This week I worked on making a mold and casting with it. I used a food safe mold so I could make a chocolate cast!

Group Assignment

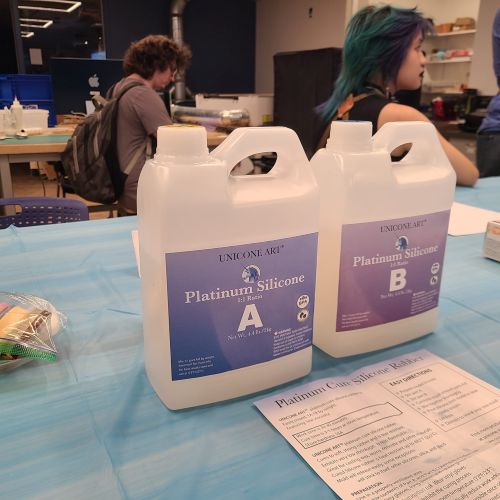

This week we learned about molding and casting. We learned how to make a mold using a SLA Resin Printer, or using a CNC machine to mill a wax block. We also learned how to cast using a silicone mold, and the various ratios required in mixing parts A and B of the silicone mixtures to obtain the perfect chemistry for mixing. While the rest of the class worked with normal molds, I had a pre-purchased DND dice mold that I used.

Process for making Mold

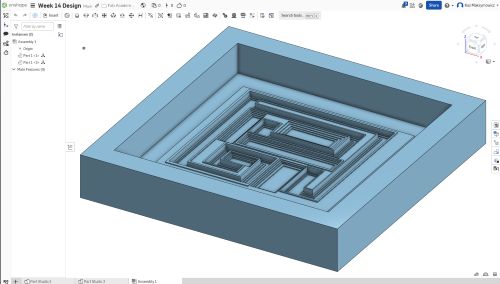

I decided that I would use an SLA Resin Printer to design my mold. I first modeled it on Onshape, the superior 3D design platform.

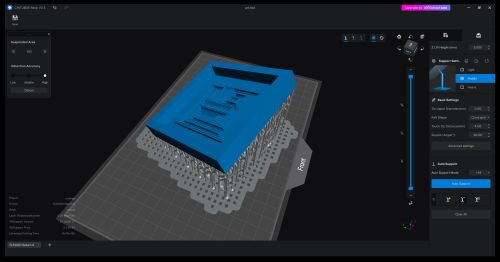

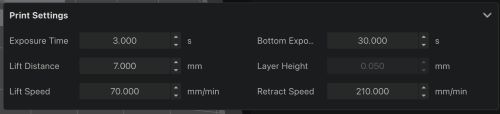

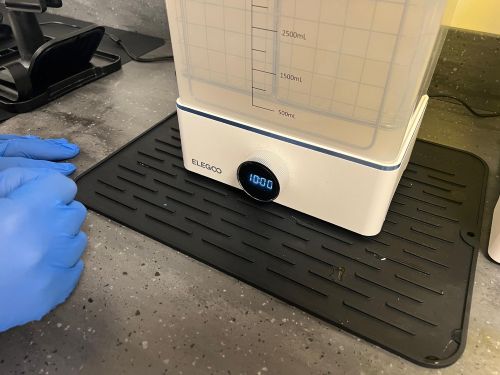

Then I loaded it into ChitubBox, the slicer software for my printer. I used Elegoo's Saturn S printer, which is a great printer for SLA resin printing. I used the default settings for the printer, but I changed the exposure time to 3 seconds, and it worked wonderfully. I also used ABS Resin.

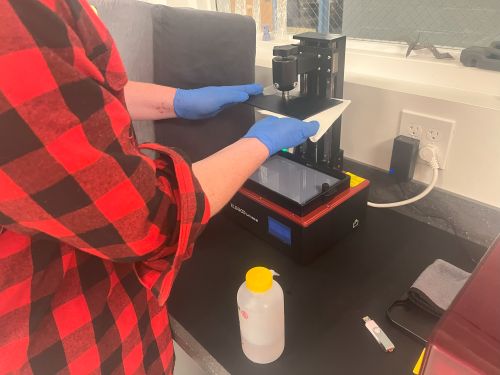

Then, I prepped the printer to be used. I had to clean the underside, which was easy. I also had to make sure the resin in the bed wasn't overflowing.

Then I removed the print from the bed, and put it in the isopropyl cleaner for 10 minutes

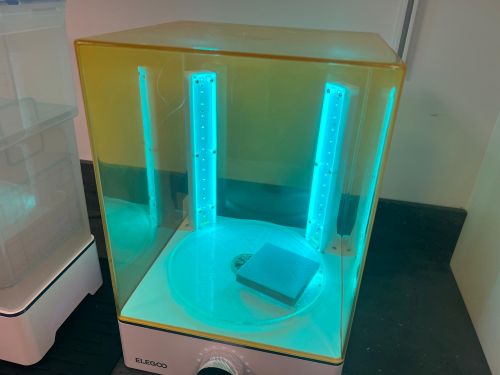

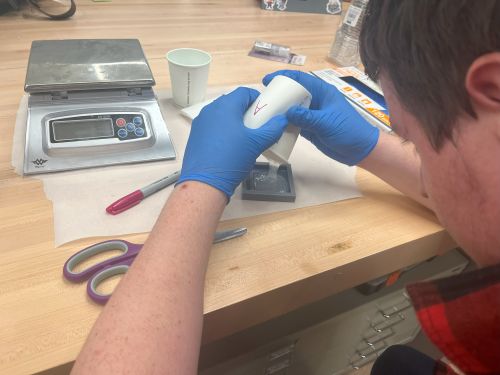

After cleaning it, I removed the supports and put it in the curing station to cure.

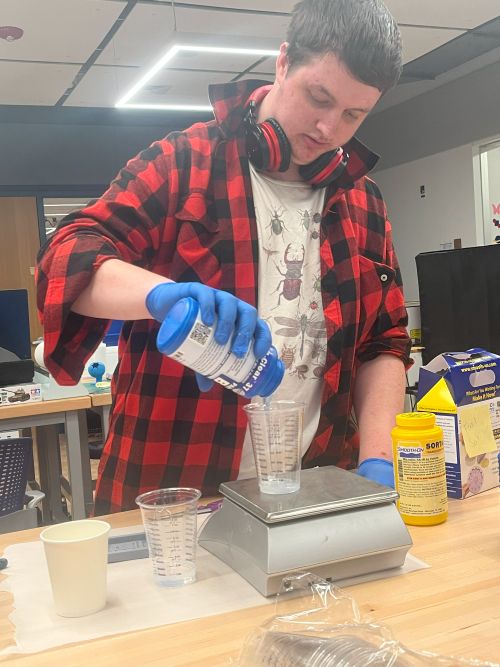

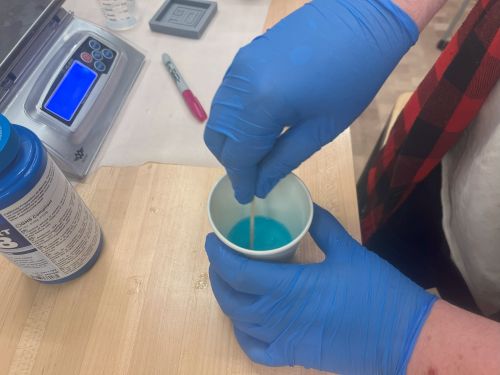

After curing, I took the print out to the table and began the process of mixing Parts A and B into one cup, which I then poured into the mold. The specific ratio was 1:1 by volume, which is to say 1 cup of Part A for every 1 cup of Part B and vice versa.

However, after all thatt work, my mold didn't set right. I think that I got the initial mixture wrong, but to shift the blame from my failure to mix properly, I will consider it a failure of the fact that I used SLA Resin for my casting material. Silicone has a unique interaction with SLA resin, and it can cause the silicone to not set properly. This is called "inhibition" and it is a common problem when using SLA resin for casting. I tried to prevent this by utilizing a mixture of IPA and Dishsoap as a release agent, but I don't think it worked.

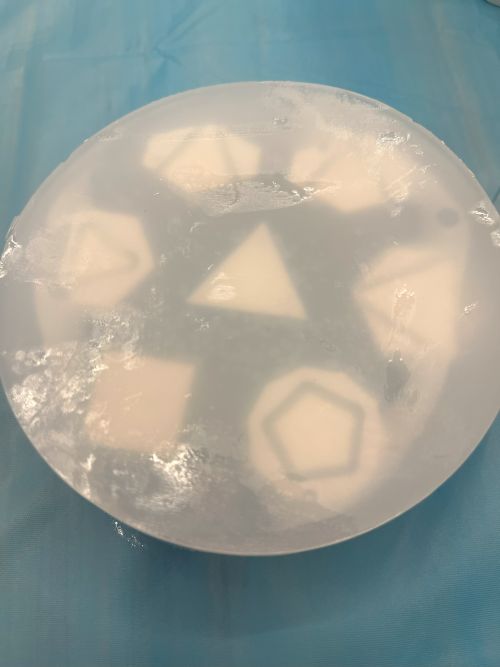

I attempted this mold again, but this time to prevent any mixture failures, I didn't use two separate cups, as I believe some of the mixture parts went missing on the sides of the wall, and my attempts to scrape it off were unsucessful. Instead, I poured directly into the same cup, mixed it, and then poured it into the mold. This was the result of that attempt

This one came out much nicer then the last one. Its firm and solid, not goopy like the last one.