1. Group Assignment

This week I meet our first team project ,and the initial hands-on experience with Laser cut equipment.

Our team's task is to design planar serrated objects for cutting and measurement, in order to calculate the error margin of the laser cutting machine at Chaihuo FabLab.

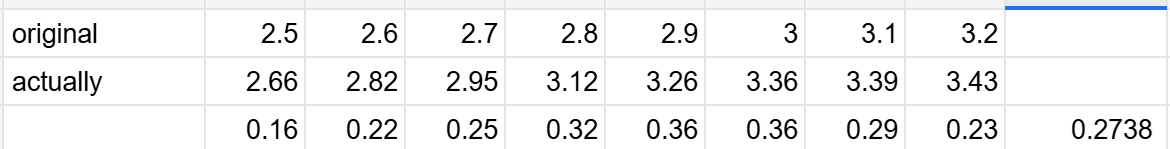

1.1 Laser Machine

The laser cutting machine in the Chaihuo FabLab is CMA1610

1.2 Design

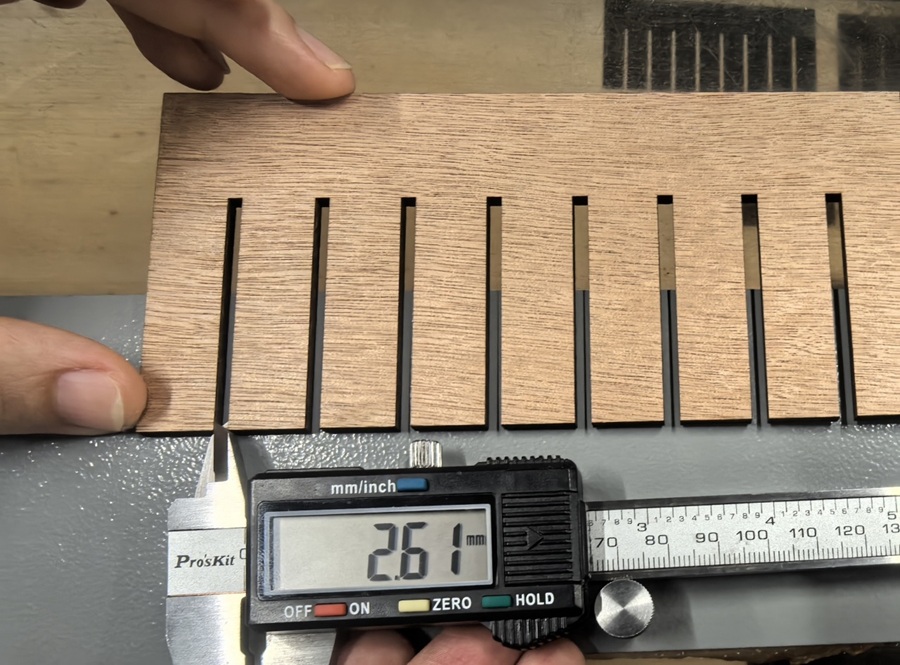

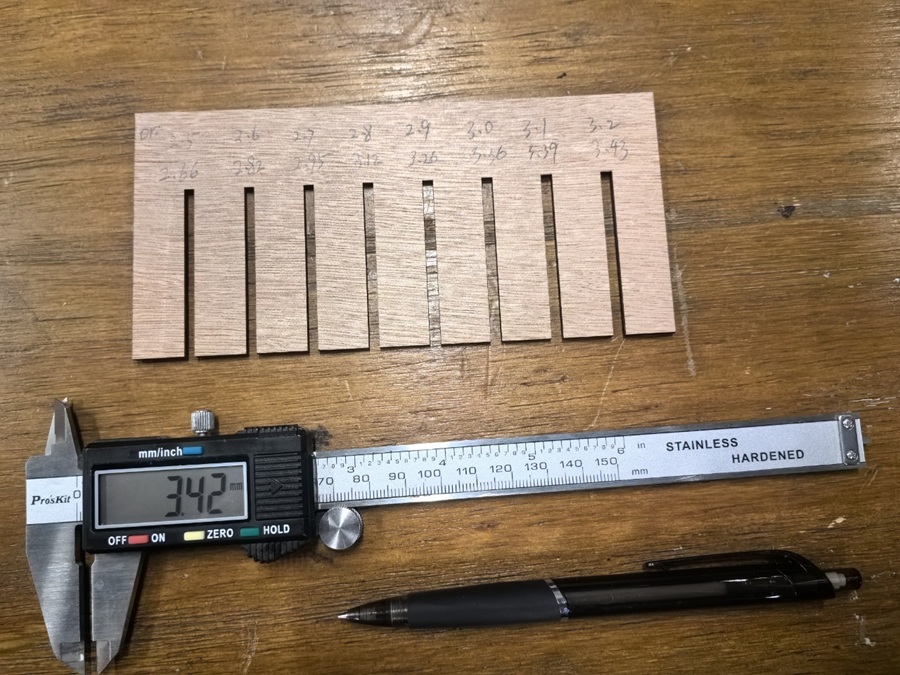

We designed a serrated object with teeth spacing gradually increasing from 2.5mm to 3.2mm, scaled at 1mm intervals.

1.3 Cutting

1.3.1 Setting Parameters

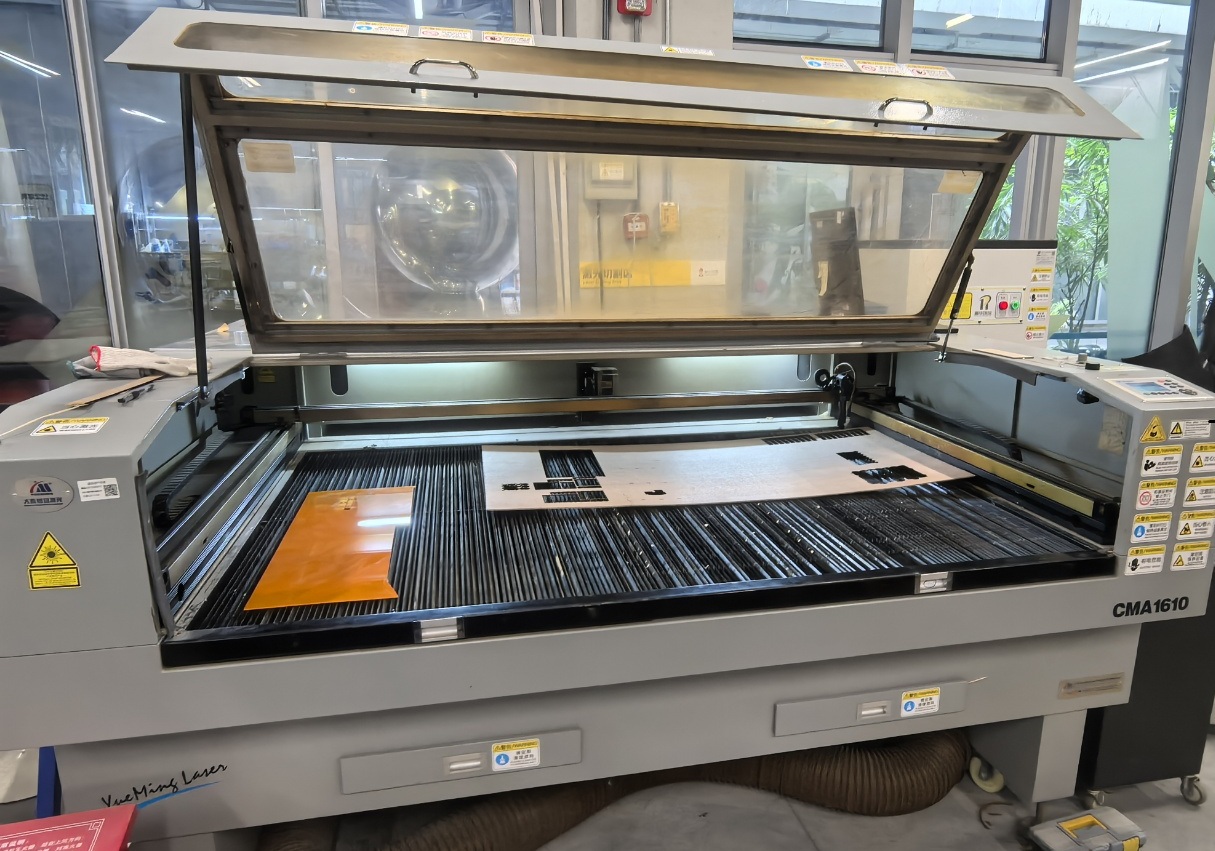

According the following settings, we can setting the parameters in laser cutting machine.

| Parameters | Panel |

|---|---|

|  |

We set the parameters of the laser cutting machine as follows:

- Material: Basswood

- Laser Power: 50

- Laser Strength Percentage: 60%

- Laser Speed: 30mm/s

1.3.2 Cutting Object

We use the control panel to manage the cutting process.

First, we use Reset to clear the previous cutting data.

Second, we use Frame to preview and simulate the cutting range.

Third, we use Start-Pause to begin the cutting process.

Finally, after the cutting is complete, we use Stop to end the process.

1.4 Calculation

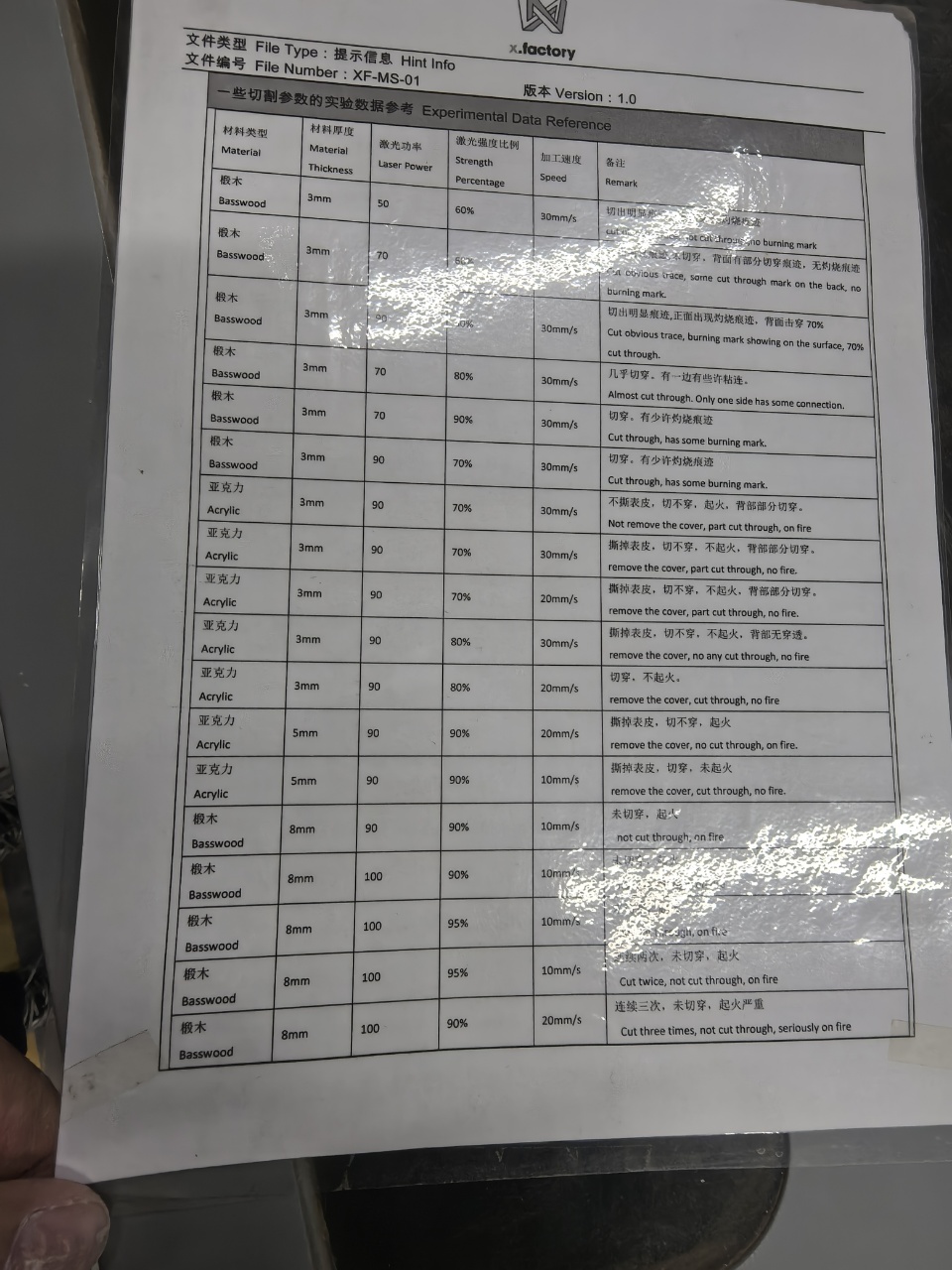

| Calculation | Calculation result |

|---|---|

|  |

1.5 Conclusion

The error margin of the laser cutting machine is 0.2738 mm.