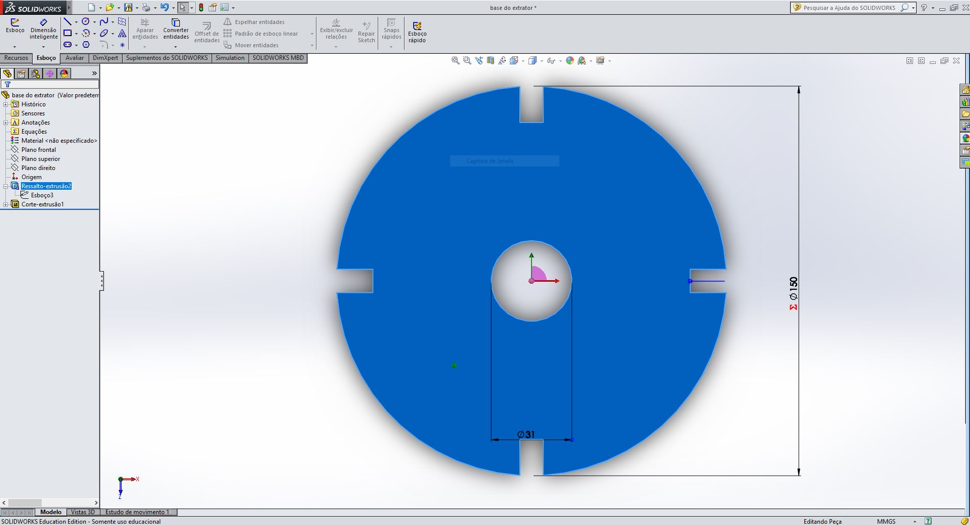

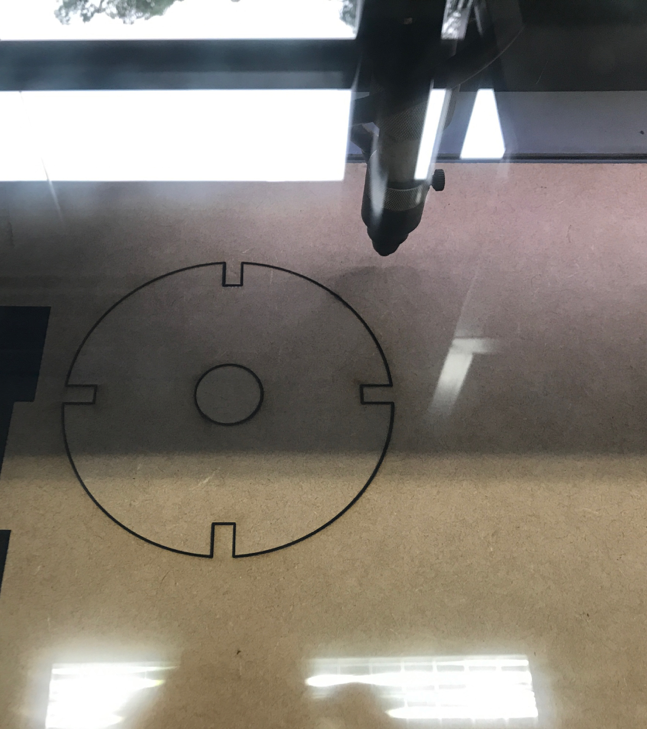

The base:

I used the same concept for the base as I used for the legs. First, I

got the diameter of 31 (the smaller circle, in the center) and I

parametrized all the other measurements starting from this

point.

To do this step I used a function (=“D1@Esboço3”*4.8387) which you can see in the image below:

Laser Cutter:

What are Laser cutters?

The laser cutter/s is one of the most useful tools in a modern

fabrication shop or lab. Laser cutters work by directing a very

powerful laser beam, at a precise focal length, onto a material which

they either cut or etch, depending on how the laser cutter has been set

up. Laser cutters cut materials similarly to other computer controlled

tools, only they do it using a beam of light as opposed to a blade.

Once the laser cutters are set up to etch something on the

surface of a material, they operate like a printer, basically using

their laser beam to etch an image onto something.

I first read a tutorial about the laser cutter before using it:

http://www.instructables.com/id/How-to-Use-a-Laser-Cutter/

Below you can see the mane steps on how to use the laser cutter:

1) You first need to have a software

such as Inkscape, CorelDraw, Illustrator to convert you image to a

vector. I used Inkscape.

2) Then you need to choose which

material between Cast Acrylic, Extruded Acrylic; ABS; Polycarbonate;

Anodized Aluminum;

Glass; Wood. I used 9 mm MDF material to cut the legs and base.

3) After that you need to place your

material inside the machine the dimensions. The machine used is model:

G-WEIKE laser cutter

model LC1390. The machine dimentions are: 130cmx90cm

4) Once everything is placed, you may need to

adjust the bed. There is a focus button on the front control panel of

the Laser Cutter.

If you push that, and

then the down arrow, you should see the bed lower. Keep lowering the

bed until you have enough space that

the laser will not come into contact with your materials.

5) Now that everything is placed, you need to

do a test run. For this step, leave the lid open, otherwise it will not

run the test and may

start to actually cut.

Before the actual cut, you may want to ensure that your print area is

contained within the space you're hoping for.

There is an easy ways to do this:

If you tape over your

print area, or tape a sheet of paper over the area you intend to print

(make sure you cover more than just

the intended

print area, in case your measurements are off, this is what makes a

test cut useful), you can etch into the paper

or tape,and make sure the laser is only going to cut the areas you plan.

6) After you run the test you close the lid.

Go back onto the computer in the File -> Print ---> Preferences

menu, select Raster

or Vector depending on what you

plan to cut. Once that's selected you can, choose the Power and Speed

settings that would

be most suitable for your piece. If

you're cutting in Vector, don't forget the Hertz setting. I used speed

of 10 and the power of 60

as you can see in the

picture below. I got the speed and power using the MDF laser cutter

test at the beginning of the page.

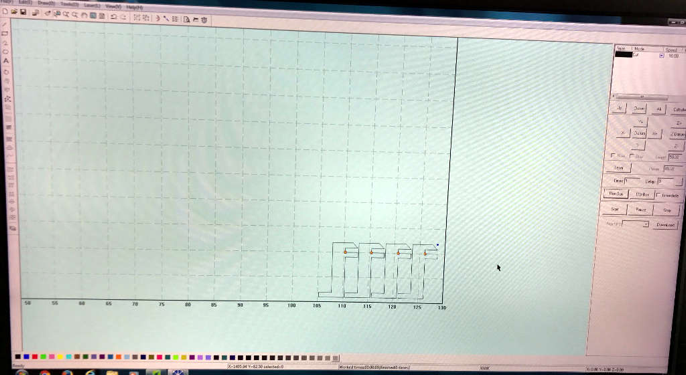

7) Here below you can see the picture of my

design in the Lasercut software. You need to configure the speed and

the power. Once

everything is selected, and properly placed, click OK to start printing from the computer.

8)

If everything looks okay, turn on the exhaust fan. If you're

doing a Vector cut, turn on the air compressor and click GO on the

laser

cutter control panel.

9) After that you will have your cut ready.

10) Then I used a hand sander for a betterr finish and a

better appearance. My 4 pieces of my extractor support was ready.

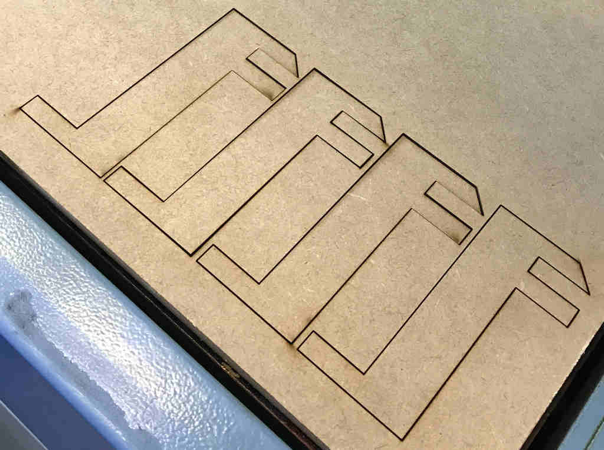

(Before Sanding)

(Finished Legs)

(The base after laser cut)

In the pictures below, you can see the base with the legs.