This weeks assignment was to make something big. in big scale. i decided to mile a rocking chair using the shopbot.

I started modeling with rhino.

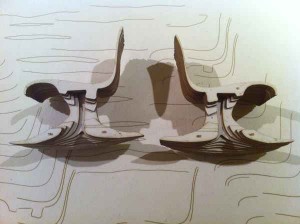

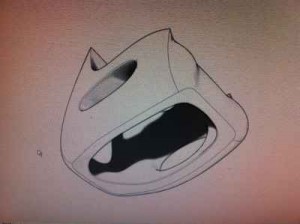

And made some models using the cardboard cut in the lazer machine.

Then i got back to rhino and made some changes in the design. i wanted to make it stronger.

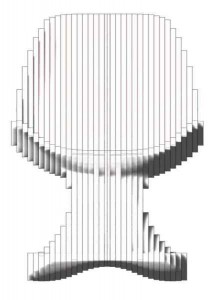

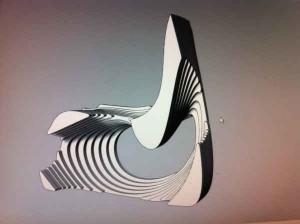

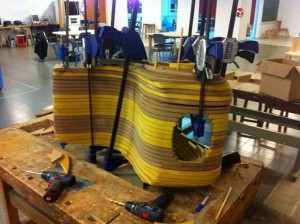

I cut the model in rhino using the contour command.I set the distance between each contour line as the thickness of the material that i am using. in this case i am usine a colored M.D.F. board, 19 millimeter width. after getting the contours, i extruded them to have a 3d model of the chair.

In the 3d model i added hole in the size of some round wood poles that go in 5 places throw the chair to help me in the assembling.I also numbered the pieces for the same reason.

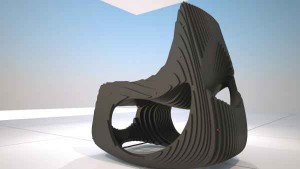

I applied some wood glue and pressed with the vise.

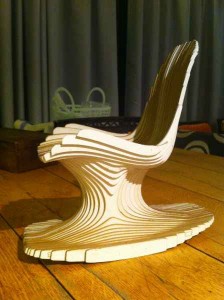

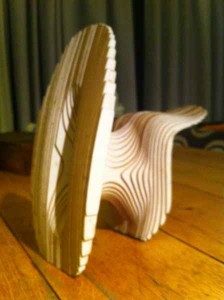

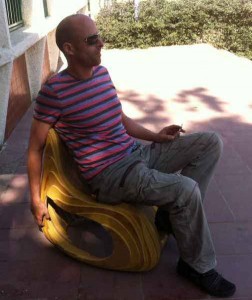

After 24 hours i released the vise. the chair is ready!!!

Some thoughts for the next time:

1. try to put wooden poles as little as possible.

2. the hole for the poles should be 1 millimeter bigger the the pole itself.

3. the chair is very heavy.next time i will try to subtract more material from the ribs trying to make it lighter.