Computer-Controlled Cutting - Assignment:

This week consisted of designing and laser cutting 2D parts to understand the

laser cutting process, material behavior, kerf, and press-fit tolerances.

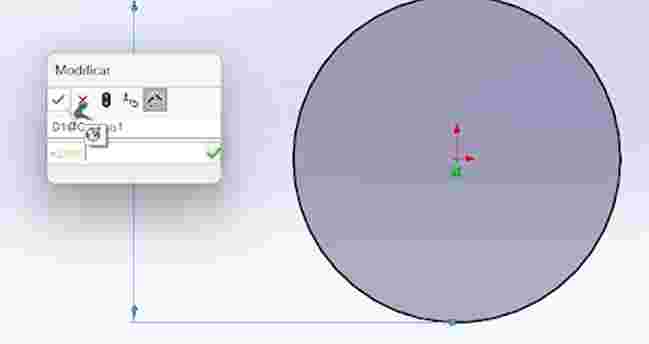

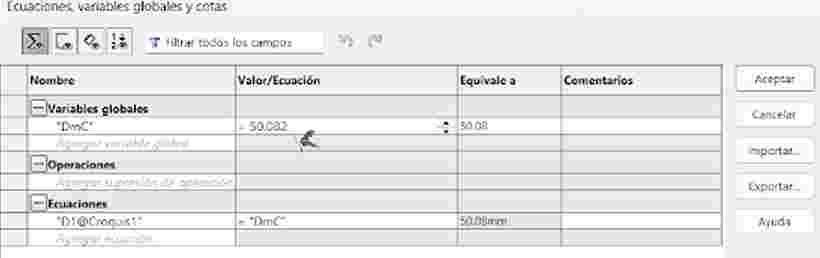

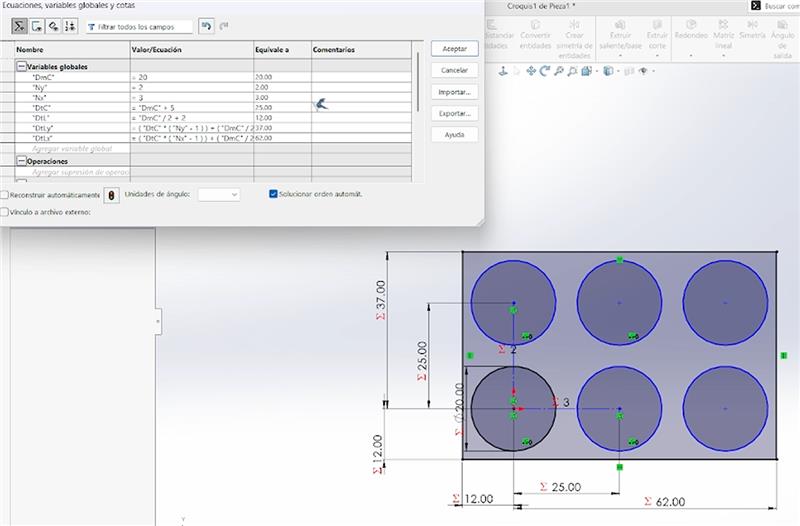

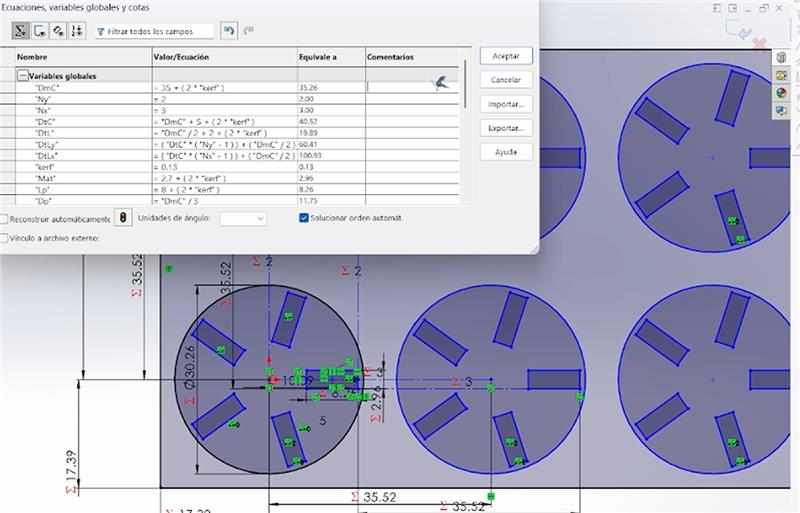

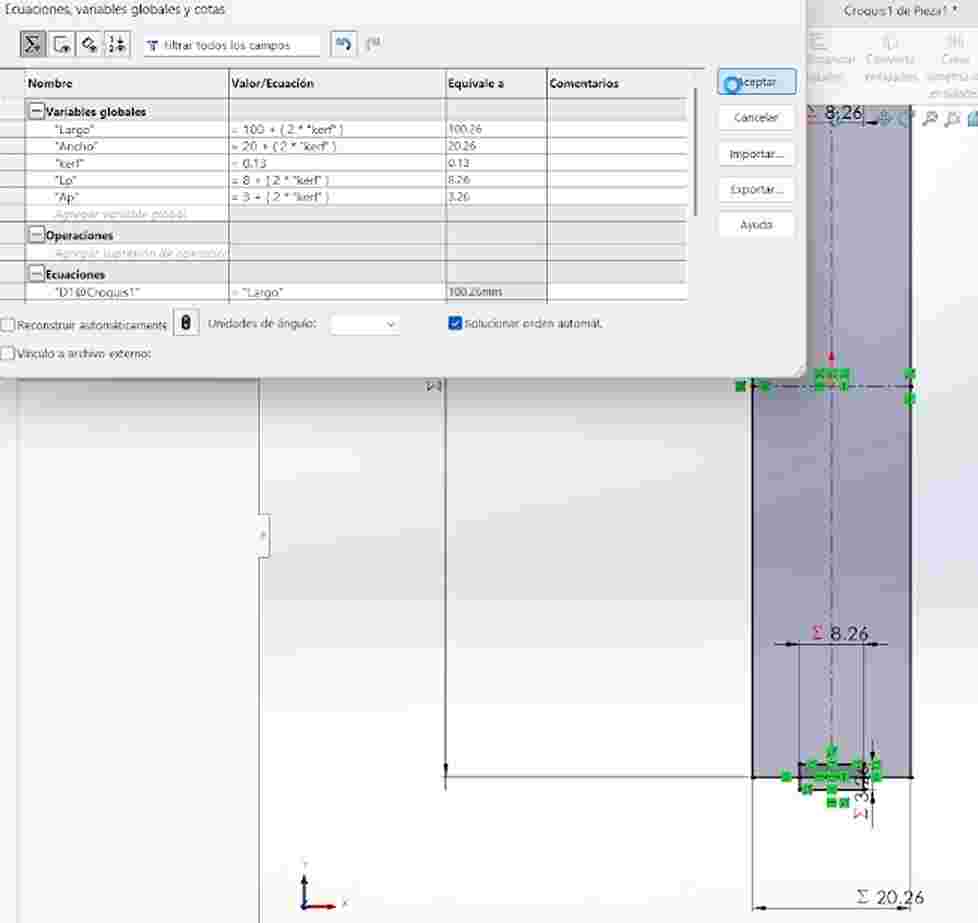

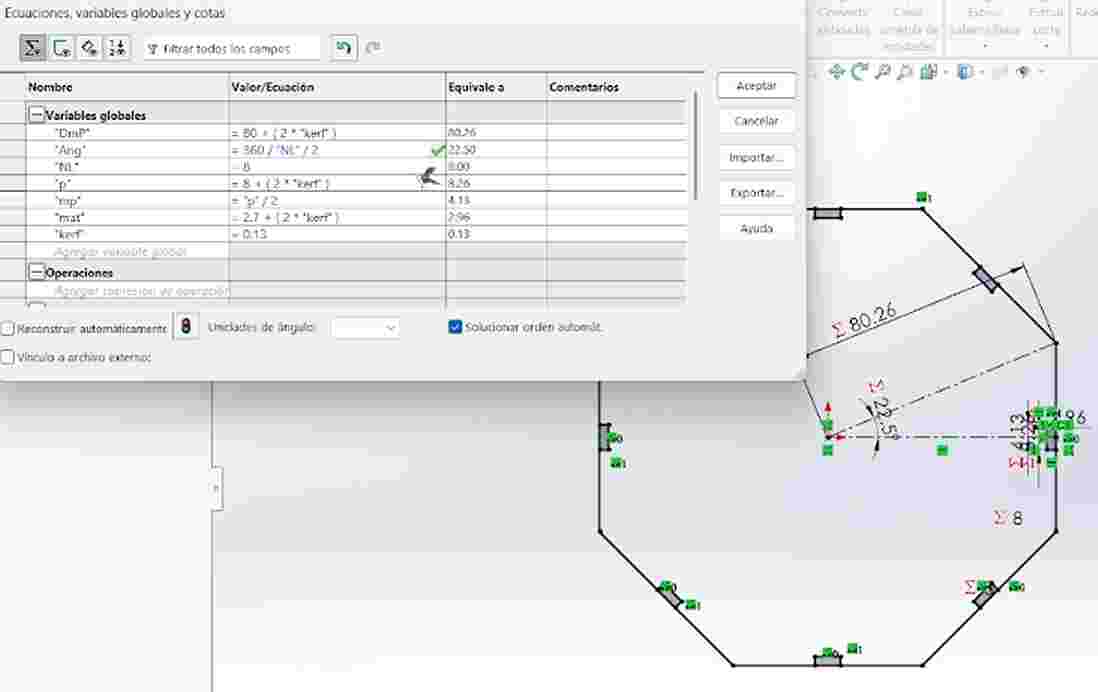

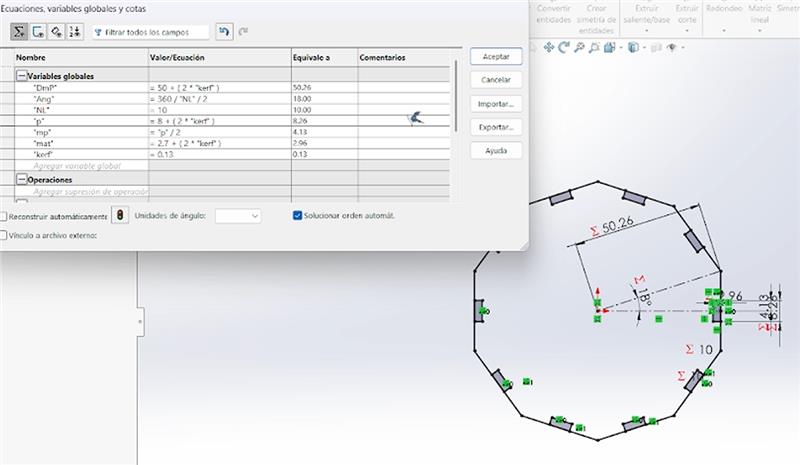

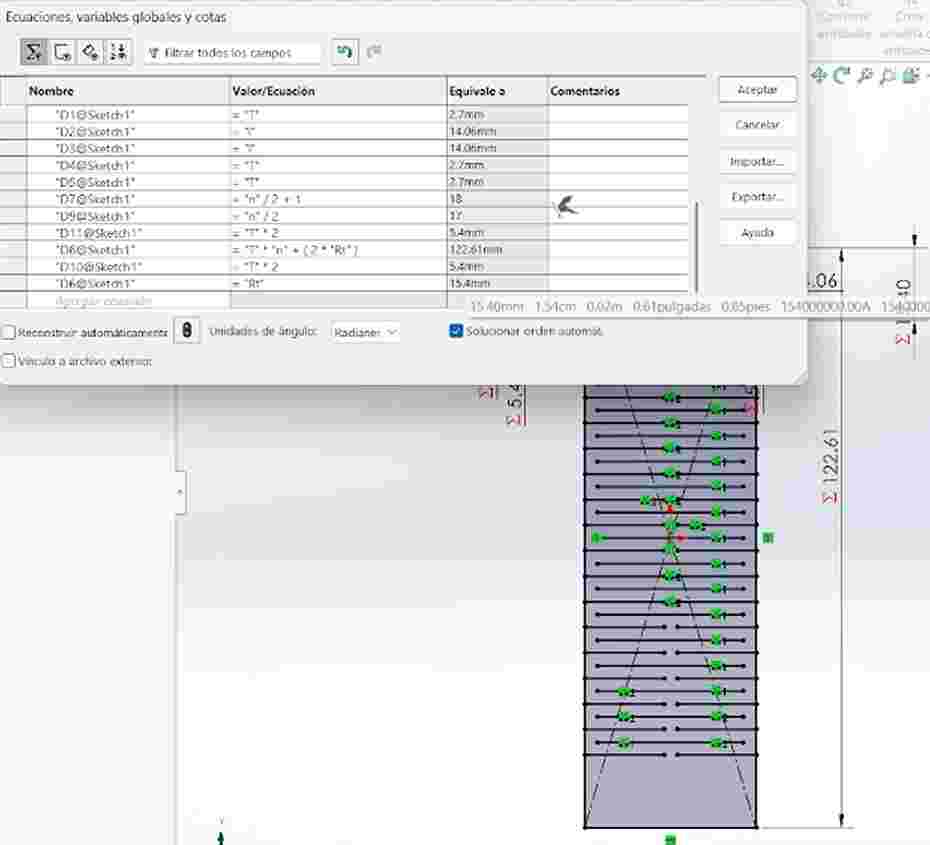

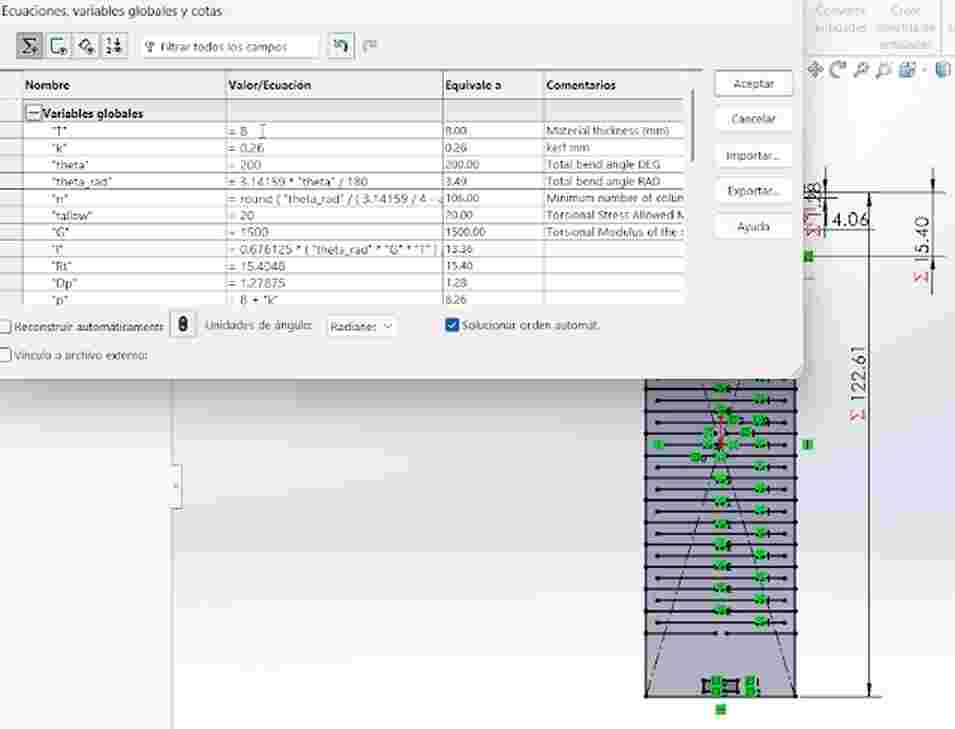

I decided to use SolidWorks for this, first to explain how do you make the parametric design of a piece,

once the piece has been drawn, we need to make a variable, we can either go to

tools-equations or directly make it by placing "=" on a dimension and create the variable, once doing this, we can change the

variable in equations and redimension the piece anytime we want.

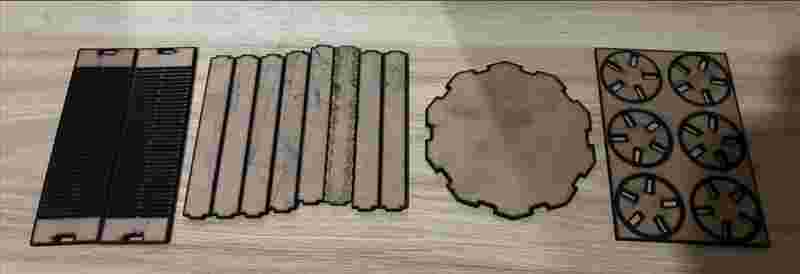

I made different pieces, first I did some circular pieces, then a kind of pilars, a polygon

and finally some flexible pieces.

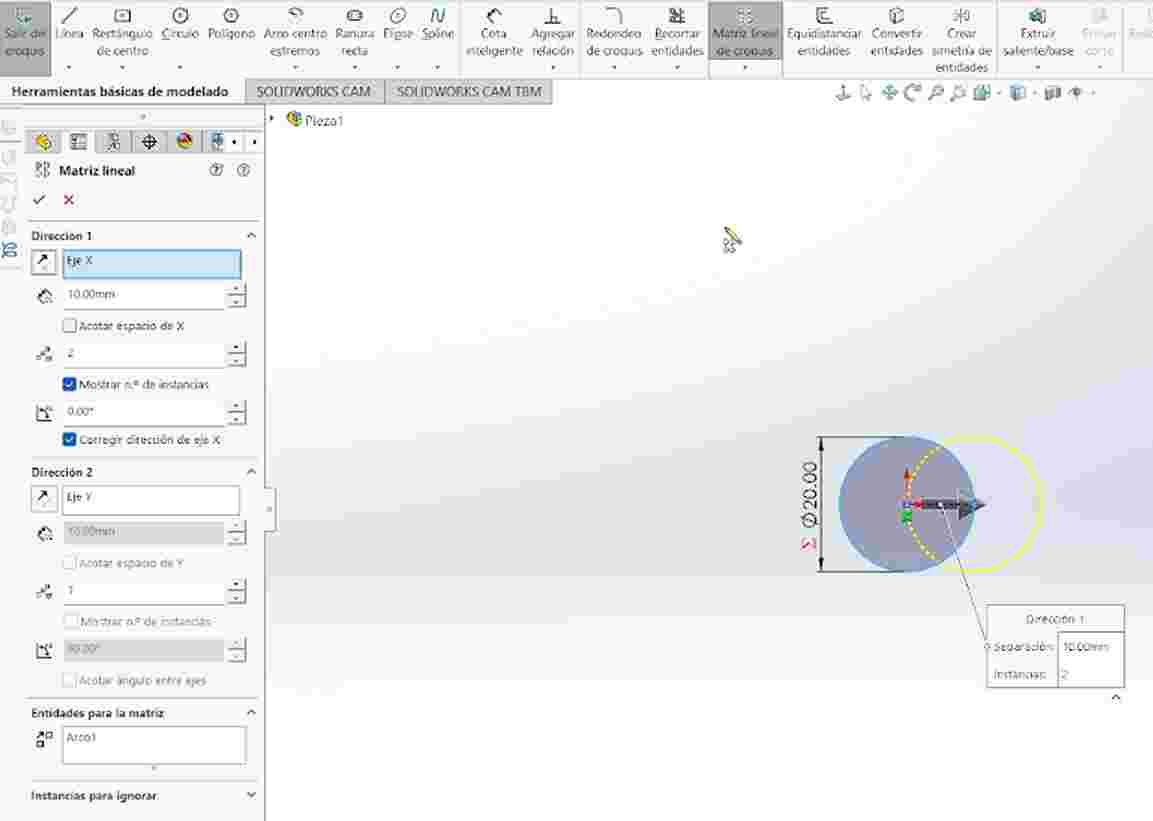

Circular pieces were made by using the inital circle I talked about and making a pattern to right and up,

then for the joint type I made a circular pattern on the circle.

Pillars were made by starting of a rectangle and again the pattern to right and up.

The polygon was quite complicated because we had to use a equation to define the angle so we could change the number of sides by the parameters.

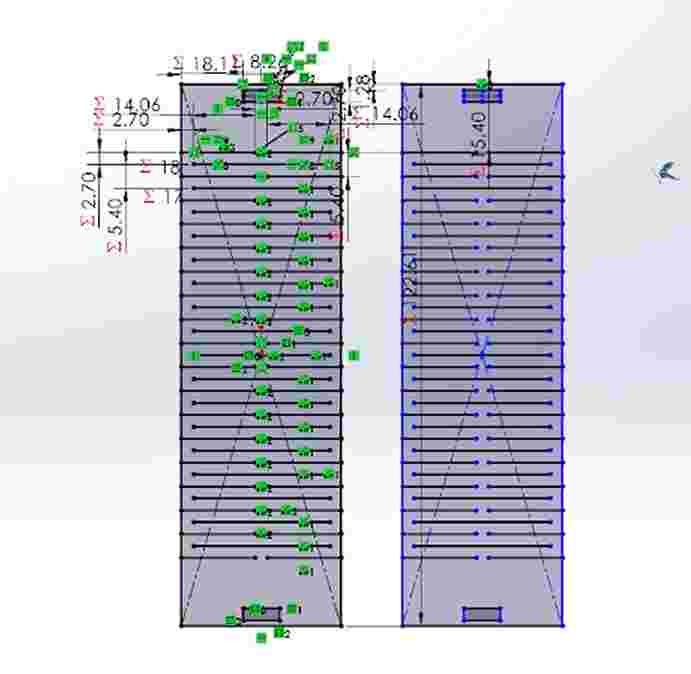

Finally the flexible piece was made by the use of a pattern we have and changing the parameters we have so we change the dimensions of the material.

Files

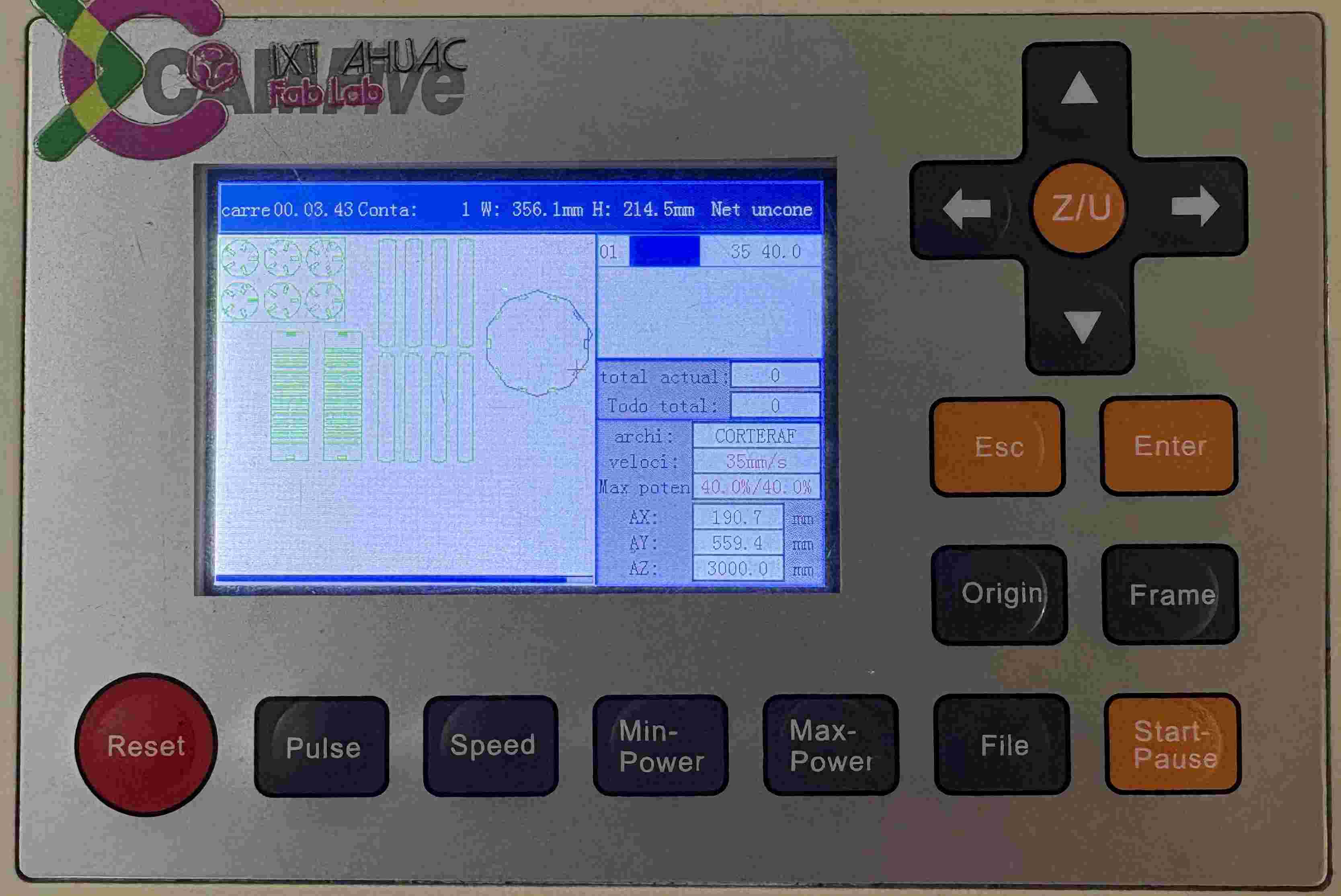

Laser cutting

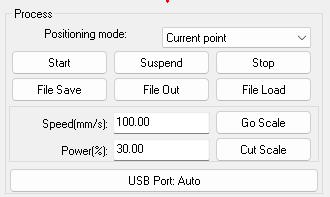

For our Laser cutting we need to import our .DXF to SmartCarve and accommodate our pieces in the main page, once doing this we go to file save and save our document as a .oud.

Then for the Laser Machine we start by following the next steps:

- The first thing we must check is the chiller that maintains a safe temperature.

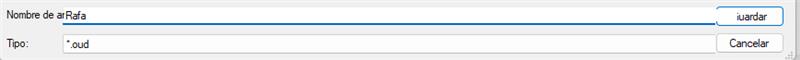

- To turn on the automatic voltage regulator of the laser.

- Turn on the machine using the button located on the right side.

- Release the emergency stop.

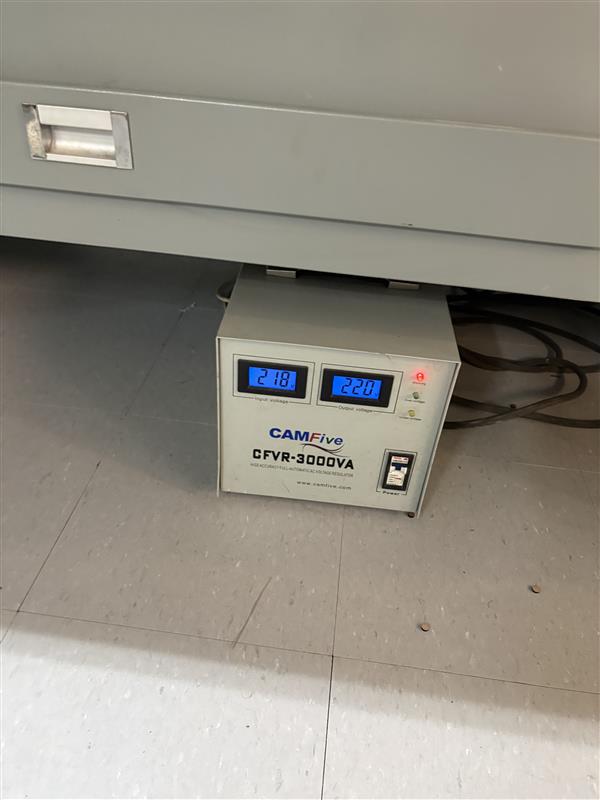

- Inserting and turning the key in order to activate the laser control panel.

- Set an origin, by pressing the Origin button.

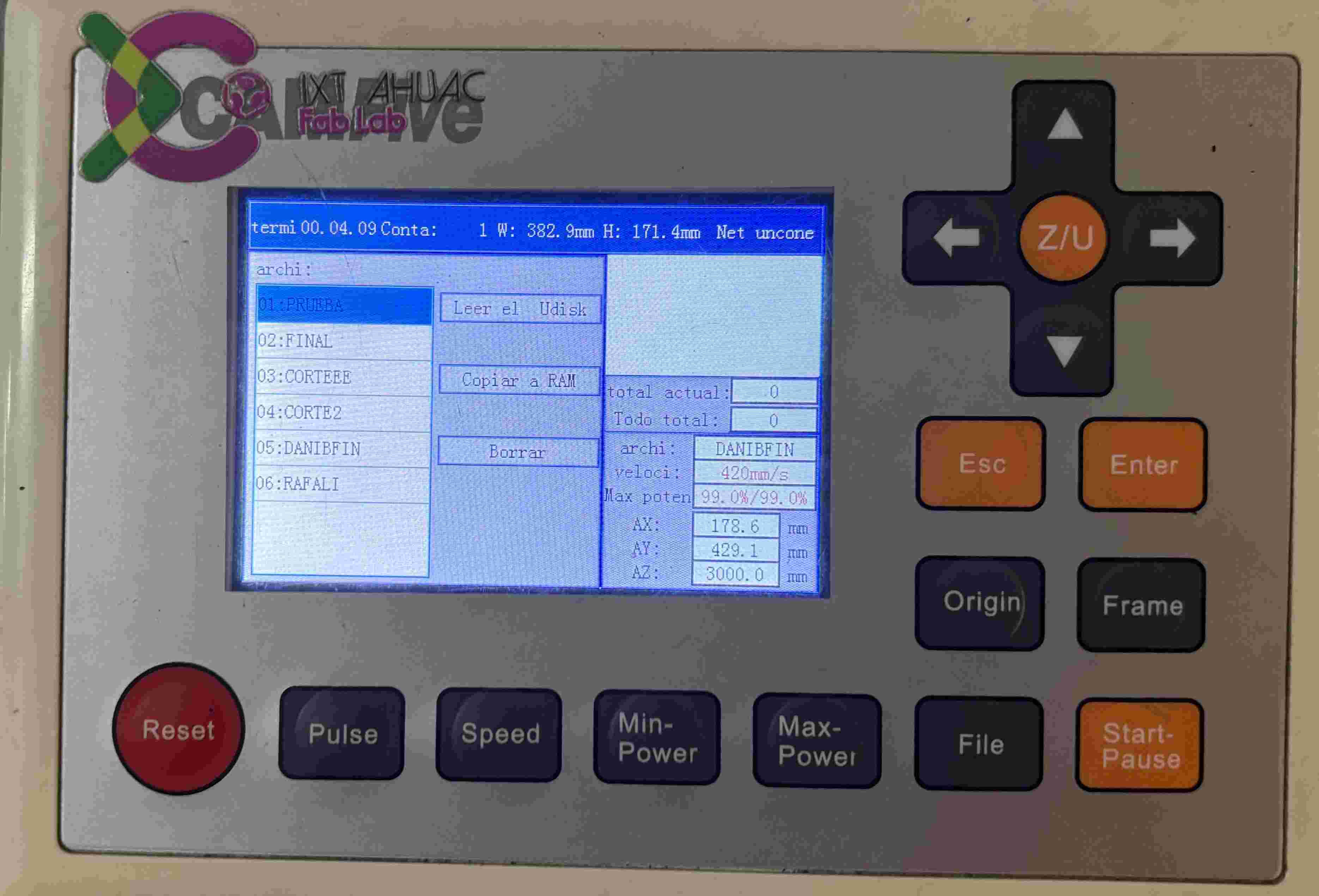

- Insert the USB with our .oud archive.

- Go to +Udisk read it and search for our file.

- Copy our file to Ram.

- Esc and select our file.

- Activate our Laser in the top bottons and Enter on the Panel.

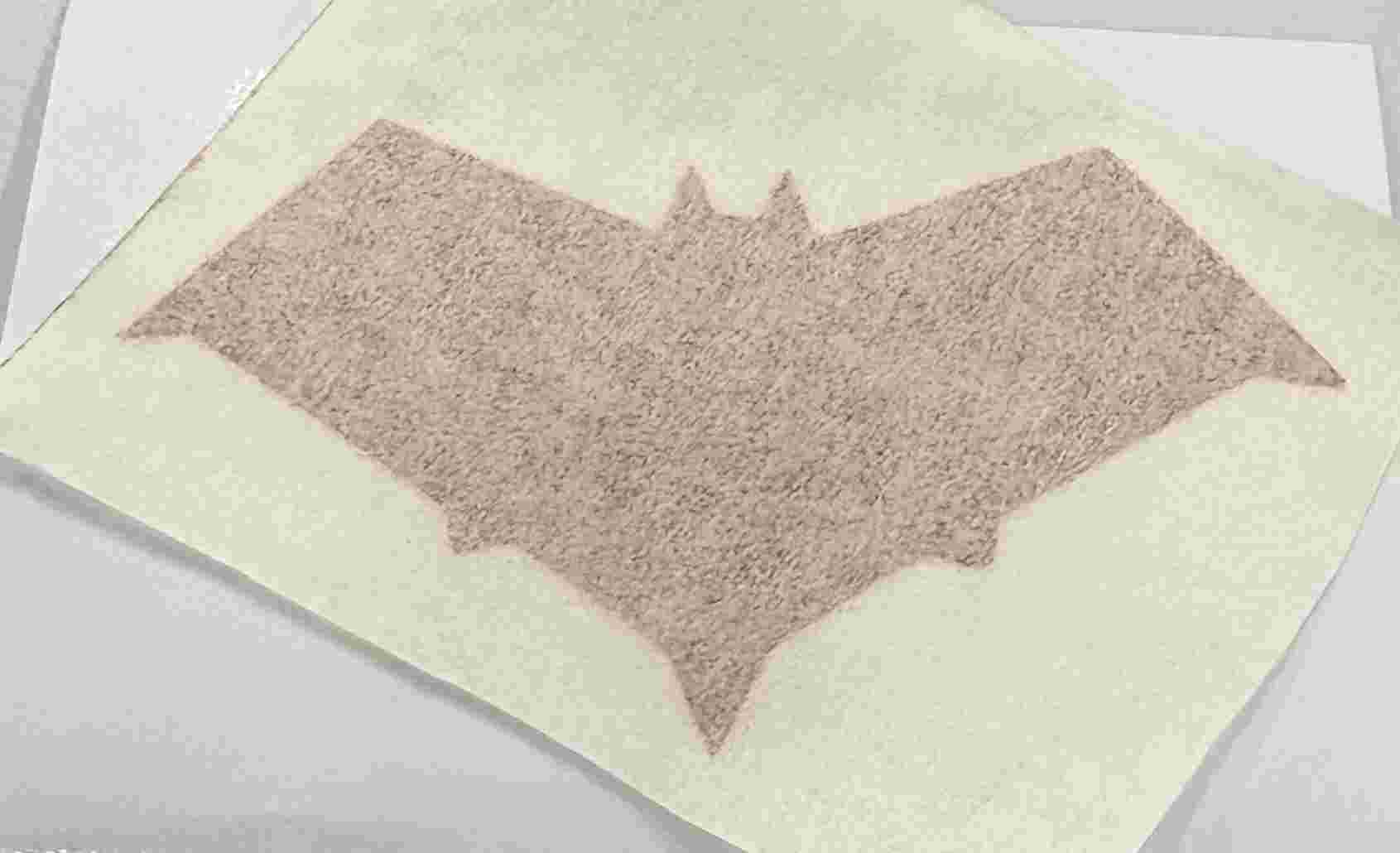

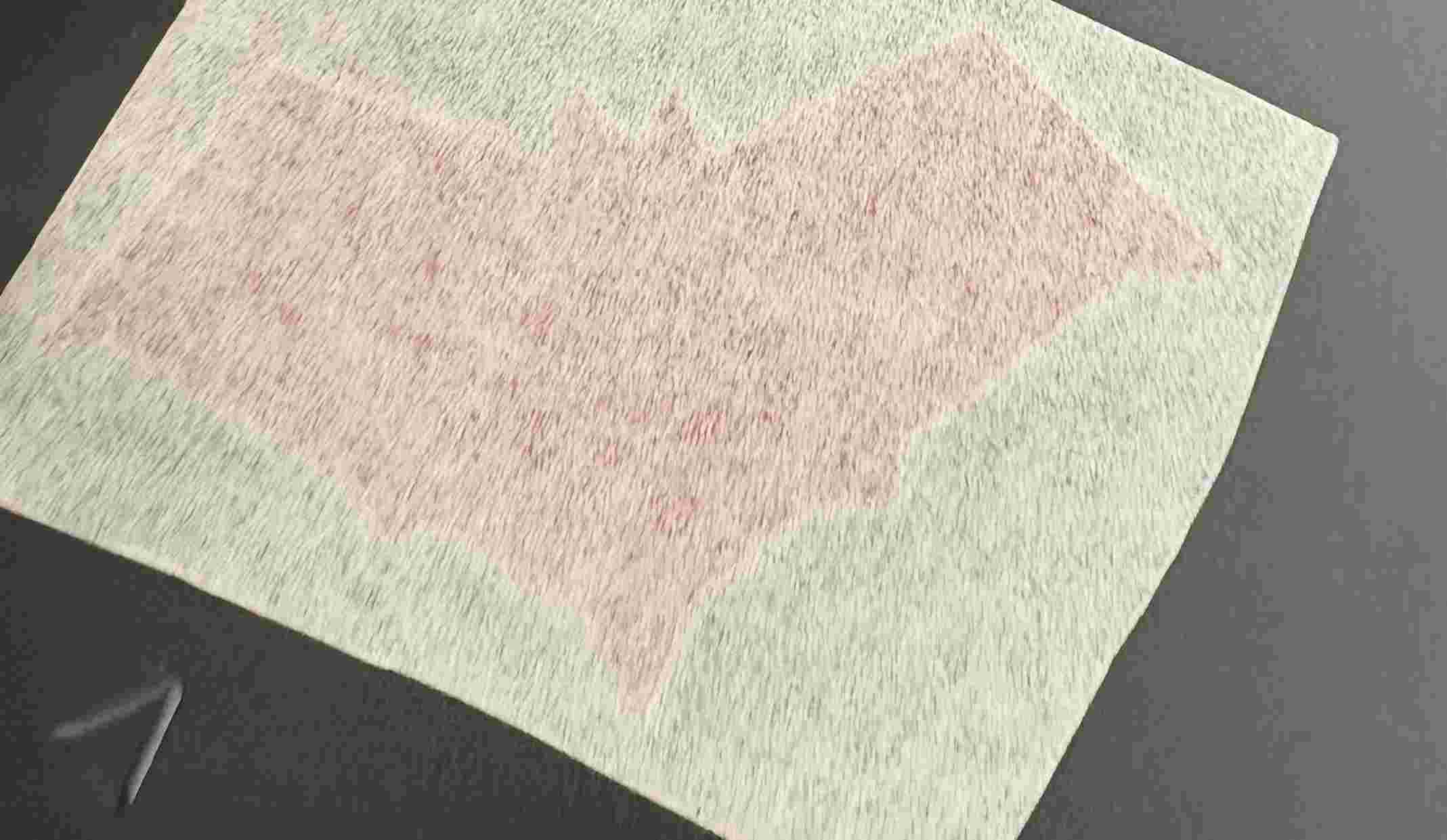

This is how my initial pieces came out.

This pieces were incomplete and didn´t come out as I wanted due to some problems I had, so later I did it again and this is how my final pieces came out definitely.

Vinyl Cutting

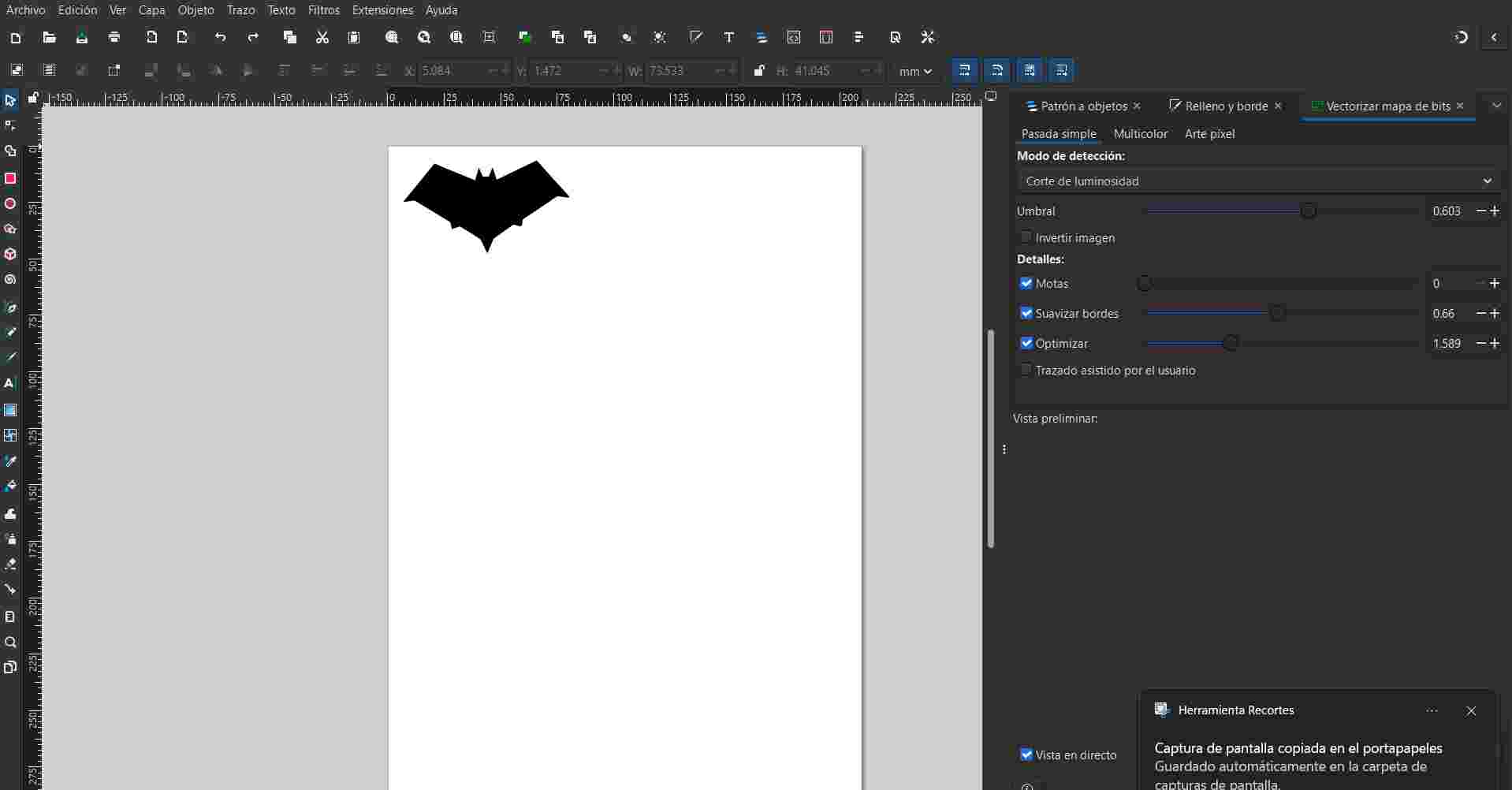

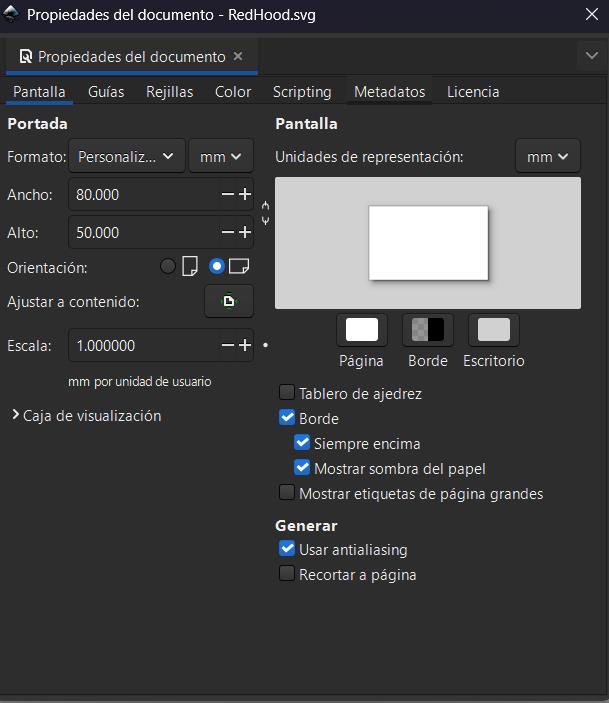

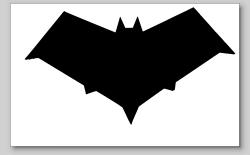

For this section we need to vectorize a bit map of an image, I made it on inkscape and save it as a .svg, after that we need to follow some steps.

- We have our vectorized image.

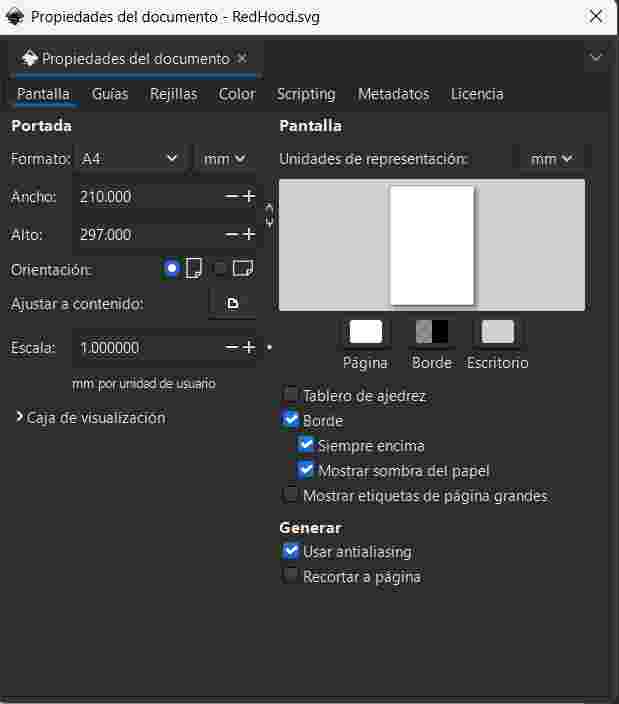

- By using ctrl + D we enter the properties of our document.

- We need to redimension our document using our bit map as reference.

- Once done, we accommodate our bit map close to the up right corner.

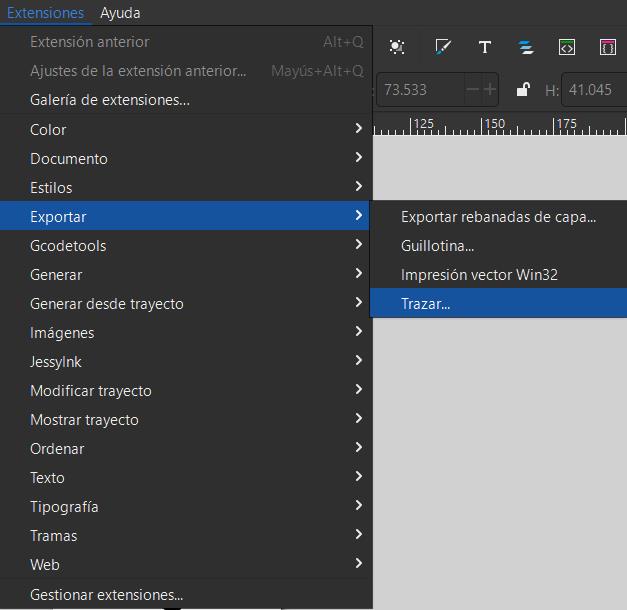

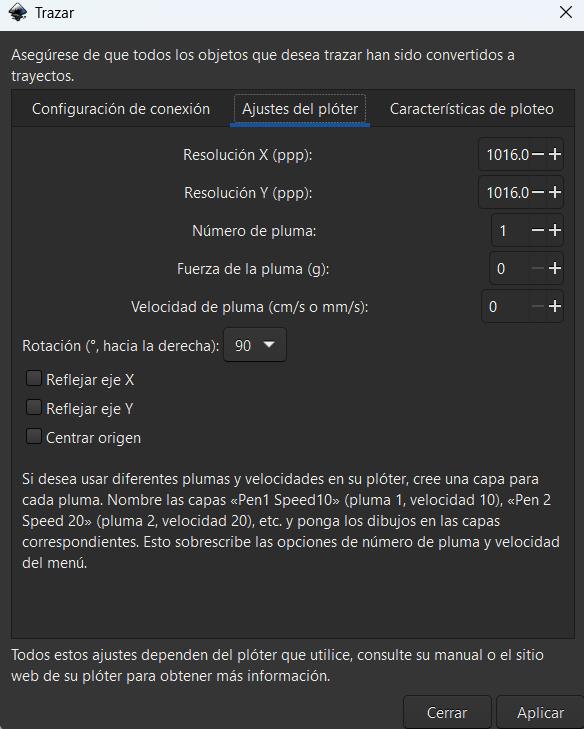

- Then we enter to extensions-export-plot.

- Here we set some parameters and once we have our cutting machine ready we apply.

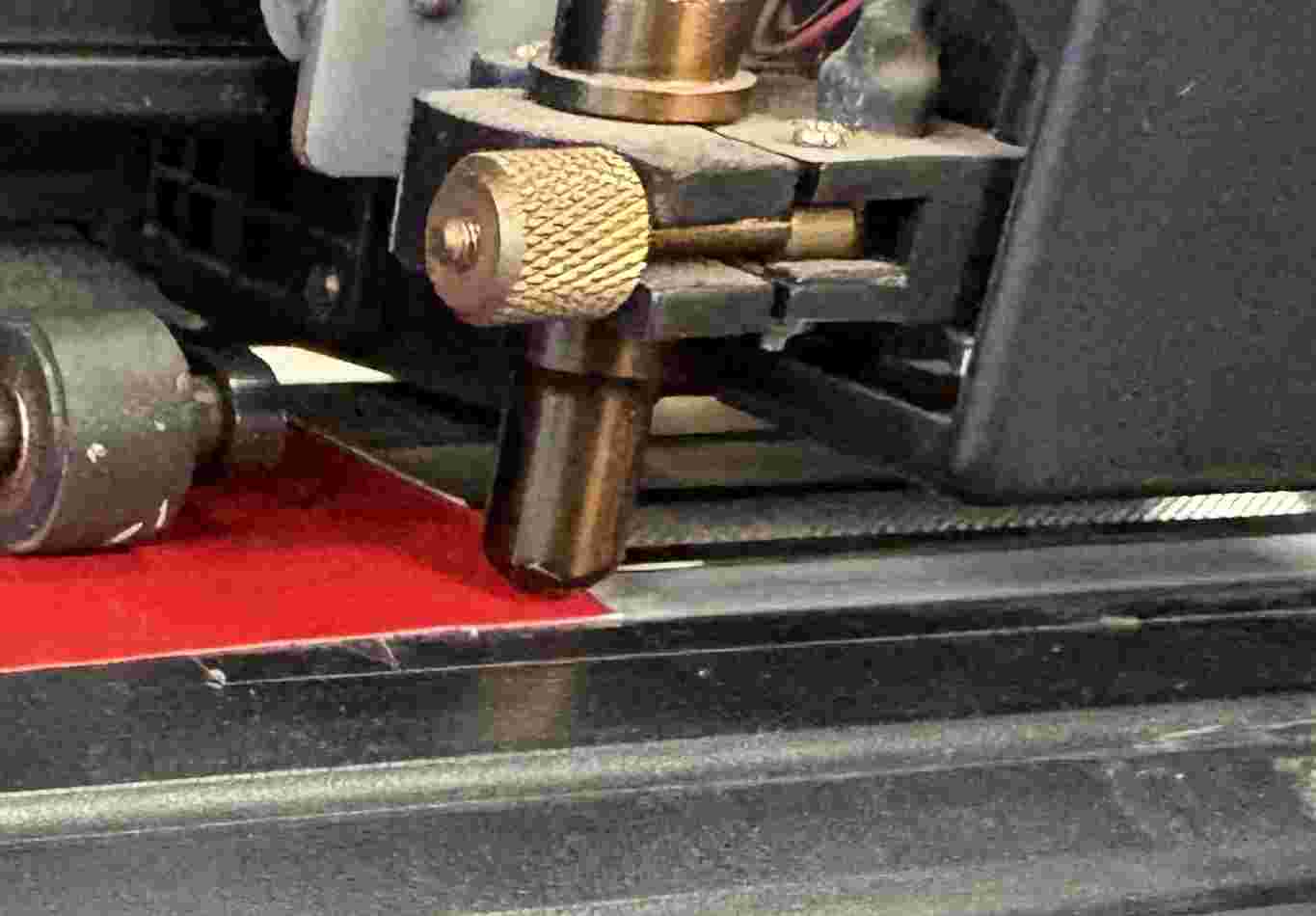

For the cutting of our Vinyl we follow the next steps:

- We have our Machine set.

- Introduce the Vinyl from the back and set in in place.

- Press manual so we can set the origin.

- Move our origin to a corner.

- Once set the variables, press apply on inkspace and start the cutting.

- Get rid of the background of our cut.

- Use the transfer paper over our cut.

- Remove the cut from the original Vinyl paper.

- Place the Vinyl were we want it to be and press the transfer paper.

- Remove the transfer paper.