Week 04

Embedded Programming

Class with Neil

During the theory class of Week 04, we learned about the basics of embedded programming and how microcontrollers work. We studied how code is uploaded to a board, how digital and analog pins function, and how to control external components such as LEDs, buttons, sensors, and motors through programming.

This helped me understand how software can control physical hardware, how to structure simple programs, and how embedded systems interact with real-world inputs and outputs. It was an important step toward making my final project intelligent and interactive.

Group Assignment:

° Demonstrate and compare the toolchains and development workflows for available embedded architectures

° Document your work to the group work page and reflect on your individual page what you learned

individual Assignment:

° Browse through the datasheet for a microcontroller

° Write and test a program for an embedded system using a microcontroller to interact (with local input &/or output devices) and communicate (with remote wired or wireless connections)

Have you answered these questions?

- I. Linked to the group assignment page. ✅

- II. Browsed and documented some information from a microcontroller's datasheet✅

- III. Programmed a board to interact and communicate ✅

- IV. Described the programming process(es) you used ✅

- V. Included your source code. ✅

- VI. Included ‘hero shot(s)’ ✅

Group Assignment Sumary

Before beginning my individual work, we ran several group tests to check the laser kerf, engraving strength, and cutting speed. These trials helped me better understand how the material reacts to different settings and allowed me to choose the best parameters for my own design. And for this Assignment we decide make our Assignment in the FAB LAB UNI.

Introduction:

This week focused on embedded programming and understanding how code can control physical devices. I learned how microcontrollers work, how to upload programs, and how to interact with electronic components such as LEDs, buttons, and sensors.

This week was essential for my final project, since the pill dispenser will rely on embedded systems to process inputs, control actuators, and make decisions. Learning how software and hardware communicate opened the door to creating a truly interactive and functional device.

Individual Assignment

For this assignment, I reviewed the datasheet of my microcontroller and developed a program to control and test its behavior. I simulated and then implemented the system to interact with local input and output devices, using a touch sensor as input and an OLED display as output.

To extend the system, I also worked with a Raspberry Pi Pico and an ESP32-S3, allowing communication between boards through wired and wireless connections. This helped me understand how different microcontrollers can exchange data and work together in a single system.

1.Instructor's Guide

To begin this assignment, I contacted my instructor Evelyn to ask for guidance and confirm the components I would need. Since I already have experience in electronics, I prepared my own list of parts and planned the system according to the requirements of the project.

After that, I went to Paruro, Lima, to purchase the remaining electronic components. This process allowed me to select the correct parts, manage my budget, and ensure compatibility with the microcontrollers I would be using.

Tutorial

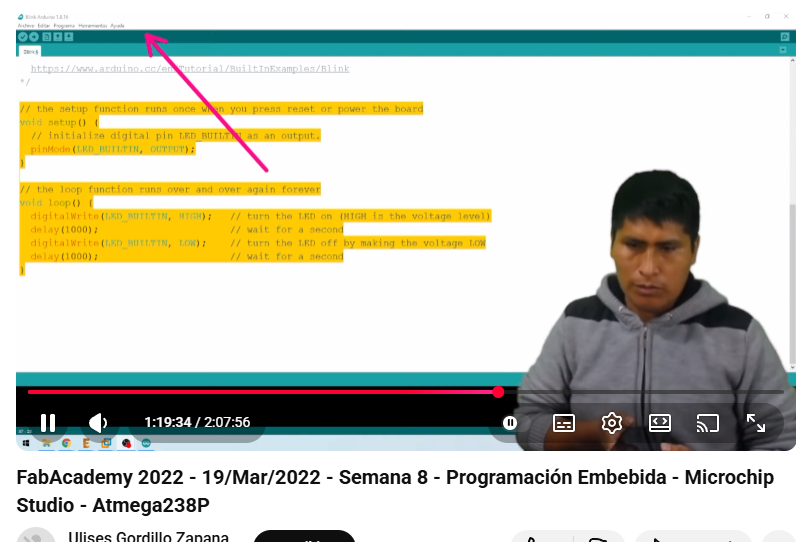

°On February 16th, I found a masterclass prepared by Ulises in Spanish, where he explained how to use programming languages such as Arduino API, C++, and MicroPython. During the session, he shared resources and practical examples that showed how these languages can be applied to real electronics projects.

Exploring Arduino IDE

°This week helped me better understand how digital designs become real physical objects. Working with the laser cutter showed me how important it is to test parameters such as power, speed, and kerf before producing final parts, since even small variations can change the fit and quality of the pieces.

° The recovery of the vinyl cutter was also a valuable experience. It taught me that digital fabrication is not only about design and machines, but also about problem-solving when things do not work as expected. Searching for compatible software and bringing an unused machine back to life was both challenging and rewarding.

Programming Protocol

Microcontroller Selection: Raspberry pico 2040 Microcontroller

| Feature | Specification |

|---|---|

| Microcontroller | RP2040 (Dual-core ARM Cortex-M0+) |

| Clock Speed | Up to 133 MHz |

| Flash Memory | 2 MB QSPI Flash |

| SRAM | 264 KB |

| Operating Voltage | 1.8 – 5.5 V (via VSYS) |

| Logic Level | 3.3 V |

| GPIO Pins | 26 multifunction GPIO |

| ADC | 3 × 12-bit ADC + internal temperature sensor |

| PWM | 16 PWM channels |

| UART | 2 |

| I2C | 2 |

| SPI | 2 |

| USB | USB 1.1 device & host support |

| Temperature Sensor | On-chip sensor |

| Programmable I/O | PIO (2 blocks, 4 state machines each) |

| Dimensions | 51 × 21 mm |

The Raspberry Pi Pico (RP2040) is a powerful and low-cost microcontroller board designed for embedded projects. It features a dual-core ARM Cortex-M0+ processor, flexible GPIO pins, and supports multiple programming languages such as MicroPython, C/C++, and Arduino. Its versatility and performance make it ideal for handling sensors, displays, and communication modules in compact electronic systems.

.png)

Programming Protocol

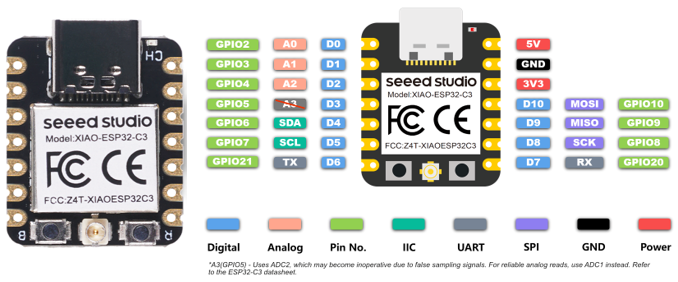

Microcontroller Selection: ESP32 S3

ESP32-3c – Features & Specifications

| Feature | Specification |

|---|---|

| Microcontroller | Xtensa® LX7 Dual-core 32-bit |

| Clock Speed | Up to 240 MHz |

| SRAM | 512 KB |

| Flash Memory | Up to 16 MB (external) |

| Operating Voltage | 3.0 – 3.6 V |

| Logic Level | 3.3 V |

| GPIO Pins | Up to 45 programmable GPIO |

| Wi-Fi | 2.4 GHz 802.11 b/g/n |

| Bluetooth | Bluetooth 5 (LE) |

| ADC | 2 × 12-bit ADC (20 channels) |

| DAC | 2 × 8-bit DAC |

| PWM | Up to 8 PWM channels |

| UART | 3 |

| I2C | 2 |

| SPI | 3 |

| USB | USB 2.0 OTG (device/host) |

| Camera Interface | 8/16-bit parallel camera interface |

| AI Acceleration | Vector instructions for ML acceleration |

| Security | Secure boot, flash encryption, AES, RSA, SHA |

The Raspberry Pi Pico (RP2040) is a powerful and low-cost microcontroller board designed for embedded projects. It features a dual-core ARM Cortex-M0+ processor, flexible GPIO pins, and supports multiple programming languages such as MicroPython, C/C++, and Arduino. Its versatility and performance make it ideal for handling sensors, displays, and communication modules in compact electronic systems.

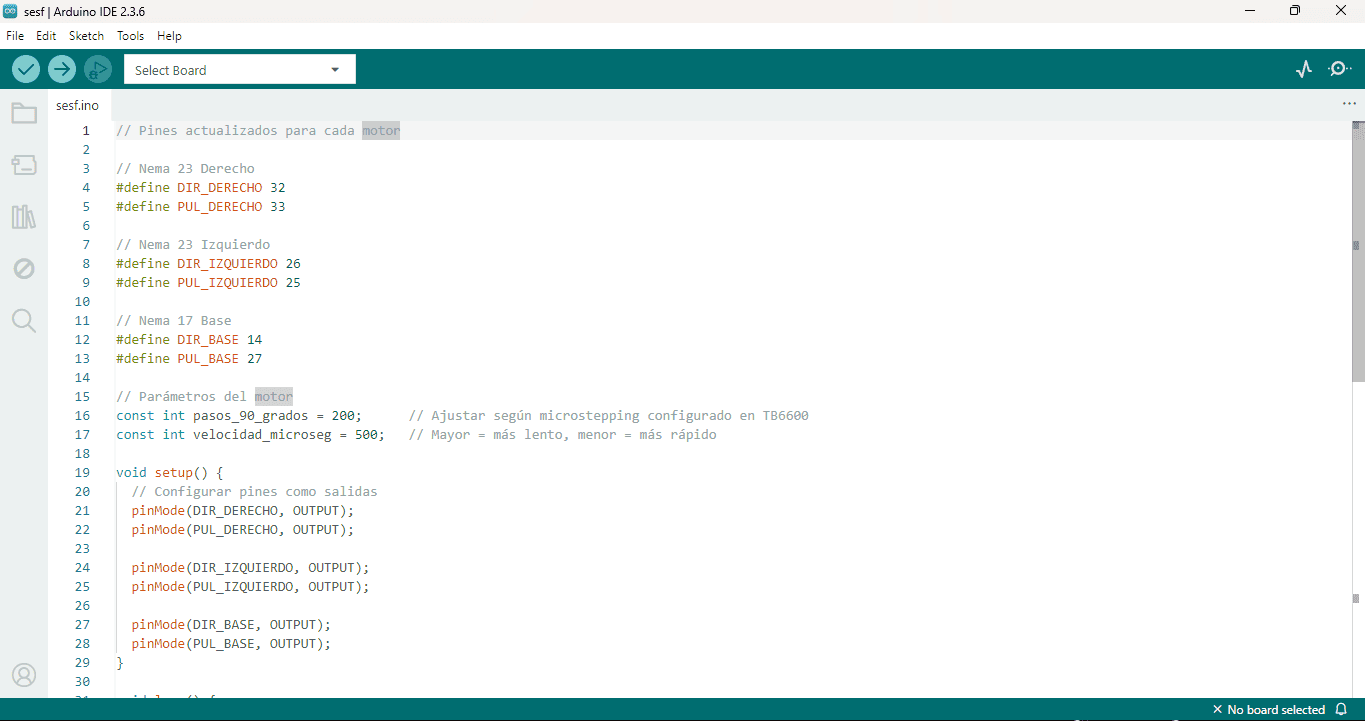

Setup Arduino IDE

At this stage, the development environment Arduino IDE (v2.3.6) was configured to program the Raspberry Pi Pico based on the RP2040; a sketch was created where the DIR and PUL pins were defined to control three stepper motors using drivers such as the TB6600, adjusting step and speed parameters, and setting all pins as outputs in setup(), leaving the system ready for motion testing and further hardware integration.

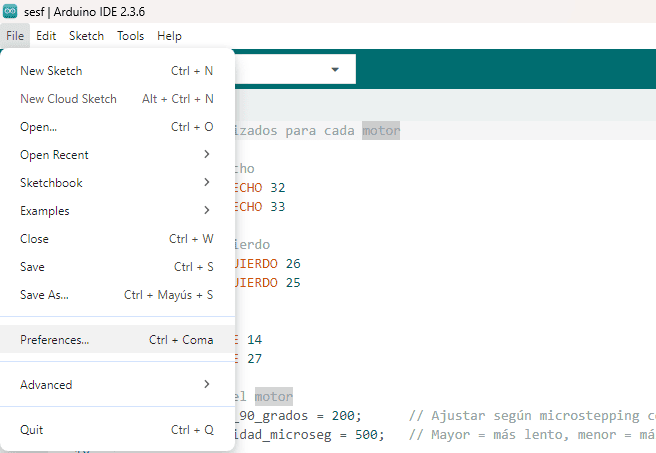

In this step, the Arduino IDE (v2.3.6) interface is shown with the File menu open, highlighting the Preferences option, which is where the necessary settings are configured to enable support for the Raspberry Pi Pico based on the RP2040. This section is essential for adding additional board manager URLs and adjusting the IDE configuration so that new boards and cores can be installed, allowing the development environment to properly recognize and program the Raspberry Pi Pico for upcoming embedded programming tasks.

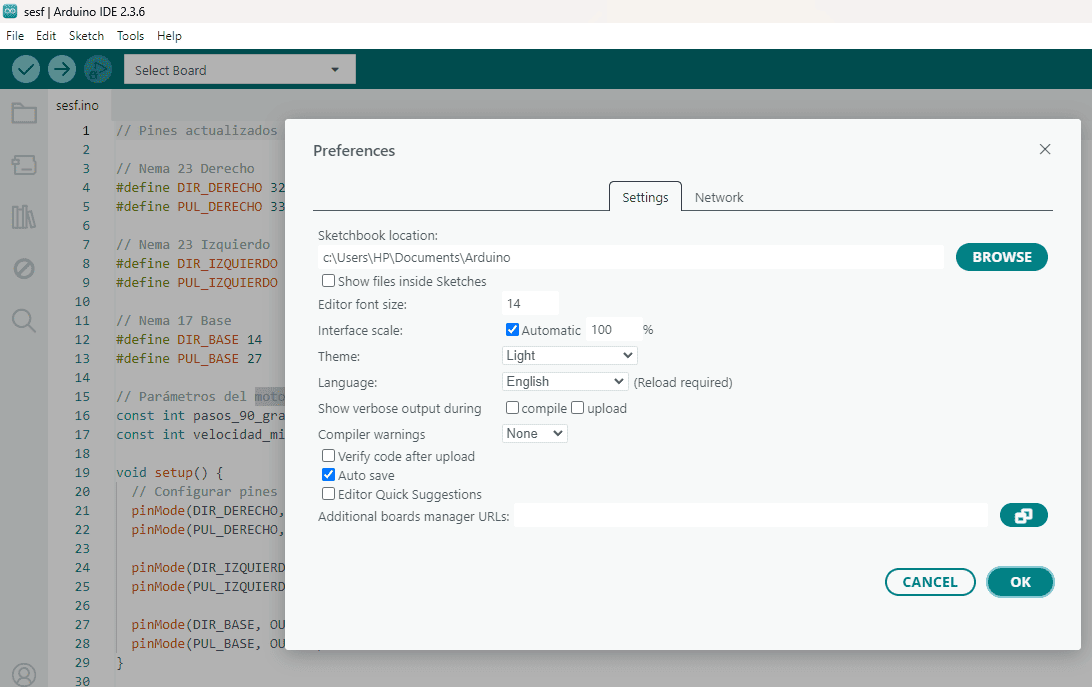

Here, the Arduino IDE (v2.3.6) Preferences window is shown, where key settings are adjusted to prepare the environment for programming the Raspberry Pi Pico powered by the RP2040. This step is crucial because the “Additional Boards Manager URLs” field is where the RP2040 core repository is added, enabling the IDE to recognize and install support for the Raspberry Pi Pico and related boards, ensuring the toolchain is fully ready for compiling and uploading embedded projects.

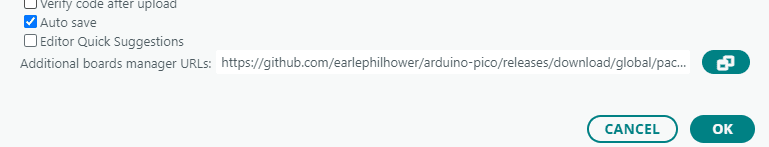

In this step, the Arduino IDE Preferences panel shows the “Additional Boards Manager URLs” field filled with the repository link needed to install support for the Raspberry Pi Pico, which runs on the RP2040. By adding this URL (from the Arduino-Pico core maintained by Earle Philhower), the IDE can download and install the correct board definitions and tools, enabling proper compilation and upload of sketches to the Raspberry Pi Pico.

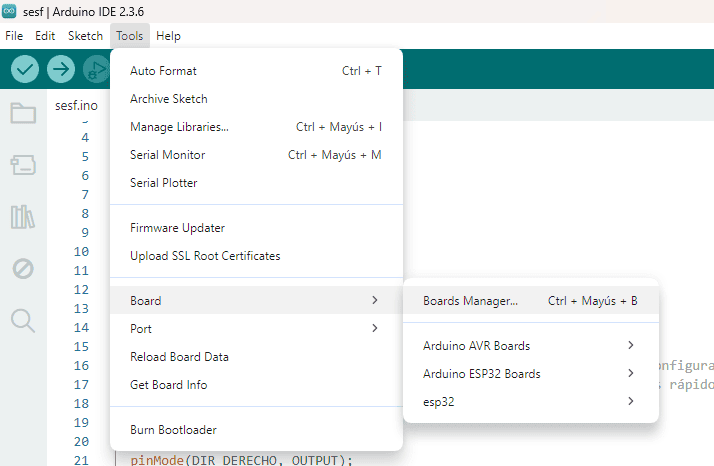

In this step, the Arduino IDE (v2.3.6) menu path Tools → Board → Boards Manager is opened to install the necessary board packages. This is where you search for and install support for the Raspberry Pi Pico (RP2040 core) after adding the Boards Manager URL, allowing the IDE to recognize the board, enable compilation for the RP2040, and make it available for selection before uploading your sketches.

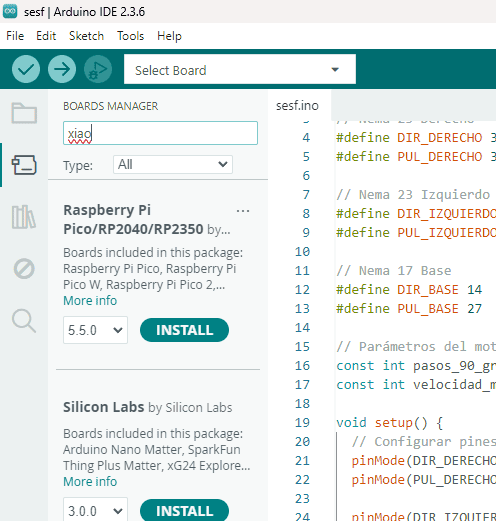

Here, the Boards Manager inside Arduino IDE (v2.3.6) is used to search for and install the board package for the Raspberry Pi Pico (RP2040 family). After adding the additional Boards Manager URL, the Raspberry Pi Pico/RP2040 package appears in the list, and by clicking Install, the IDE downloads the core, drivers, and toolchain needed to compile and upload sketches to boards based on the RP2040, completing the setup to start programming the Pico.

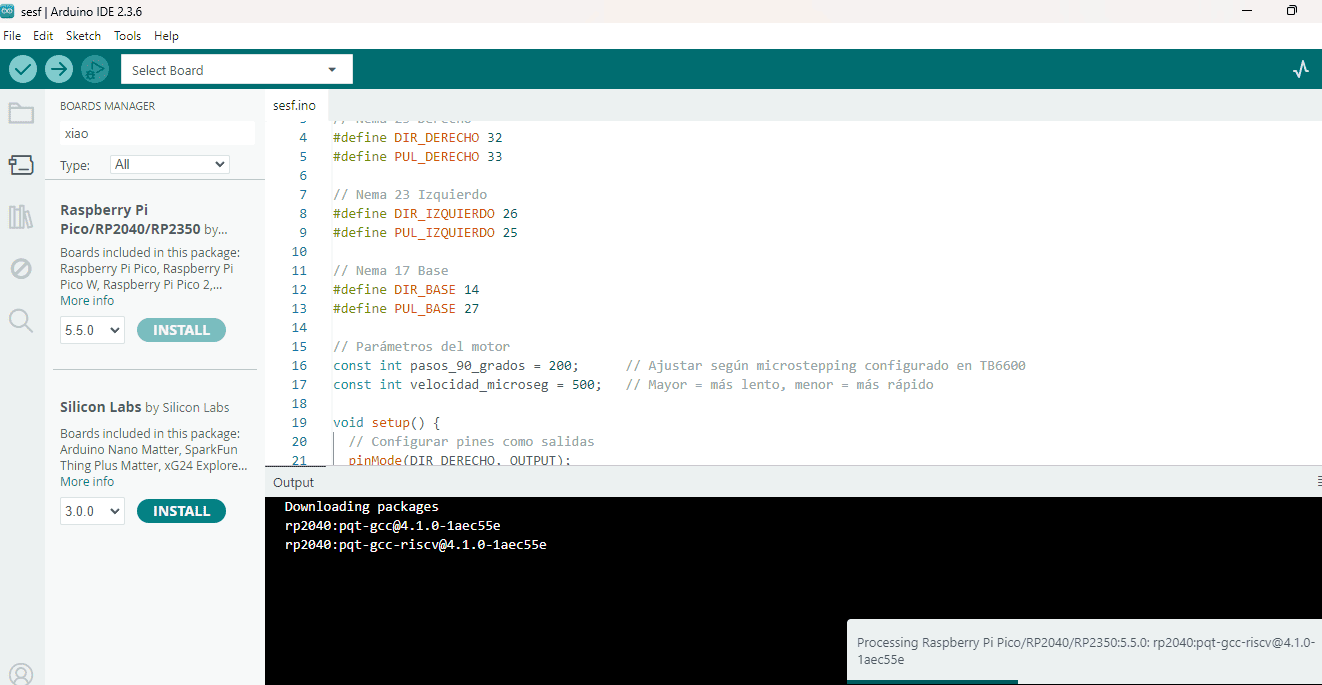

At this point, the Boards Manager in Arduino IDE (v2.3.6) is actively downloading and installing the required packages for the Raspberry Pi Pico family. The output console shows the toolchain components being fetched (such as the RP2040 GCC compilers), which are necessary to compile and upload sketches to boards based on the RP2040. Once this process finishes, the board will be fully available for selection in the IDE and ready for development and testing.

Code Writing in Arduino IDE - LED Blink Example

// LED Blink Example - Arduino

int ledPin = 13;

void setup() {

pinMode(ledPin, OUTPUT);

}

void loop() {

digitalWrite(ledPin, HIGH);

delay(1000);

digitalWrite(ledPin, LOW);

delay(1000);

}

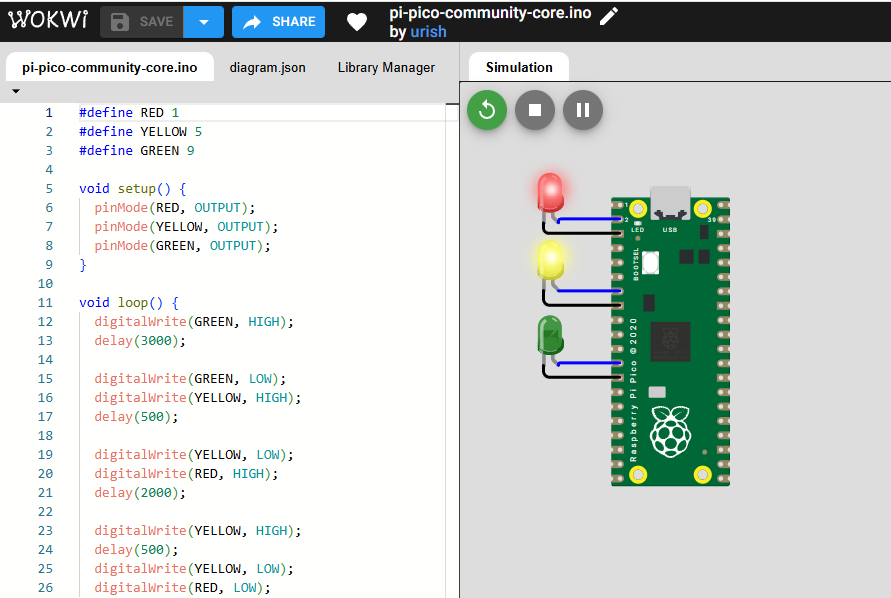

Simulation in Wokwi Led

This scene shows a simulation in Wokwi where the Raspberry Pi Pico is being programmed and tested using an Arduino-like sketch. The left panel displays the code that defines three pins (RED, YELLOW, and GREEN) configured as outputs, while the right panel shows the virtual circuit with three LEDs connected to the board. The simulation executes an on/off sequence that mimics a traffic light (green, yellow, and red) with varying delay times, allowing the program logic and connections to be validated before physical implementation on real hardware. 🚦

Code Execution

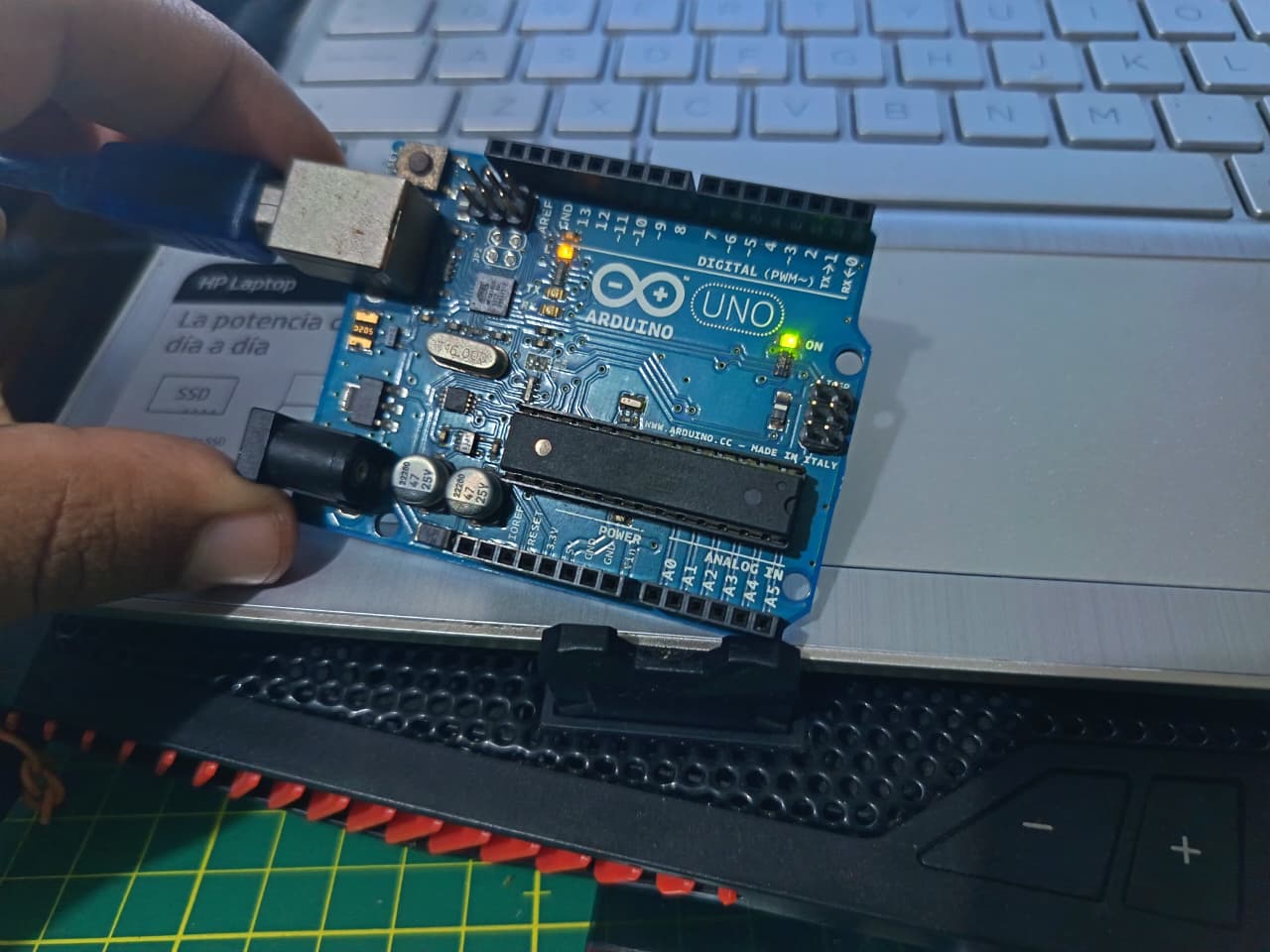

This step shows the physical setup of a Raspberry Pi Pico mounted on a breadboard and powered via USB from a computer. The onboard LEDs are illuminated, indicating that the board is receiving power correctly and that the uploaded program is running as expected. This quick hardware test helps verify proper power delivery, device recognition by the development environment, and basic functionality before moving on to integrating sensors, actuators, or other modules into the project.

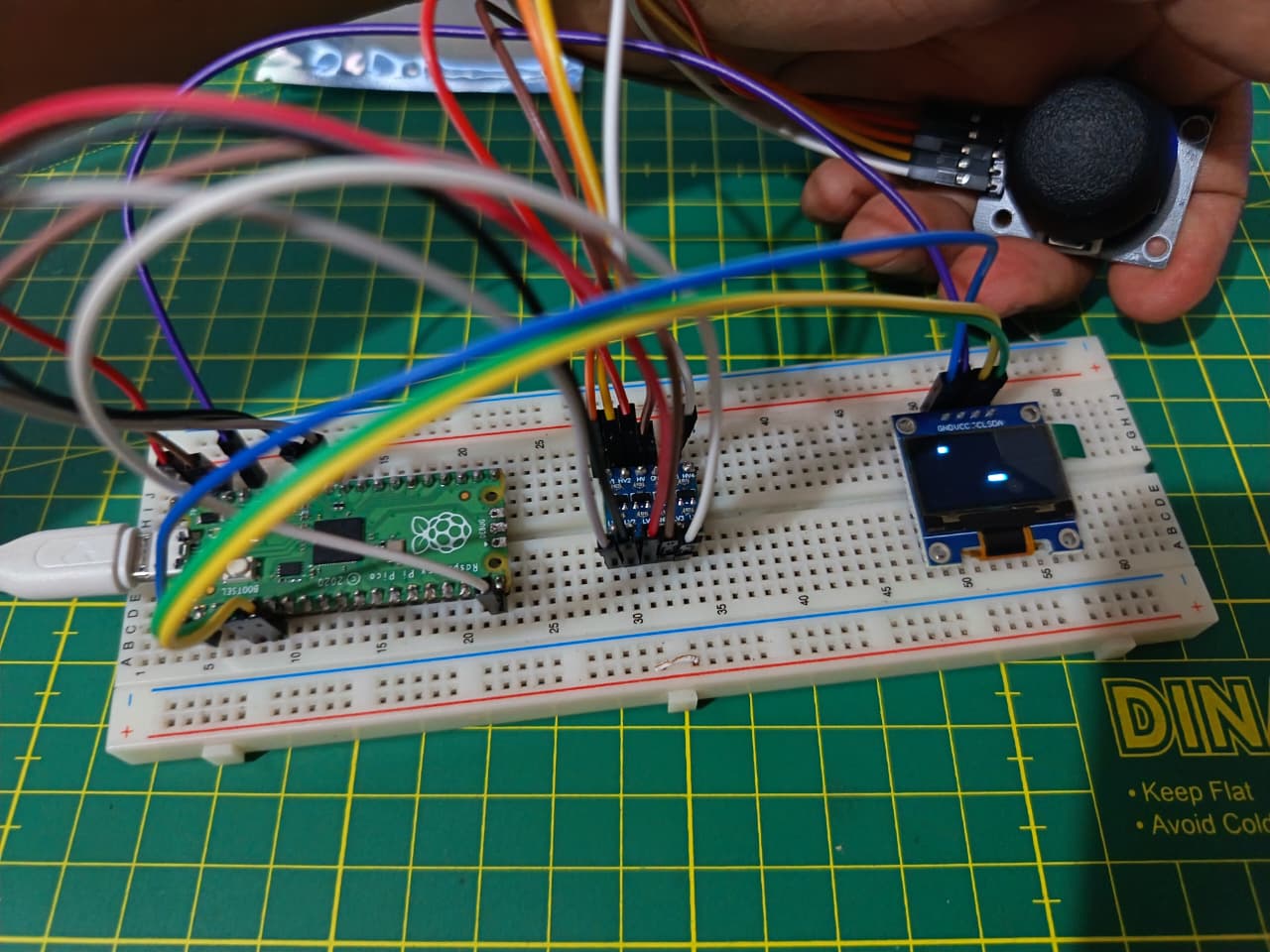

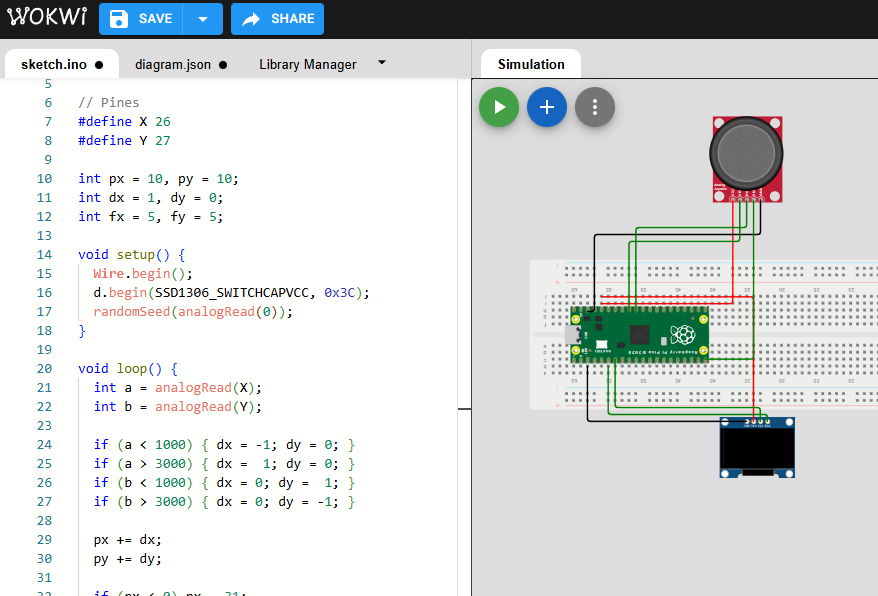

🧩 Joystick and OLED Display Simulation with Raspberry Pi Pico

This image shows a simulated electronics setup where a Raspberry Pi Pico is connected on a breadboard to a joystick module and a small OLED display. The wiring links the joystick’s power and signal pins to the Pico’s GPIO and analog inputs, allowing the microcontroller to read directional movements, while the OLED screen is connected via an I²C interface to display real-time feedback or system status. This simulation is useful for validating pin connections and interaction logic in a virtual environment before building the circuit on real hardware, reducing wiring errors and speeding up prototyping.

Code Writing

Joystick OLED Game - Arduino Code

#include <Wire.h>

#include <Adafruit_SSD1306.h>

Adafruit_SSD1306 d(128, 64, &Wire, -1);

// Pines

#define X 26

#define Y 27

int px = 10, py = 10;

int dx = 1, dy = 0;

int fx = 5, fy = 5;

void setup() {

Wire.begin();

d.begin(SSD1306_SWITCHCAPVCC, 0x3C);

randomSeed(analogRead(0));

}

void loop() {

int a = analogRead(X);

int b = analogRead(Y);

if (a < 1000) { dx = -1; dy = 0; }

if (a > 3000) { dx = 1; dy = 0; }

if (b < 1000) { dx = 0; dy = 1; }

if (b > 3000) { dx = 0; dy = -1; }

px += dx;

py += dy;

if (px < 0) px = 31;

if (px > 31) px = 0;

if (py < 0) py = 15;

if (py > 15) py = 0;

if (px == fx && py == fy) {

fx = random(32);

fy = random(16);

}

d.clearDisplay();

d.fillRect(fx * 4, fy * 4, 4, 4, 1);

d.fillRect(px * 4, py * 4, 4, 4, 1);

d.display();

delay(120);

}

By distributing the slots symmetrically and constraining them to the center of the circle, the design remains balanced and fully adjustable. This allows the same piece to be reused in different configurations, such as building a phone holder or other creative structures depending on the user’s imagination.