Preparation

The first task I had to undertake was preparing the equipment for PCB prototyping, this is where things become dramatic.

Machine & Tool Maintenance

Tooling

Unfortunately, upon opening the toolbox that holds the FabLab collection of small milling tools for the MDX-40A I discovered that things were not in the state they should be.

The first issue I encountered was a total lack of intact tooling, unfortunately I had forgotten to inventory the cutters last year and thus had not ordered any replacements. Express Shipping to the Rescue (Which, in WA, means a 2+ week wait).

A selection of ⌀0.30mm endmill bits did eventually arrive, along with some V-bit engravers and a new set of PCB drills.

Handy Hint

At 0.3mm and with a sharpened cutting face these little endmills have absolutely no trouble making their way through human skin (I learned this through empirical experimentation), they do however like to resist coming out easily.

The Collet

At this point I thought it was about time to do a test run, so I put the first of the new endmills into the 3.175mm collet and started the spindle to check alignment.

Oh No! I exclaimed as I watched the tool wobble by about 1mm as it rotated (Well, some stronger language may have been used), it was then that I discovered that the collet itself had become deformed.

The collet we used for non-metric tools was an adapted Dremel-type collet chuck that in turn mounted into the 6mm Roland collet, the shaft that inserted into the Roland collet had been crushed. Again enter the world of getting things express shipped. It arrived fairly quickly (5 days) and I was good to go!

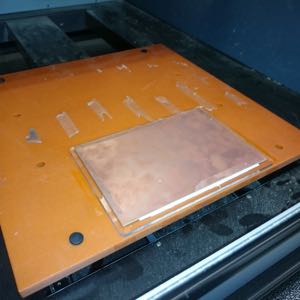

Preparing the FR1

Now that I had all of the required equipment, I needed to affix the FR1 blank to the bed of the MDX-40A, for this I used some 'temporary carpet tape' sourced from Masters Hardware, I've used this extensively on the small mill as it is relatively low tack, extremely flat, leaves no residue and has a strong vinyl substrate that is very easy to peel off. I adhered the FR1 first to a sacrifical layer made from scrap acrylic and then adhered the whole assembly to the bed of the MDX-40A.

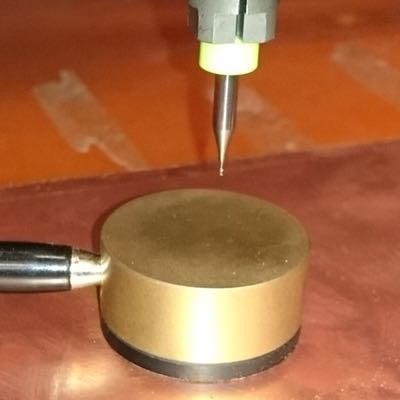

Setting up the Machine Coordinates

I will admit to a few moments of terror as I watched the tiny endmill approach the tool detection pad, I was conviced I was about to be given a first hand demonstration in the brittle nature of tungsten carbide, fortunately it worked just as intended and detected the tool, after setting the X and Y job home slightly inside the border of the FR1 blank I was ready to proceed.

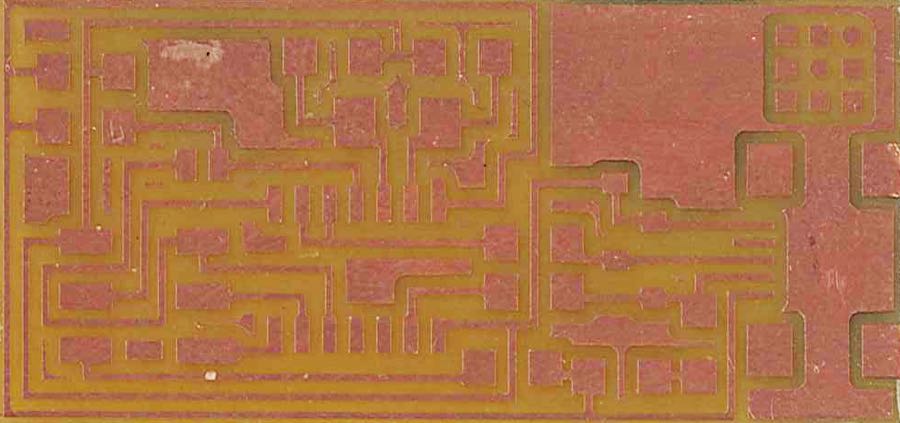

Manufacturing!

The milling went swimmingly, with the result nicer than anything I have ever managed with previous attempts (I had to use FR4 historically as there was no source I could locate for FR1).

I generated the toolpath with the new HTML5 FabModules but rather than using FabModules to directly drive the MDX-40A I used V-Panel to send the generated RML files to the machine. This was primarily due to time constraints, I fully intend to get the FabModules working directly on the machine once FabAcademy is finished and my brain has some spare CPU cycles again.

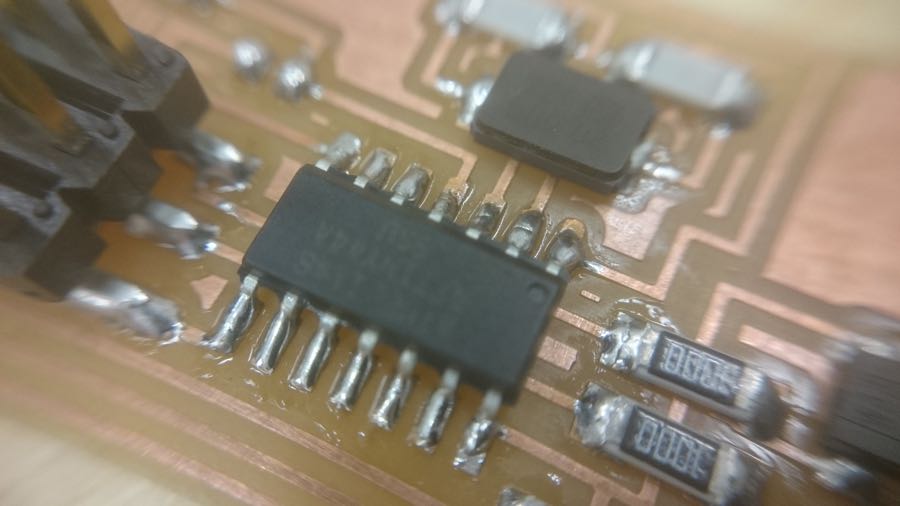

Populating

Populating the board tool about 15 minutes and was relatively uneventful, no severe burns, no explosions and no unexpected emergent sentience in a cluster of ATTinys.

Testing

Now for the moment of truth, will the board program? Will I be forced to fish out my oscilloscope and spend the night debugging? Will I inadvertently reprogram myself? These questions and more answered... Now.

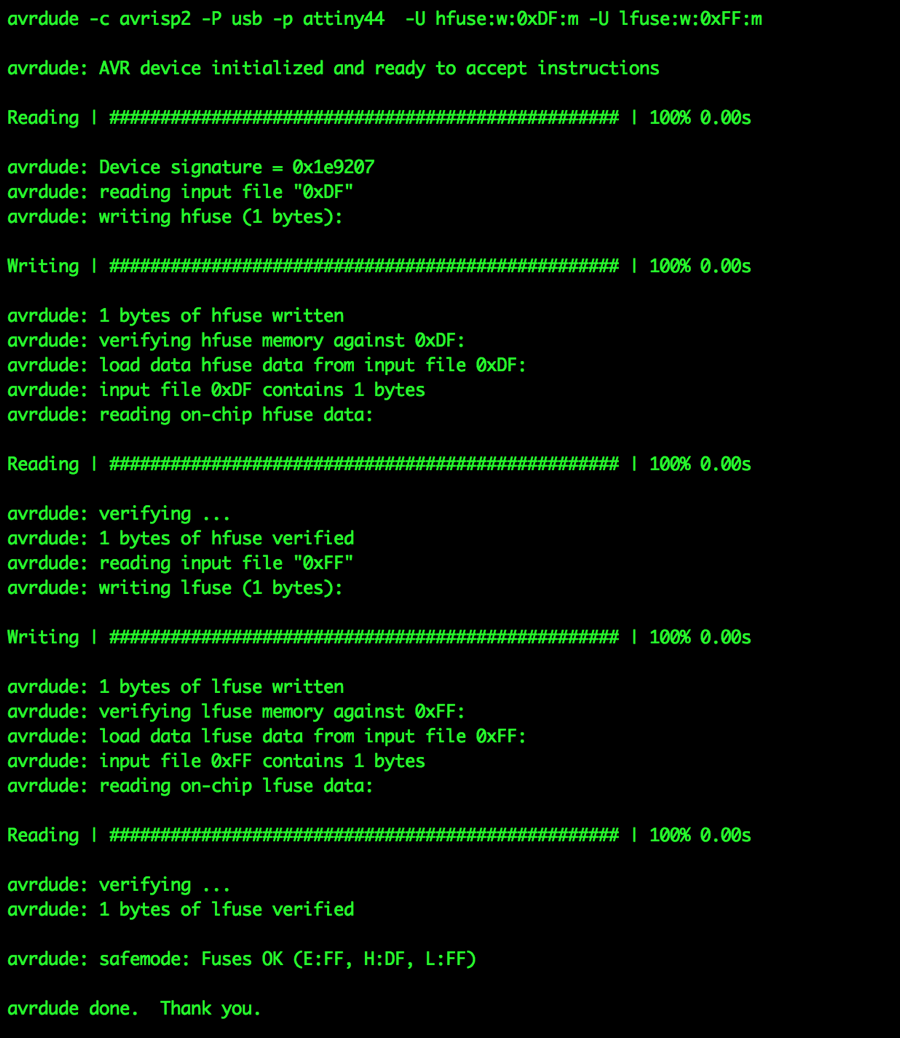

It Works! The firmware uploaded to the FabISP perfectly, on the first try no less. Shown above is the AVR ISP Mk II setting the appropriate fuses on the ATTiny44. Next step, verify that the FabISP can upload a program to a second board.

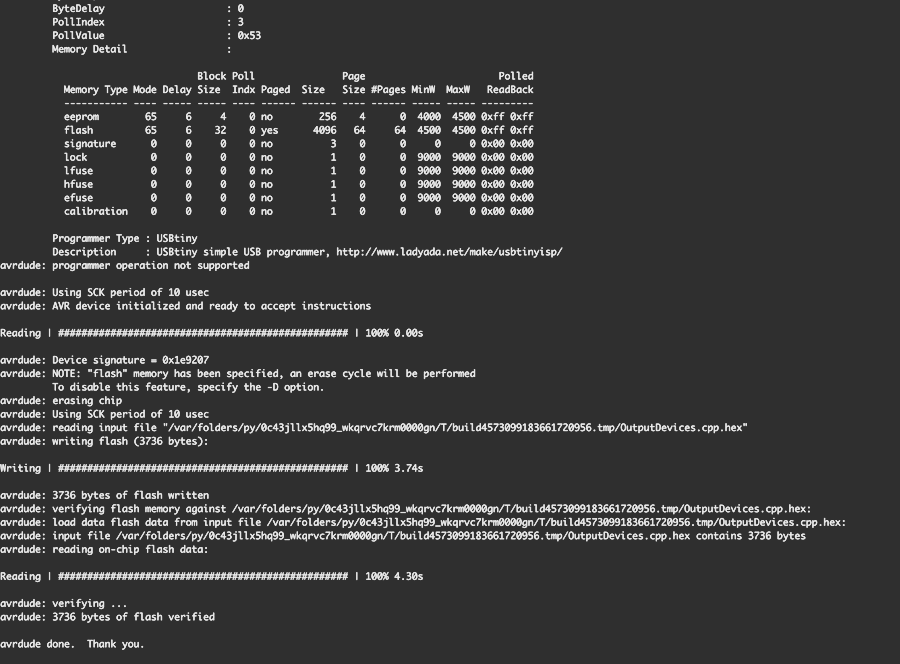

And it worked too! I used the FabISP to program my ouput multiplexing board from week 11 and it succeeded. Huzzah!