3. Computer-controlled cutting

This week I used the plotter and laser cutter to cut vinil and cardboard respectively.

It was very useful to know about vectors and 2D design. This way I was able to create and edit the pieces I planned to cut.

I even tried creating a 3D puzzle to cut on the laser, but I got stock and wasn't able to crate what I imagined.

Some of of my learnings:

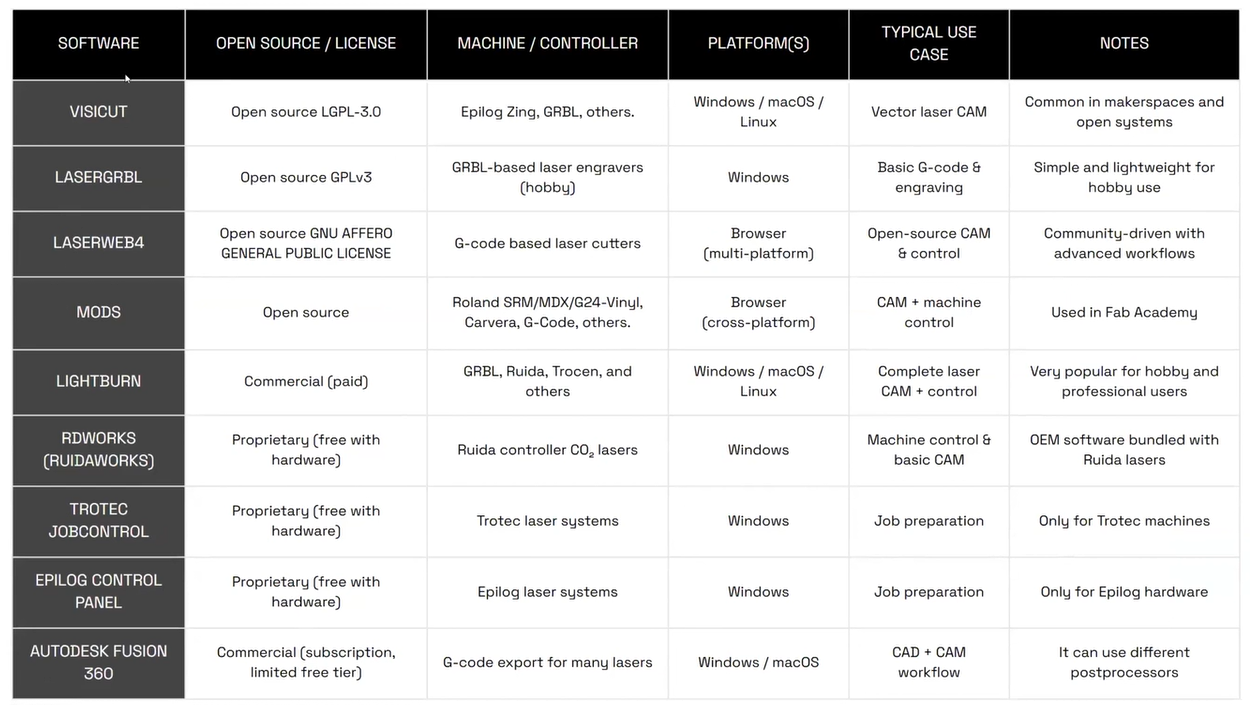

We learned about many options for CAM edition.

Plotter

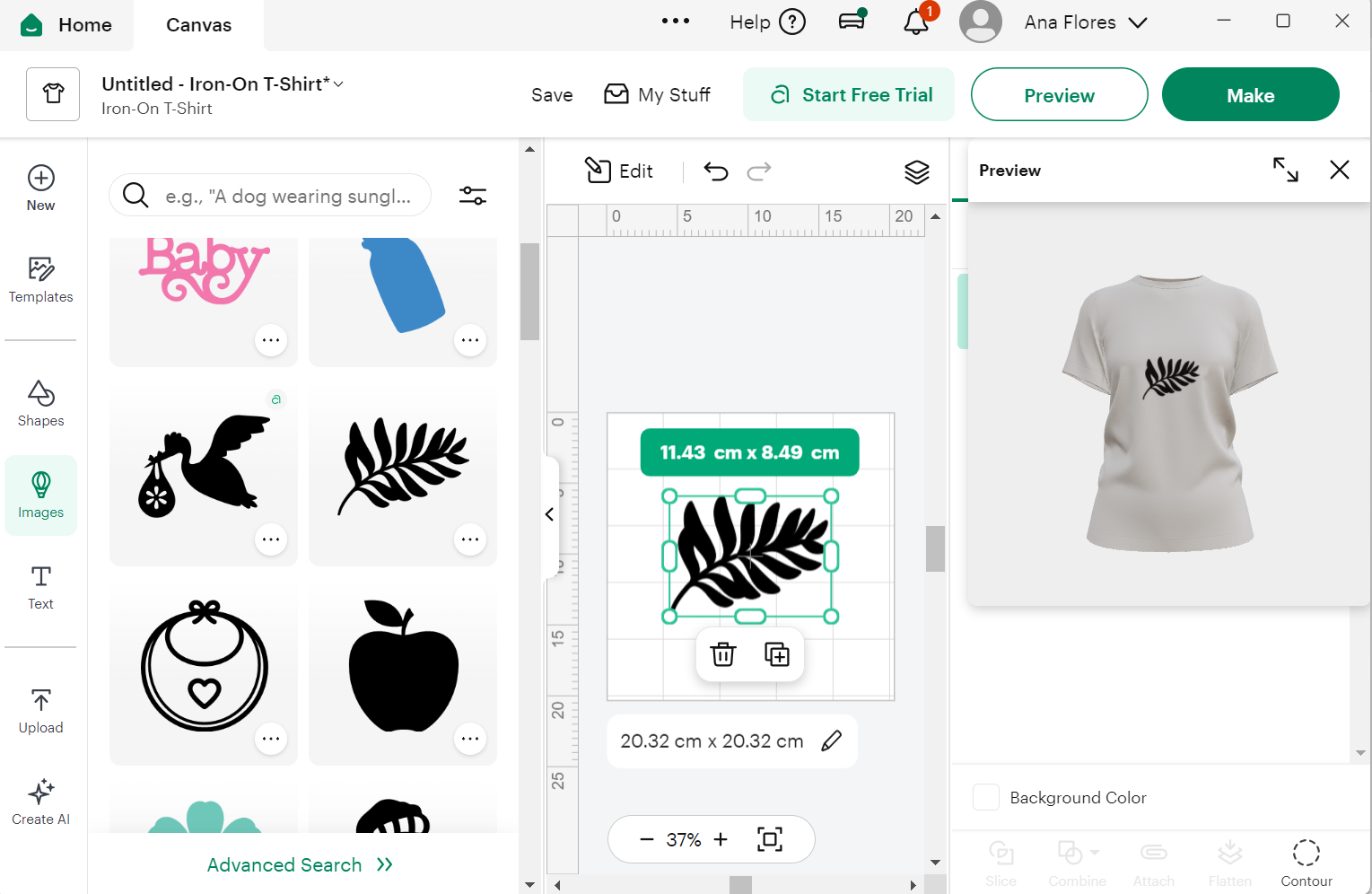

The first machine I used was a plotter: Cricut Explore Air 2. With it's correstponding software.

I got some fabric vinil so we selected a shirt preview and looked for cool designs.

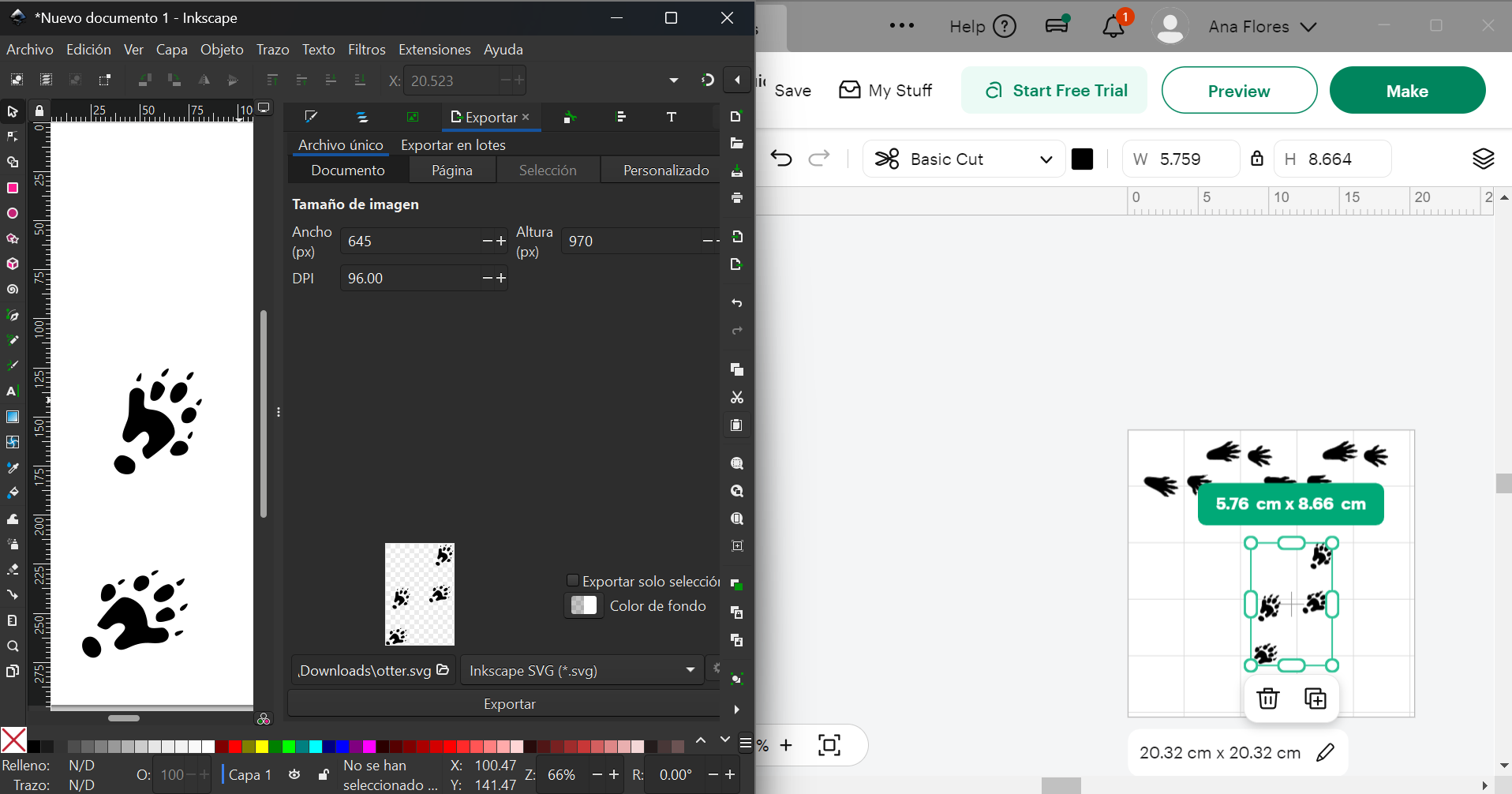

Then I had an idea so I searched for an image online, converted it to vectors with Inkscape and used that on the cricut software.

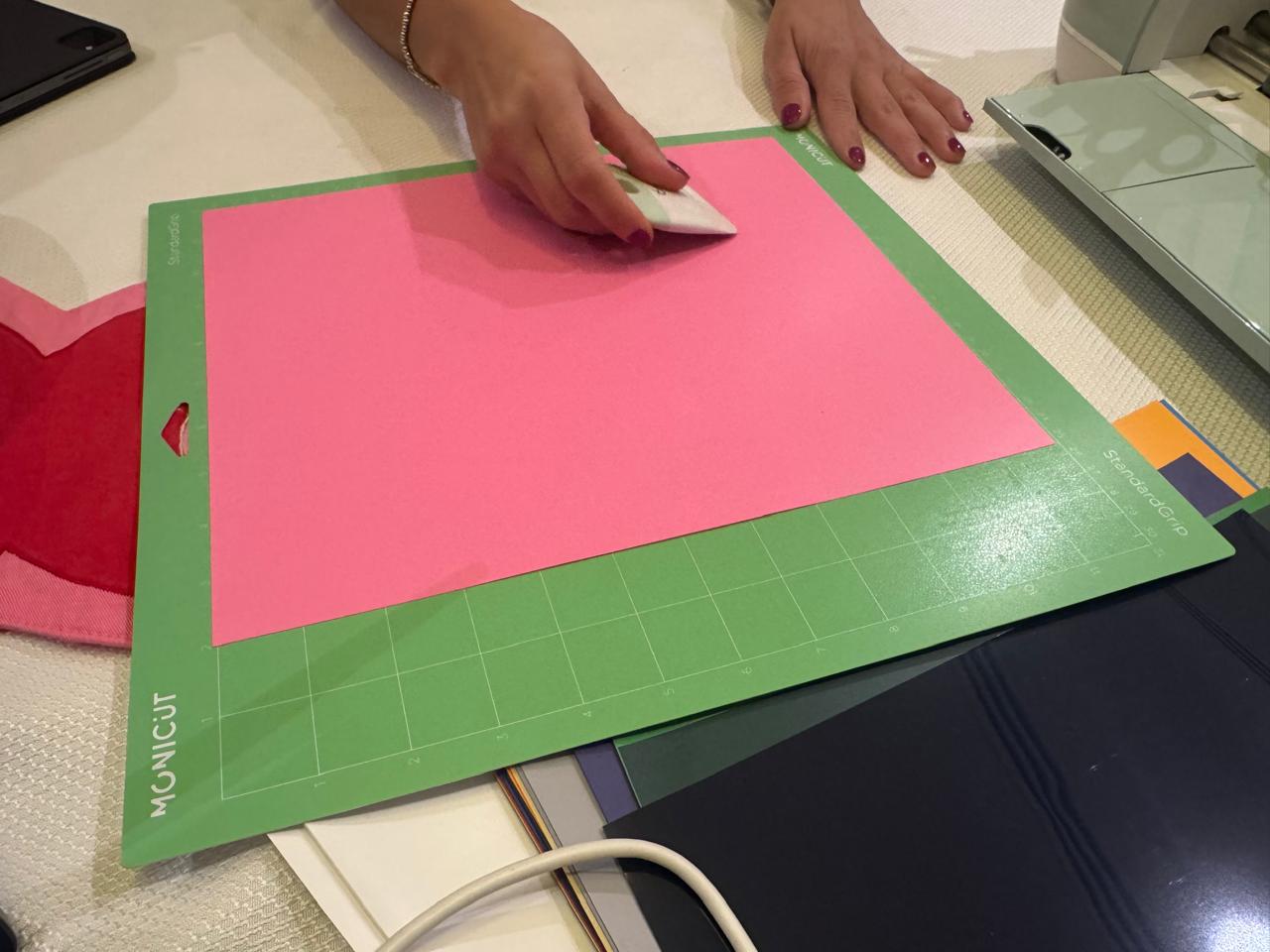

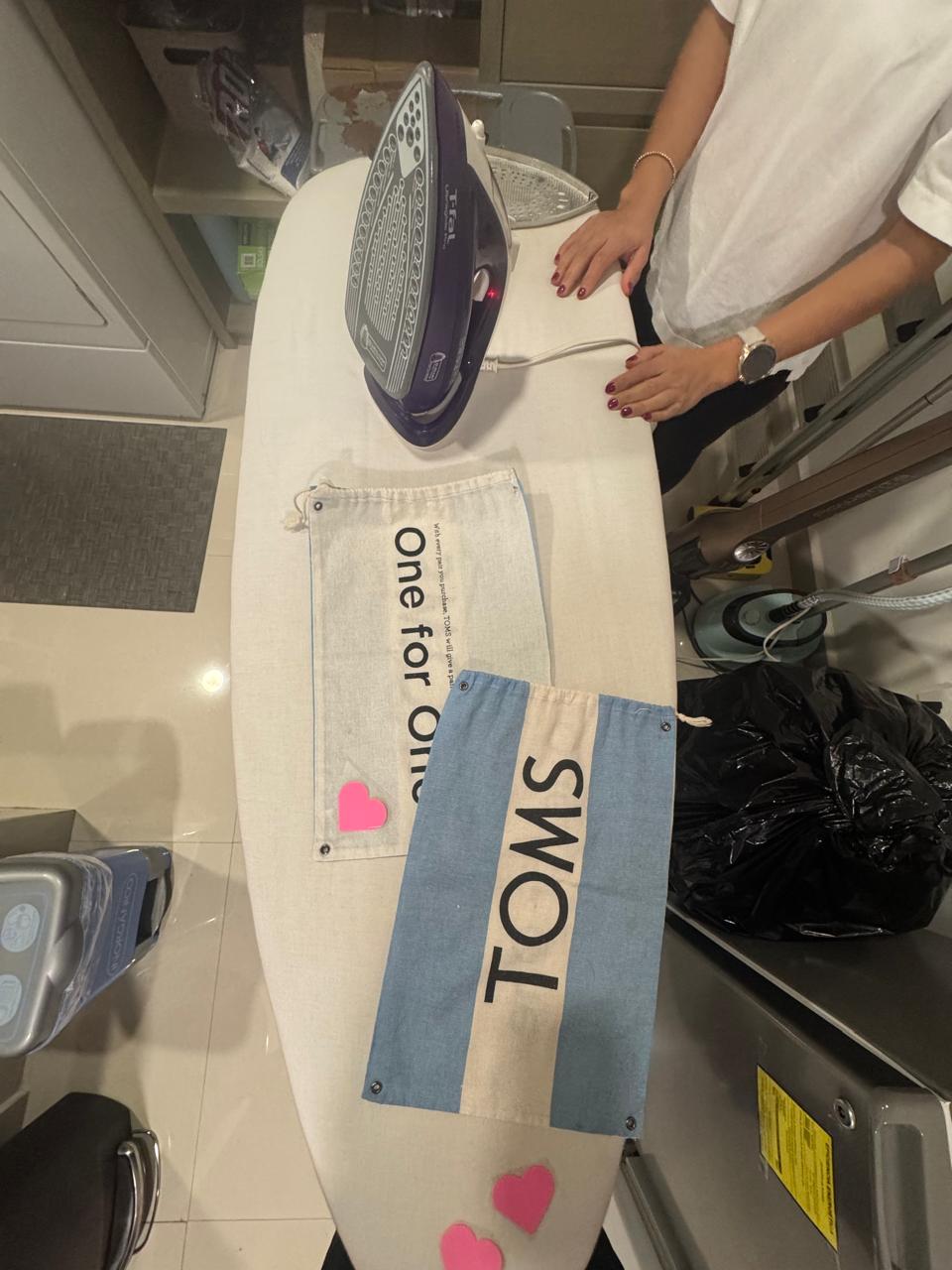

Before cutting, the vinil had to be prepared in the sticky board and inserted into the plotter.

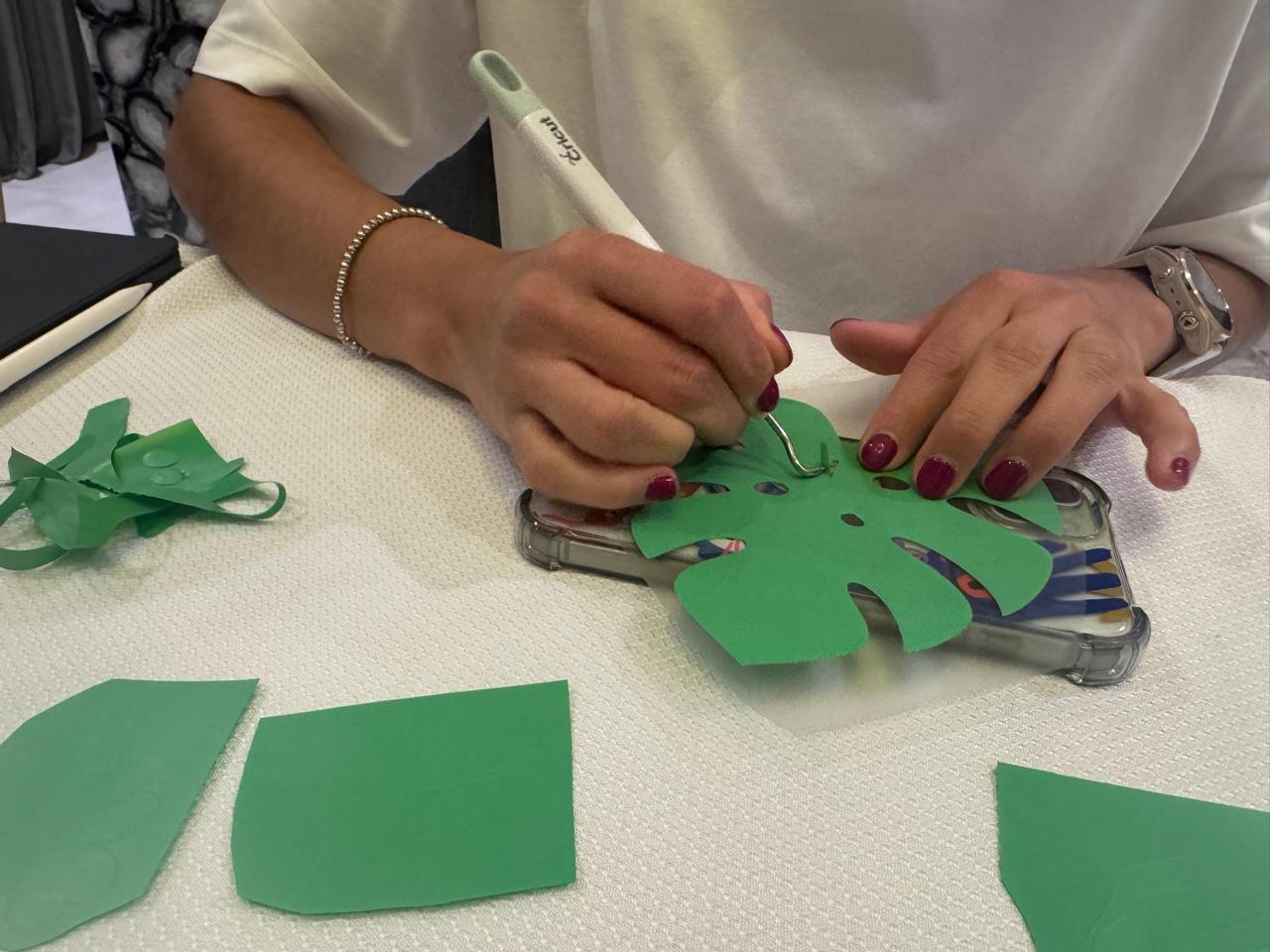

After cutting, the outcome had to be cleaned in order to leave just what was part of the design.

Once the cut was clean, it could be ironed on the fabric. Using beaking paper or another fabric on top so the plastic doesn't stick to the iron.

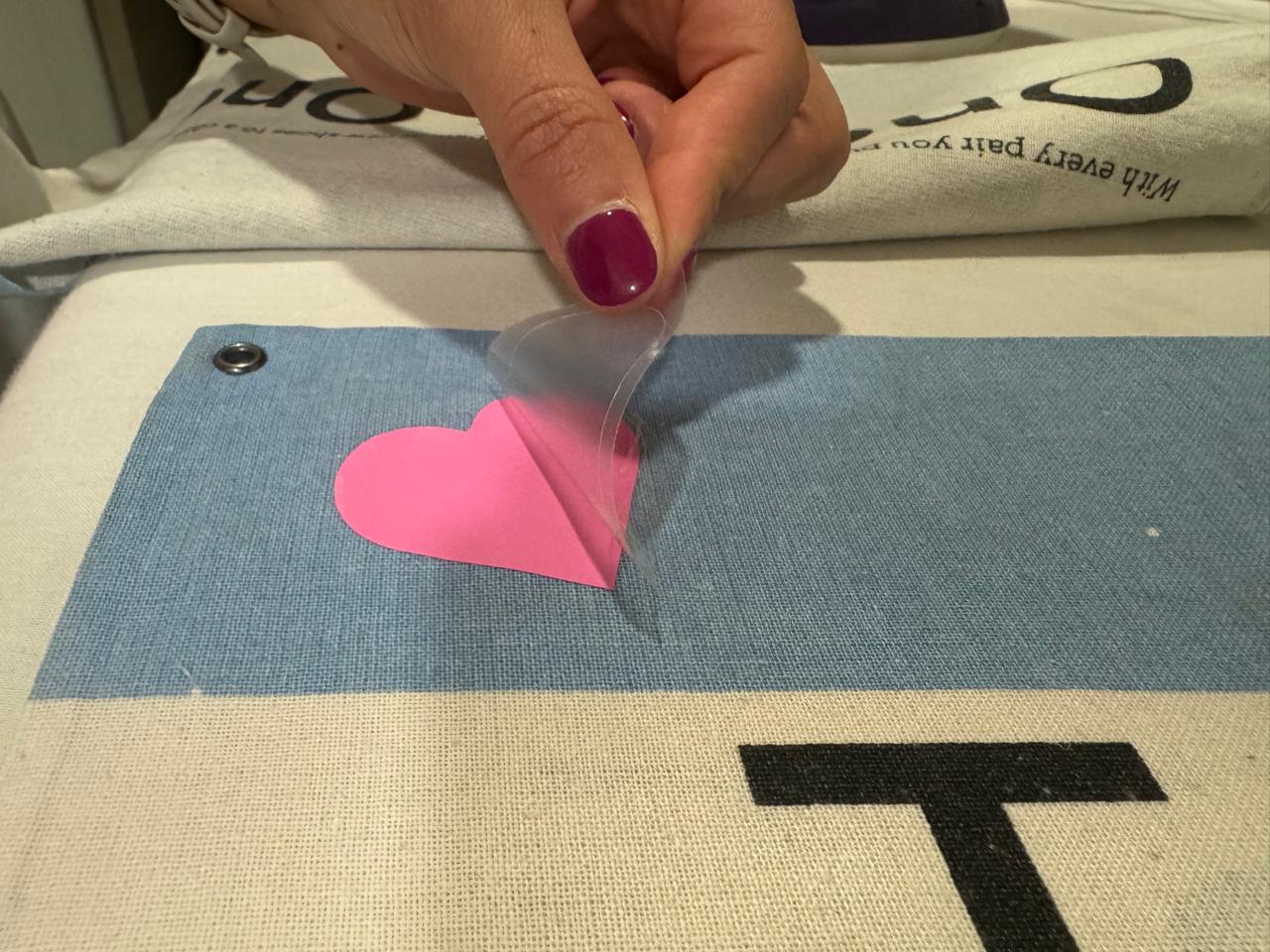

Finally, some time has to pass for the plastic to cool down and the shiny plastic can be detached to get the final outcome.

Laser

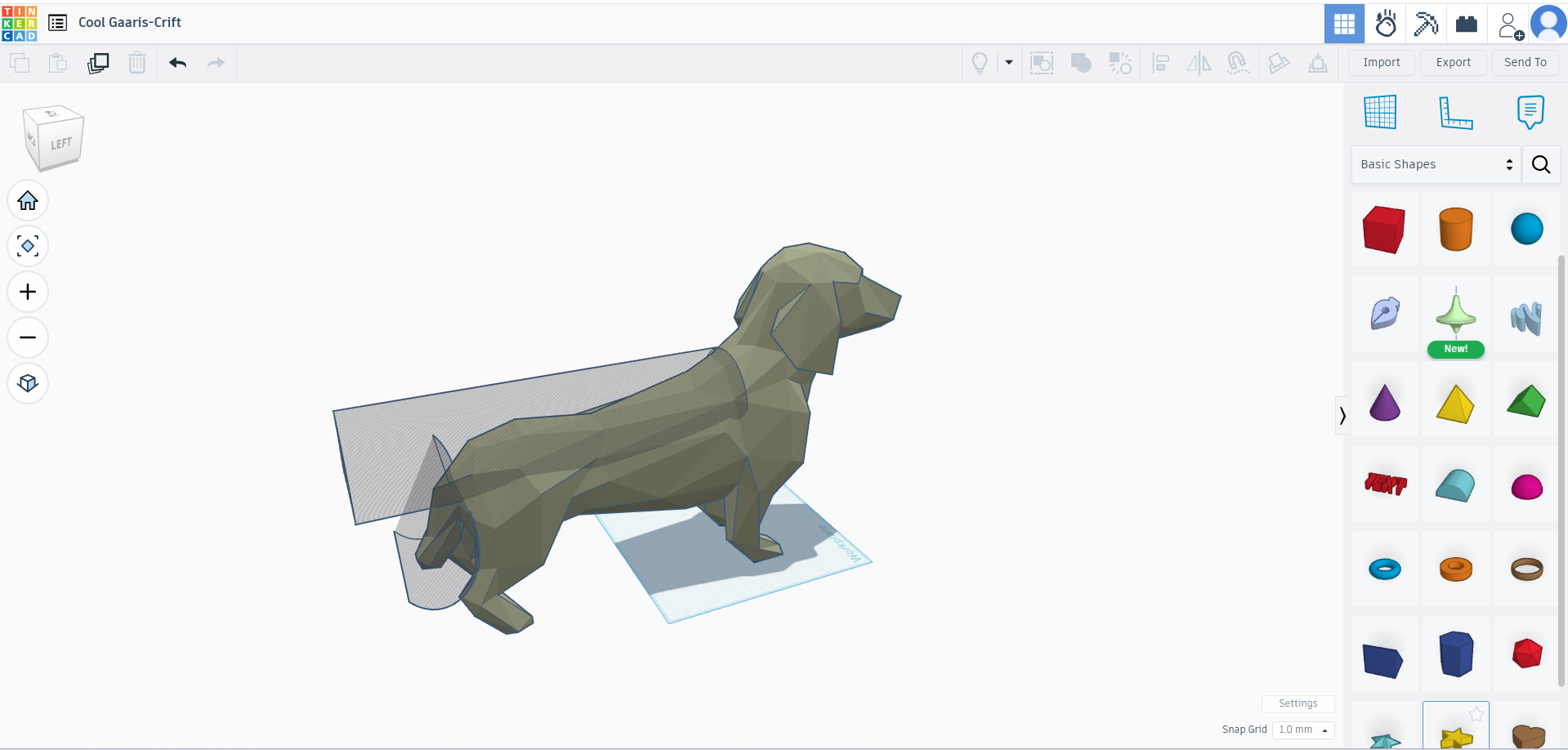

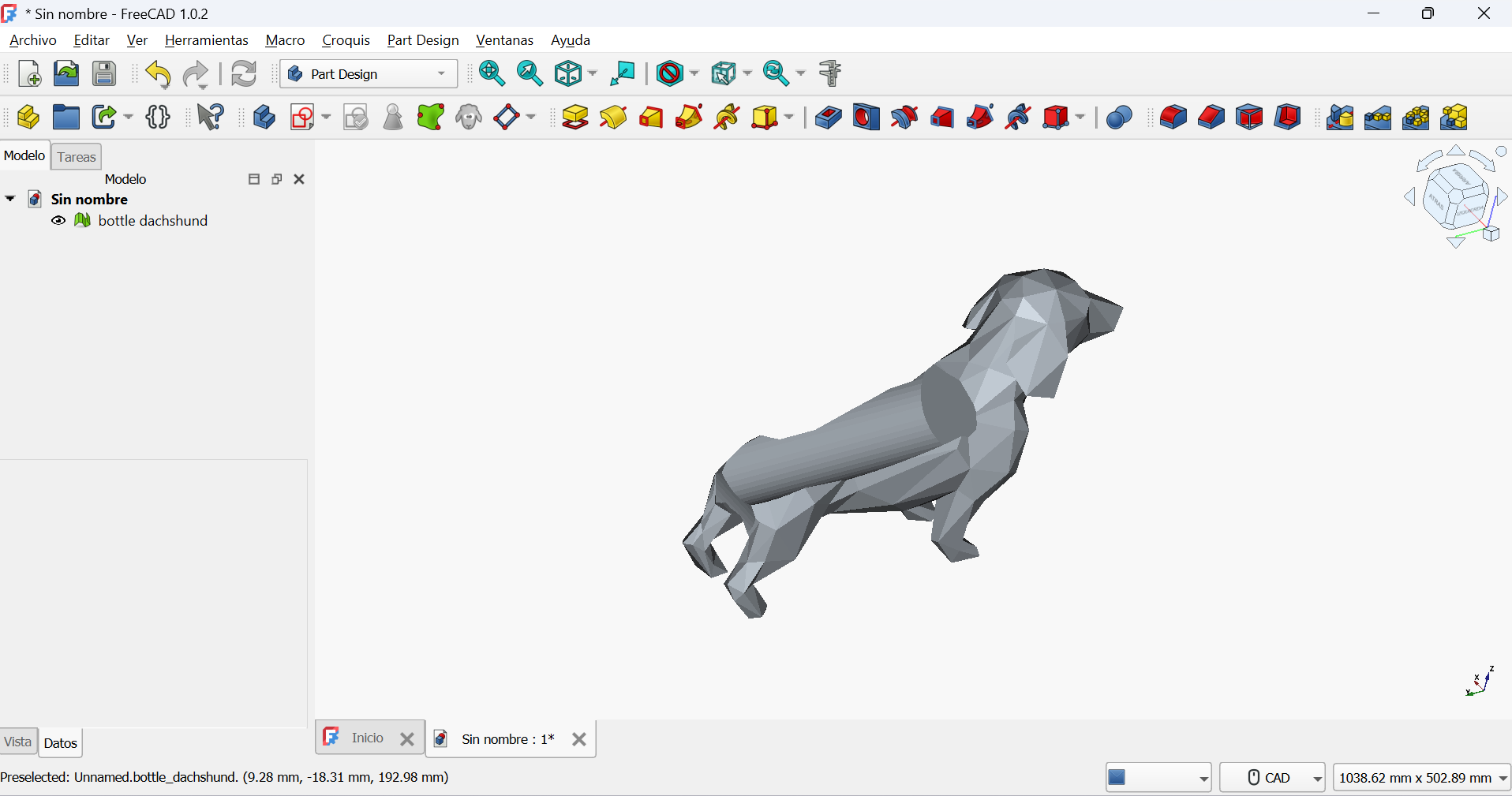

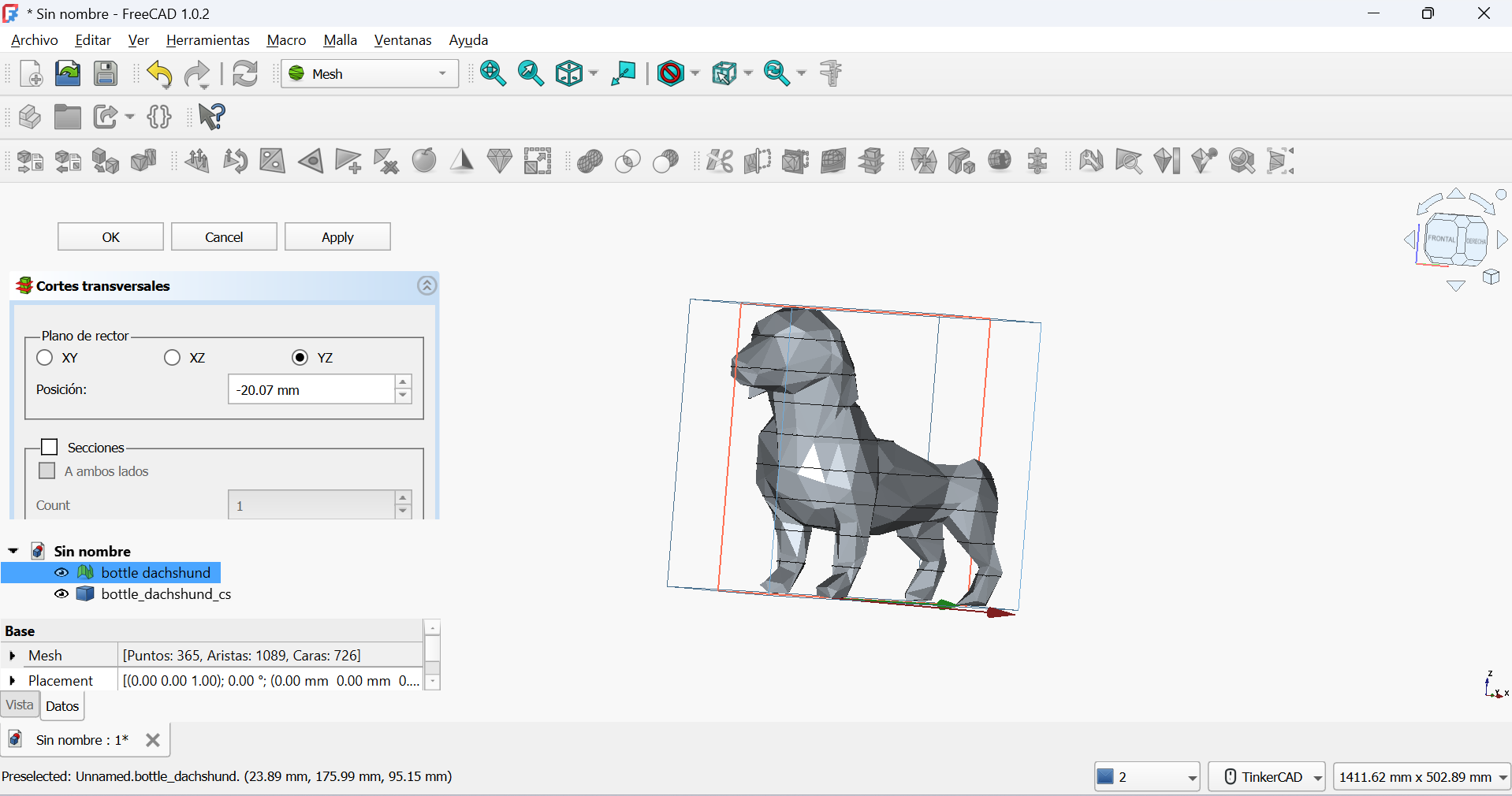

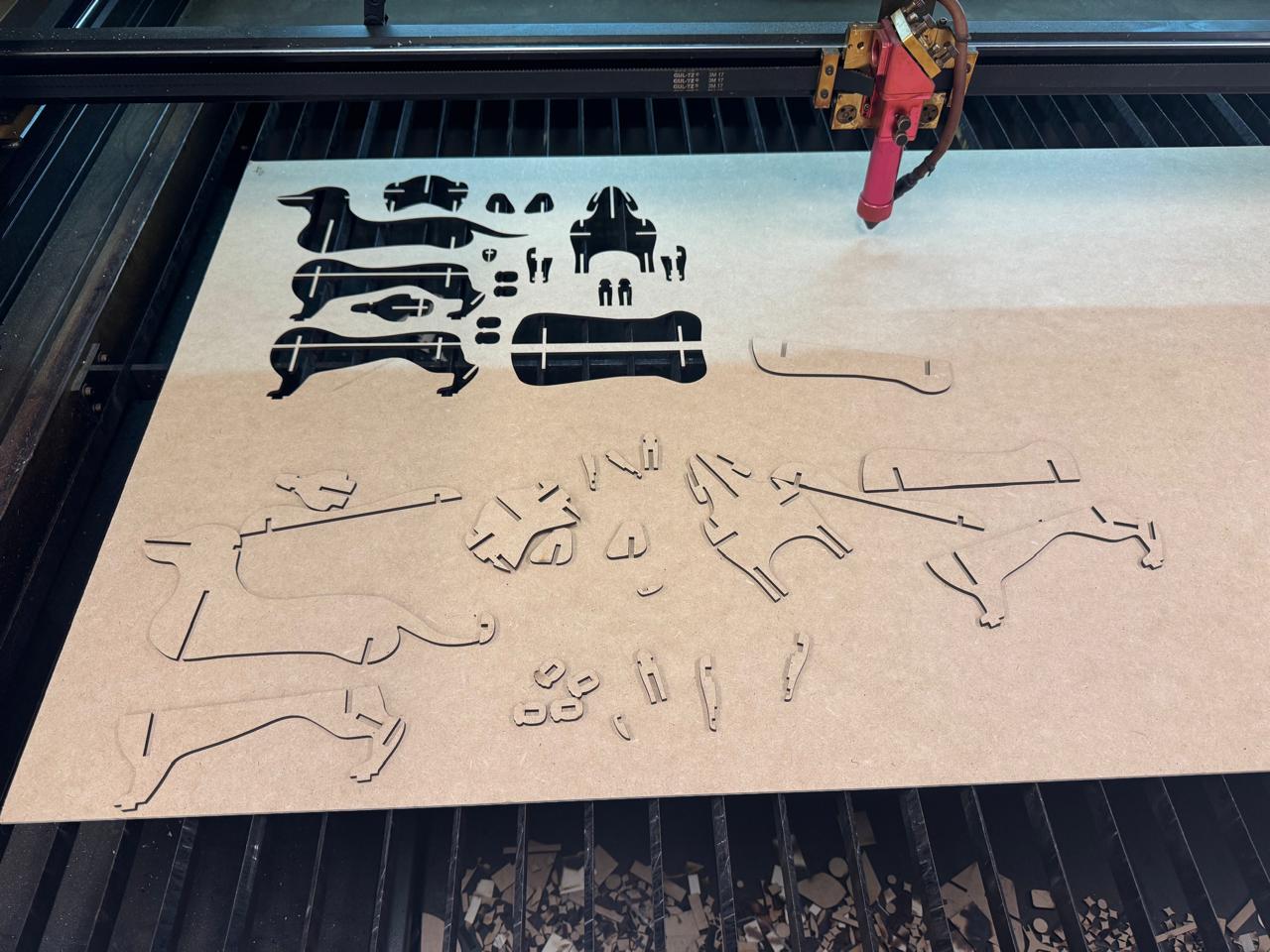

First, I had the idea of editing this 3D design to later create 2D pieces from slices of it.

I tried editing, slicing and spent some hours on this but when I realized I didn't have enough time, I decided to look for a similar svg file and go on.

I arrived to my favorite lab (Innovaction Gym) and followed the security measures instructed by the lab manager.

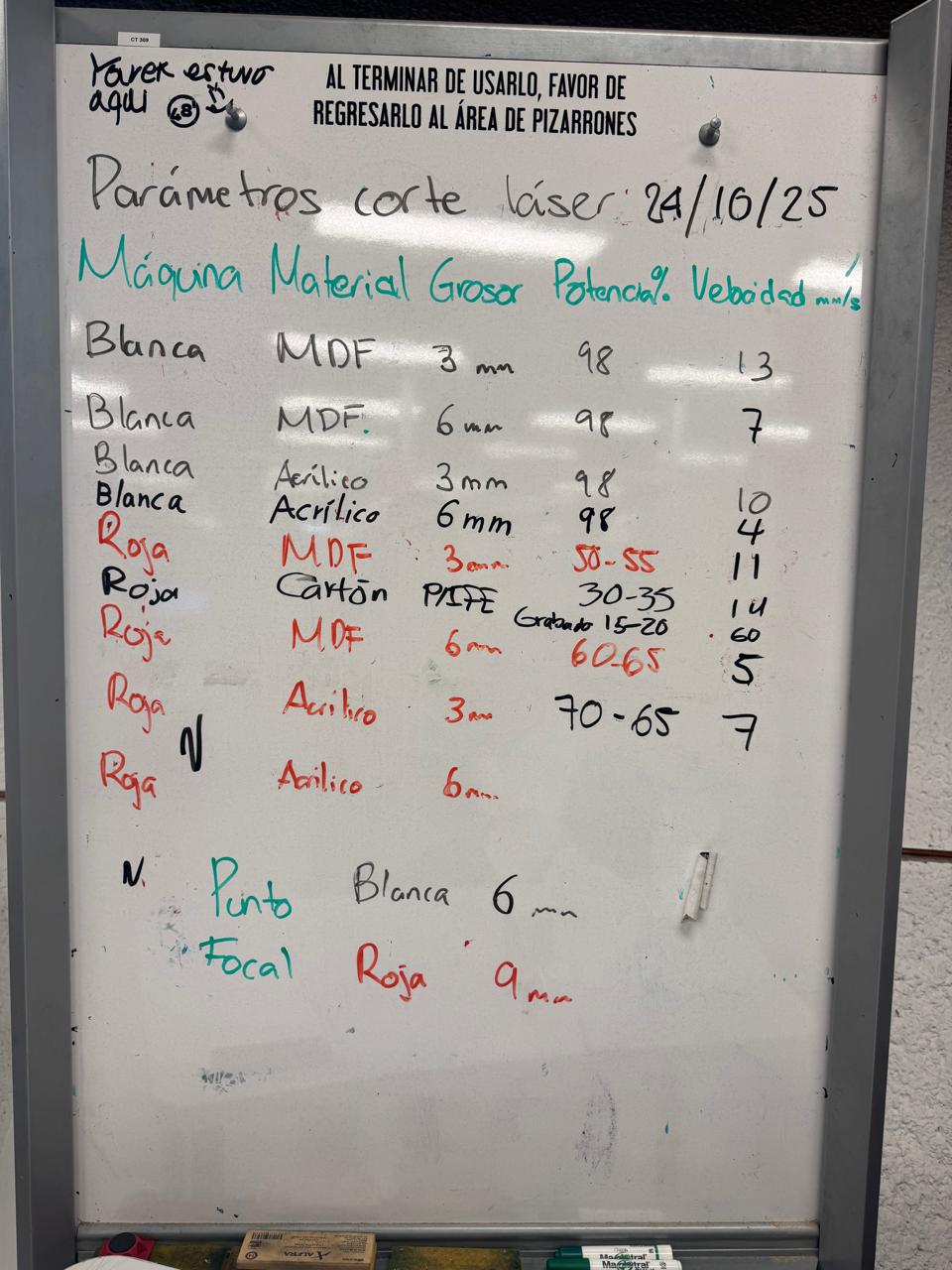

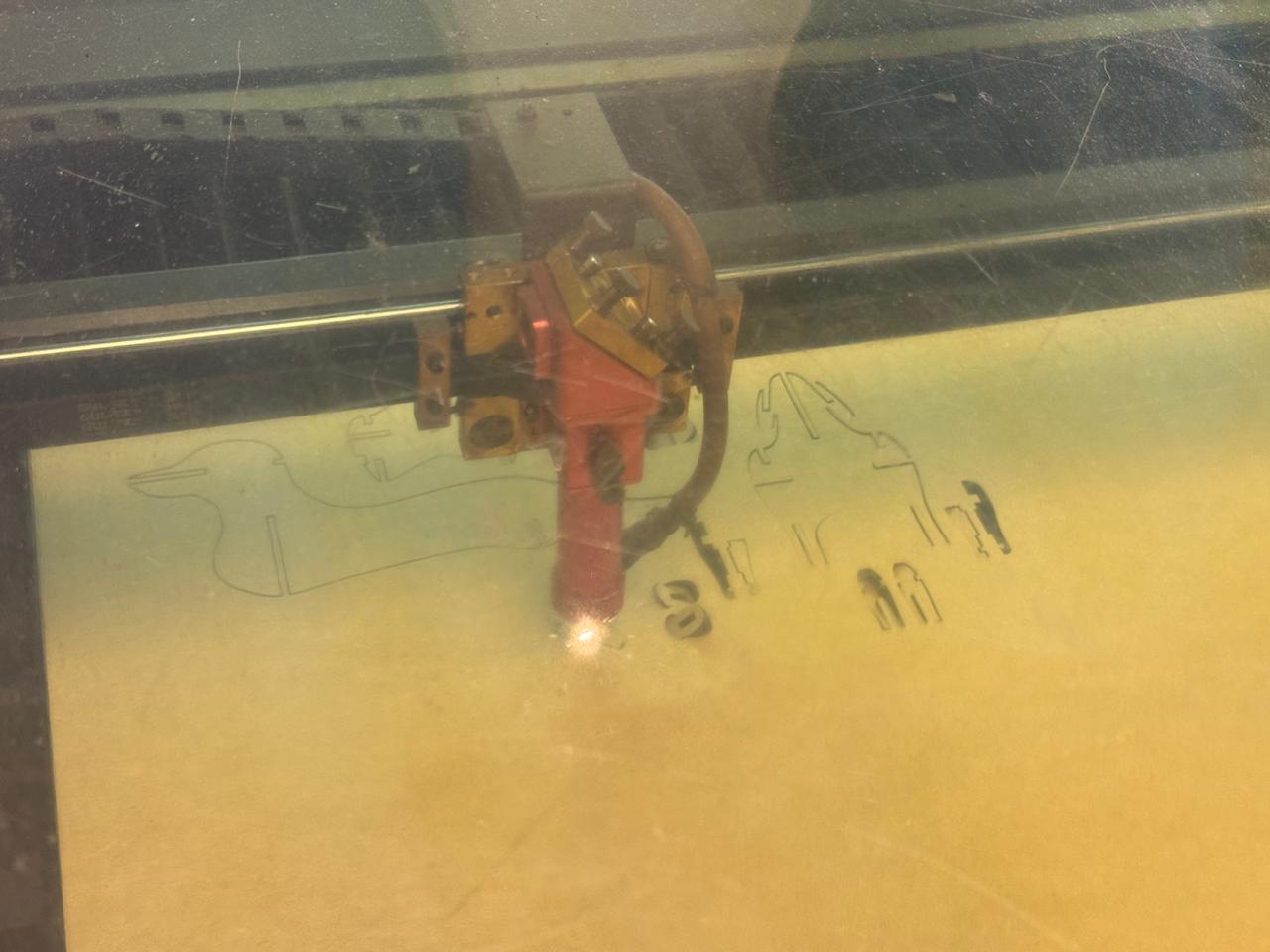

I chose the laser cutter to use and checked the parameters according to my material (3mm MDF).

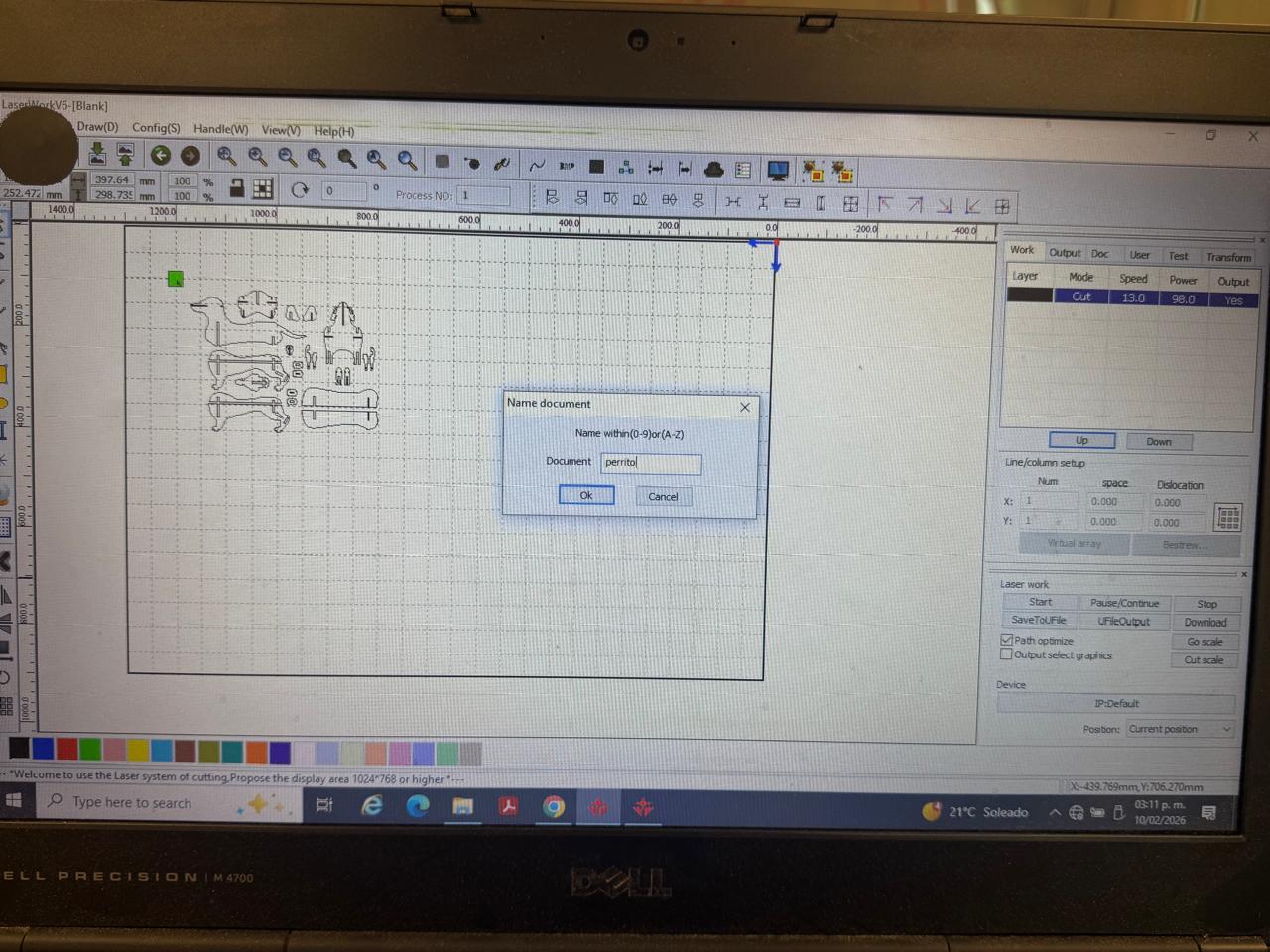

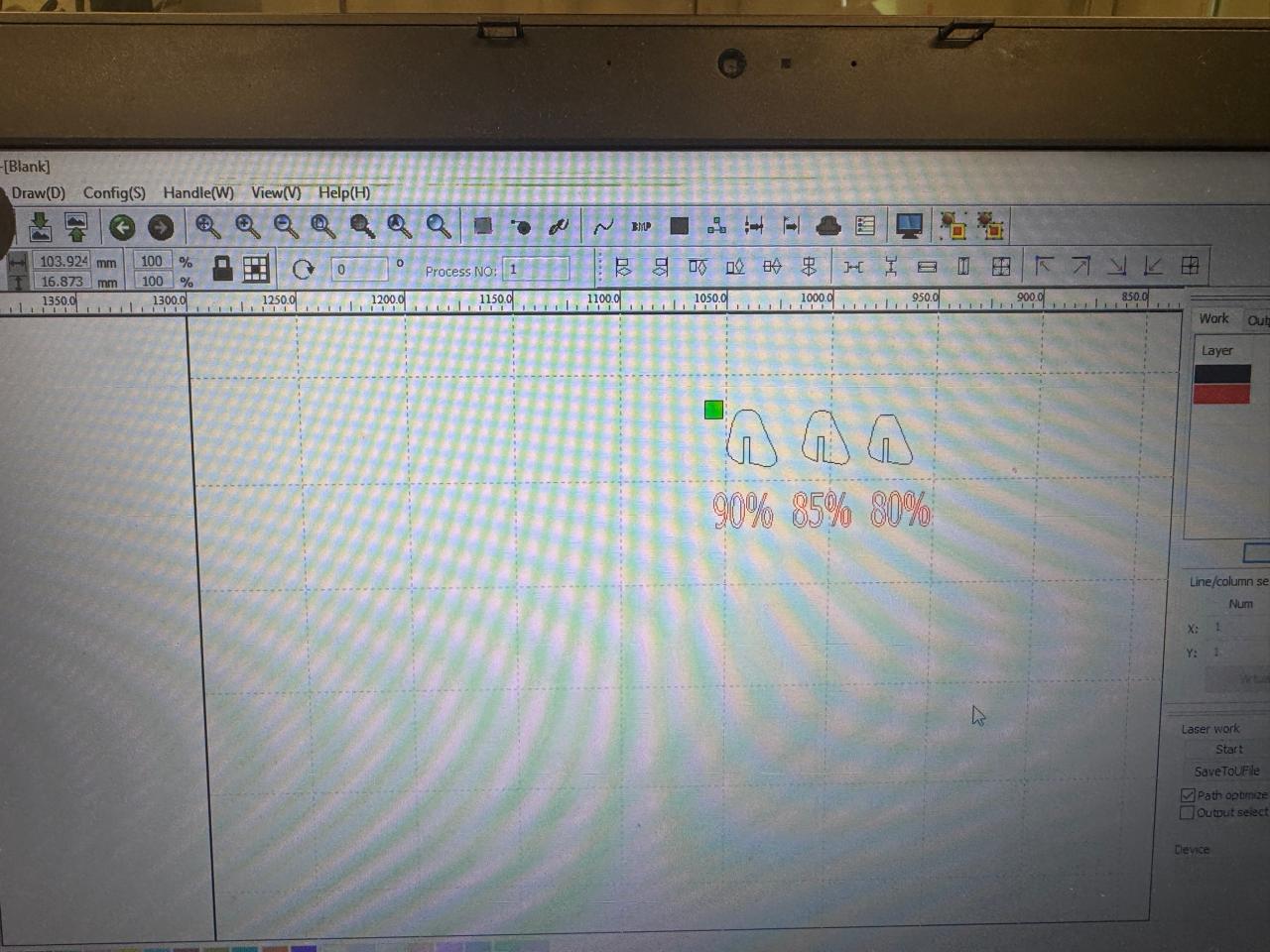

The program used to set parameters was RDWORKS. Here I was able to edith my design's size until I found the right fit.

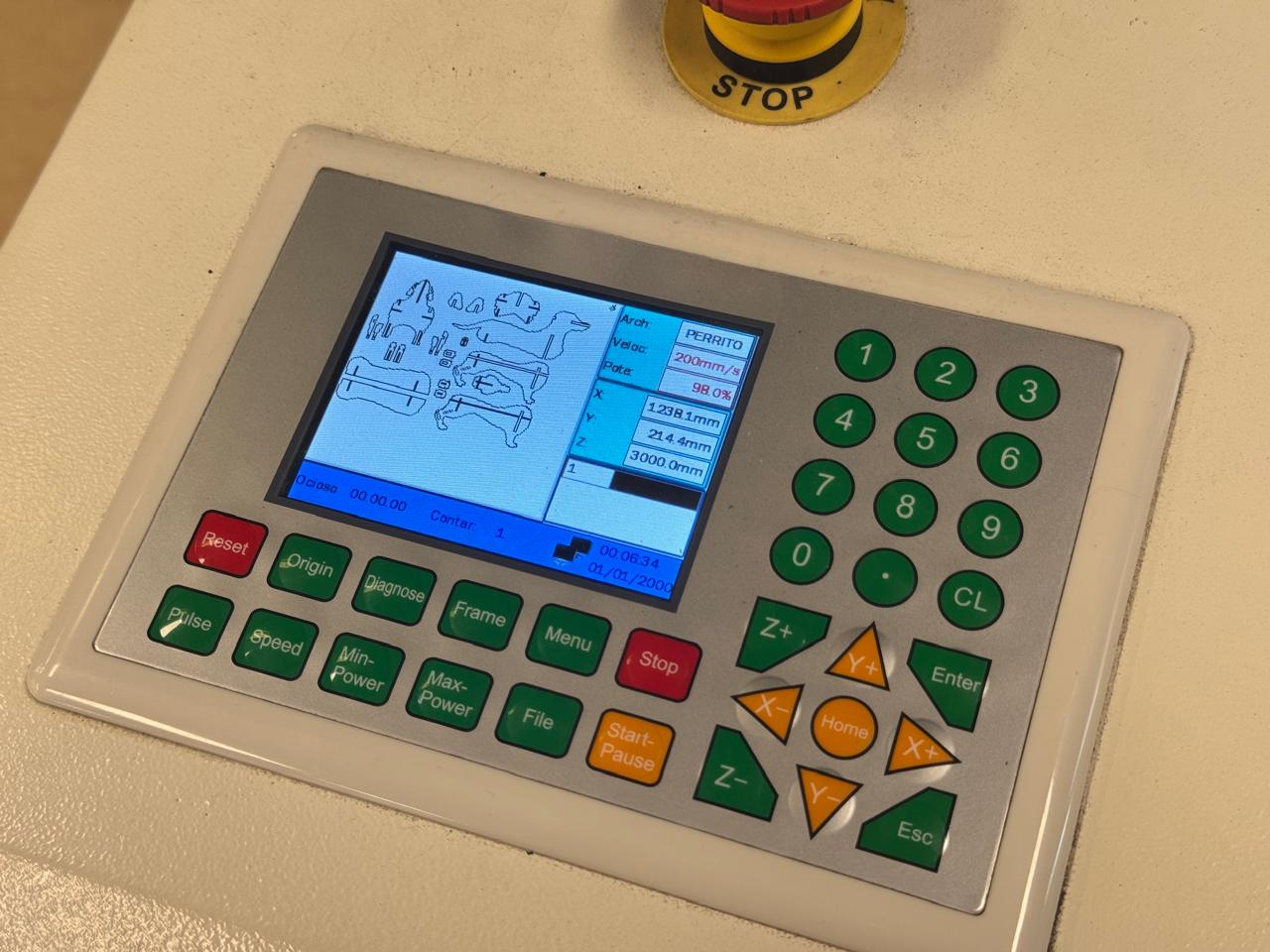

All axis of the machine had to be set manually or with the panel.

It took several tries to get that fit right.

Finally, I got it right and it turned out great. I even gave it away as a gift.