Designing and making an iphone 5S press-fit case kit

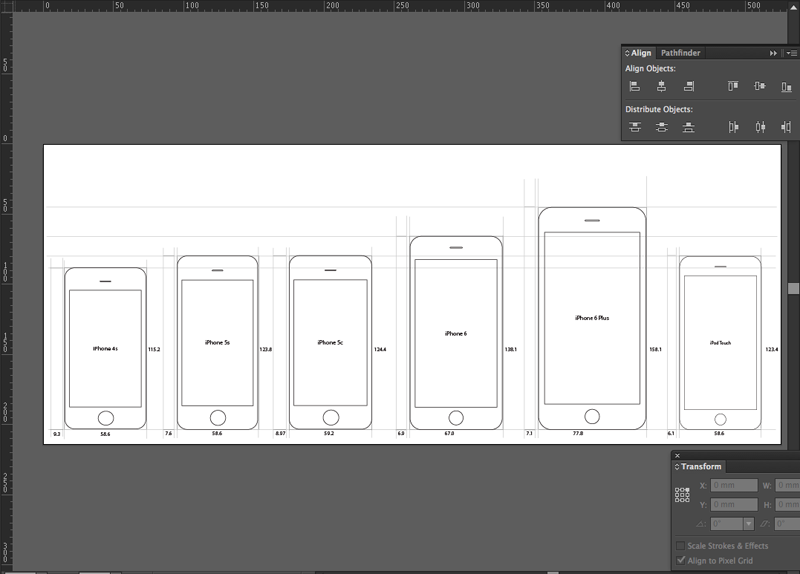

A press-fit kit, is a set of shapes that are able to create a construction that stands in place without screws or anything, just by putting one piece into another and pressing them together. For this week I wanted to create a cardboard case for my iphone that will be assembled on the fly. The first step was to create a file of exact measurements

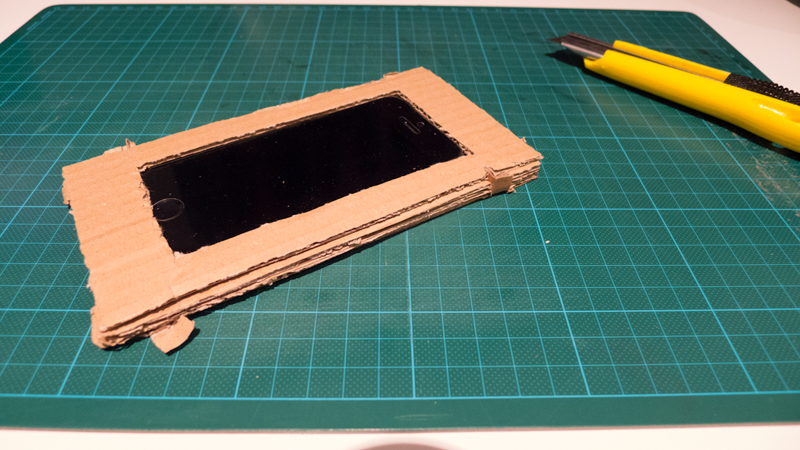

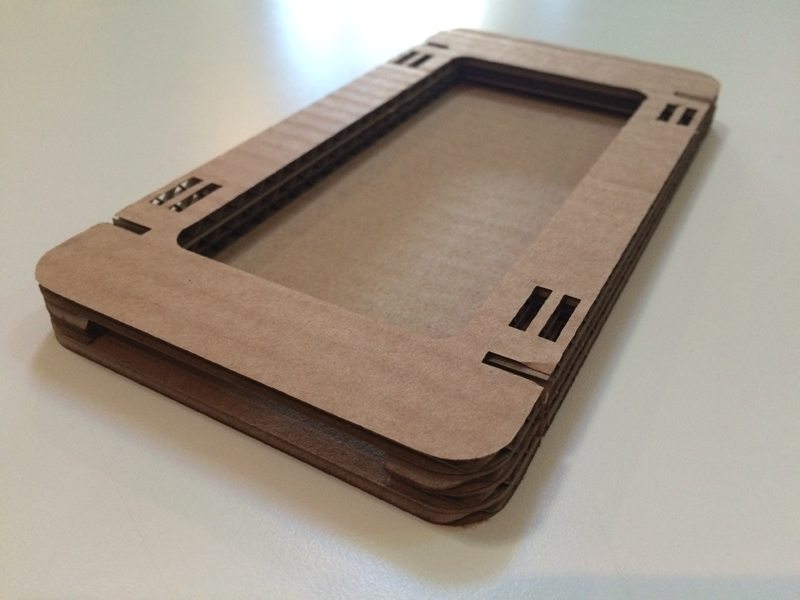

The second step was to design an actual case, and the idea was to follow a "sandwich" strategy for the case where many layers of cardboard would create a placeholder for the iphone and vertical pieces will secure the whole construction in place. Before designing this I made a very quick and dirty hand-made prototype of that just to see the idea roughly

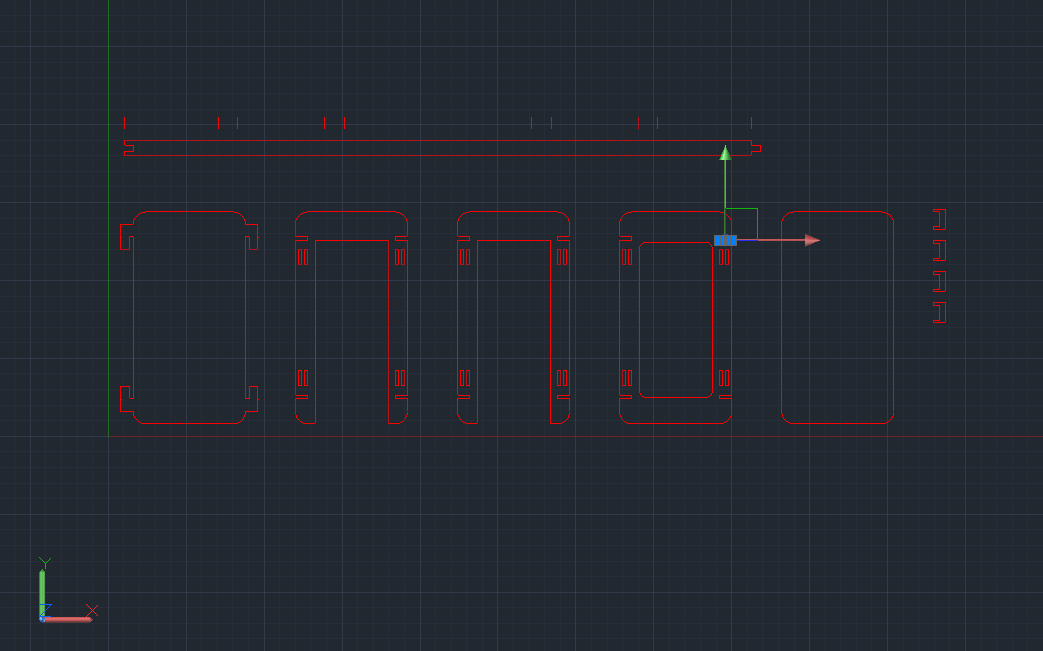

Having in mind that I would need a very precise model, I started designin in Autocad, but that proved to be a waste of time. The design was precise, indeed, but when I transfered the saved vector to the machine it was printed as if there were gaps between the lines (e.g in the corners). That resulted in a highly complex vector that would be never able to be printed out as it would take forever for the machine to even start cutting something

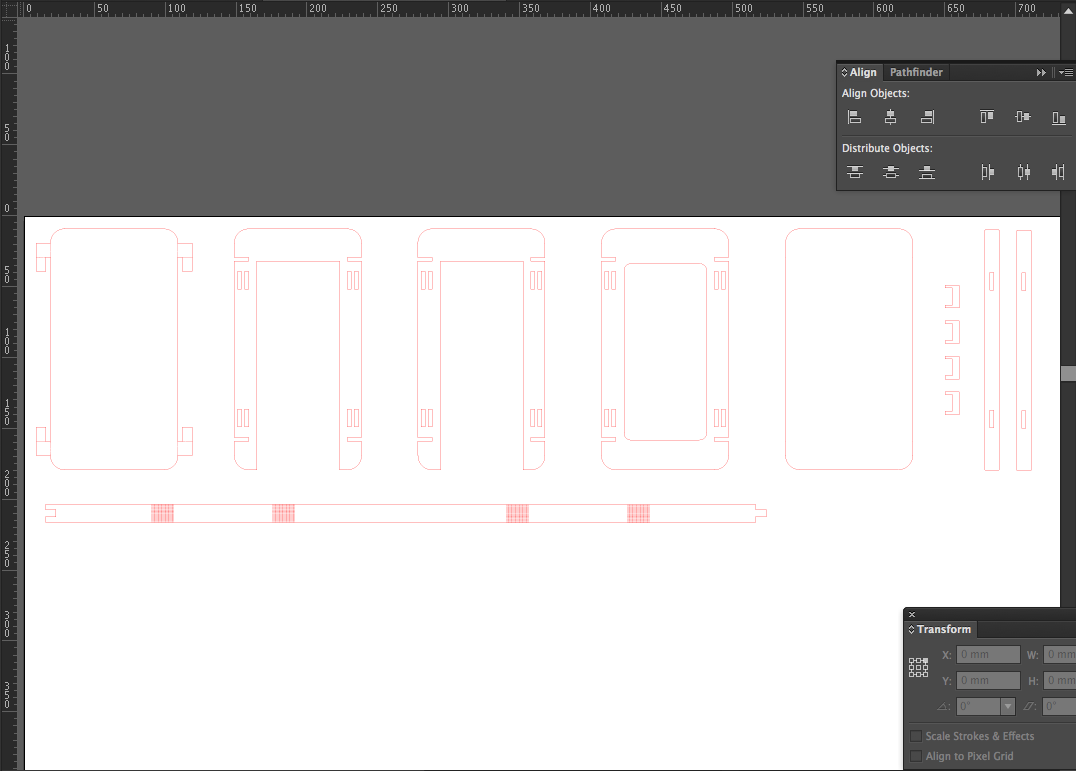

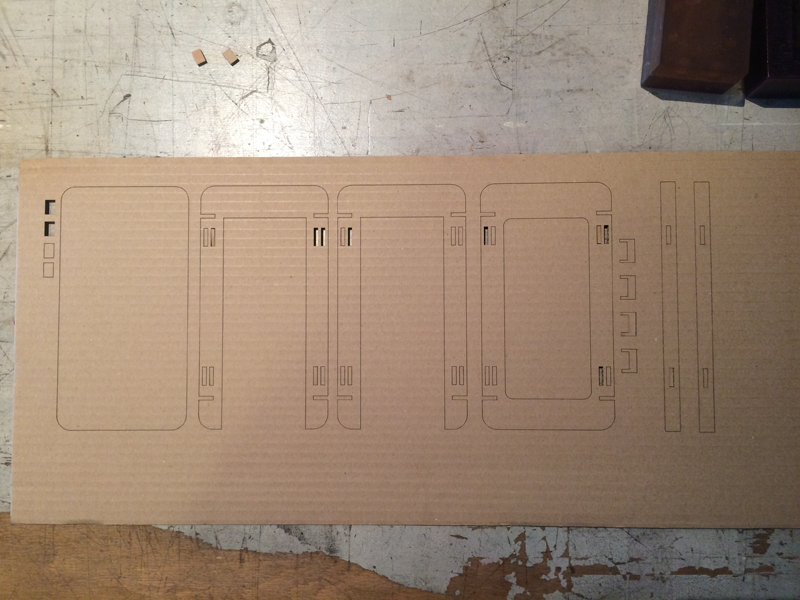

So I decided to go with the flow and design the case in illustrator. I made several trials into cutting an outer layer to wrap it around the case, but the cardboard was always too fragile for the piece to remain whole after folding few times. So I just went with the side "dents" and a future option to tight it further (using the double cuts).

After that the process was pretty straightforward. The kit was laser-cut and assembled

The end result was deceiving to the eye and everyone was skeptic whether the iphone will stay put, just because nothing was holding it within the screen area, it only had side forces. But it was so tight (because the dimensions of the design were so precise), that Alex kept on trying to make the phone pop-out of the case, but he didn't manage to (luckily, for my phone the press-fit was a success!).