Laura Cristina Massaglia

|

|---|

| HOME |

ABOUT ME |

ASSIGNMENTS |

FINAL PROJECT |

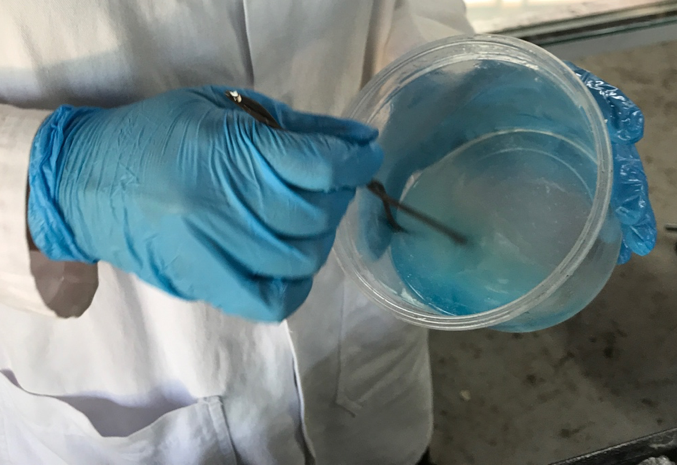

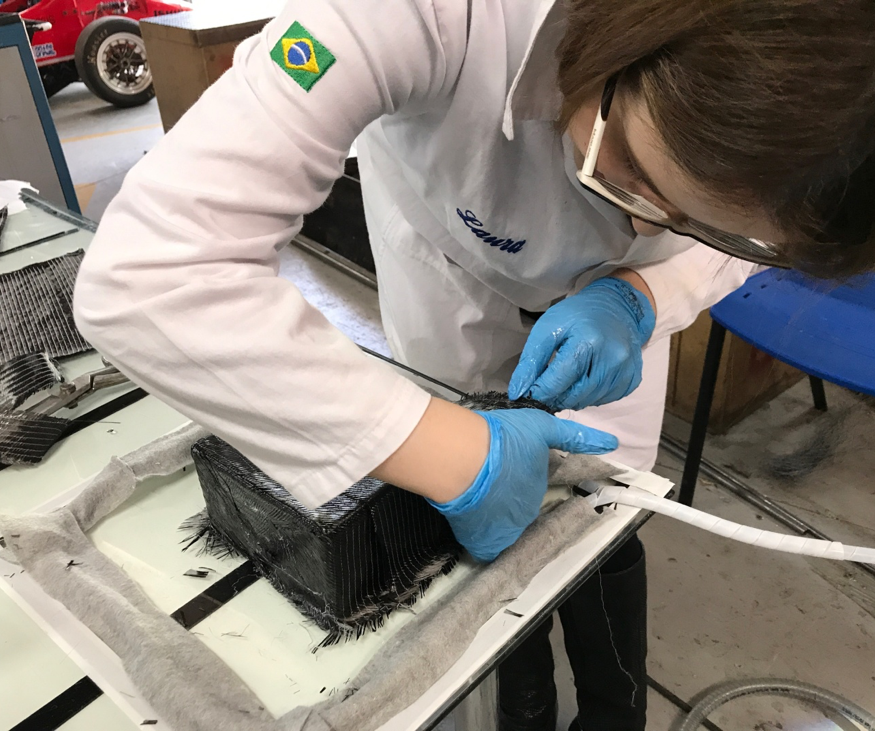

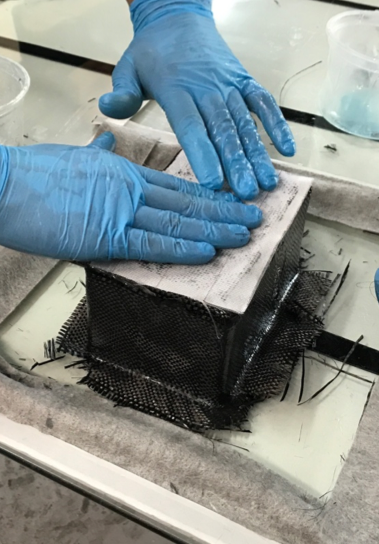

Click the link to learn more about the following: Health Risks: Working with carbon fibers is a potentially very dangerous task. Carbon fibers are thin and can easily break off. So, when in contact with skin it can cause irritation. It can also be ground into a fine dust when cutting that, when uncontrolled can stick in your skin and or mucus of your nose. Health effects of solvents used in carbon fiber manufacture: Many of the epoxy’s and resins used in coting carbon fiber layers can cause chemical irritations. They are also very unstable, flammable and irritating to the skin. Many health effects of these solvents include, irritation of the eyes and upper respiratory tract, dizziness, drowsiness, nausea and vomiting. Visual troubles may also occur. It can also cause dermatitis with prolonged skin contact. It is always very important to read the Material Safety Datta Sheets before using any material. Risk management: It is always important to be careful around poorly machined and fractured surfaces of carbon fiber. One should always ware personal protective equipment PPE (heavy style gloves, lab coat, protecting eye ware and respiratory protection). Carbon fibers are electrically conductive. Dust or waste can cause short-circuits within electrical equipment and or shocks which, is why a specific vacuum cleaner (designed specifically for extraction of conductive substances) should be used. Also, a suitable HEPA filter must be used as well. Surrounding equipment must be fully insulated at connection points, exposed wires or cables must be covered by an appropriate insulation. The outlets in the room must be thoroughly checked for dust unless they are dust proof outlets because, one can cause shorts or may even get electrocuted when something is plugged in. Special equipment should only be used when wet processing carbon fibers or composite materials. Safe work practices: • Staff and students using carbon fibers or composites must be trained in its use. • Tasks involving dry machining of carbon fiber must be undertaken using an appropriate extraction or ventilation system. • Tasks involving the use of solvents and resins must be done within MSDS requirements. This includes using in a well-ventilated area, a fume cupboard or spray booth. • When machining of carbon fiber, minimize dust or particulate generation by: 1. Wet processing of the material - see electrical safety 2. Using non-powered hand tool 3. Cutting the material while still 'green' or partially cured. • Emergency eyewash stations and hand washing facilities must be available for each work area. • A first aid kit must be available for each work area. • All skin and eye contact must be avoided. • Student and staff exposure may also be controlled by scheduling operations with the highest exposure risk at a time when fewer people are present. • Following any contamination of clothing with carbon fiber or resin solutions, remove the garments and dispose of as waste. PPE may be washed under running water; disposable gloves are to be discarded after contamination. • Waste Disposal: 1. Cured or raw carbon fiber double bagged and disposed of through the regular waste stream. 2. Fine waste such as dust and loose fibers may be disposed of in a similar way however, care needs to be taken in collection and PPE must be worn. 3. Chemical waste must be disposed of as prescribed waste through a licensed contractor. • Spills: 1. Spills of solvent materials or resins must be cleaned up immediately using local or building spill kit to MSDS directions. First aid • Skin: 1. Irritation and rashes - Wash under cold or warm water with soap or use sticky tape to help remove the fibers from the skin. • Eye: 2. After removing contact lenses if any, wash eyes with clean running water for approx. than 15 minutes. Remove contact lenses if worn before washing. Seek medical assistance • Ingestion: 3. Wash out mouth immediately with clean fresh water. Seek medical assistance • Inhalation: 4. If dusts and fine fibers are breathed in and or embed into mucous membranes. Remove person to fresh air and seek medical assistance. |