My Final Project

This project focuses on the automation of traditional craftsmanship used in high-end lighting.

Project Overview

The project consists of a cut glass assembly machine designed to automate a process that remains manual for small and medium-sized enterprises. This accelerates production and reduces costs for these businesses.

Why this project

My family owns a business in Oaxaca, Mexico, dedicated to selling chandeliers, lamps, and other items. One of our products is the "Imperial Chandelier"; to give you an idea of their scale, they are frequently installed in churches. However, we only purchase the chandelier's metal frame. Separately, to "dress" the chandelier, we buy the crystals (made of cut glass) and the "bows," which are a type of staple used to link the cut crystals together.

While the supplier offers the chandelier fully assembled (already dressed), the price increases approximately fivefold. This leaves us with virtually no profit, as our selling price is nearly the same as their wholesale cost. On the other hand, the manual assembly process for the cut crystals takes about one week per chandelier ; consequently, it is difficult to meet demand during peak sales seasons due to the time required for each piece. Furthermore, keeping them in stock fully assembled is not a viable option because they occupy too much warehouse space.

Research & Inspiration

Beyond "Fine Blanking" or jewelry settings, I researched automated crimping and linking systems:

- Automatic Eyeletting Machines: Used in the textile and stationery industries to clinch metal rings.

- Pneumatic Crimping Tools: Used in electronics for wire terminals; they provide the exact pressure needed to fold metal without breaking the core material.

- Rosary/Chain Making Machines: Specific machines in the religious jewelry sector that link beads using wire looping or metal pins.

- Automatic Stapling Heads: Industrial units used in packaging that share the "feed and fold" logic required for aluminum staples.

Design & Planning

Processes and Mechanisms

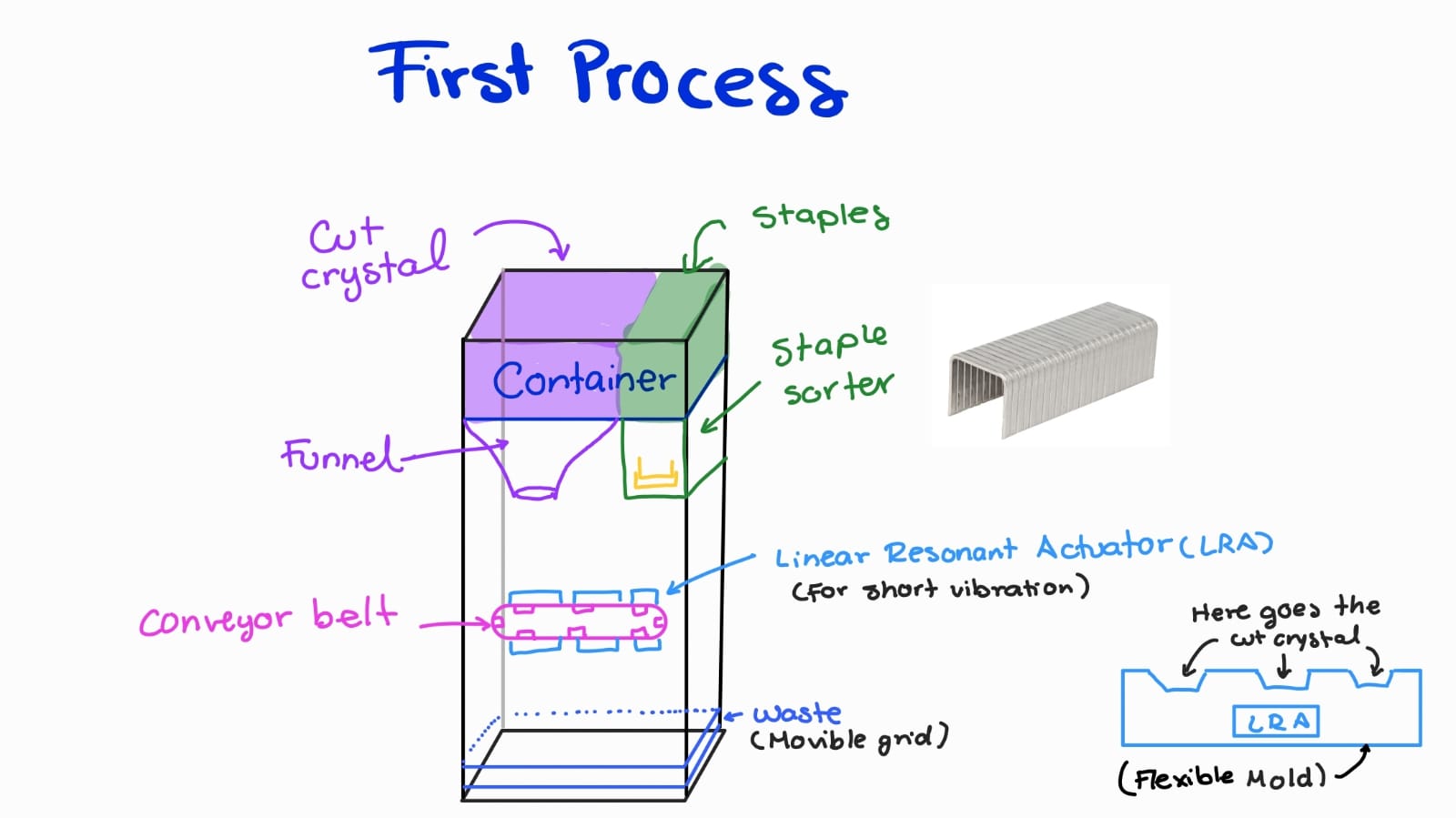

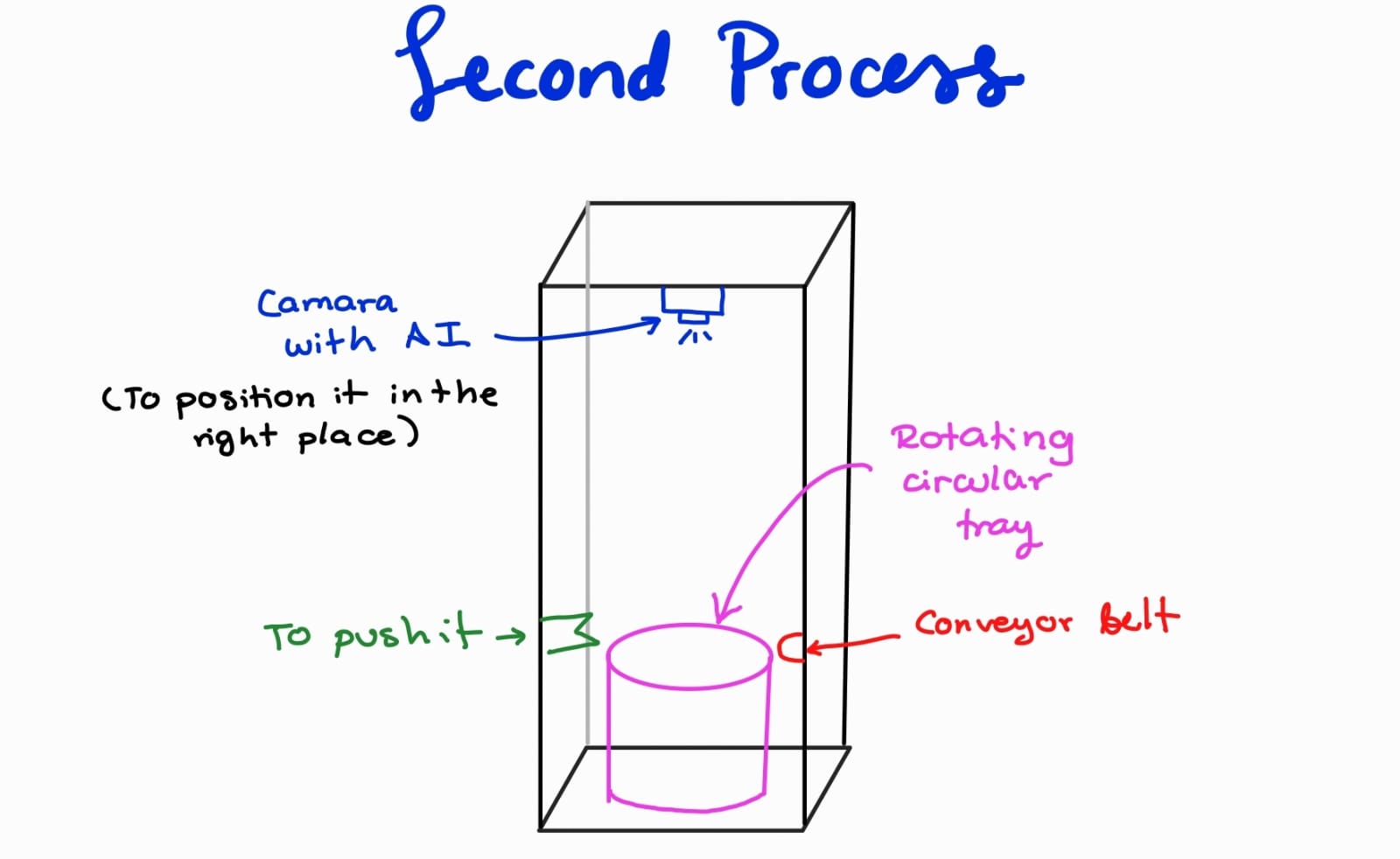

- Crystal Positioning: A jig or "nest" to hold two crystals in place.

- Staple Feeding: A gravity-fed magazine or a vibrating bowl to align the aluminum staples.

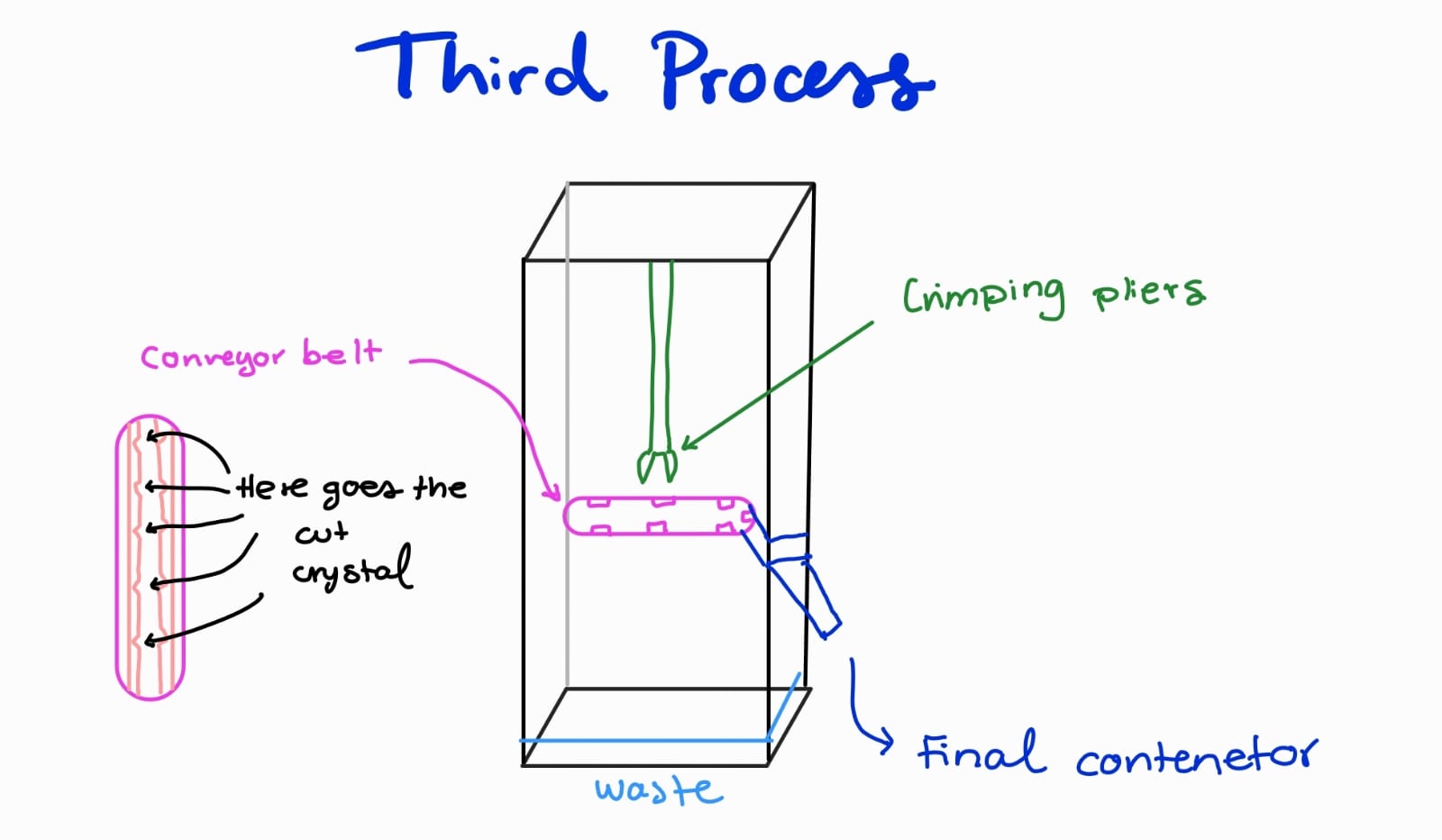

- Folding (Crimping): A vertical actuator (pneumatic or lead screw) that pushes a die to bend the staple arms.

Workflow Sketch

The machine follows a 3-step vertical process:

- Top Magazine: Staples descend through a rail. ↓

- Actuator (Plunger): Pushes the staple through the crystal holes. ↓

- Folding Die (Anvil): A base with a specific geometry that forces the staple arms to curl inward as the plunger descends. → ←

Note: The plunger must have a soft-touch tip to prevent cracking the glass.

Figure 1: First part of the process

Figure 2: Second step of the process

Figure 3: Third step of the process

Implementation Timeline

The implementation will follow this iterative schedule:

- Weeks 1-3: CAD design of the structure and crimping die.

- Weeks 4-6: Prototyping mechanical parts (3D printing/CNC) and testing staple folding.

- Weeks 7-9: Electronics (PCB design for motor/actuator control).

- Weeks 10-12: Final assembly, testing with different crystal sizes, and UI design.

Resources & Materials

- Structural: Aluminum profiles (V-Slot) from the Fab Lab inventory.

- Mechanical: 3D Printed parts (PETG/PLA) and custom-milled steel for the folding anvil.

- Electronics: Microcontroller (ESP32 or Xiao), stepper motor (NEMA 17), and motor drivers.

- Consumables: 0.5mm Aluminum staples and octagonal facet-cut crystals.