Laser Cutting

Group Assignment

Safety Training

- Never look directly at the laser beam.

- Do not insert your hands while the machine is operating.

- Do not cut with the door open.

- Avoid unknown plastics (toxic fumes).

- Stay alert for fire hazards due to incorrect parameters.

- Turn off the laser button before moving the head manually.

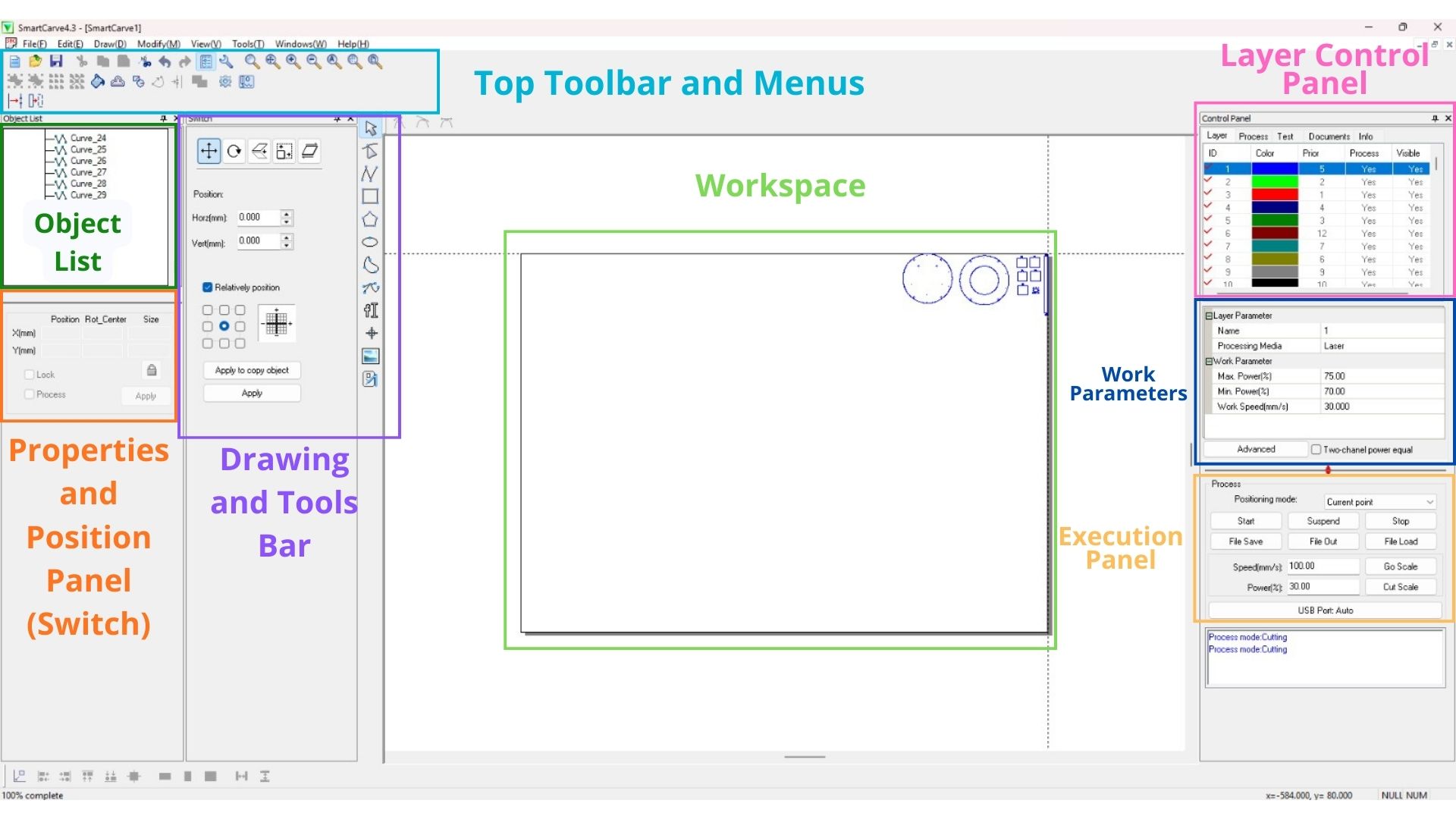

Software Used

- Smart Carve 4.3: Primary laser cutter software.

- Lightburn: Advanced alternative for design and cutting.

Setting Parameters in Smart Carve 4.3

The program interface is divided into the following key sections:

- Top Toolbar and Menus: Quick access to files, editing, and zoom tools.

- Drawing and Tool Bar (Left Side): Object selection, geometric drawing, and node editing.

- Object List: Shows all elements present in the design (e.g., Curve_24, Curve_25).

- Workspace: Where the design is visualized over the machine's bed.

- Work Parameters: Adjustment of speed and power for each color layer.

- Execution Panel: Command center to Start, Stop, and "Go Scale" (Frame).

Kerf

What is it?

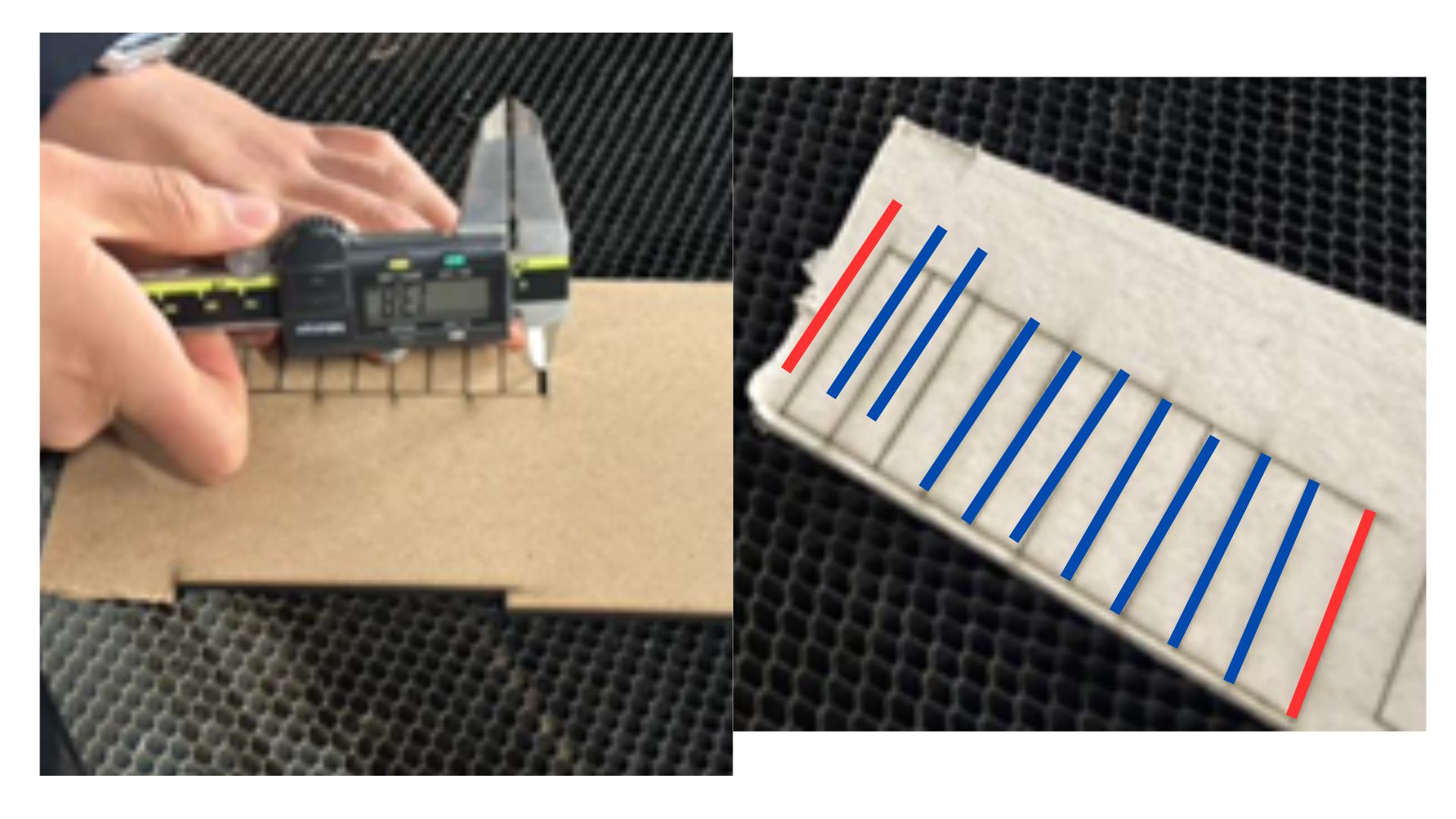

Kerf is the width of the groove or the material lost during the cutting process. Various test files were created to measure these lost millimeters accurately.

How is it calculated?

- A rectangle with internal lines is designed in the software.

- The design is sent to the laser cutter.

- The resulting distance is measured using a vernier caliper. In this test, there were 9 internal lines (marked in blue) and 0.5 for each external line (marked in red), totaling 10 lines. The total measured value is divided by this number (1.38 / 10 = 0.138 mm, which is the Kerf).

Formula: Total space (1.38 mm) / Number of lines (10) = 0.138 mm

Design Conclusions

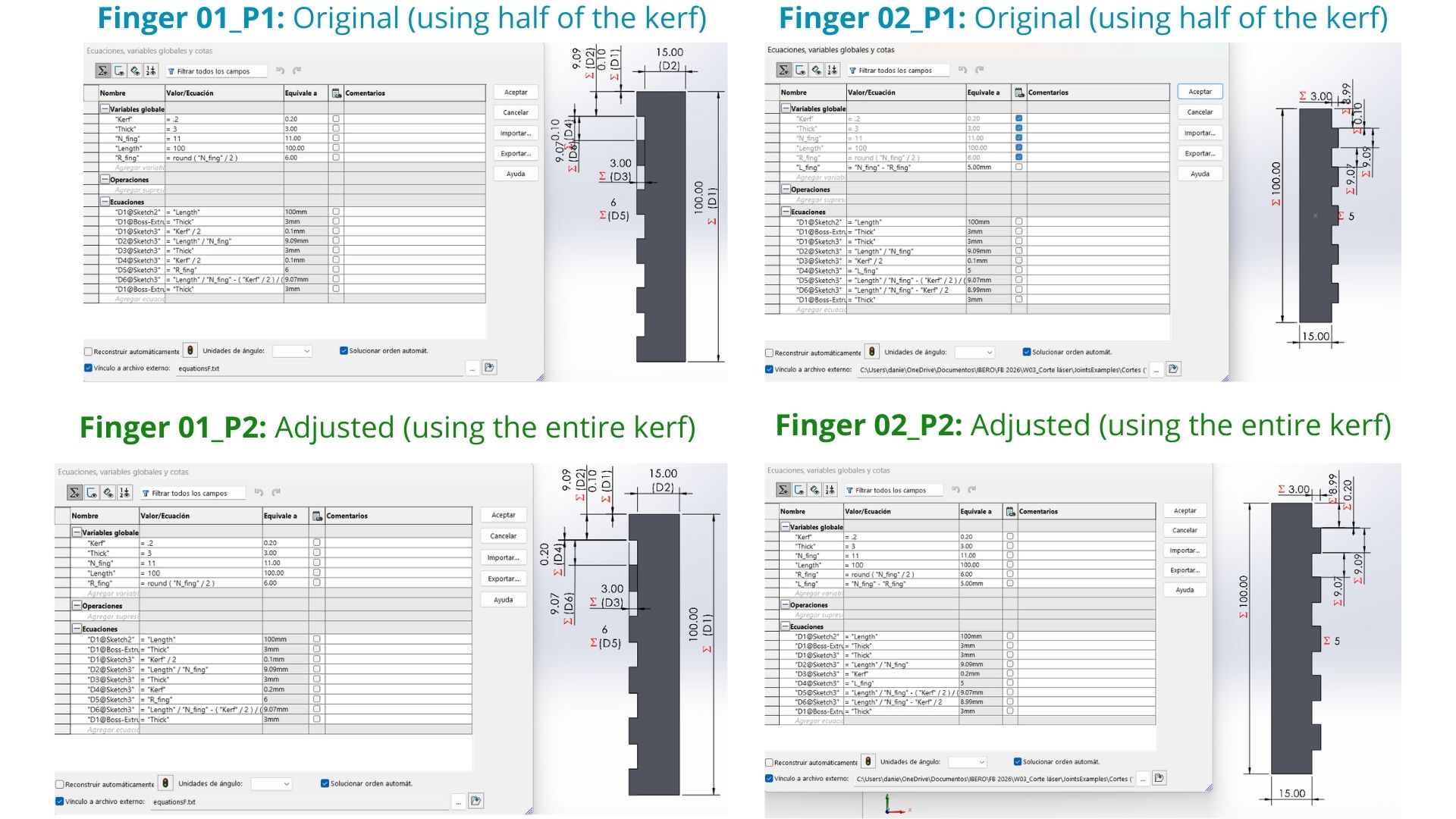

Personally, I found it challenging to understand how tolerances work during the design phase. After many trials, I reached the following conclusions:

- Male Piece (external parts): Increase the size by Kerf / 2.

- Female Piece (internal parts): Decrease the size by Kerf / 2.

Joints and Kerf Variations

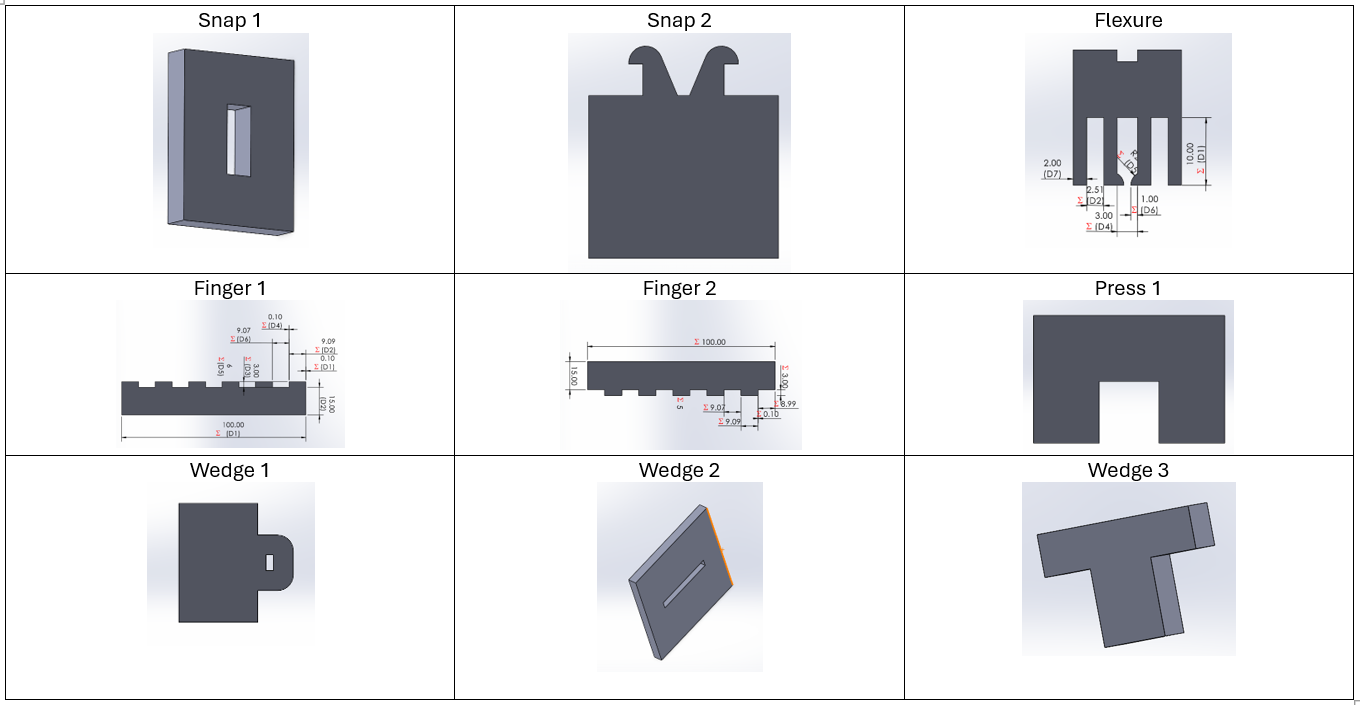

I utilized various joint designs from a folder shared by my instructor. Although some tests were not part of my final design, I performed several trials with Kerf tolerances.

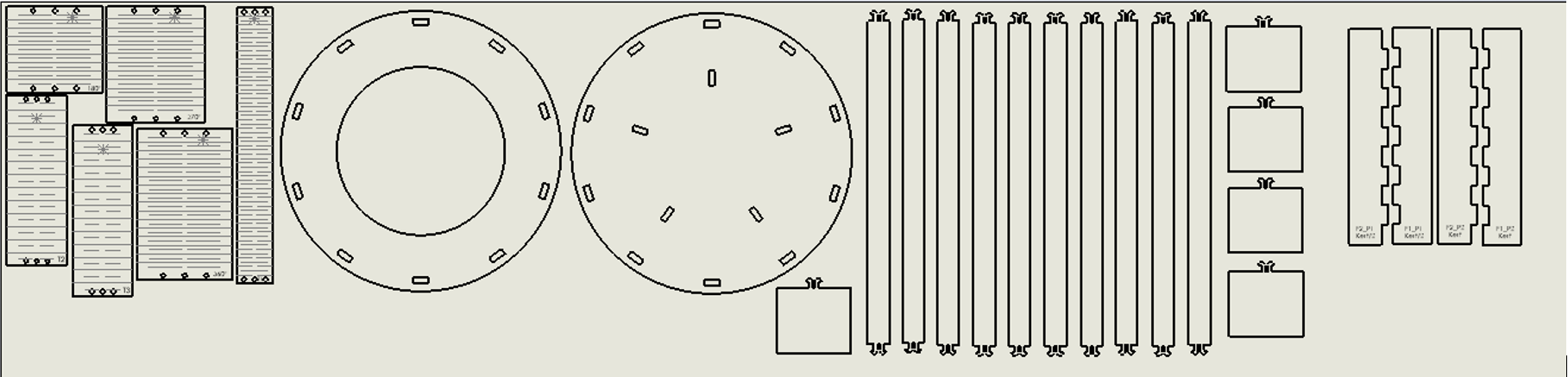

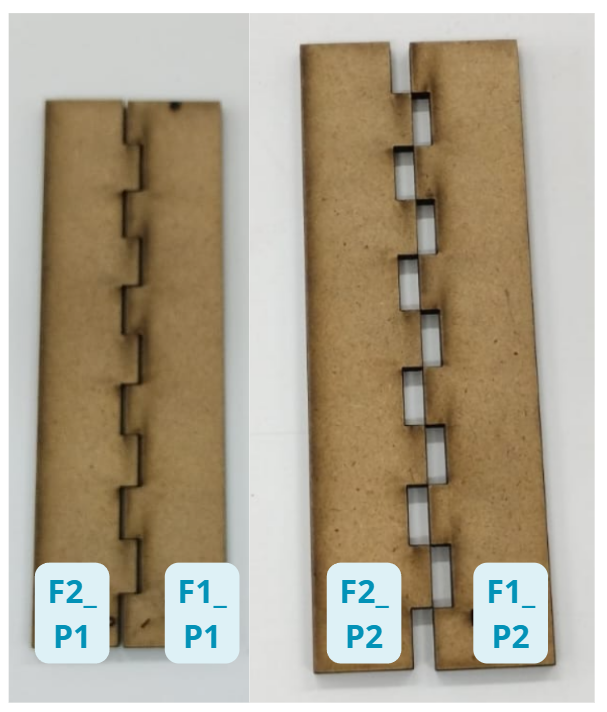

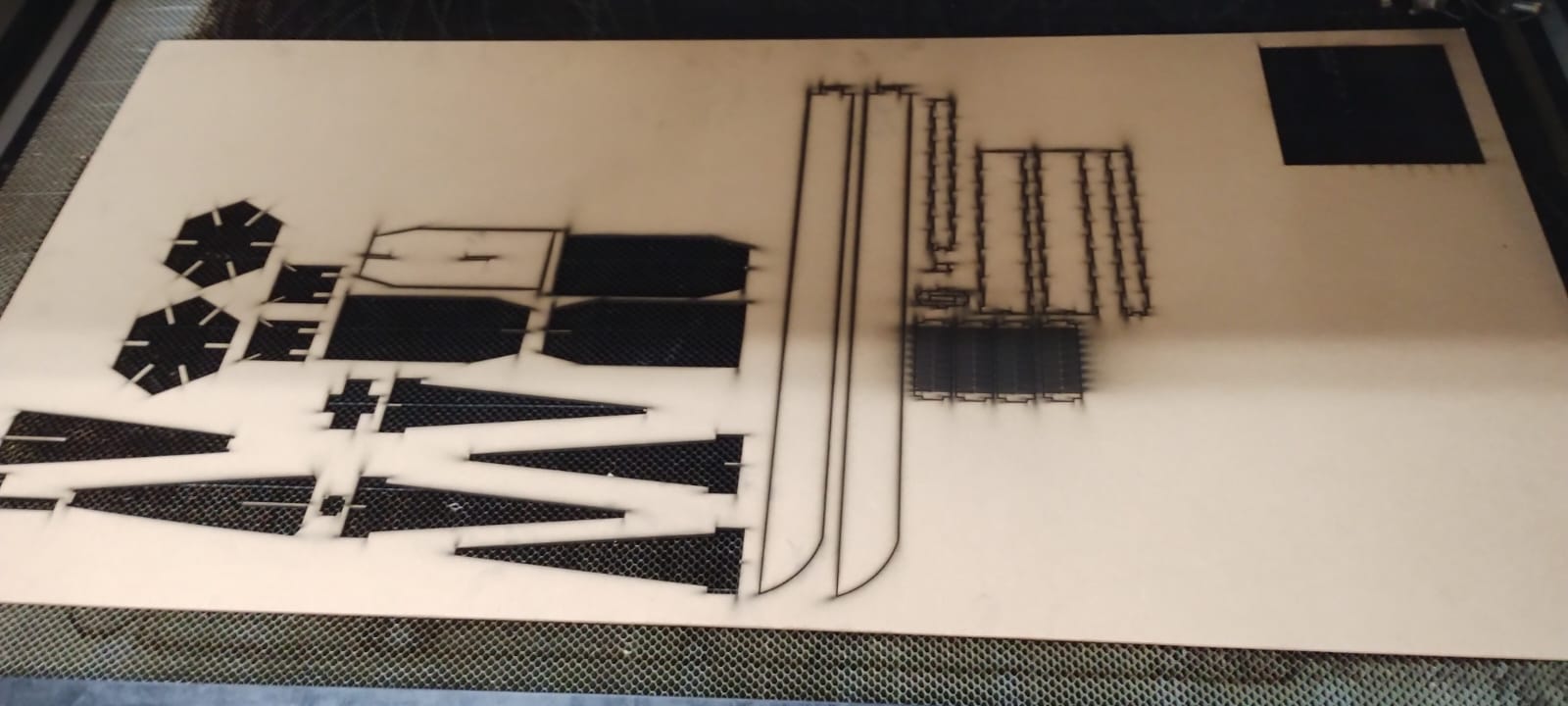

As such, this was no longer part of my design; however, I performed the following tests with kerf tolerances. The following image shows each of the pieces that were cut along with their parameters.

After testing, the best-fitting joints were "Finger 2_P1" and "Finger 1_P1"; in both cases, the fit was achieved by subtracting half of the Kerf.

Tolerances for Assembly

| Fit Type | Calculation | Observation |

|---|---|---|

| Loose Fit | Design + 0.0695mm (1/2 Kerf) | Slides in smoothly but falls out when flipped. |

| Perfect Fit (Press) | Design + 0.08 to 0.1mm | Ideal adjustment for assemblies. |

| Very Tight | Design + 0.139mm (Full Kerf) | Enters very forced; may break the material. |

What was my project?

Design & Parametric Joints

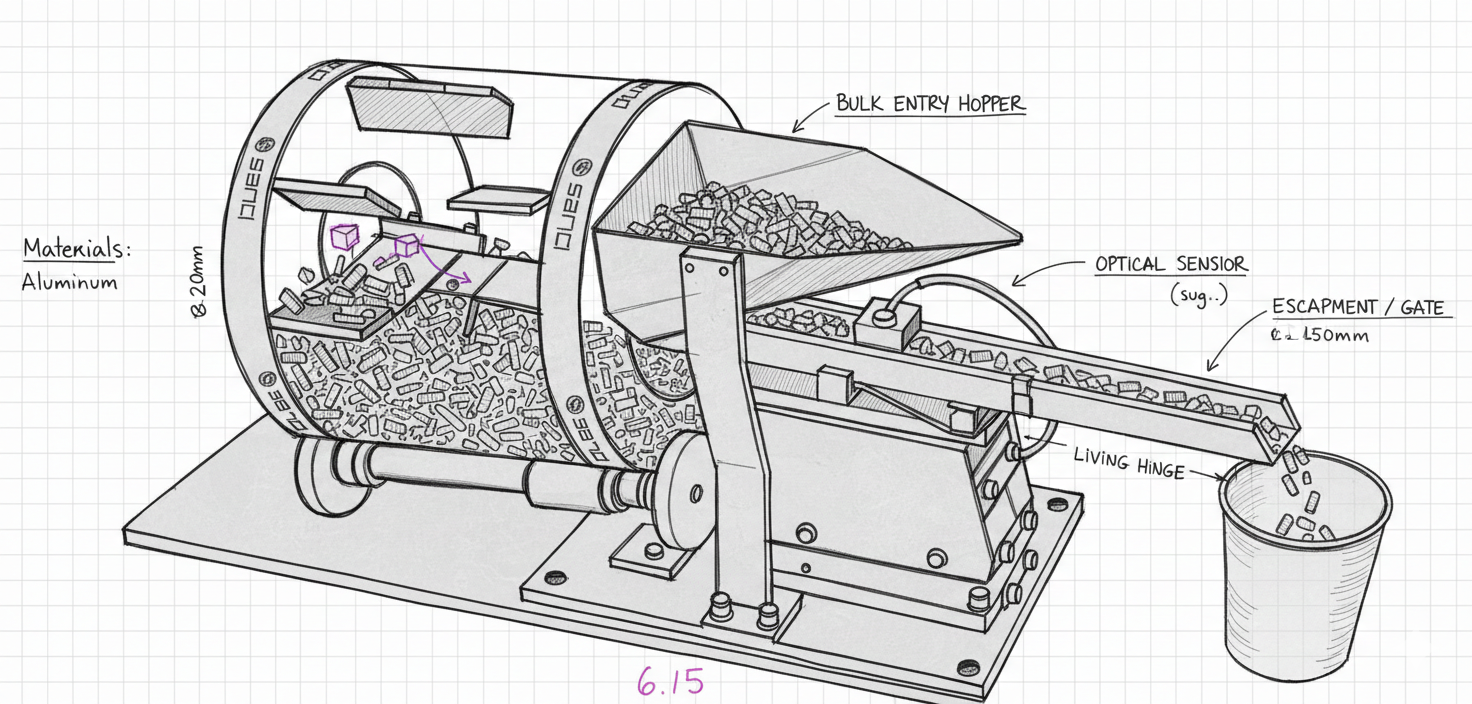

Inspiration: Drum Feeder

My design was based on a drum machine used for organizing staples. I used AI (Gemini) to clean the sketch and structure the assembly steps.

I gave Gemini the following prompt to clean up my sketch:

“Hola! quiero que me ayudes a hacer un boceto en limpio de una máquina que funcionará como una organizadora de unas piezas que parecen unas grapas. Te adjunto el boceto que yo hice (del cual necesito que hagas en limpio el diseño y que le pongas los nombres traducidos al inglés de cada parte que señala mi boceto) para que lo pases en limpio. Además, te adjunto el link de youtube de la máquina de la que sacamos la inspiración del funcionamiento y algunas piezas: Drum Feeder with Piezo Vibratory Linear and Loading Chute”

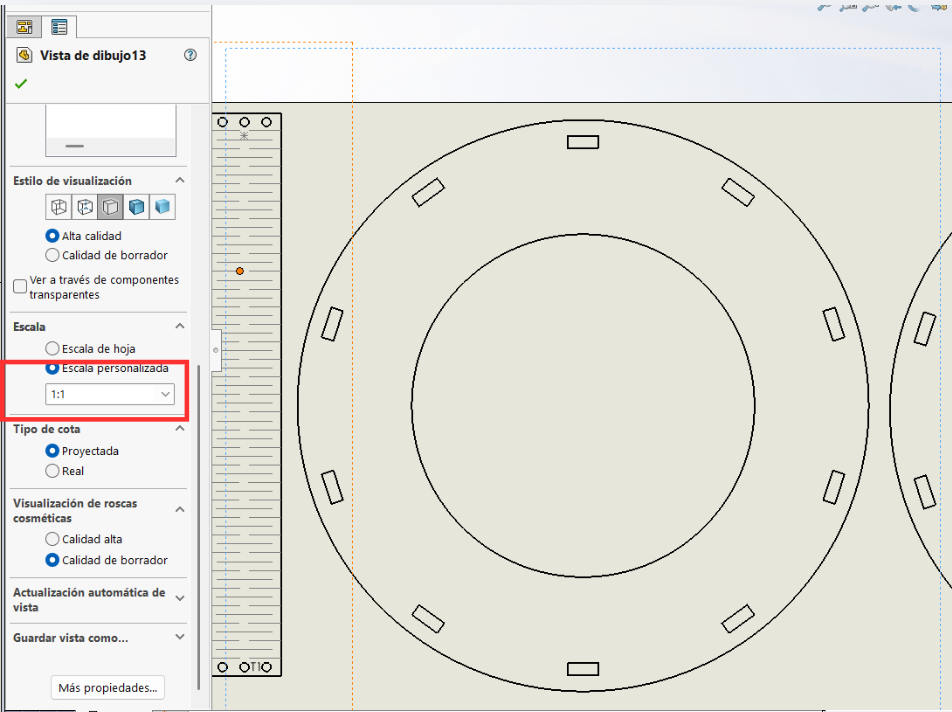

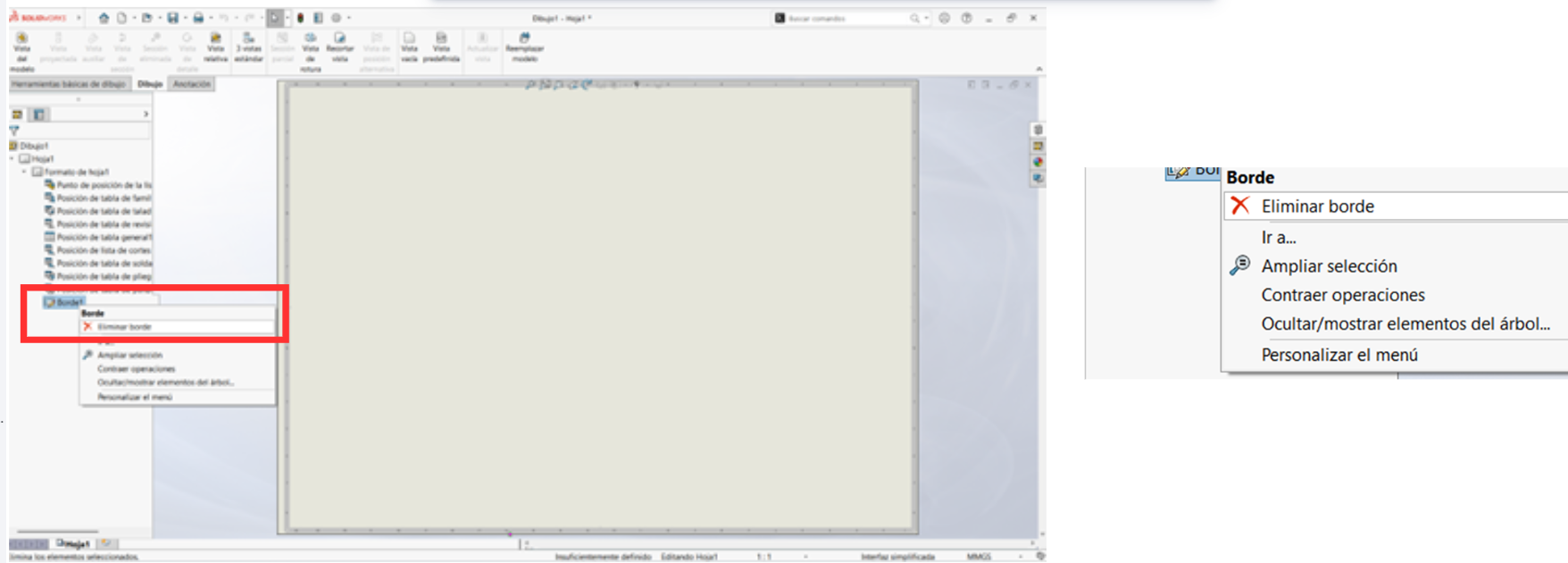

Parametrization on SolidWorks

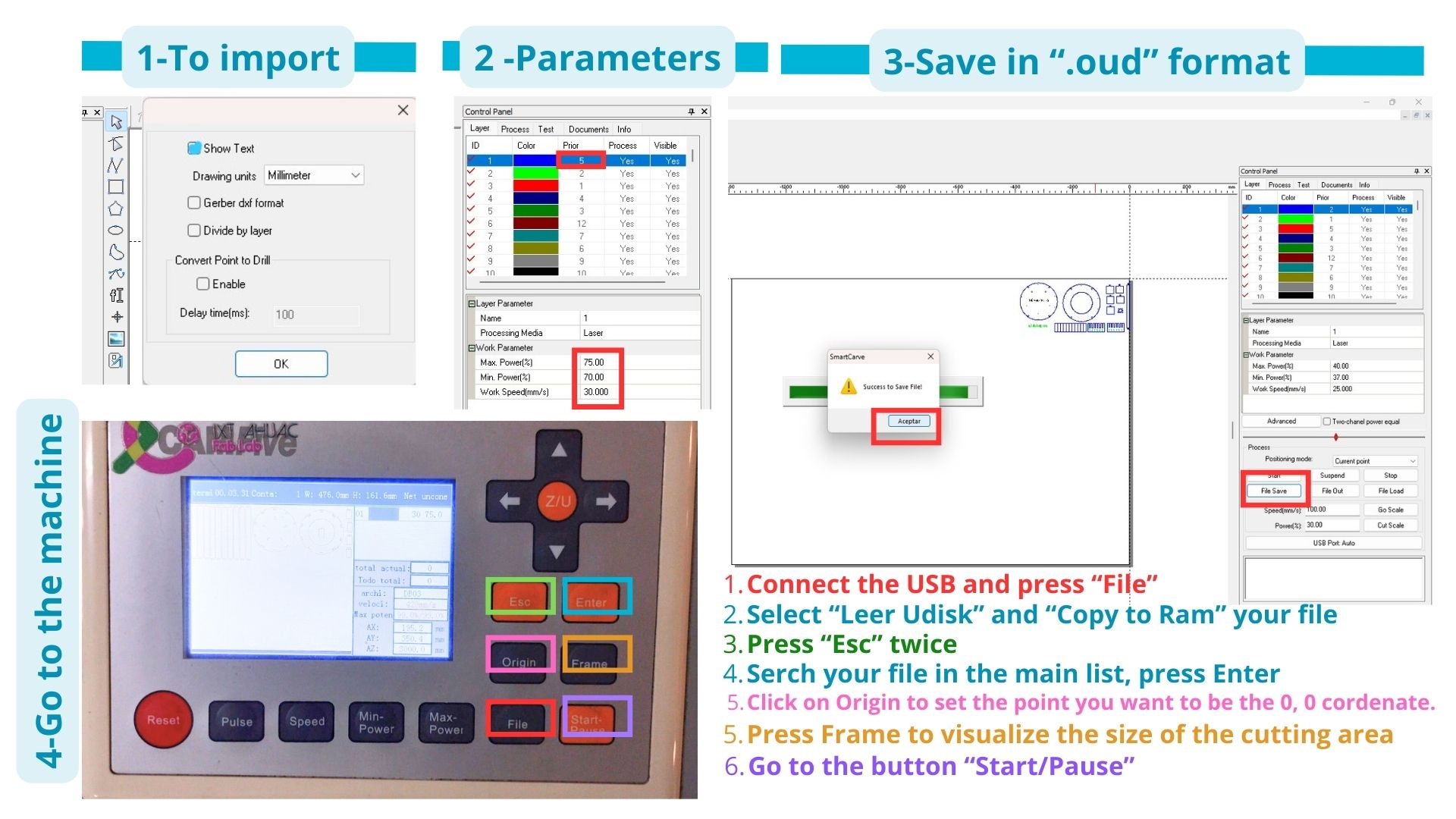

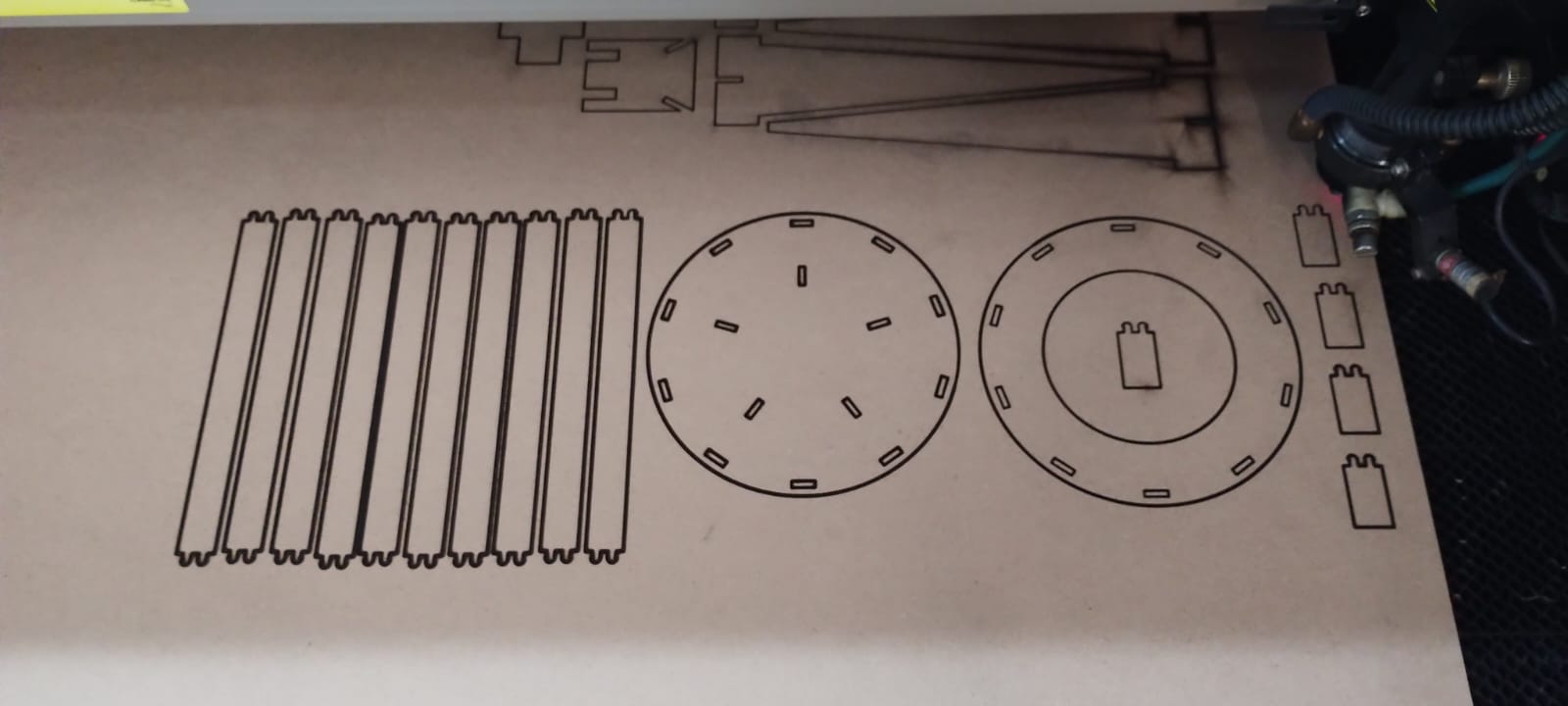

Cutting on the Machine

The first time I attempted to cut with the machine, I made the mistake of using laser number 2 instead of laser number 1, which is the one typically used for cutting. As a result, the piece was only scorched but not cut through. I know it wasn't due to my parameters, as they were the same ones I used later to successfully cut using laser number 1.

Another interesting situation occurred when I sent some pieces to be cut for another project I am working on. I sent everything in the same DXF document using the same parameters (Max Power: 75, Min Power: 70, Speed: 30), yet it only cut through the first half of the pieces. For future occasions, I recommend using slightly more power, as the bed leveling may not be perfectly uniform across all areas due to wear and tear.

Extra Tools

From the instructor's page (Group Assignment: Computer-Controlled Cutting | Ibero Puebla), these are the resources used for the project:

| Resource | Description / Link | Format |

|---|---|---|

| Downloadable Document | Joints Examples - Kerf variation and tests | ZIP File |

| Reference Book | Snap-Fit Book - Types of joints and mechanics | PDF Document |

| Design Tool | Lattice Hinge Design — Choosing Torsional Stress | Web Link |

| Living Hinge Template | Parameterized hinge provided by the instructor | SolidWorks (.SLDPRT) |

Vinyl Cutting

1. Software and File

A driver for Inkscape was used. We opened the file in .smv format (Inkscape header format).

2. Machine Preparation

Connect the machine, place the vinyl, and adjust the pinch rollers to secure the material.

3. Origin and Setup

Use the arrows to adjust the cutter nozzle to your desired origin point. In the software, documents are placed in "mirror" layout (just for arrangement, do not flip the image itself).

.png)

4. Final Parameters

Measure the actual length and width of the vinyl to set the workspace parameters before sending to cut.

Living Hinges

What is it?

A living hinge is a thin, flexible type of hinge made from the same material as the rigid parts it connects. Instead of using pins or external mechanical components, it leverages the material's own flexibility to allow movement.

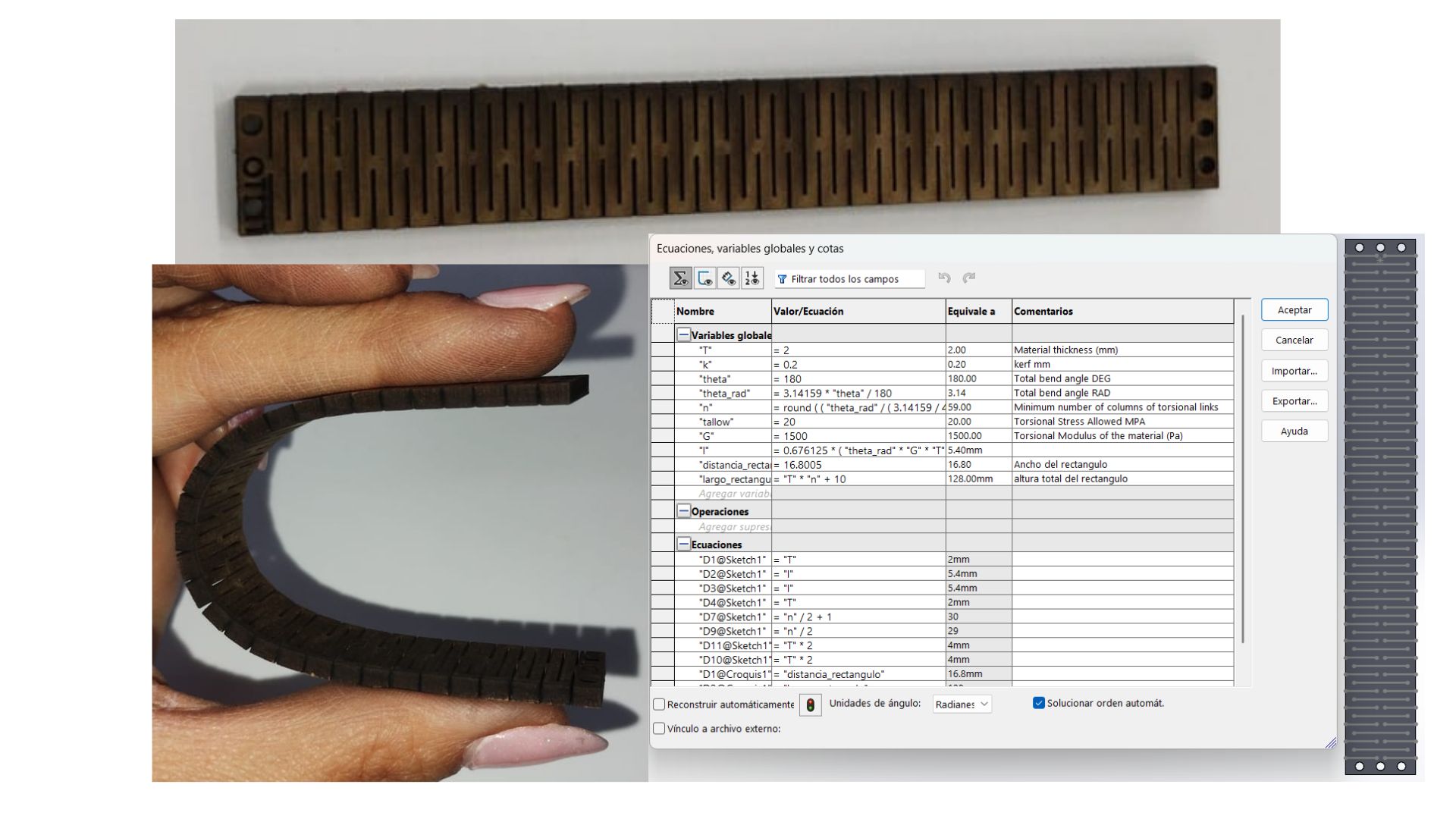

To use a living hinge in my project, I wanted to test different parameters to create a conveyor belt. To achieve this, I provided the Gemini AI with an image of a parameterized hinge document given by our instructor, along with the following prompt to determine which parameters to modify for my tests.

Prompt: "These equations are part of a living hinge; I want you to explain each parameter in the table. Additionally, I want you to recommend which parameters I can change to perform several tests so my living hinge behaves like a conveyor belt (like the ones in supermarkets). Create a table with the different tests you want me to do, where the columns are the parameters to change and the rows are the test number along with the objective of each."

Parameter Analysis

Based on the equations table, here is the explanation for each variable:

| Variable | Description |

|---|---|

| n | Number of columns or cuts in the pattern. |

| T (Thickness) | The thickness of the material being used. |

| tallow | Allowed torsional stress; determines how much the material can twist without breaking. |

| L (Length) | The total length of the area covered by the hinge. |

Test Table for "Conveyor Belt" Effect

The main objective is for the piece to be flexible enough to rotate over a roller, yet dense enough so that objects do not fall through.

| Test # | Objective | Parameters to Change |

|---|---|---|

| Test 1 | Maximum flexibility | Increase n and decrease tallow. |

| Test 2 | Structural balance | Medium n and standard tallow. |

| Test 3 | High resistance | Decrease n and increase tallow. |

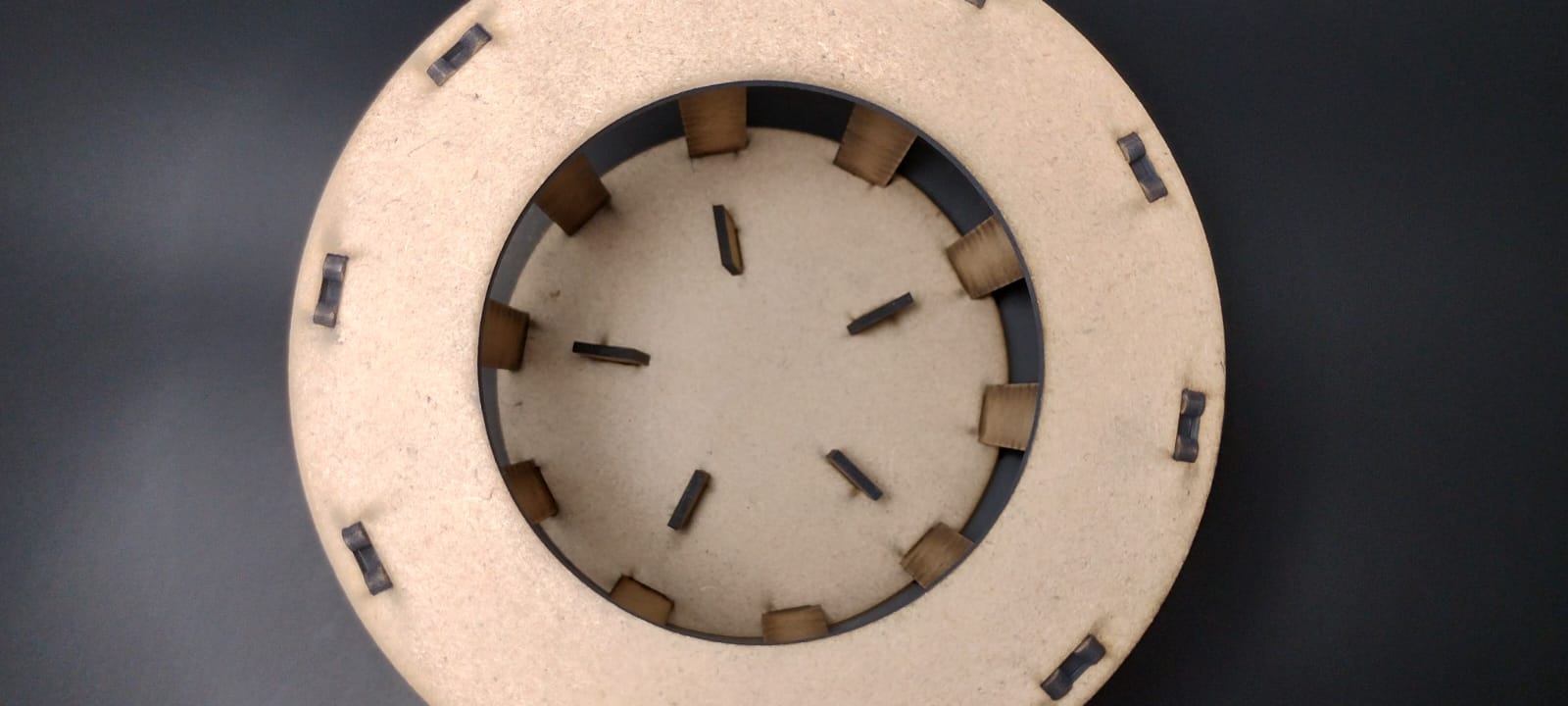

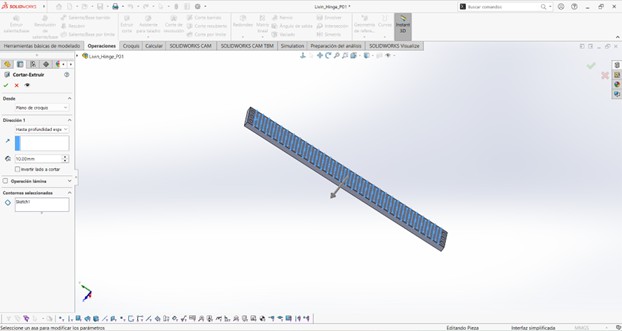

This is how the hinge was made in SolidWorks.

Results

The only hinge that worked correctly was "Test 1"; it can easily bend up to 180°. However, it turned out smaller than expected. An area for improvement is learning how to make it longer, which I believe can be achieved by copying and pasting the pattern more times or using a "Mirror" operation.

In all other tests, I made the mistake of allowing the long cut line to converge with the edge of the piece, causing them to break into several fragments.

Cutting Challenges and Tips

Cutting on the Machine

The first time I attempted to cut with the machine, I made the mistake of using laser number 2 instead of laser number 1, which is the one typically used for cutting. As a result, the piece was only scorched but not cut through. I know it wasn't due to my parameters, as they were the same ones I used later to successfully cut using laser number 1.

Another interesting situation occurred when I sent some pieces to be cut for another project I am working on. I sent everything in the same DXF document using the same parameters (Max Power: 75, Min Power: 70, Speed: 30), yet it only cut through the first half of the pieces. For future occasions, I recommend using slightly more power, as the bed leveling may not be perfectly uniform across all areas due to wear and tear.

Extra Tools

From the instructor's page (Group Assignment: Computer-Controlled Cutting | Ibero Puebla), these are the resources used for the project:

| Resource | Description / Link | Format |

|---|---|---|

| Downloadable Document | Joints Examples - Kerf variation and tests | ZIP File |

| Reference Book | Snap-Fit Book - Types of joints and mechanics | PDF Document |

| Design Tool | Lattice Hinge Design — Choosing Torsional Stress | Web Link |

| Living Hinge Template | Parameterized hinge provided by the instructor | SolidWorks (.SLDPRT) |