Week 02

Computer-Aided Design

Assignment:

This week’s task focused on developing the digital models of my final project, including 2D and 3D design, basic rendering, and visualization of the system. I also optimized images and videos to reduce file size and documented the entire process on my Fab Academy class page.

Week 02 Tasks

- I. Assignment Introduction ✅

- II. Software & Tools ✅

- III. Raster Graphics ✅

- IV. Vector Graphics ✅

- V. CAD Modeling ✅

- VI. Compressing Videos & Images ✅

- VII. Project Files ✅

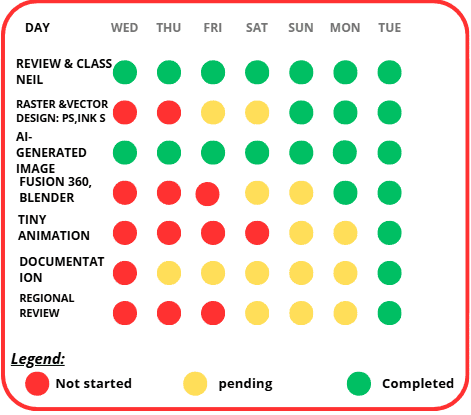

Plan of the week:

The weekly plan shows the progress of tasks from Wednesday to Tuesday, using colors to track their status: red for not started, yellow for pending, and green for completed.

At the beginning of the week, most activities were not started. As the days passed, they moved from red to yellow, and finally to green by Monday and Tuesday. Tasks like Review & Class and AI-generated image were completed throughout the week, while others such as Tiny Animation, Documentation, and Regional Review were finished at the end.

Overall, the plan shows a strong improvement during the week, with all tasks completed before the deadline.

Introduction:

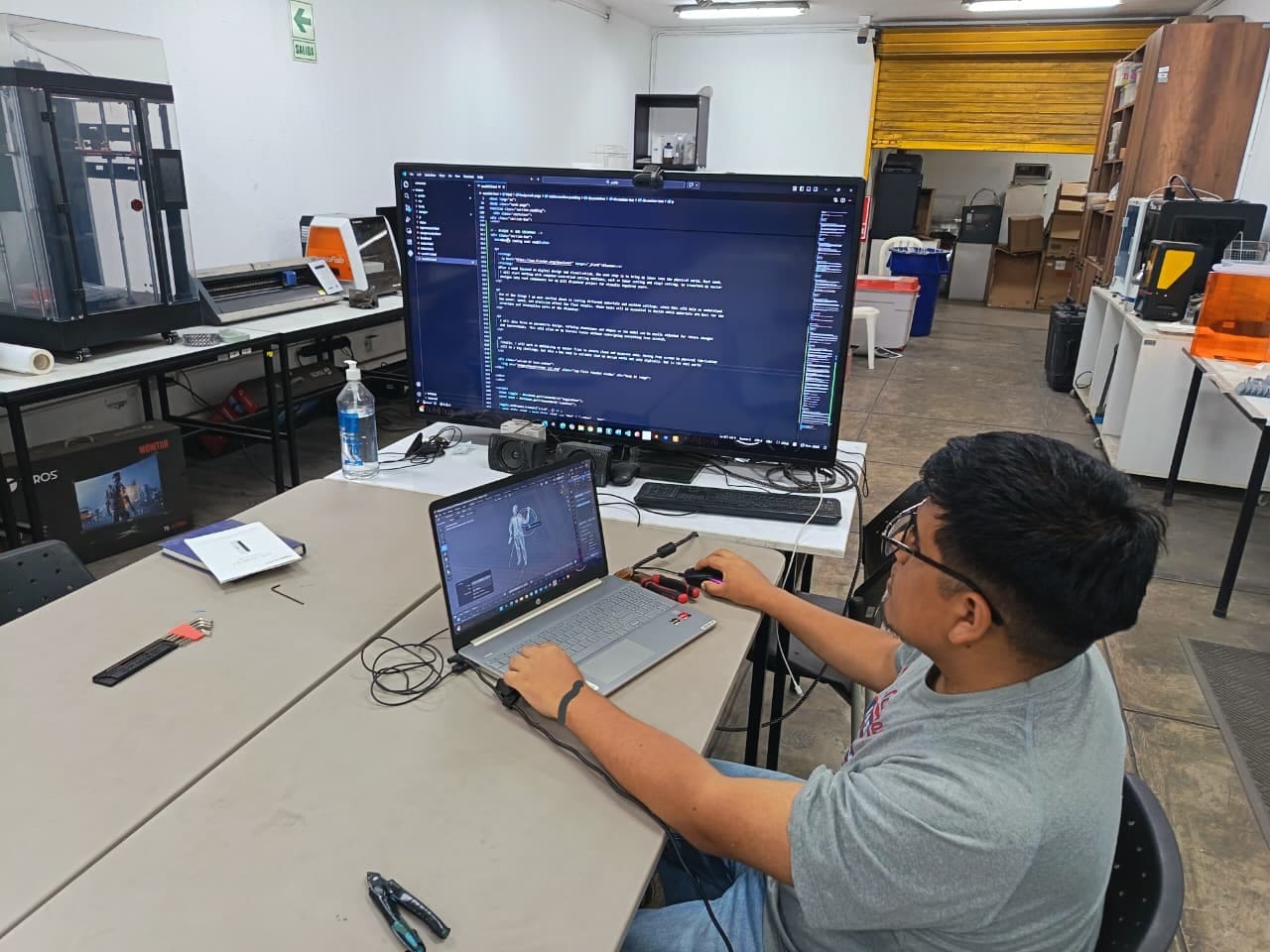

This week was focused on exploring different digital tools to visualize and refine my final project. It became a space for experimentation, where I worked with raster and vector design, 3D modeling, and basic visualization to better define my ideas.

I also rethought the approach to my project, making it more functional and accessible while keeping digital fabrication in mind. Moving from simple sketches to digital models helped me shape the concept, and switching between different tools allowed me to find the workflow that best fits my design process.

IMAGE COMPRESSOR

To optimize the images for my Fab Academy website, I used the online tool iLoveIMG This platform allowed me to easily compress my images without losing too much quality, which is important to keep the website fast and lightweight.

By reducing the file size, my web pages load faster and are easier to upload to GitLab. This also helps keep the repository organized and prevents heavy files from slowing down the site. The tool was simple to use and very effective for preparing images for web documentation.

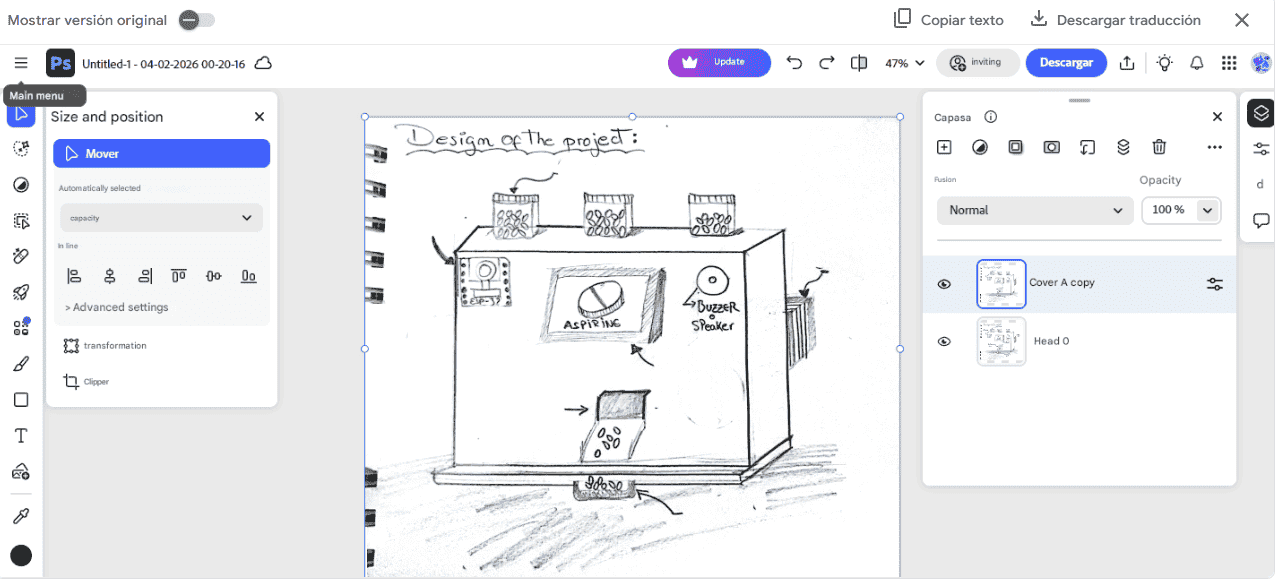

Raster Design Photoshop: Sketching and Image Editing

I began my design process using Photoshop to organize ideas, create sketches, and build moodboards as visual references for my final project. It became an important tool to refine the main concept and improve the initial sketch of my idea.

With Photoshop, I explored different compositions by combining reference images and testing layouts. I worked with selection tools, layers, blending modes, and brushes to adjust details and experiment with visual styles. The use of layers allowed me to work in a non-destructive way, making it easier to modify and refine the design without losing the original structure.

Once my main sketch was clear, I transferred it to Illustrator to continue the process using vector graphics.

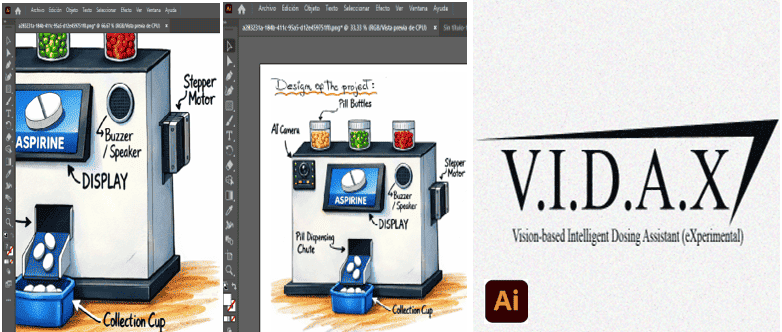

Vector Design: Illustrator & Inkscape – Clean Lines & Structure

After creating my first sketches, I used Illustrator to refine and organize them into clean vector designs. I imported my Photoshop sketches and converted them using Image Trace, then adjusted the shapes, edges, and details. I also created new illustrations from scratch with the Pen Tool.

The Pathfinder tool helped me combine and modify shapes to build more complex designs and prepare clean final files. I also tested how to integrate text into the layout, which is important since my project is an interactive learning tool.

To compare workflows, I tried Inkscape. It was useful for quick vector edits, especially for node adjustments, even though the interface felt less intuitive than Illustrator.

AI-Generated Images – Speeding Up the Process

Curious about how AI could speed up my design process, I decided to test AI-generated images to explore different visual concepts for my final project. This allowed me to quickly visualize ideas, experiment with styles, and refine the overall look before moving into detailed modeling and fabrication.

To guide the AI, I used the following prompt:

> “Using my sketch, I need you to generate a painted image of the sketch.”This helped me transform my original sketch into a more polished and artistic version, which I later used as visual reference for the next stages of the design process.

Exploring 3D Design: Blender & Fusion 360:

For my final project, a pill dispenser with artificial vision, I explored 3D design using Fusion 360 and Blender to address both functional and aesthetic aspects of the device.

In Fusion 360, I worked on the parametric and mechanical design, defining the main structure, pill compartments, and spaces for electronic components such as the camera and motors, considering measurements and assembly.

°Fusion 360 for more structured, parametric modeling.In parallel, Blender was used to explore the external form and ergonomics, allowing me to experiment with shapes and visualize a user-friendly design suitable for a medical device.

°Blender for organic shapes and animation.Using both tools helped me balance precision and creativity in the development of the project.

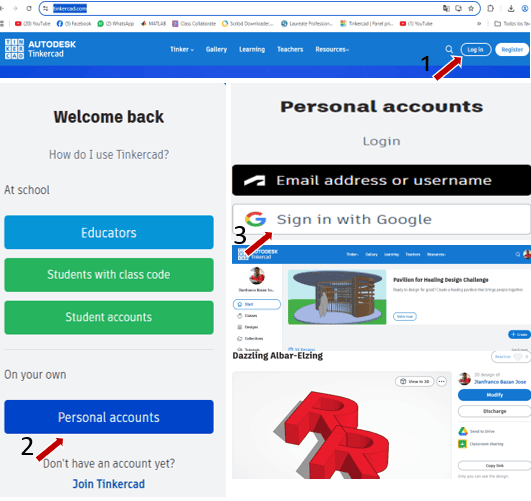

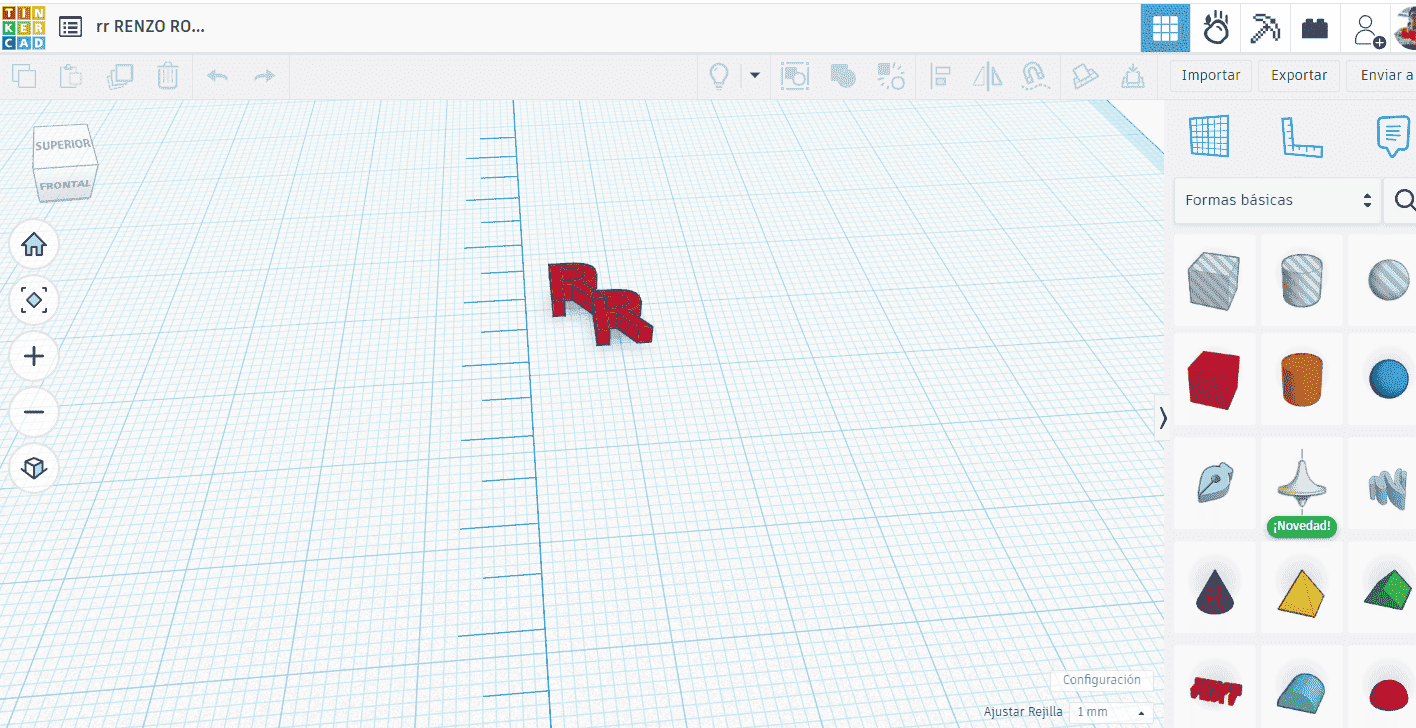

Exploring an Open Source Program: Tinkercad 3D

As part of the 3D design exploration for my final project, a pill dispenser with artificial vision, I used Tinkercad as an open-source and beginner-friendly design tool.

Tinkercad allowed me to quickly create and modify simple 3D geometries, helping me understand basic spatial relationships and component layout. It was especially useful for early concept tests and rapid iterations of simple parts related to the dispenser structure.

This tool served as an accessible introduction to 3D modeling and supported the early design stages before moving to more advanced software.

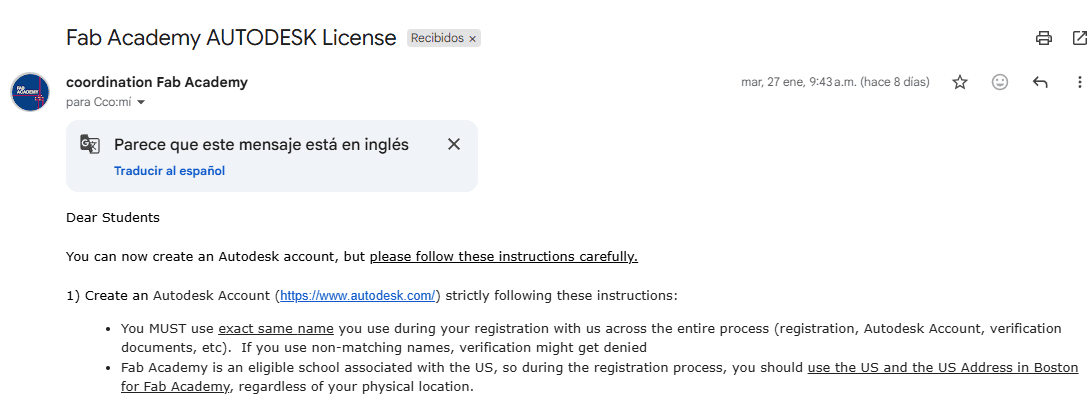

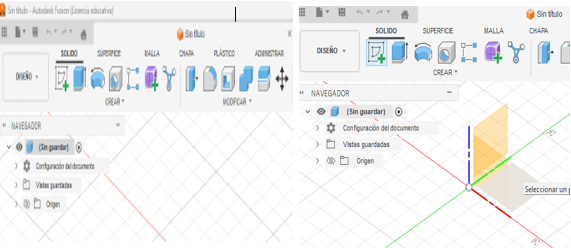

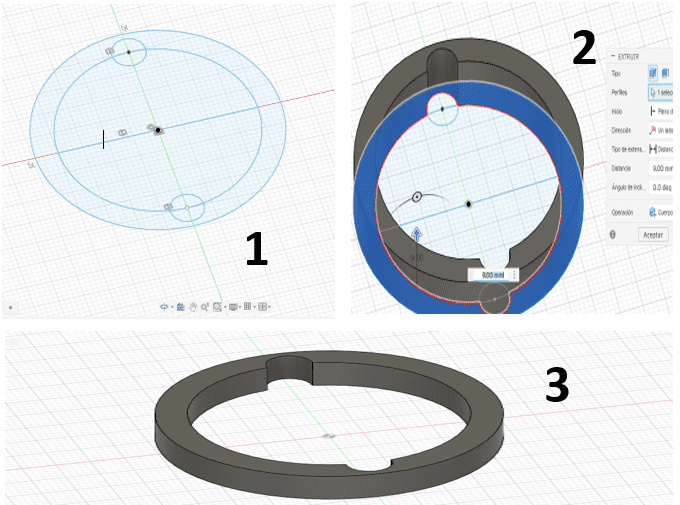

Fusion 360 – Understanding Precision & Parametric Modeling

For my pill dispenser with artificial vision project, Fusion 360 played a key role in understanding precision and parametric modeling. By using constraints, parameters, and dimensions, I designed the main structure and internal components, such as pill compartments and supports for electronic elements like the camera and motors.

Parametric modeling allowed me to easily adjust measurements and test different design variations without rebuilding the model from scratch. This was especially important to ensure proper assembly, tolerance control, and compatibility with digital fabrication processes such as 3D printing and CNC machining.

Overall, Fusion 360 helped translate conceptual ideas into a functional and manufacturable design.

Finally, the designs were exported as STL files, preparing the models for fabrication and allowing direct testing of the parts through rapid prototyping.

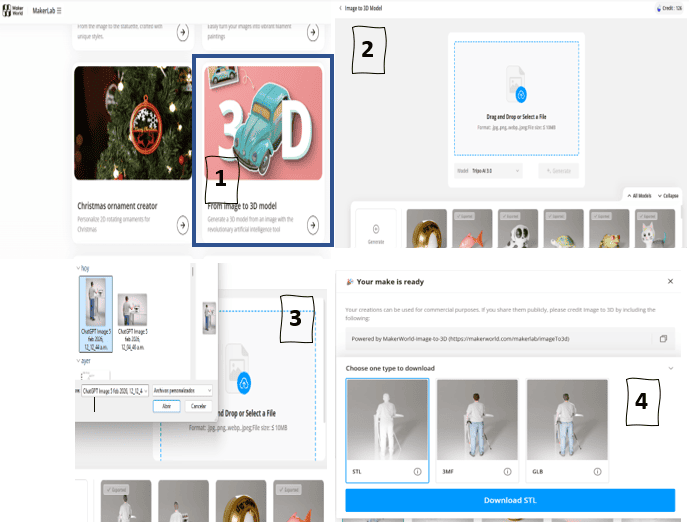

Image to 3D Model

To achieve a more realistic representation of my pill dispenser with artificial vision, I used ChatGPT to generate a realistic image based on a hand-drawn sketch of the project. This step helped me better visualize proportions, details, and the overall form of the device before moving into 3D modelin

Once the realistic image was generated, I used the MakerWorld platform, which provides an image-to-3D model feature. This tool allowed me to convert the generated image into a basic 3D model, serving as a starting point for further refinement.

>This workflow helped bridge the gap between concept sketches and 3D modeling, speeding up the design process and providing a visual reference for later adjustments in CAD software.

Blender – Animation

Blender was the tool where my project really started to come to life. My goal was not only to model elements of my final project, but also to animate them, so I began by testing simple movements, such as how the pages of my concept could flip.

I started with basic shapes like planes and cubes to represent the structure of my design. Then, I explored Blender’s animation tools and used keyframes to control rotation and movement.

To continue improving my animation, I plan to add an armature (bones) to my 3D model. This will allow me to create a scene where a blind user approaches the pill dispenser and shows the medical prescription, making the interaction more realistic and meaningful. You can see a tutorial here.

This process helped me understand how animation can be used to simulate real use and communicate the purpose of my final project.

.png)

Final Thoughts

This week helped me clearly visualize my final project and understand how each digital tool plays an important role in the design process. Moving from hand sketches to raster design, vector graphics, 3D modeling, and animation allowed me to shape my idea into something more concrete, functional, and visually clear.

Learning to use Photoshop and Illustrator was a key part of this process. Photoshop helped me improve and refine my initial concept, while Illustrator allowed me to transform those ideas into clean vector designs. Through Illustrator, I also designed the logo and name of my project, which gave it a strong visual identity and made the concept feel more real and professional.

For the 3D development, I started by using Tinkercad to take my first steps in 3D design and understand basic modeling concepts. Then, I moved to Fusion 360, where I created the main 3D design of my pill dispenser, focusing on dimensions, structure, and fabrication feasibility.

To make my idea more realistic, I also used ChatGPT to generate visual representations of both the concept and the prototype. After having a more realistic 3D reference, I used MakerLab from MakerWorld, specifically the “From Image to 3D Model” option, to generate a first 3D model directly from the image.

Once I had this model, I imported it into Blender, where I added bones (armature) to the character and components. This allowed me to start creating a 3D animation in which a blind user approaches the dispenser and shows the medical prescription. Step by step, this process is helping me build a more engaging and realistic interaction.

Working with all these tools taught me that design is an iterative process. Each step revealed new details, improvements, and challenges that pushed me to rethink parts of my project. This constant refinement helped me better understand how users—especially blind users—will interact with the system.

Overall, this experience strengthened my confidence in digital fabrication and design workflows, and motivated me to continue developing my intelligent pill dispenser into a functional, accessible, and meaningful product.

Files

Here are the project files available for download:

- Blender File: Download .blend

- Illustrator Vector Design: Download .ai

- Photoshop File: Download .psd

- Tinkercad File: Download .stl

- Fusion 360 File: Download

What’s coming next week?

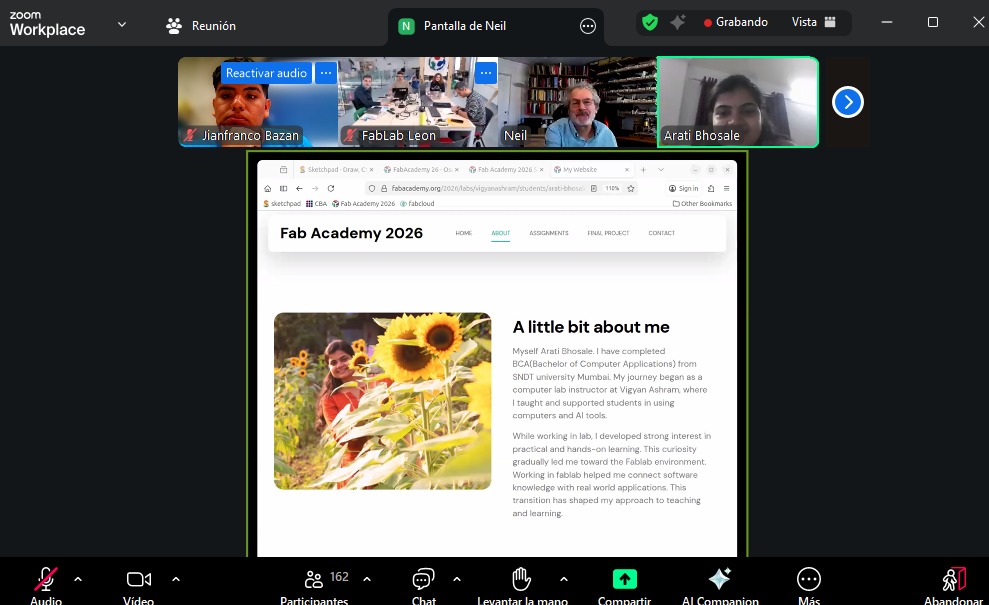

After a week focused on digital design and visualization, the next step is to bring my ideas into the physical world. Next week, I will start working with computer-controlled cutting machines, such as laser cutting and vinyl cutting, to transform my vector designs into real components for my pill dispenser project for visually impaired users.

One of the things I am most excited about is testing different materials and machine settings, since this will help me understand how power, speed, and precision affect the final results. These tests will be essential to decide which materials are best for the structure and interactive parts of the dispenser.

I will also focus on parametric design, refining dimensions and shapes so the model can be easily adjusted for future changes and improvements. This will allow me to iterate faster without redesigning everything from scratch.

Finally, I will work on optimizing my vector files to ensure clean and accurate cuts. Moving from screen to physical fabrication will be a big challenge, but also a key step to validate that my design works not only digitally, but in the real world.