Onshape is a cloud-based 3D design (CAD) and product data management (PDM) platform. Its main functions include creating three-dimensional parts, assemblies, and technical drawings. It is a practical and intuitive program that allows multiple users to collaborate on the same design in real-time, and also maintains a detailed history of every change made.

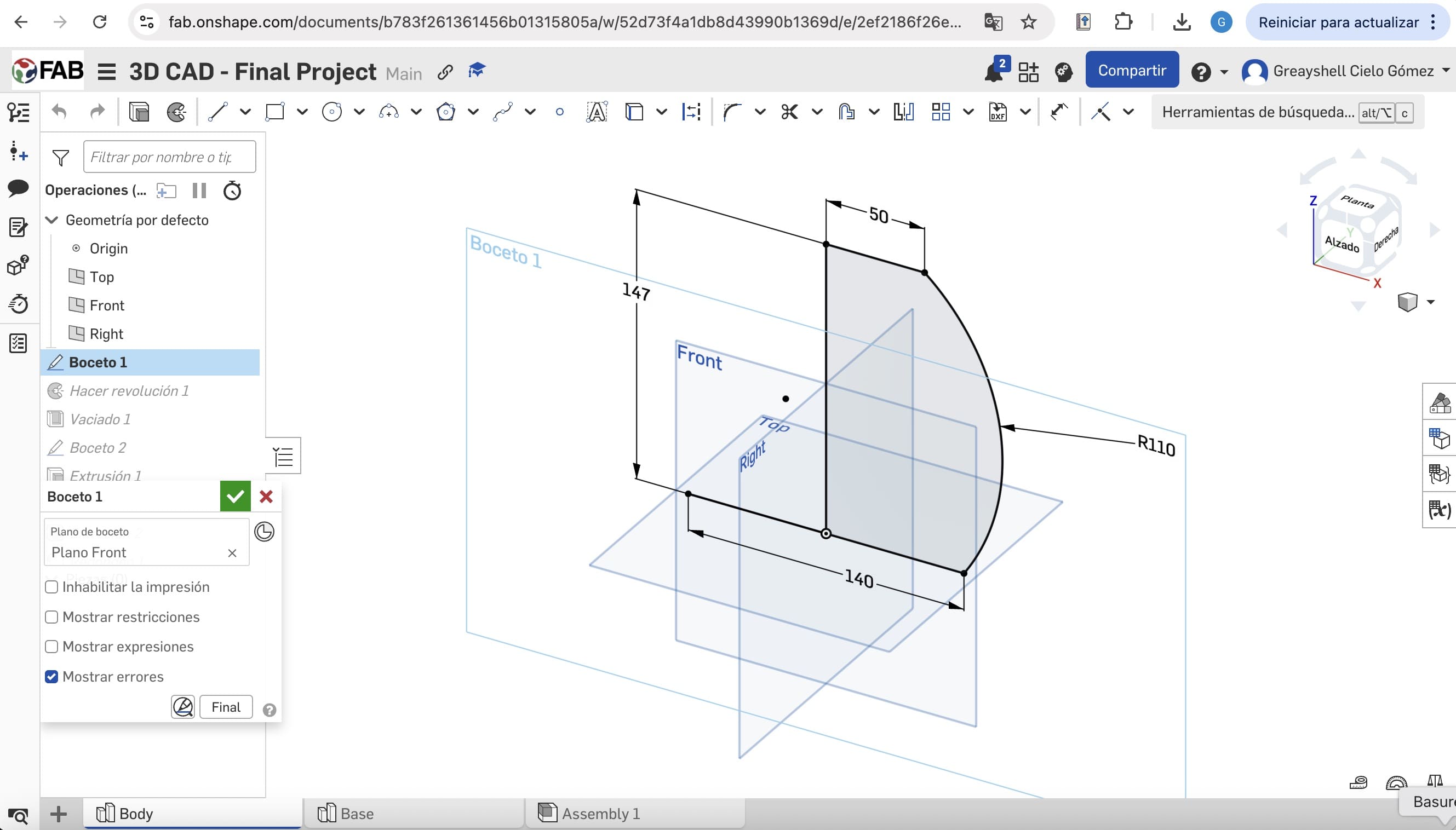

01. New Part Studio

Defining initial constraints and 2D parametric geometry. Using tools such as: line, circle, arc position relationships.

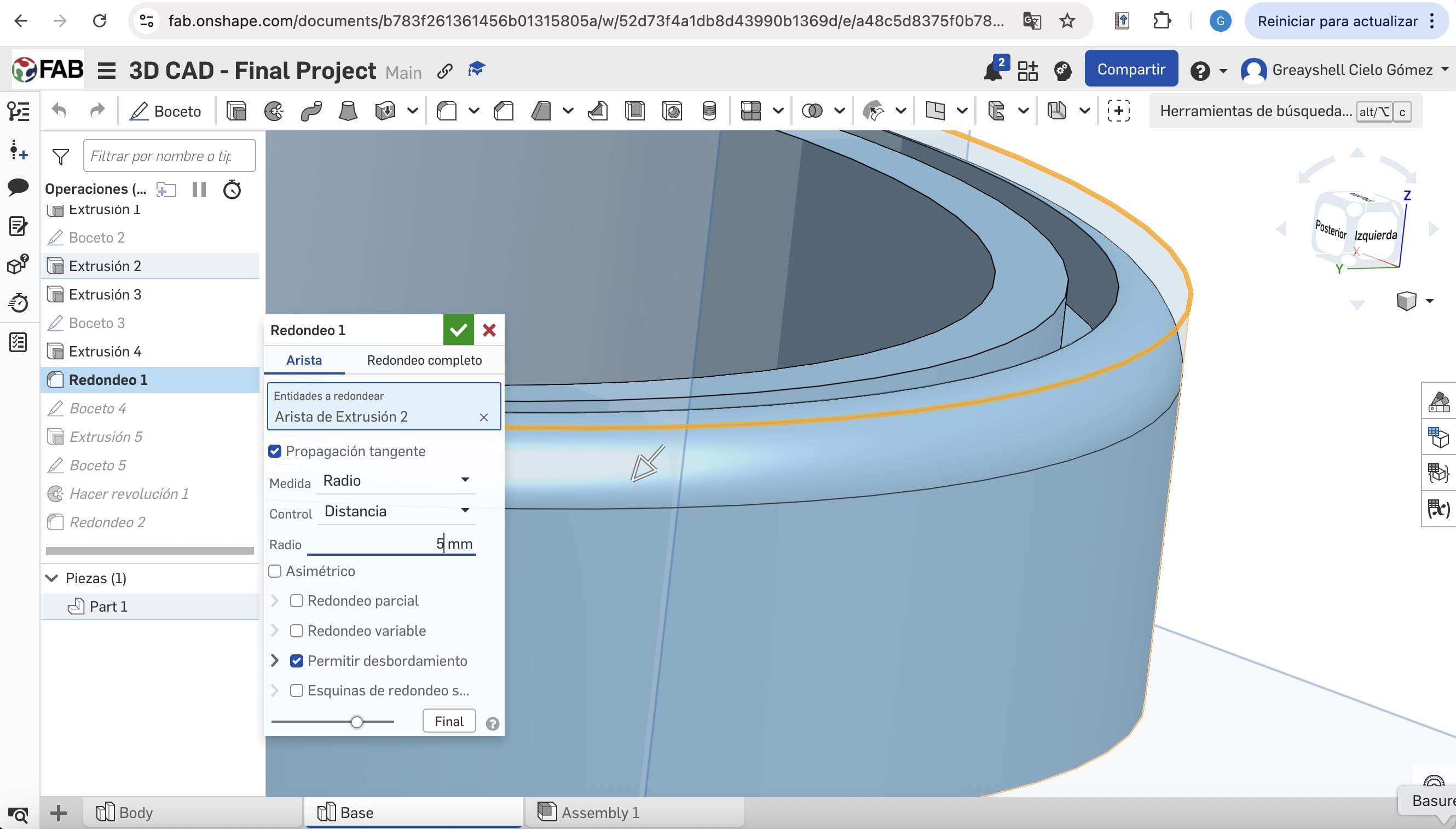

02. Main Operations

Applying extrusions and revolves to create solid parts. Applying Shell and Fillet operations to the base.

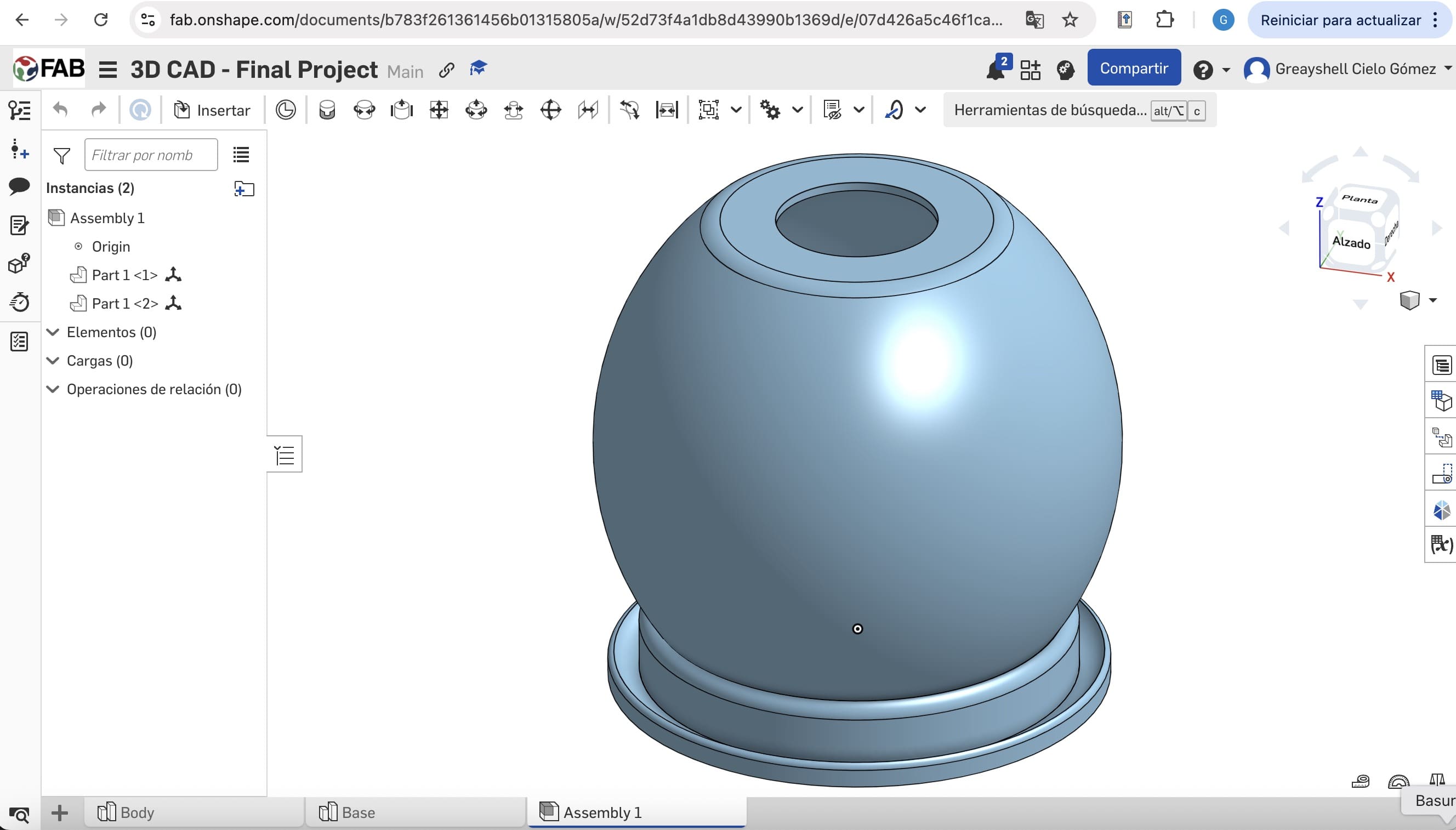

03. Final Assembly

Finalizing the Assembly by mating the base components to verify the fit and tolerances of the device.

Shapr3D is a 3D modeling application designed for a fluid and mobile workflow. It’s primarily built for use on iPads and touch devices, allowing for a more direct and natural interaction with the design. It enables the creation of three-dimensional models and structural plans, as well as the visualization of materials and finishes on the final parts. It’s an excellent tool for rapid prototyping and bringing ideas to life quickly.

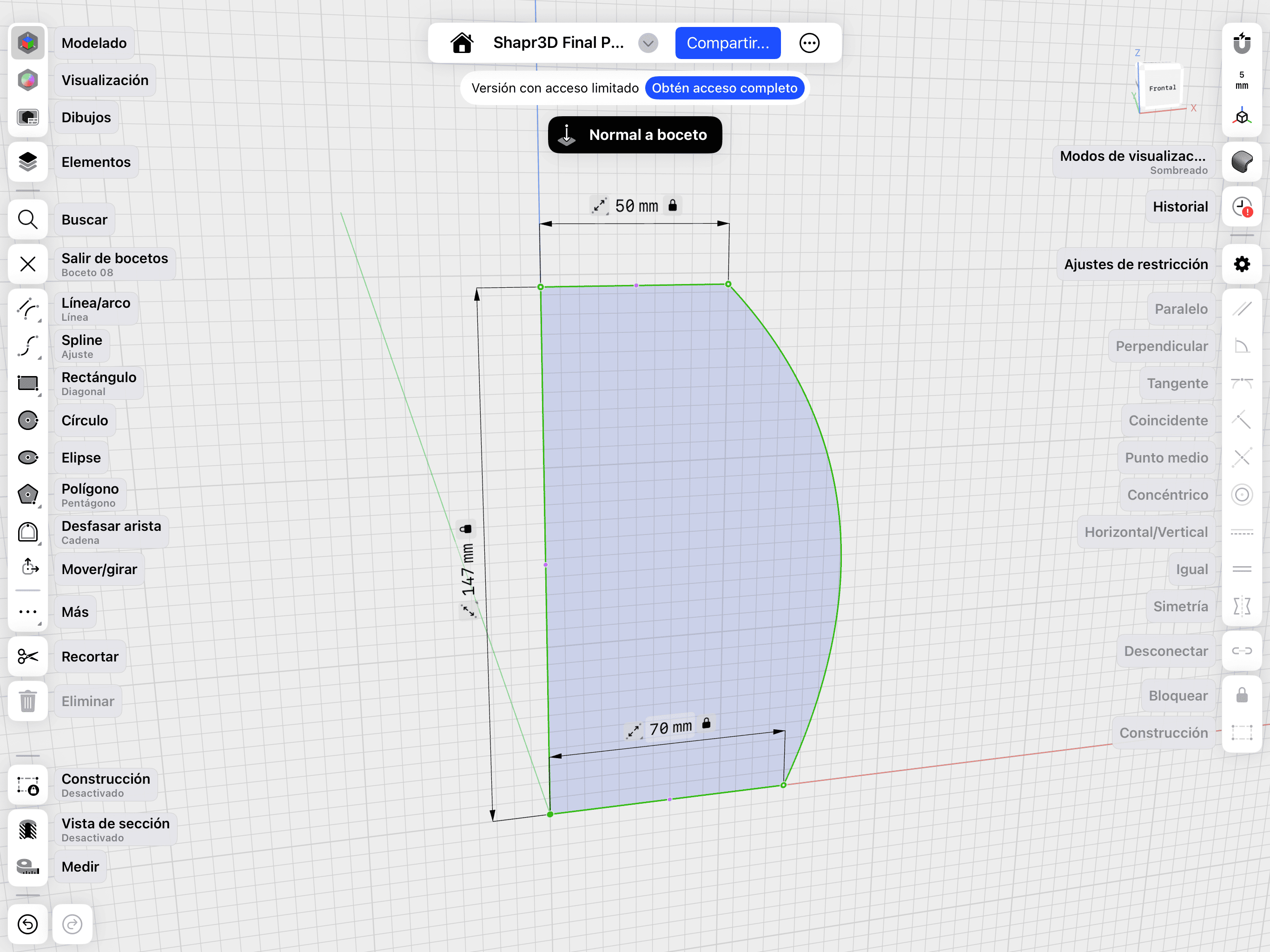

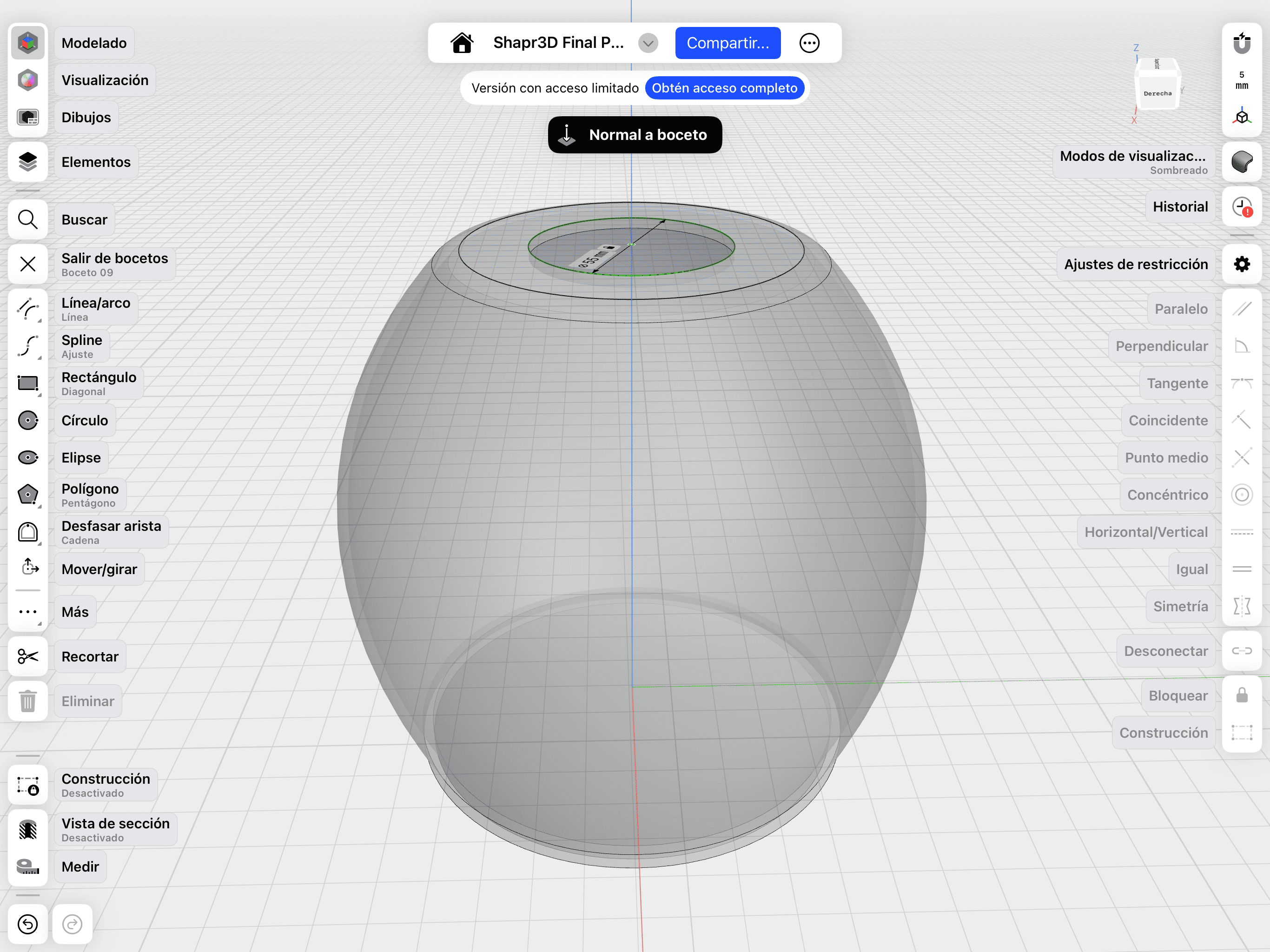

01. Mobile Sketching

Using touch interface for organic shapes and quick drafts.

02. Revolve & Cut

Applying the Revolve tool to the profile sketch and executing a boolean cut for the top circular opening.

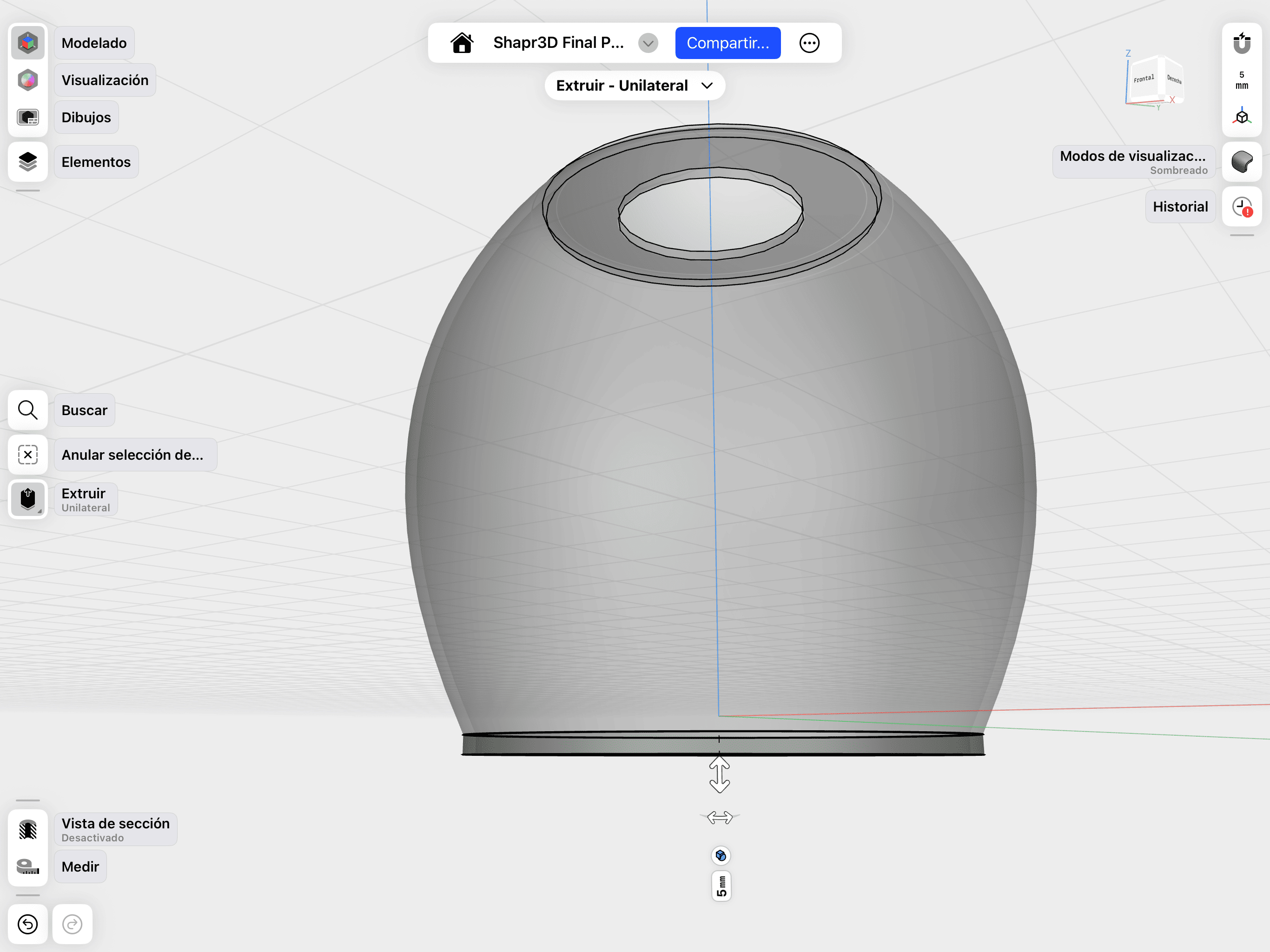

03. Shell & Surface Extrusion

Using the Shell command to create hollow geometry and extruding specific surfaces.

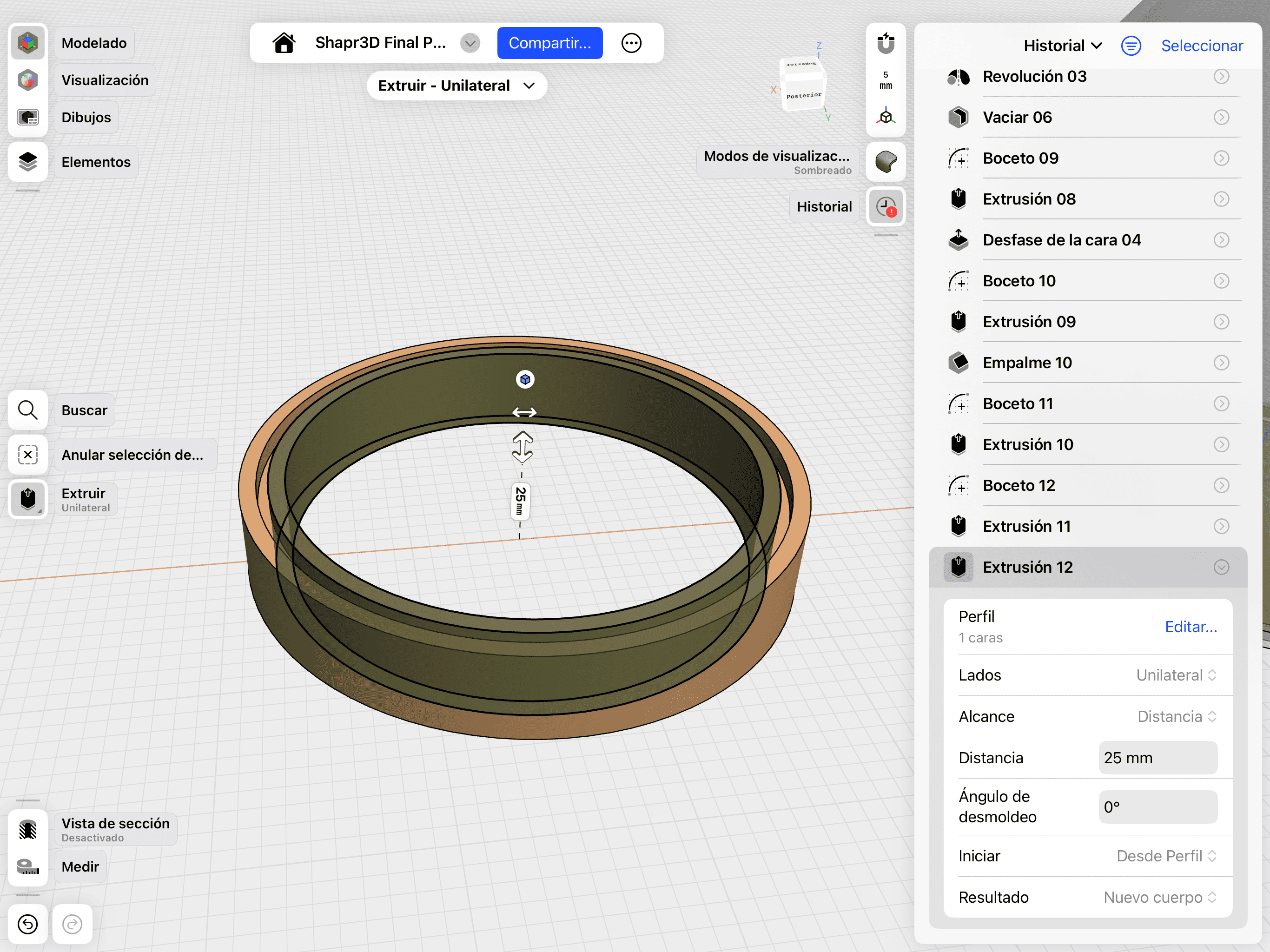

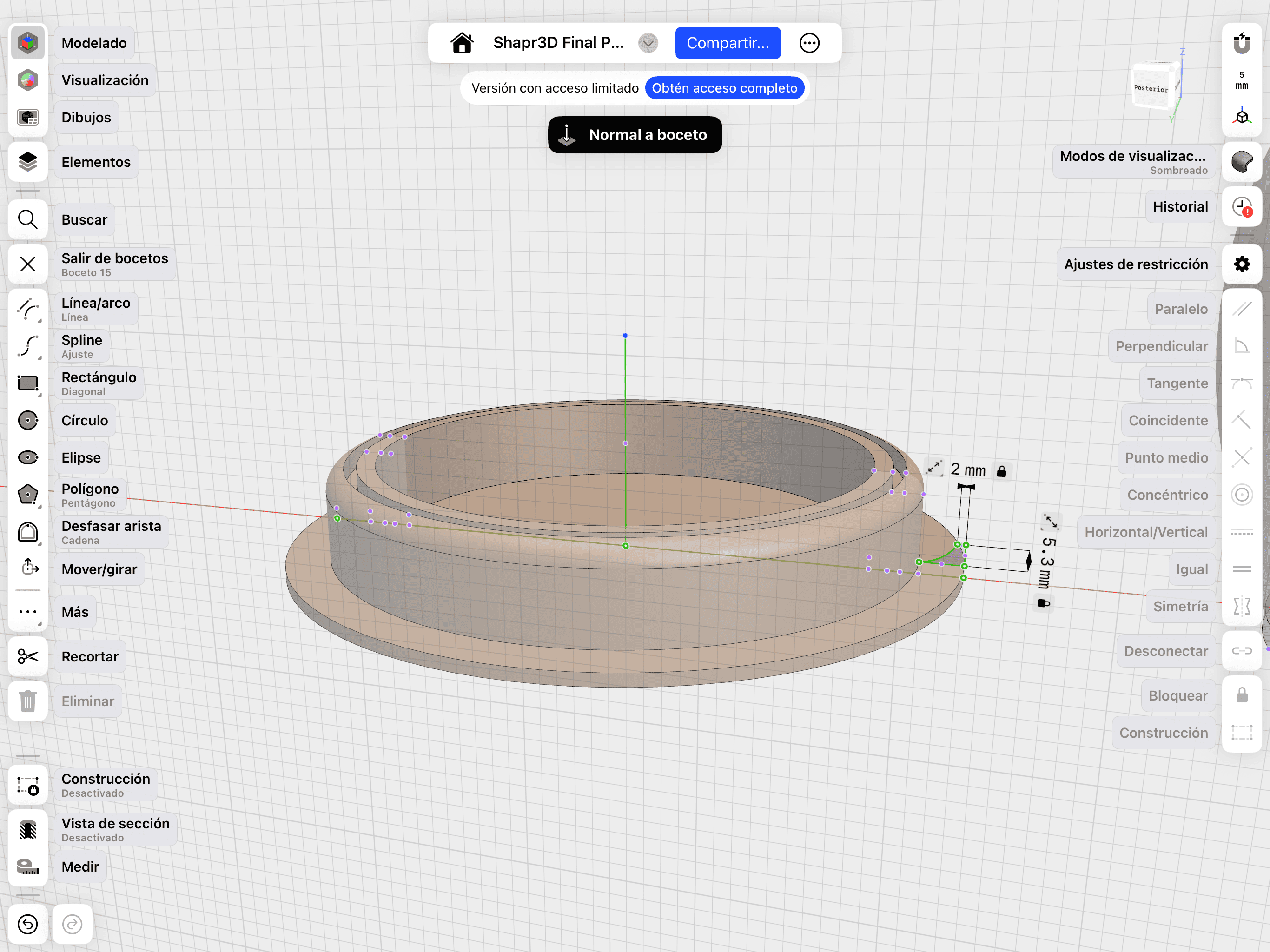

04. Base Extrusion

Converting 2D concentric circles into 3D volumes to define the device's base.

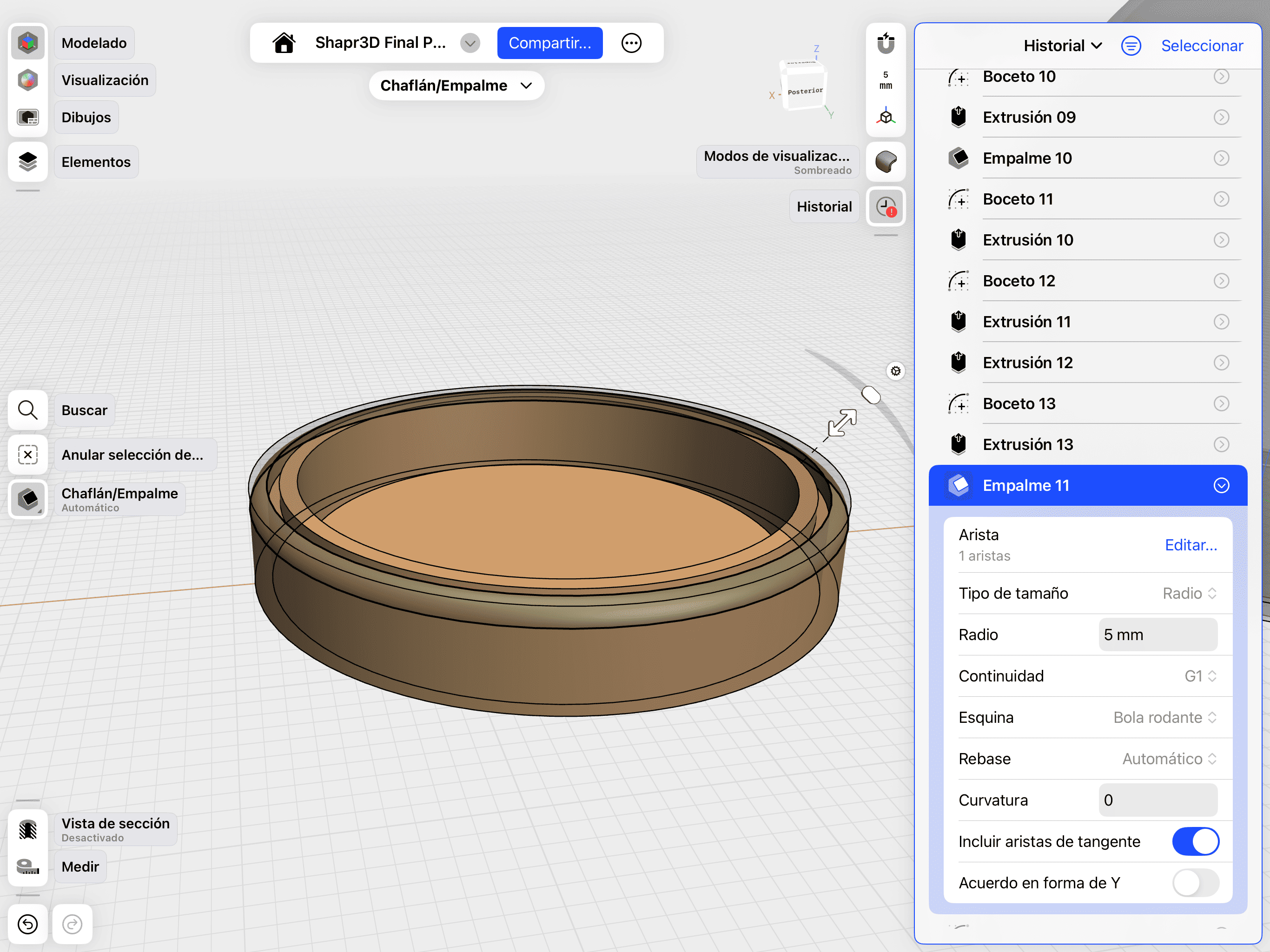

05. Fillet & Ergonomics:

Adding Fillets for a more ergonomic, professional and aesthetic finish.

06. Final Details

Refining the base profile and sketching final outlines.

Final Visualization

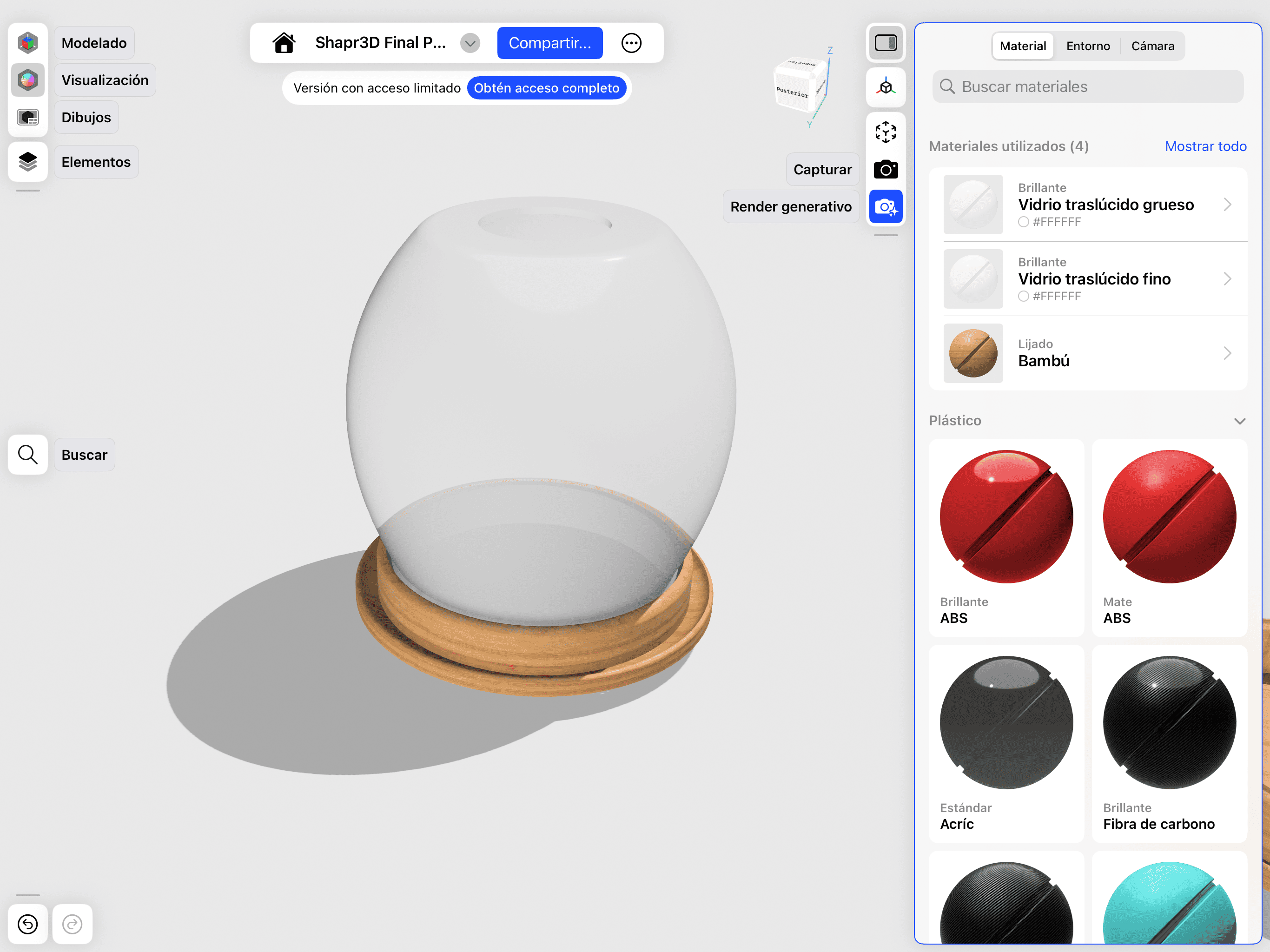

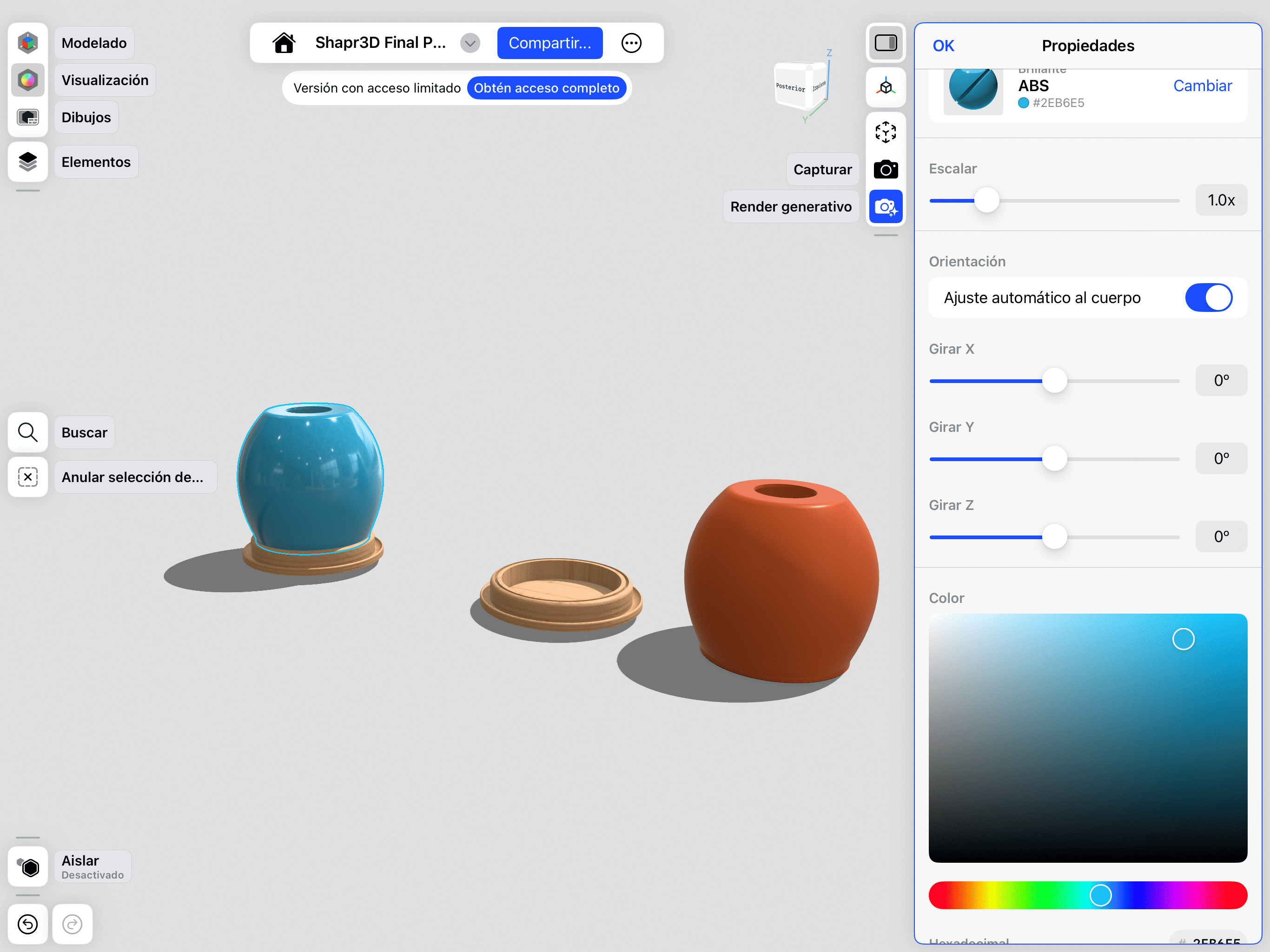

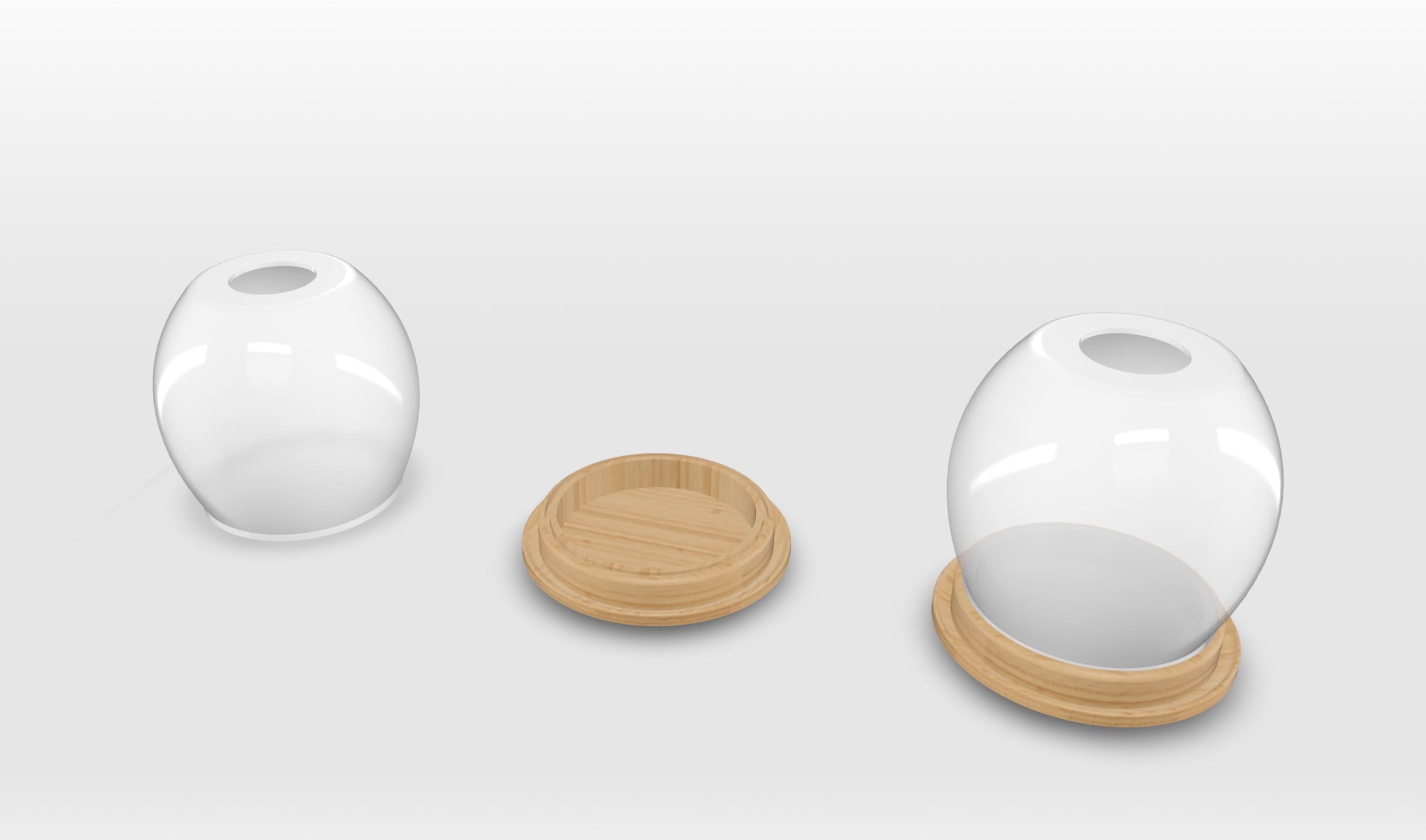

Documentation of the rendering process in Shapr3D to visualize materials, lighting, and final finishes of the device.

01. Material Application

Testing textures and surface finishes for the casing.

02. Setup

Configuring color, lighting, and angle.

03. High-Quality Render

The final visualization of the proposed project.

Design Files

In this section, you can find the downloadable source files for the 3D models developed during this week.

OnShape Export

STEP/STL files for the main assembly and electronics base.

02. Shapr3D Model

Native and high-fidelity 3D files for the outer casing.

03. Project Bundle

Complete documentation and optimized mesh files for fabrication.

OnShape vs. Shapr3D

Both platforms proved to be exceptionally powerful tools for 3D modeling. Having prior experience with Onshape, I found its parametric environment and assembly constraints very reliable for technical precision. However, Shapr3D's intuitive interface allowed for a much more direct and seamless manipulation of geometry. A standout feature of Shapr3D is its rendering tool, which allowed me to visualize materials and lighting on my models instantly. This is why in my future workflow, I plan to use both, Onshape for complex mechanical engineering and Shapr3D for prototyping and high-quality visual presentations.

2D Modeling Software

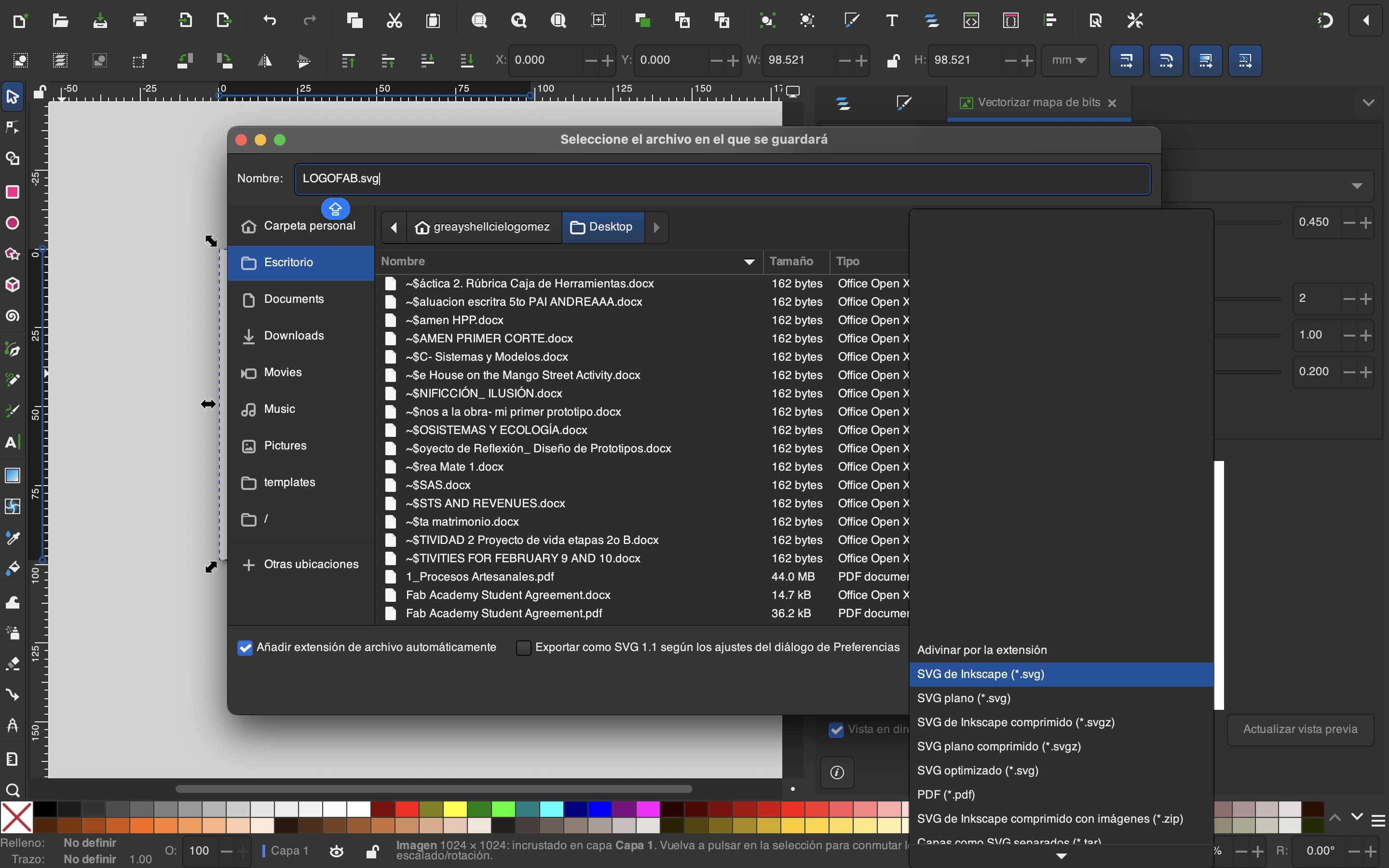

InkScape

Inkscape is an open-source vector graphics software that utilizes the Scalable Vector Graphics (SVG) format. It offers a comprehensive set of tools for object creation and manipulation, including advanced node editing and boolean path operations. It is a key tool for preparing files for laser cutting and CNC machining.

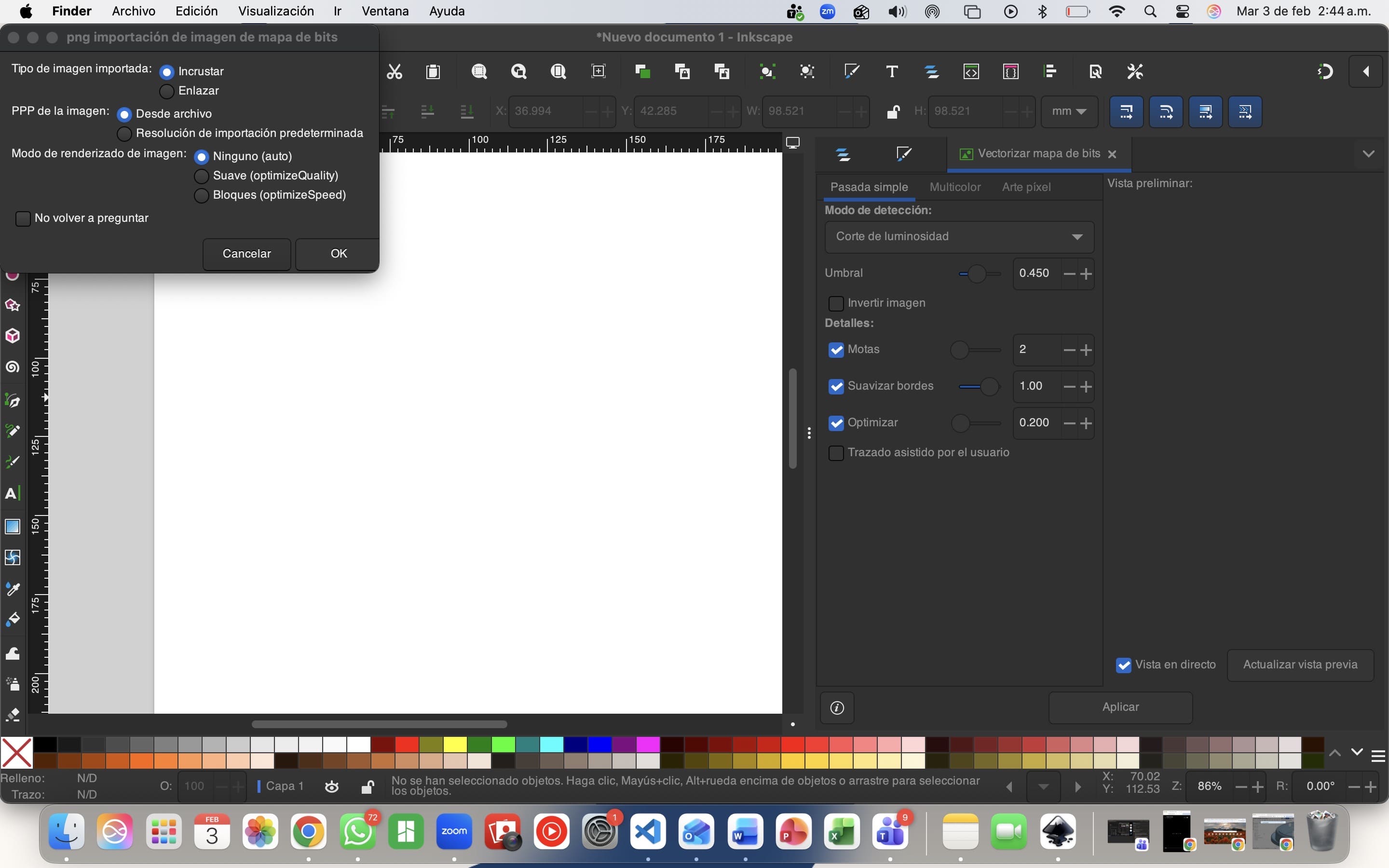

01. Image Import

Initial setup of the workspace and importing the raster source.

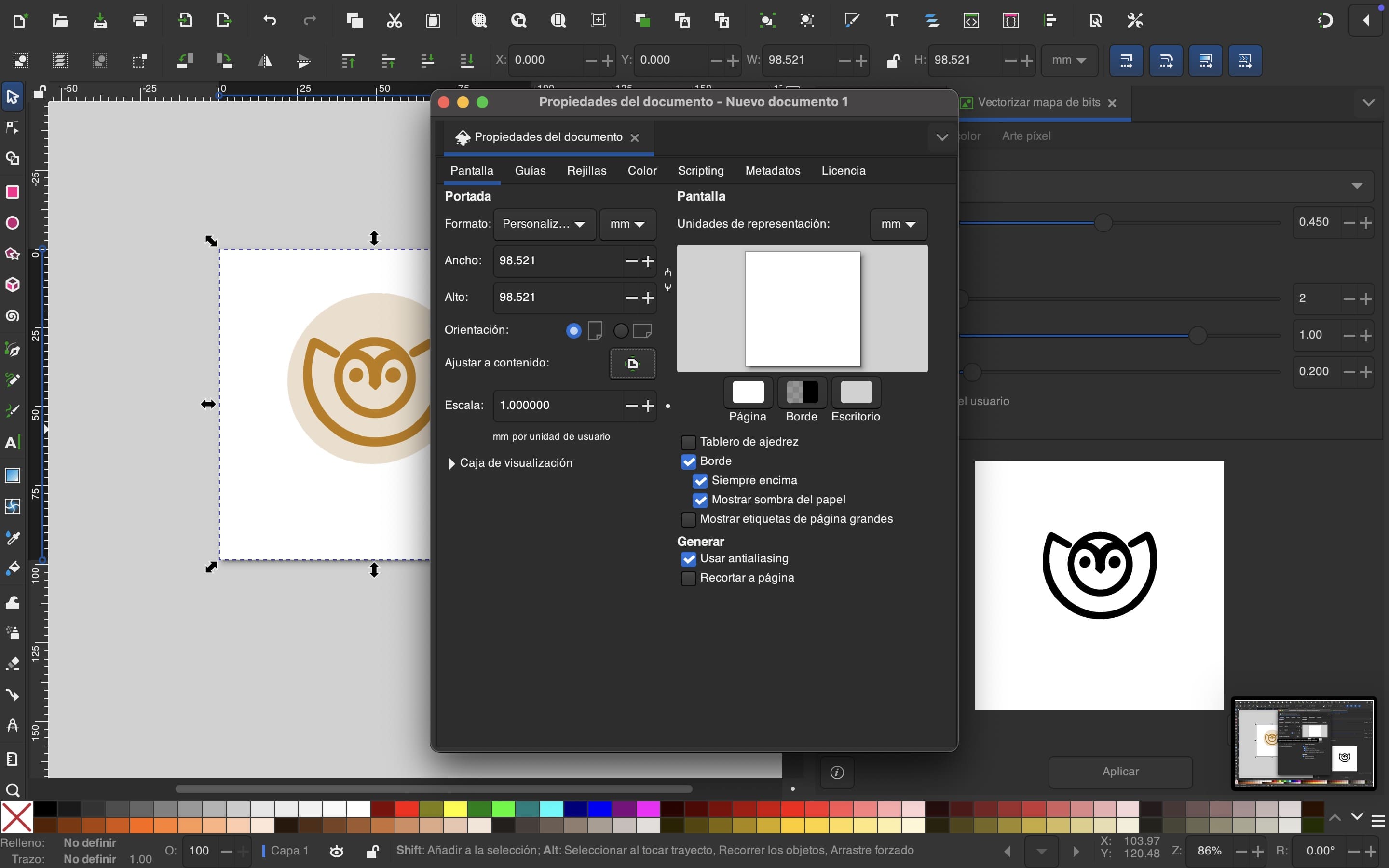

02. Canvas Adjustment

Using "Fit Page to Selection" in document properties for an organized workflow.

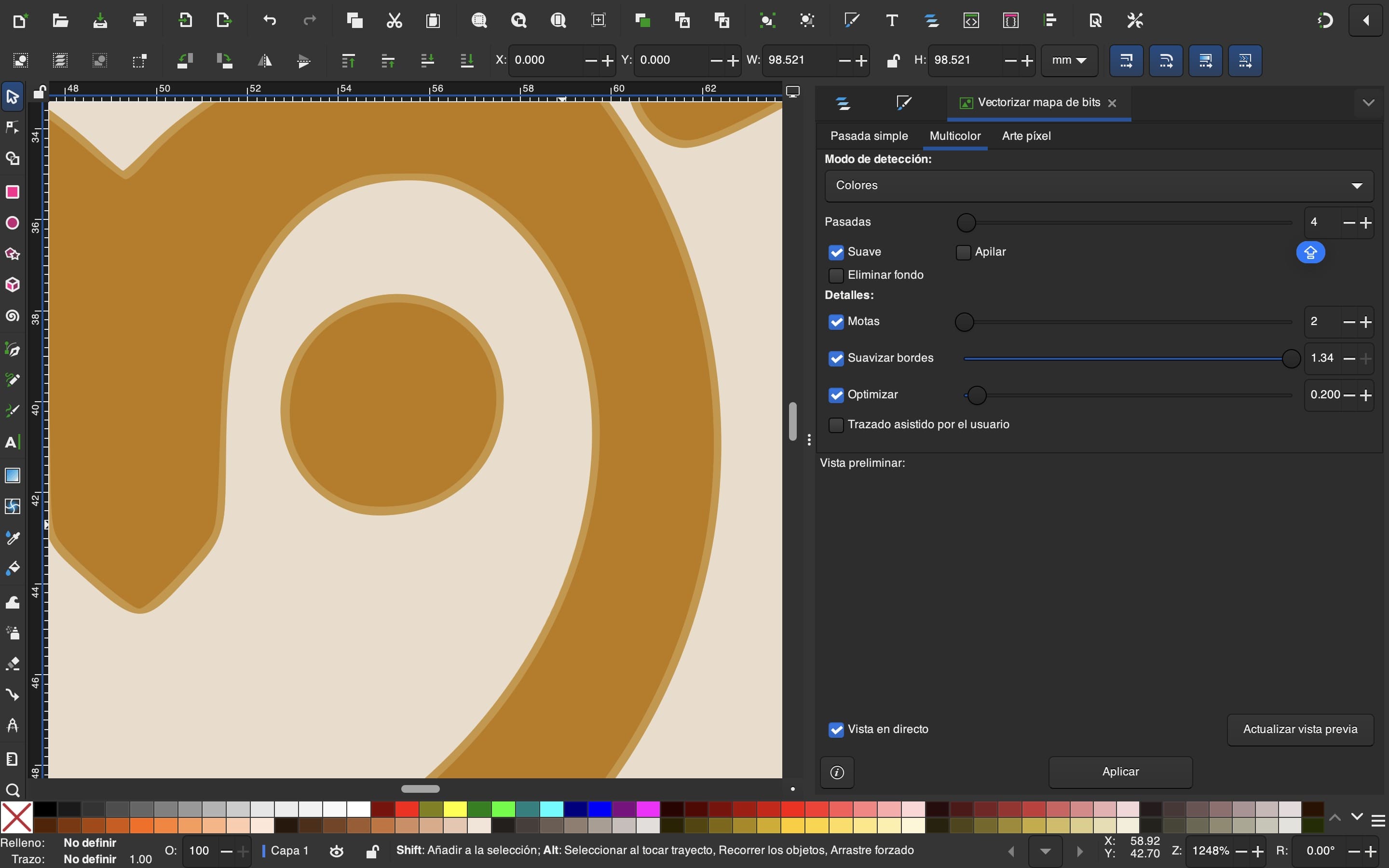

03. Bitmap Tracing:

Converting raster to vector using the "Trace Bitmap" feature with multicolor detection.

04. Path Optimization

Smoothing nodes for cleaner vector geometry.

05. SVG Export

Saving the final design in Scalable Vector Graphics (*.svg) for machine compatibility.

Affinity

Affinity Designer is a professional vector graphics editor. It combines vector and raster design tools within a single interface. Its main functions include the creation of scalable graphics, complex layouts, and precise typography. It is an excellent tool for preparing vector files for digital fabrication.

01. Project Setup

Initializing a new artboard and placing the reference image.

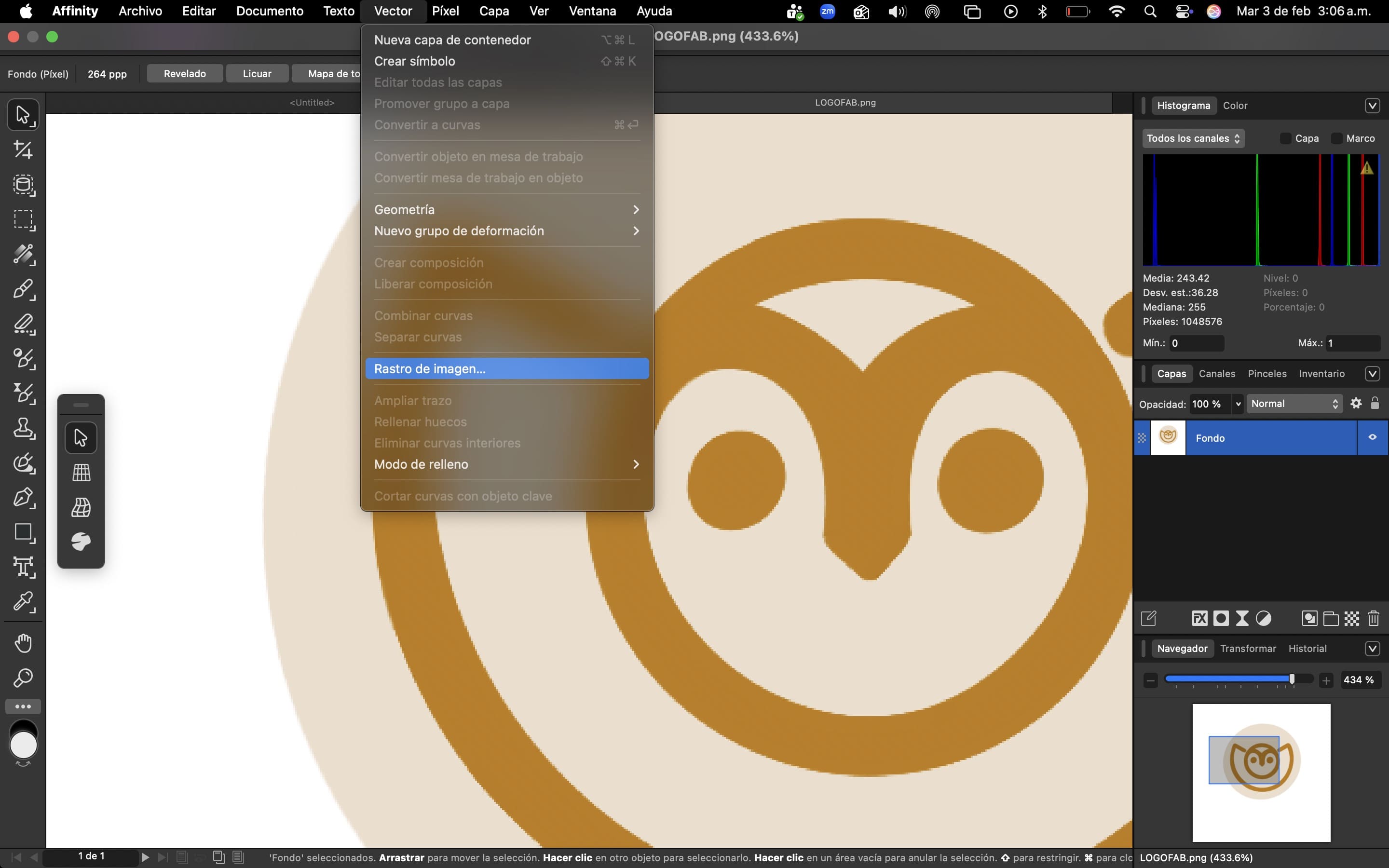

02. Image Tracing

Using the "Image Trace" option to detect shapes and outlines.

03. Vector Conversion

Converting the traced image into editable and scalable paths.

04. Quality Comparison

Analyzing the fidelity between the original raster and the new vector output.

05. Layer Management

Organizing the hierarchy of paths and groups for precise editing.

06. SVG format

Exporting the final assets in standard SVG format for digital fabrication.

Downloadable Assets

Here you can find the source files for my 2D designs and vector experiments.

Inkscape Design

Vectorized logo and paths for laser cutting.

Affinity Source

Original project with editable layers and curves.