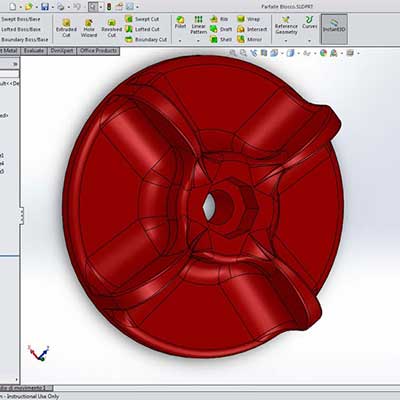

My first idea was to make a mold for some big timing pulley that I need to build a 4th axis ( indexer ) for my CNC, the idea was to copy an expensive 72 teeth XL pulley, and compare the results with a 3D printed one. Unfortunately I'm still waiting my aluminium "master", so I decided to mold the knobs for my Pc desk.

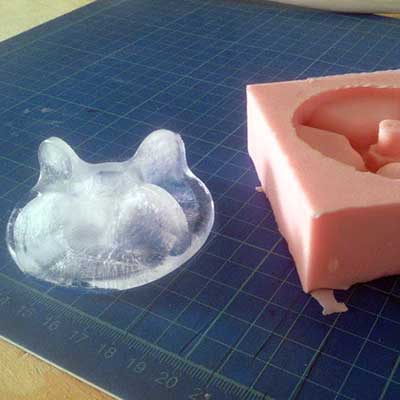

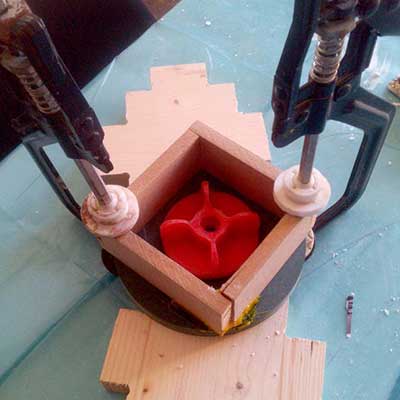

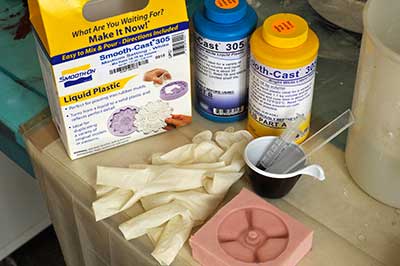

First I tested the mold with water and put it inside a freezer, I obtained an "impermanent" Ice knob, then I used the Smooth-Sil 940, combining the two part in a proportion of 10:1 in weight. the mold was treated with vegetal oil to better separate from the silicone ... which was an error because I used too much :-) and some holes due to residual oil were made. The result is a perfect copy of all the small details/imperfections of the 3D print plus some imperfection due to the excess of oil.