Cyclops

Cyclops is the name of the machine I designed using 4 Gestalt stages. The movements are calculated on real time analyzing a webcam image. It is done using augmented reality.

The documentation can be found on the documentation page

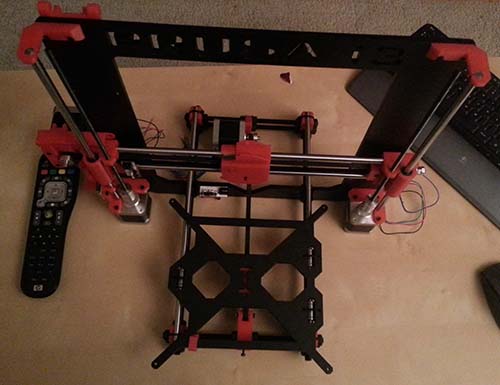

Prusa i3

This semester I built my own 3D printer. The process is documented in thePrusa i3 page

In3

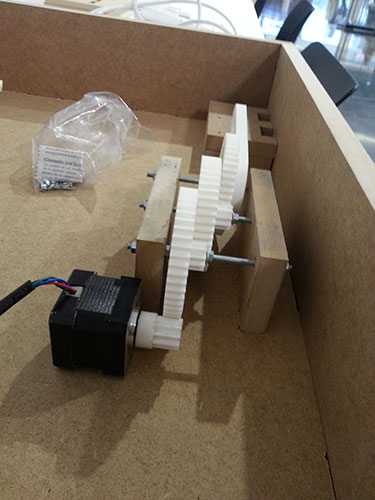

The incubator should be as simple as possible. Despite that I decided to add a mechanism to tilt the bed automatically, so the nurse nor the doctor have to be calculating the inclination degrees. This mechanism won't be mandatory for the final prototype.

As shown in previous classes, the incubator has a box below the bed to store the electronics and be a department where all the parts of the incubator fit. Therefore, the entire mechanism should fit inside this box.

Gears, gears, gears!

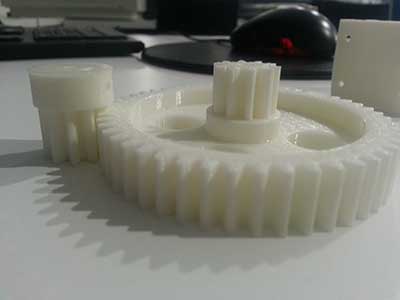

Last days I have been reading a lot about gears and mechanisms. That got me to the conclusion that I had to use, for sure, some kind of gears in my design.

After a little bit of research, I found a Rhino script (Gear Generator) that (supposedly) was able to design a gear from its modulus and its radius.

At first I designed two little modulus 1 gears to see if they fit without making any adjustments. Once printed I got surprised, this was the first try and those little pieces of plastic were matching perfectly.

Although they were very small and strong, I decided to use a slightly bigger module for the mechanism of the incubator [1.5] to make them even stronger.

Modeling the mechanism

First approach

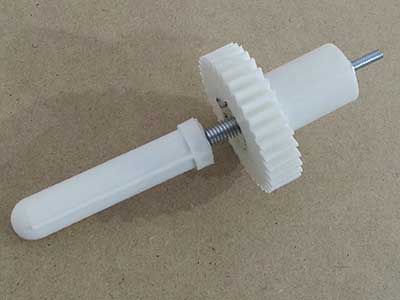

The first design that came to me was using a piston. That approach had a reduction stage using gears, so that the NEMA 14 is able to tilt the bed at least 15 degrees while it has on top a maximum weight of about 10kg. This stage has a reduction has 3 gears, with a reduction factor of 10.5.

As seen the third gear is a little bit strange, that's because I needed as much space as possible to accommodate the piston.

Finally, to allow the piston to go up and down I added a couple of small tabs that will act as a rail to guide de movement and avoid that piece to spin with the gear.

I printed the gears and all other pieces I designed using Rhino. I didn't quite liked the result, the piston was surprisingly strong, but the guides of the piston were not, probably I had to redesign it a little bit thicker. Anyhow, when I started building the mechanism, it was not stable at all. Some of the gears were tilting a little bit while applying vertical forces, and the piston required a lot of space. Concluding,... I decided to do a second iteration and redesign the mechanism.

Second approach

Instead of using a piston I used a connecting rod at the end of the reduction stage.

This approach requires a bigger torque to make the bed tilt as expected, so I designed a mechanism that, standing by its own is able to tilt the bed correctly. In spite of it, the final version will include, probably, two reduction mechanisms like this one to give more stability to the design.

After printing the gears using the MakerBot, I decided to build a new box for the incubator just to try this approach. In order to maximize the inclination of the bed, the lever fulcrum was moved from the middle of the bed to 1/3rd of it. After that, six pairs of squared holes were added to the bottom of the bed (as can be seen in previous designs) to hold the mechanism using press-fit.

The first attempt were not successful. The reduction stage were working as expected under low load conditions, but when load is applied, the gear teeth were not being able to hold it still. The problem were not the gears, they were fine, the problem were the holes of the gear shaft. They were too far apart from each other. Once I adjusted those distances, the gear worked perfectly.

At this moment, the mechanism fits inside of the box, but it can be reduced if I change the gear from the NEMA 14 to the NEMA 17. The problem is that the weight will be doubled and that is more expensive.

Files

Modeling the mechanism - 1st approach

- Download nema14_base.stl or view

- Download small_gear.stl or view

- Download gear_1-3.5.stl or view

- Download gear_1-3_two_levels.stl or view

- Download piston.stl or view

- Download piston_base.stl or view

- Download rail.stl or view