Learning Experience

I gained practical experience in computer-controlled cutting, focusing on laser and vinyl cutters. I learned about safety protocols, machine optimization, material compatibility, and design preparation. Additionally, I gained insights into maintenance procedures, laser curve measurements, and troubleshooting. While teaching others how to use the vinyl cutter, I also shared knowledge about materials. I paid special attention to 2D design, which allowed me to design and cut with precision.

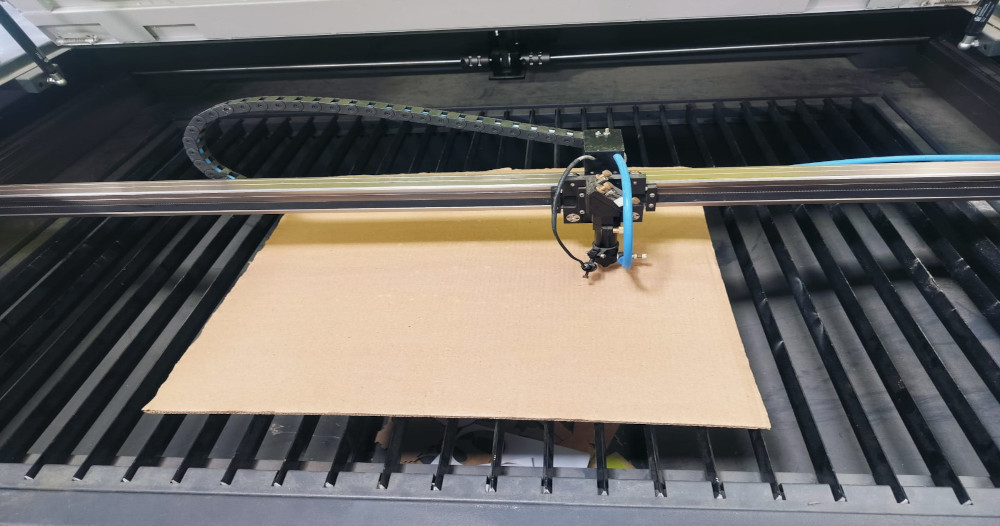

Laser Cutter

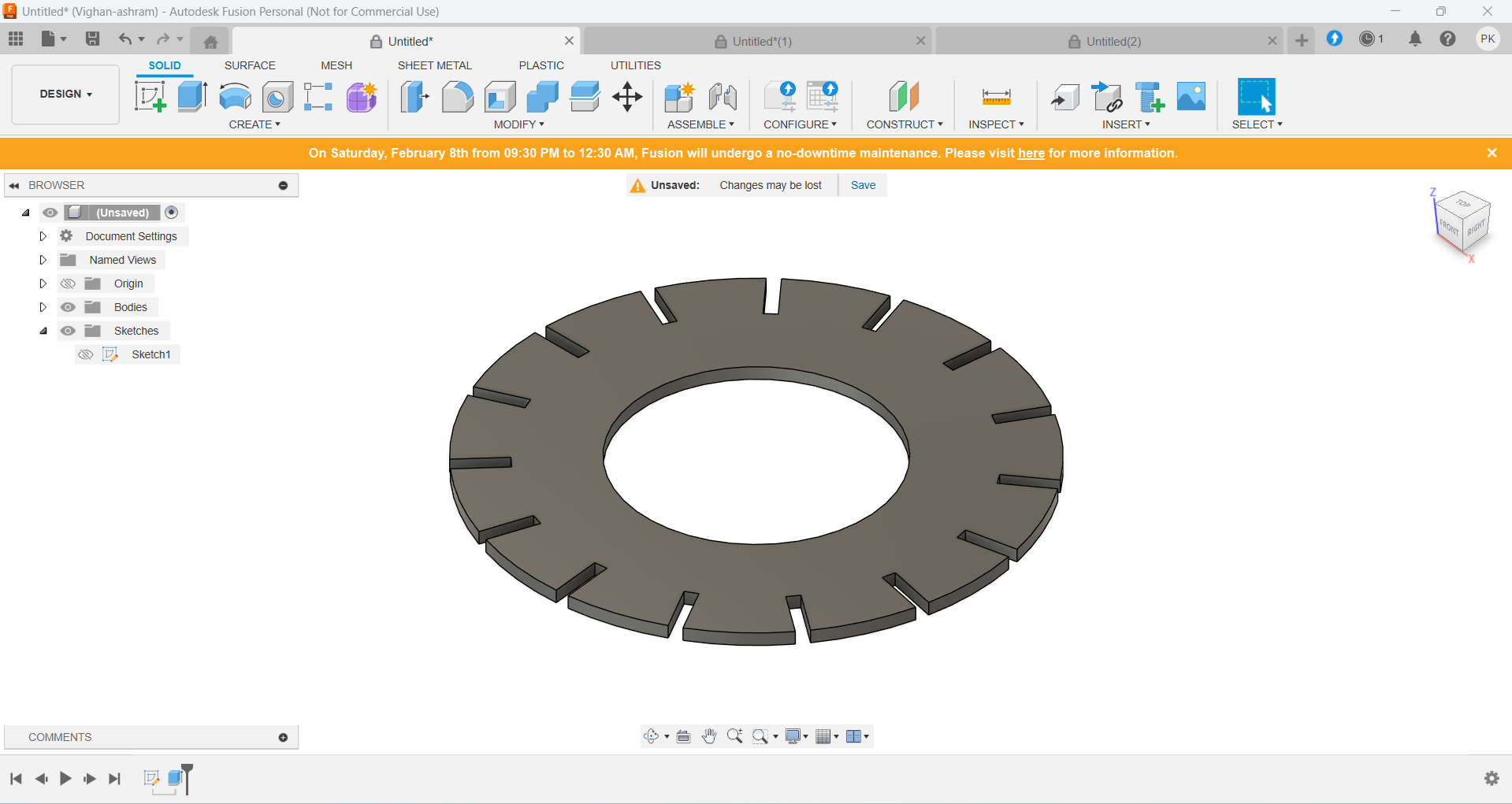

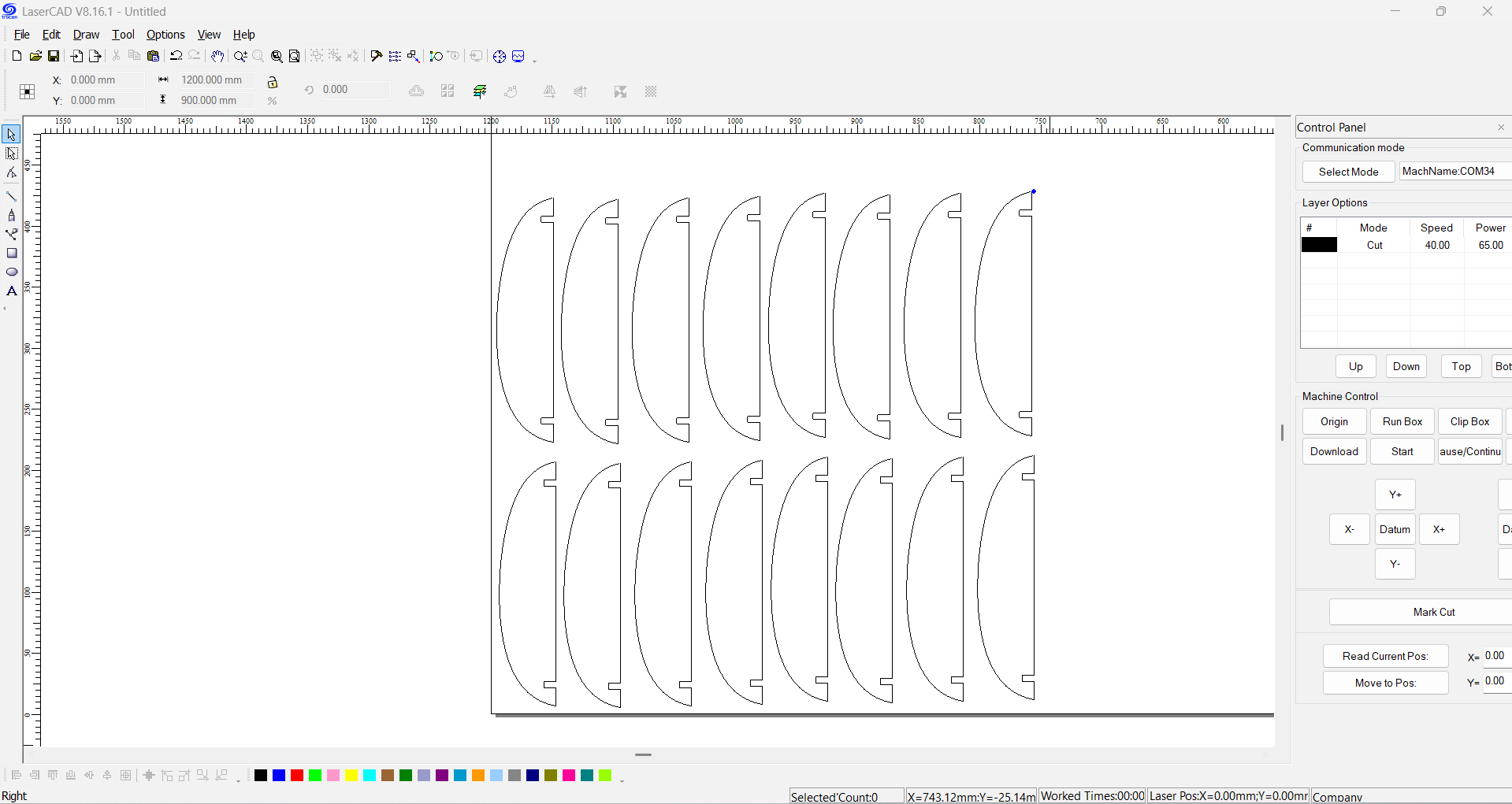

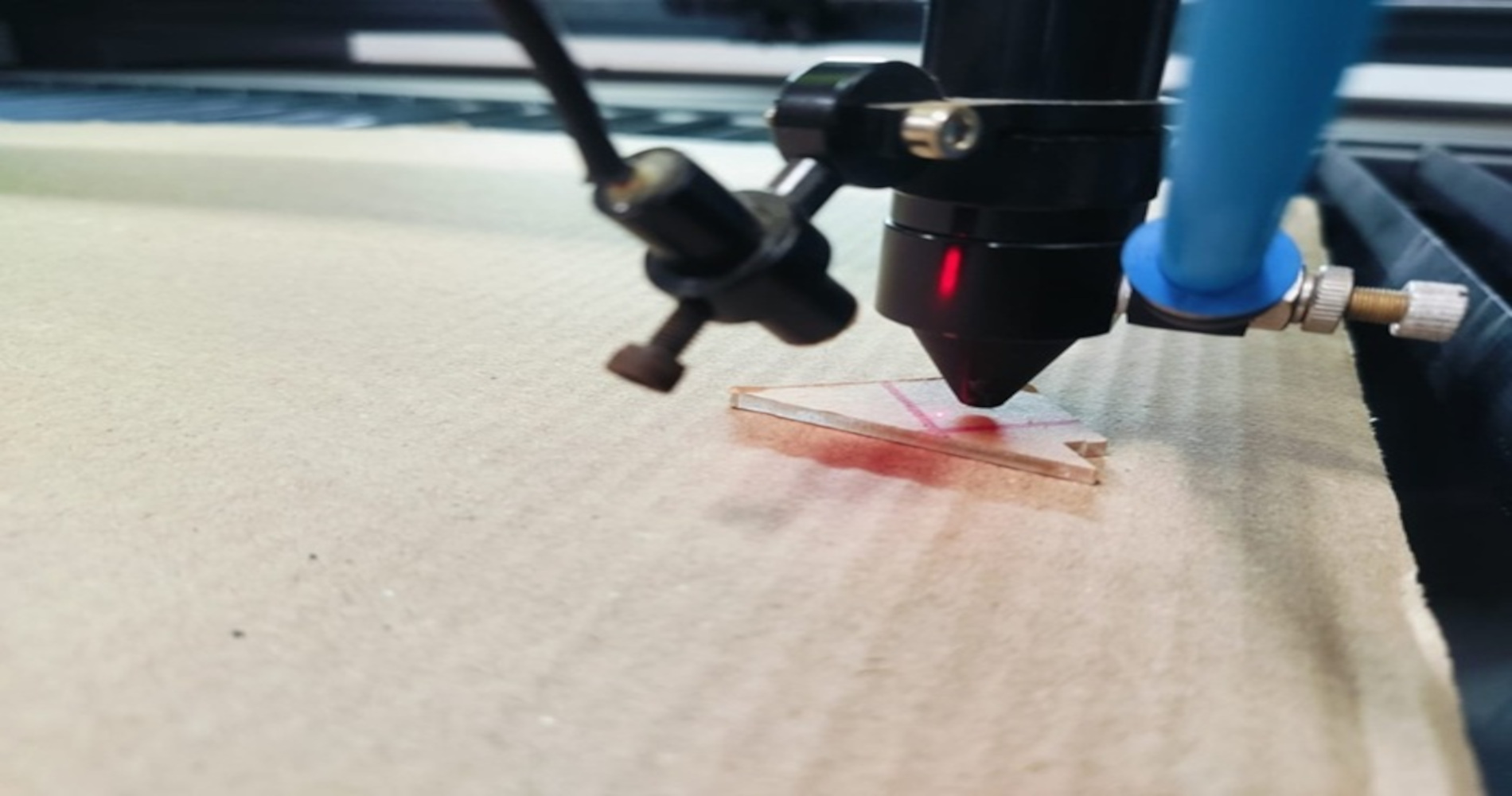

A laser cutter is a strong machine that cuts or engraves many materials, including leather, fabric, acrylic, and wood, using a concentrated laser beam. To accomplish the incision, the laser travels through mirrors and lenses before melting or burning the material. Laser cutting is quick, precise, and capable of handling intricate designs. It is frequently utilized in sectors like textiles, arts and crafts, industry, and signage. The majority of laser cutters are best suited for non-metal materials, and their maximum thickness is limited. Additionally, laser cutting minimizes material waste. My parametric design will be cut with a laser cutter.

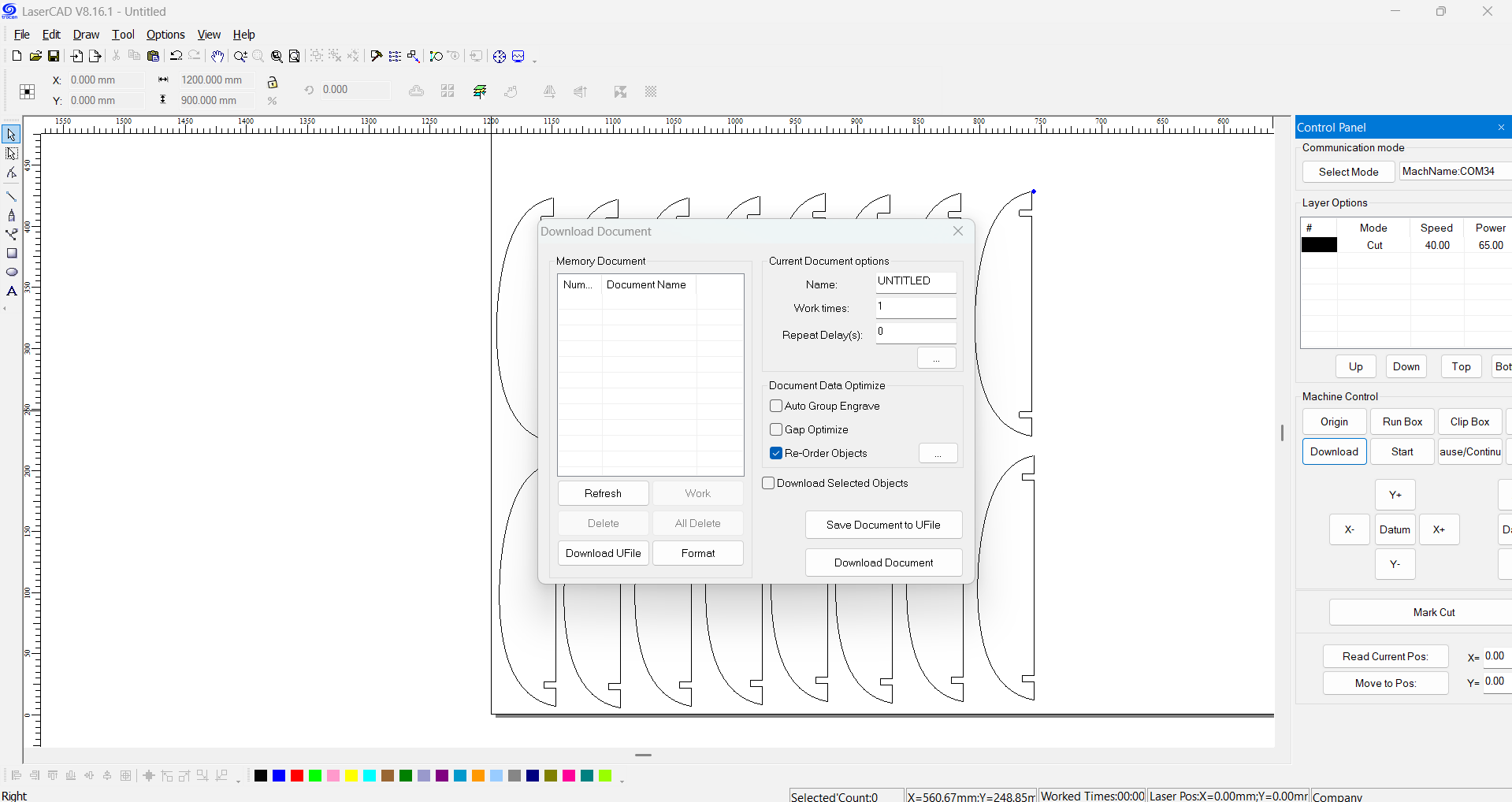

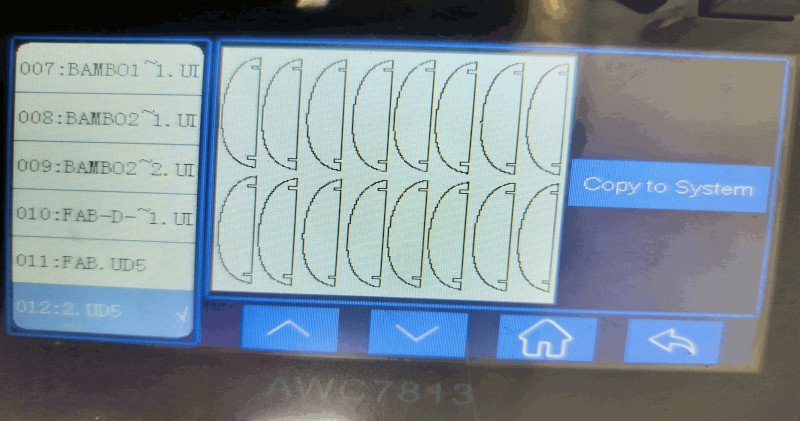

Parametric Design & Laser Cutting

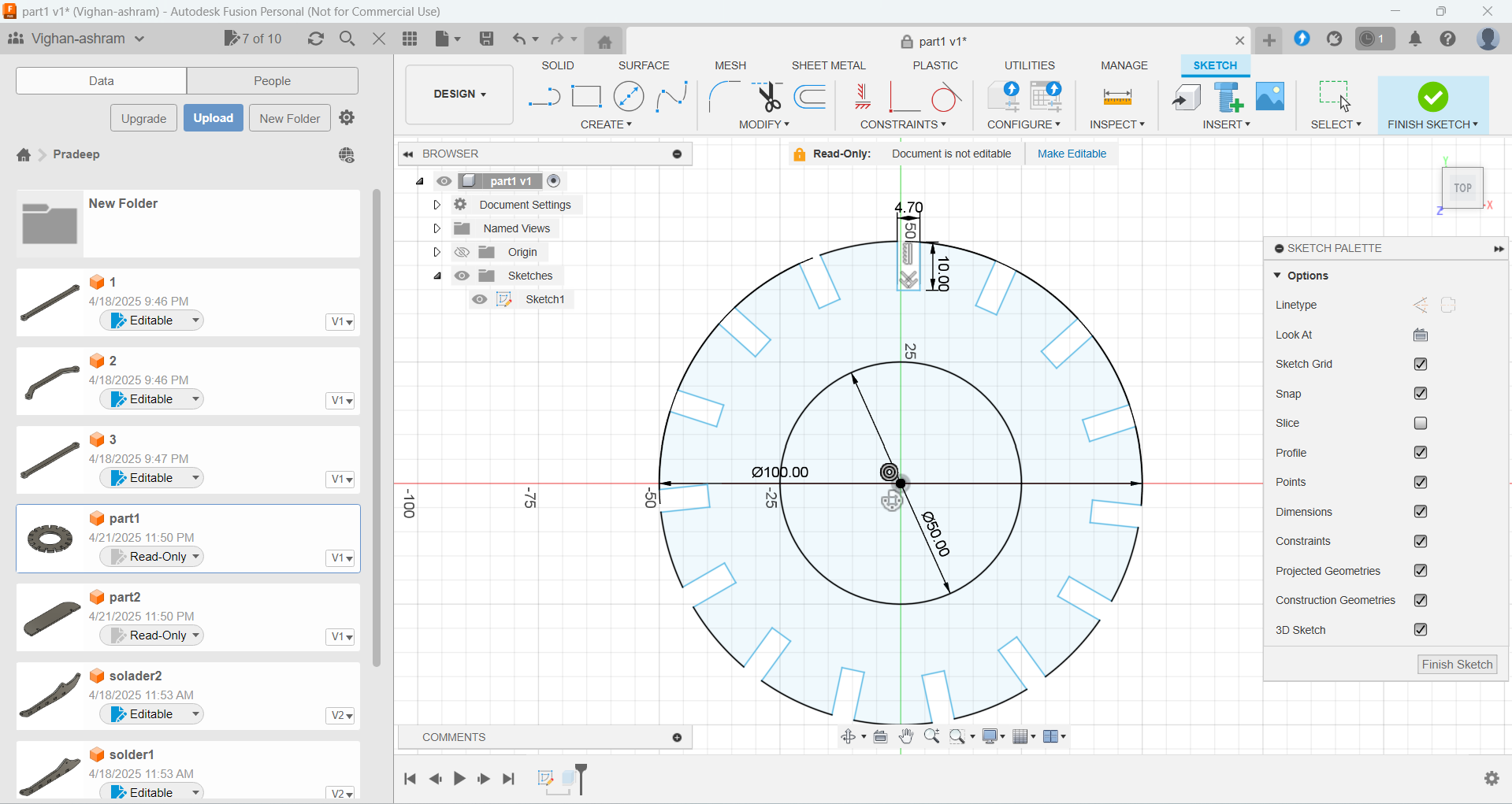

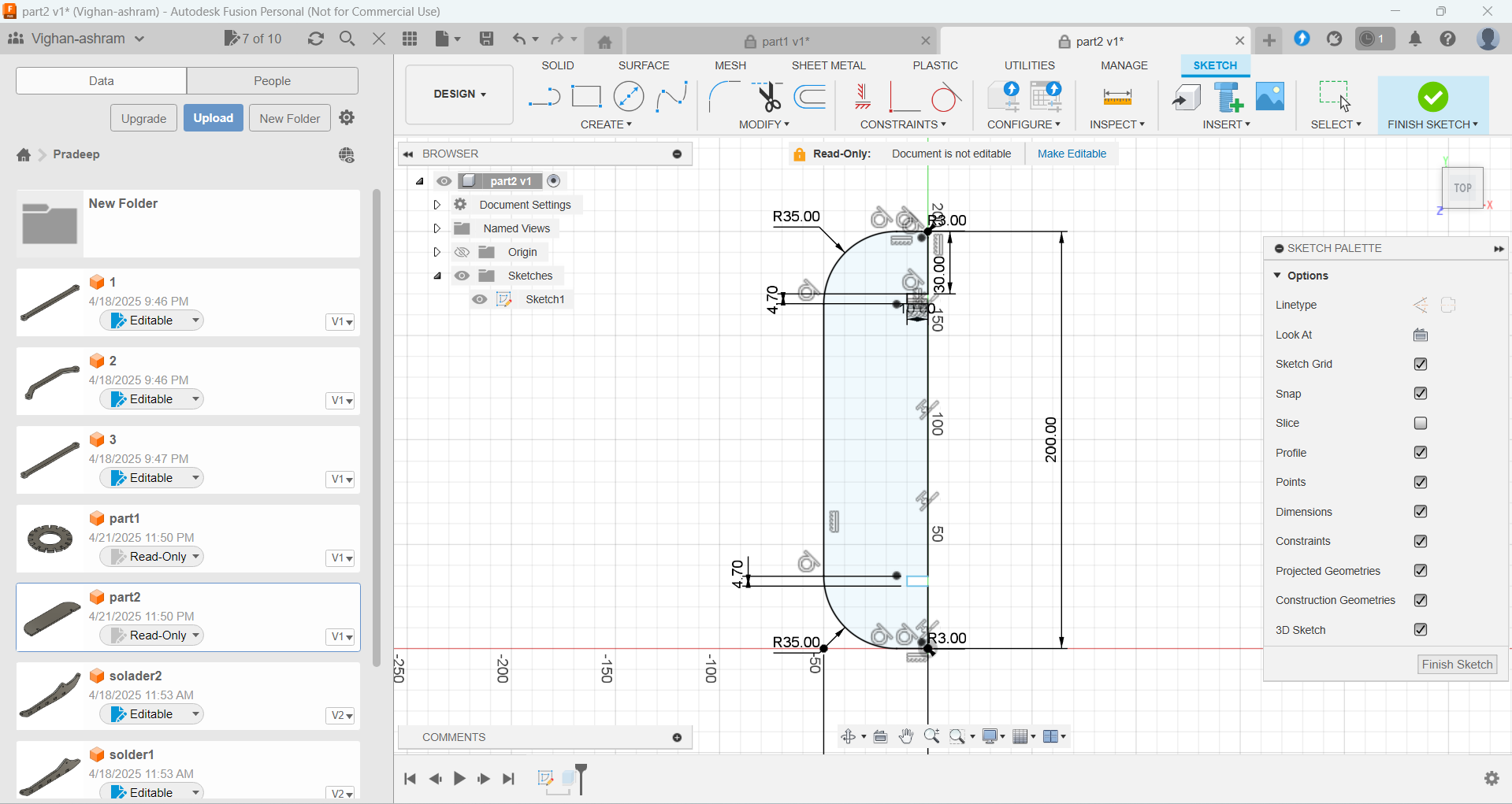

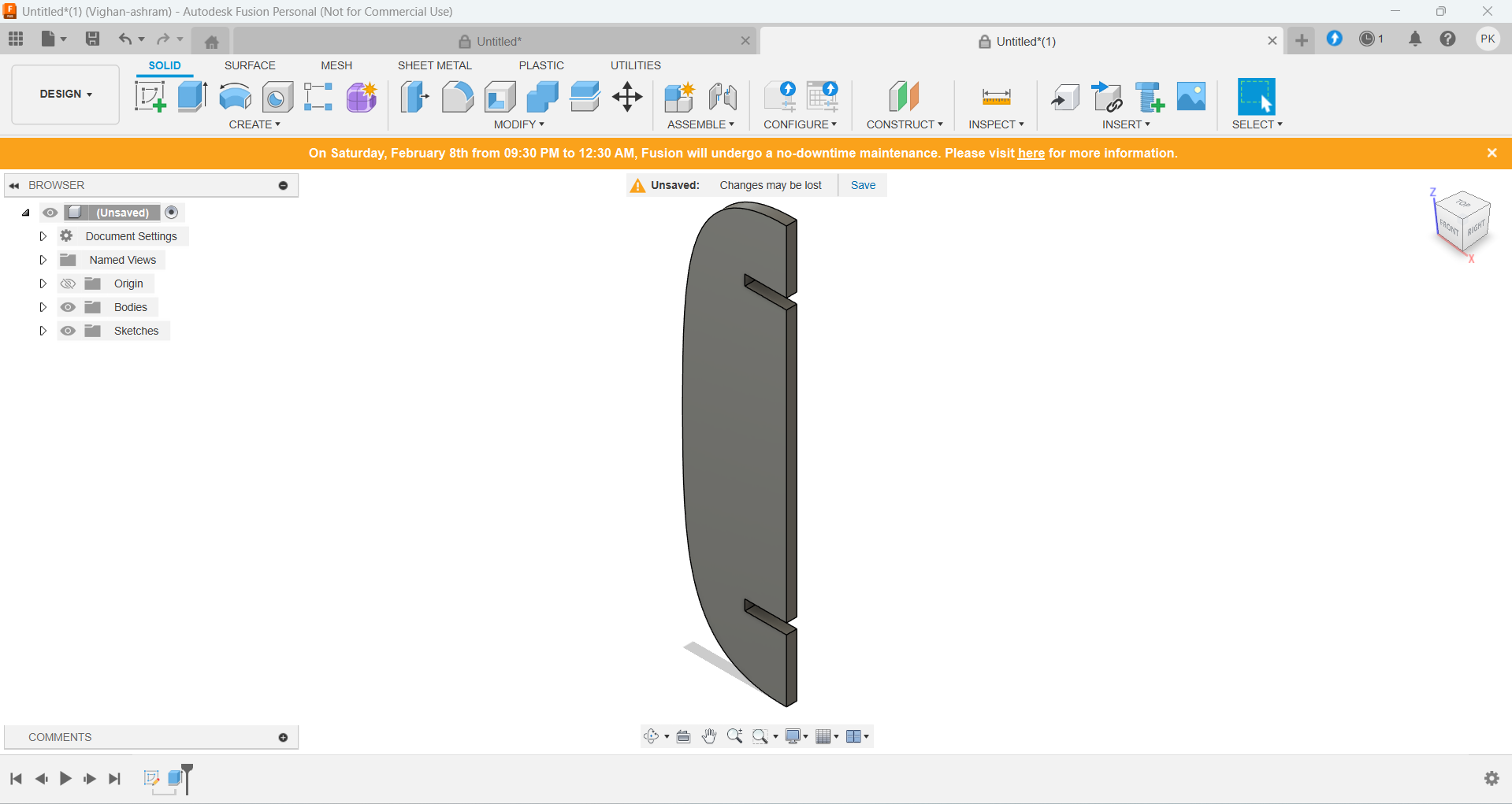

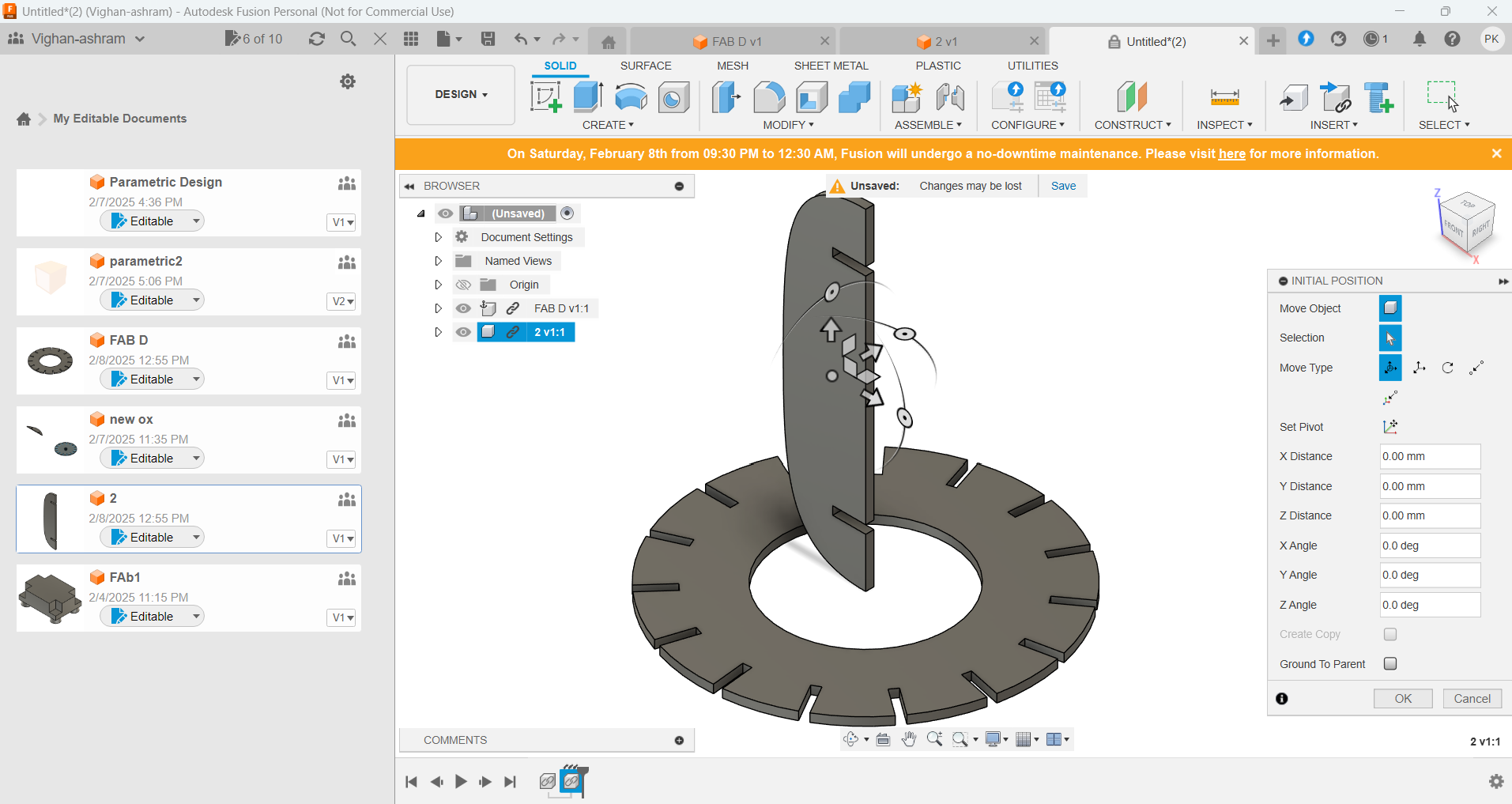

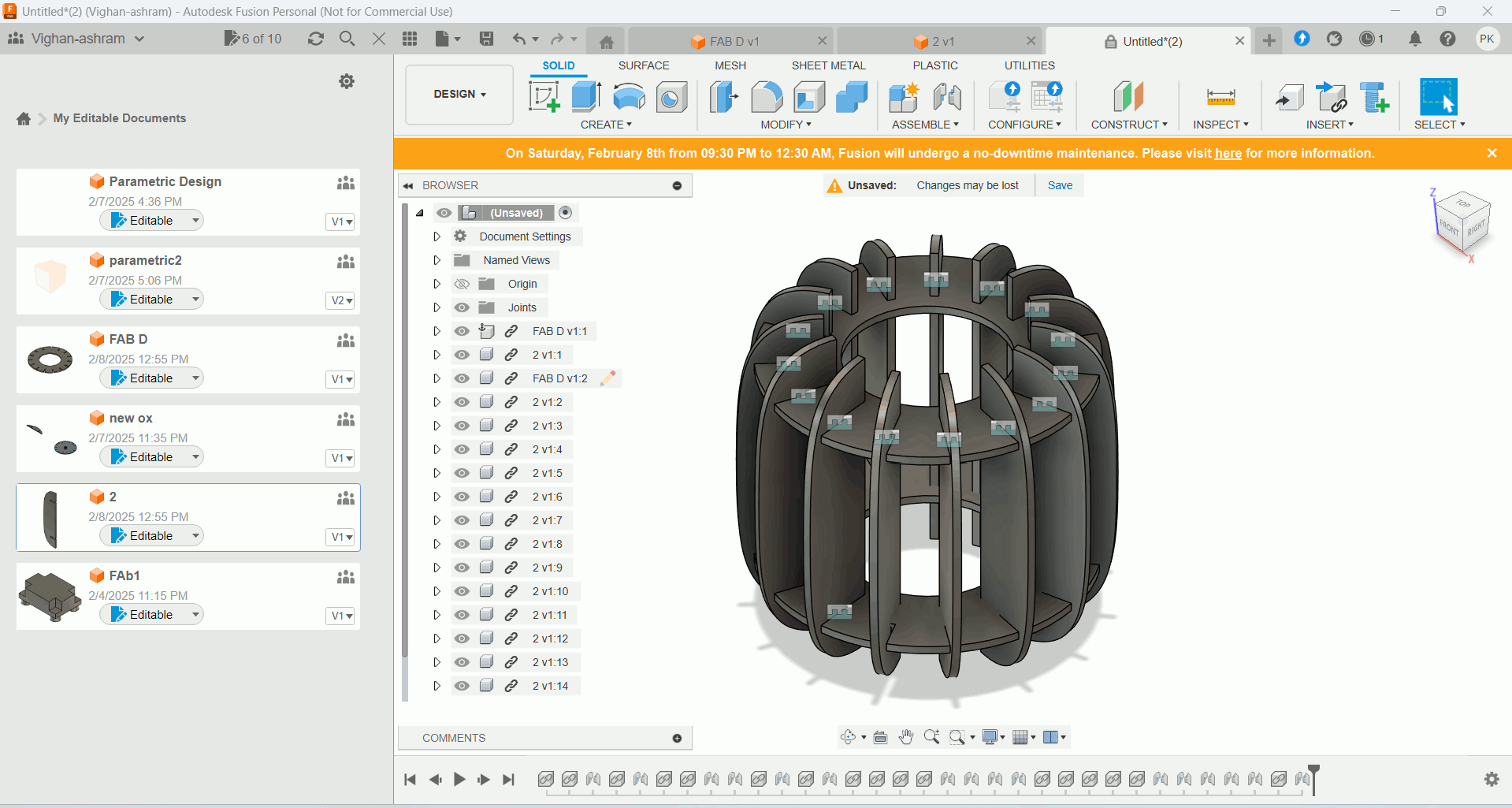

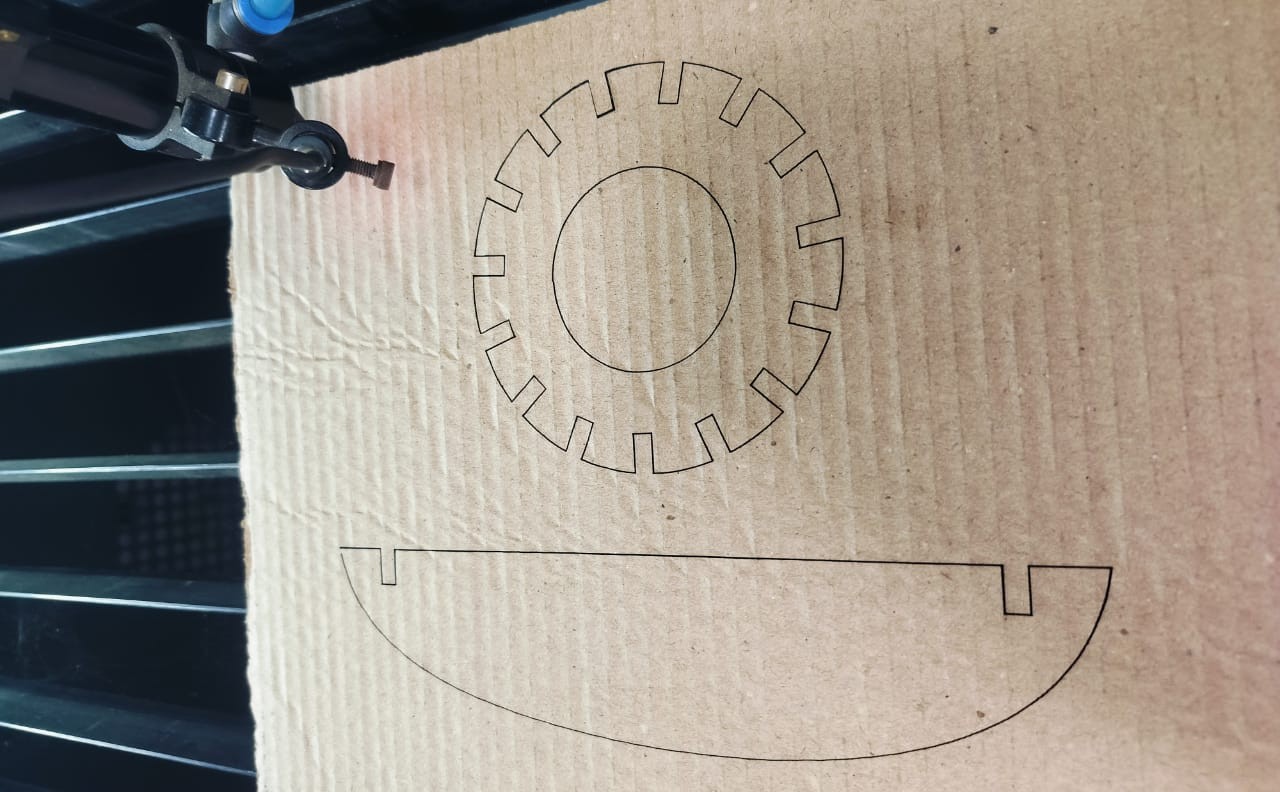

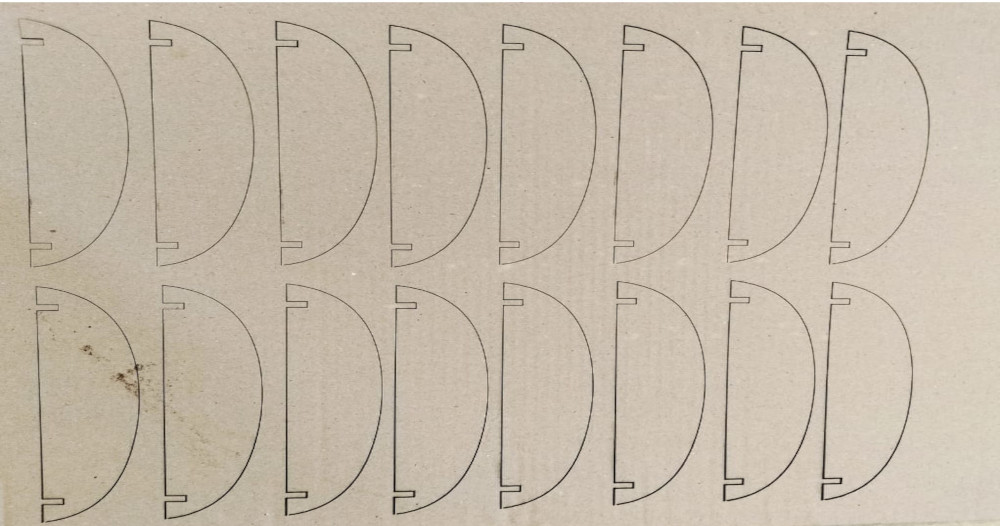

For my parametric design assignment, I chose to create a circular lamp that could accommodate an LED bulb. To bring this idea to life, I used Fusion 360 to develop a parametric model of the lamp. The completed design can be seen below.

Kerf in Parametric Design & After Laser Cutting

I used 5mm cardboard and implemented the press-fit technique for my design. During our group activity, I performed a kerf test and found the kerf value to be approximately 0.62 mm using 50 speed and 20 power settings. Based on this outcome, I updated the design parameters to achieve accurate and secure joints after laser cutting.

.png)

Used 4.70 mm press-fit in Part One to ensure tight joints.

.png)

Applied 4.70 mm press-fit again in Part Two for consistency.

|

Kerf observed in Part One was approximately 0.60 mm.

Similar kerf value of around 0.60 mm was recorded in Part Two.

|

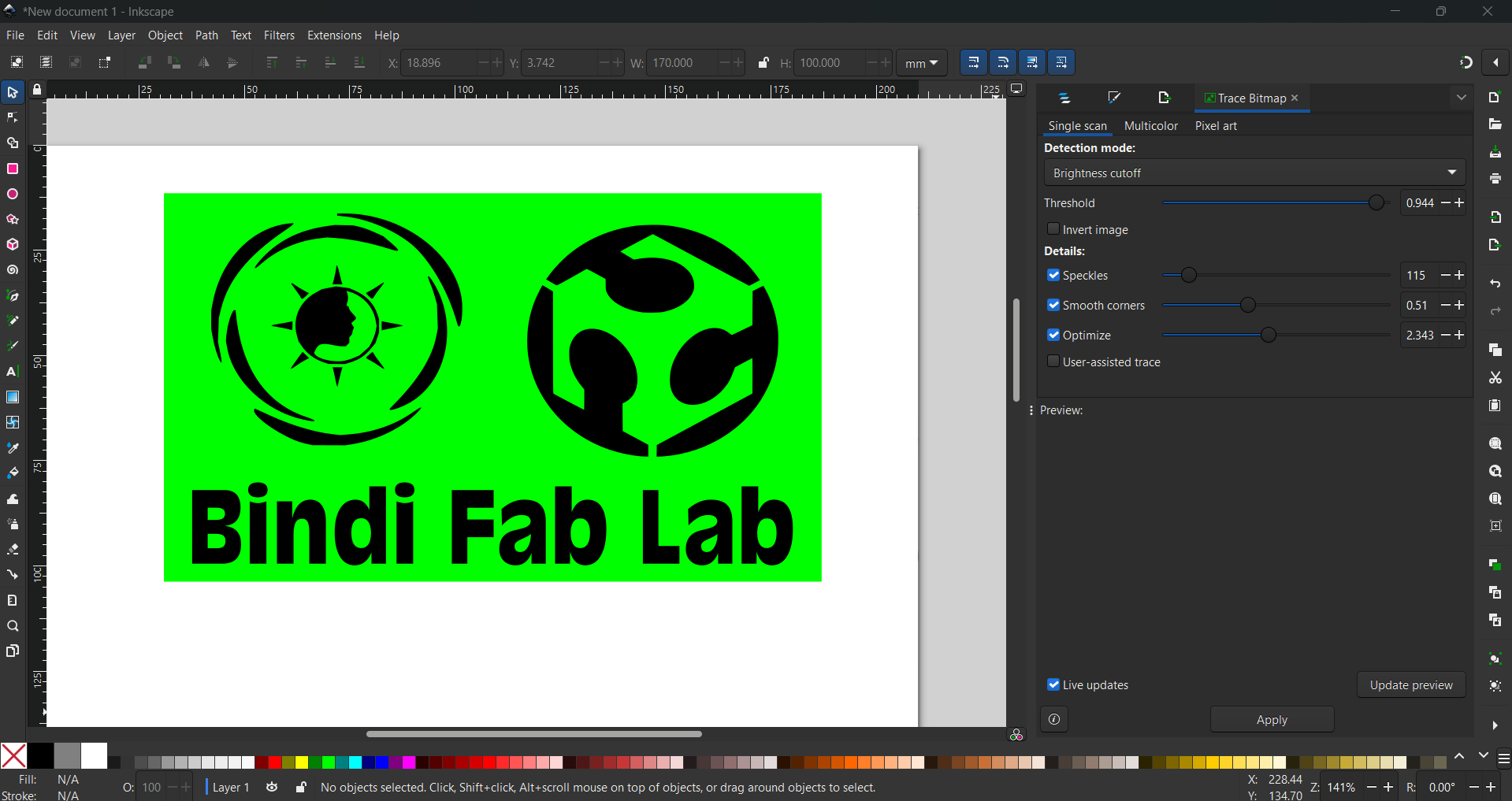

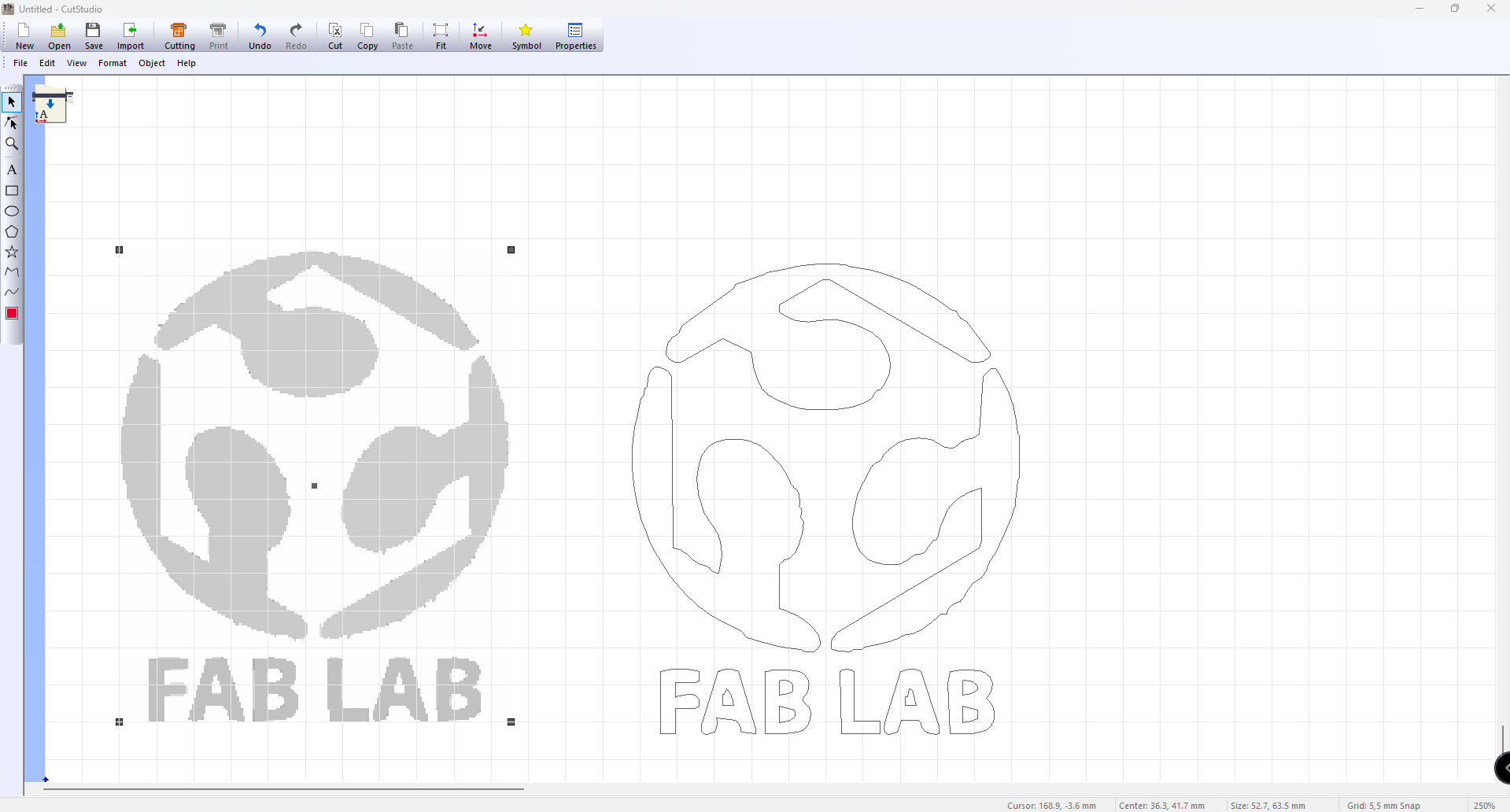

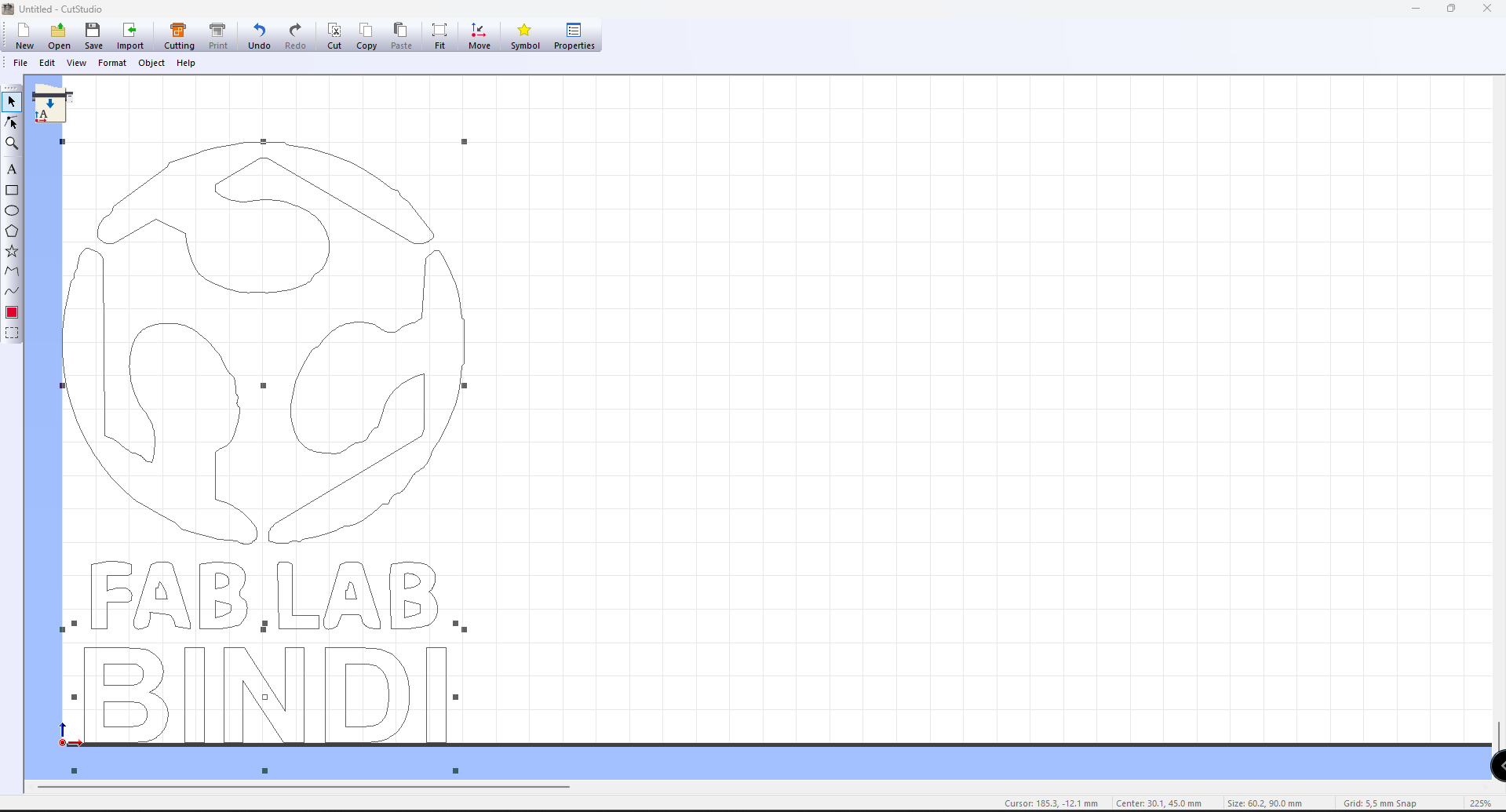

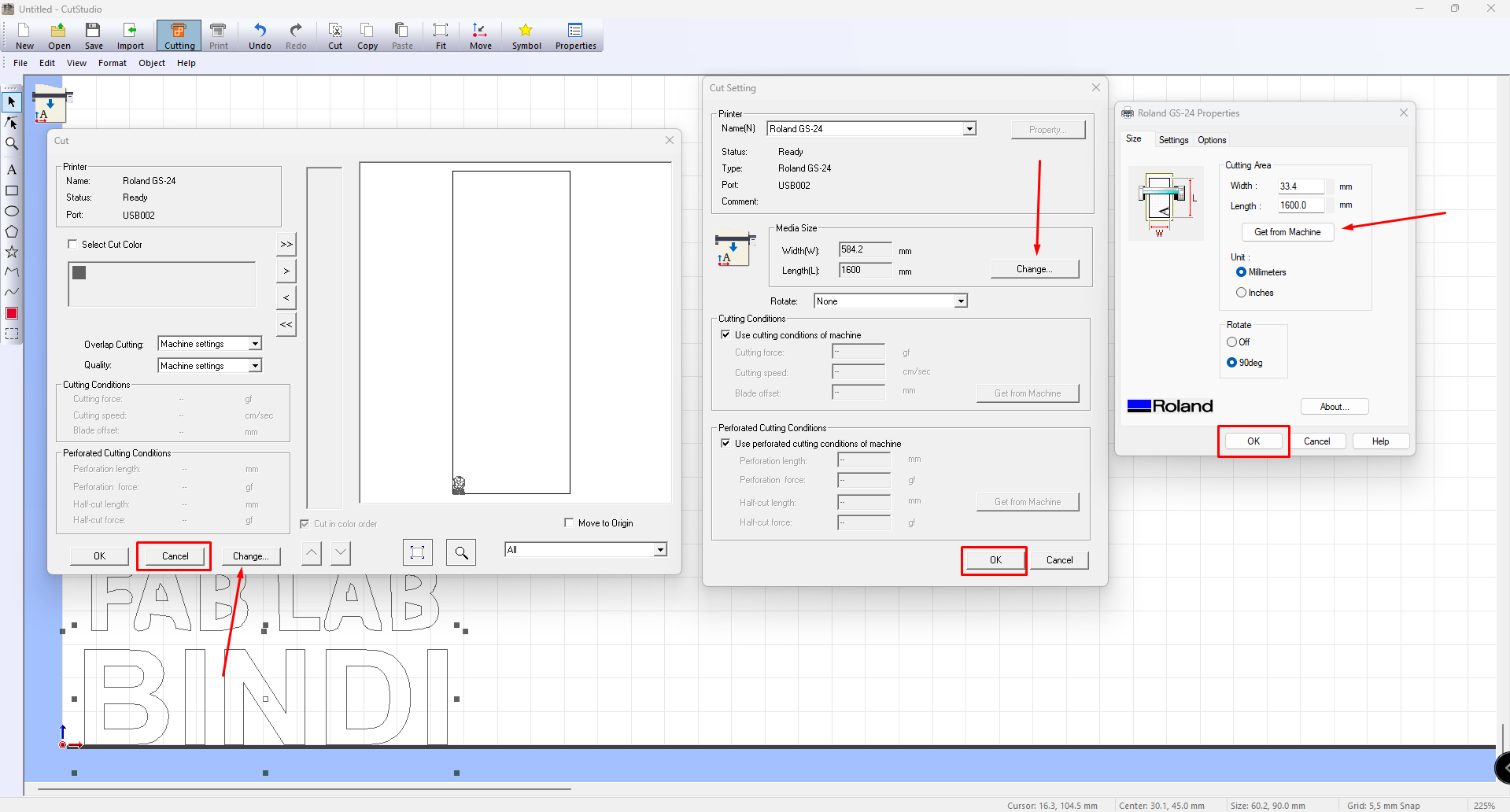

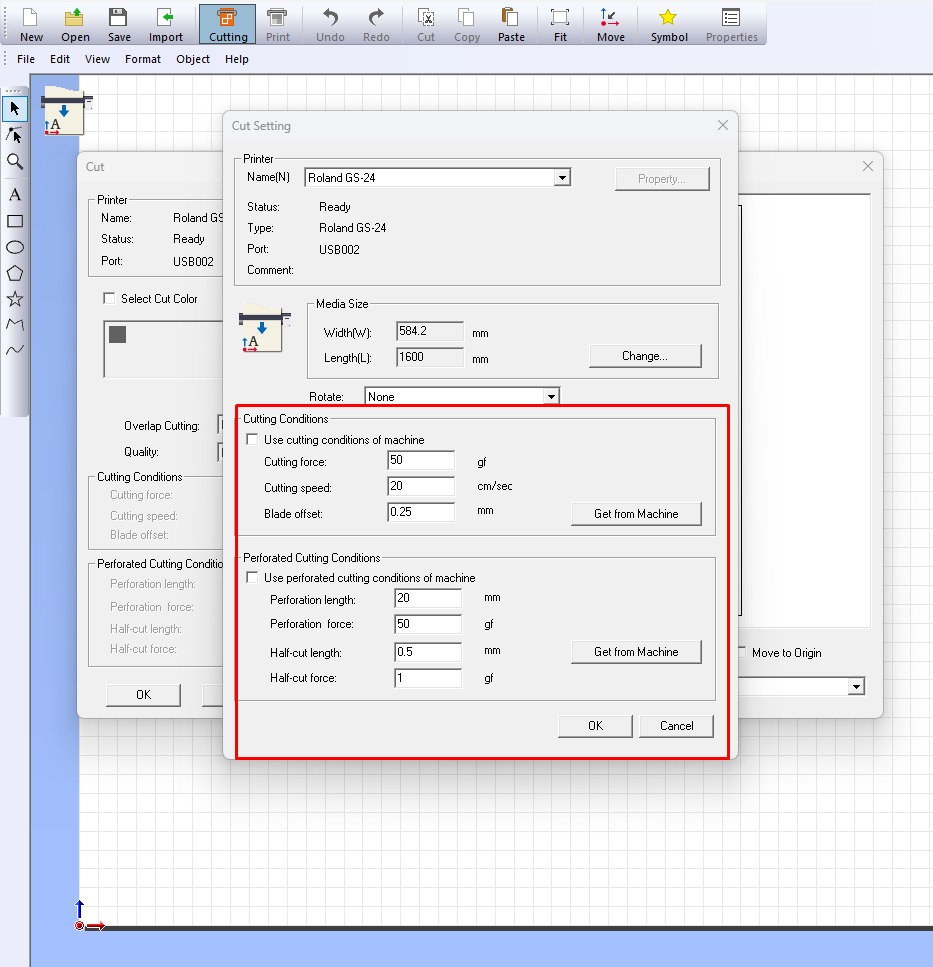

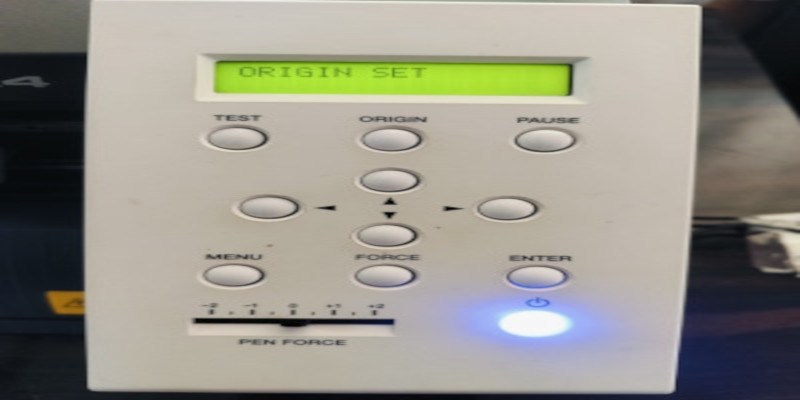

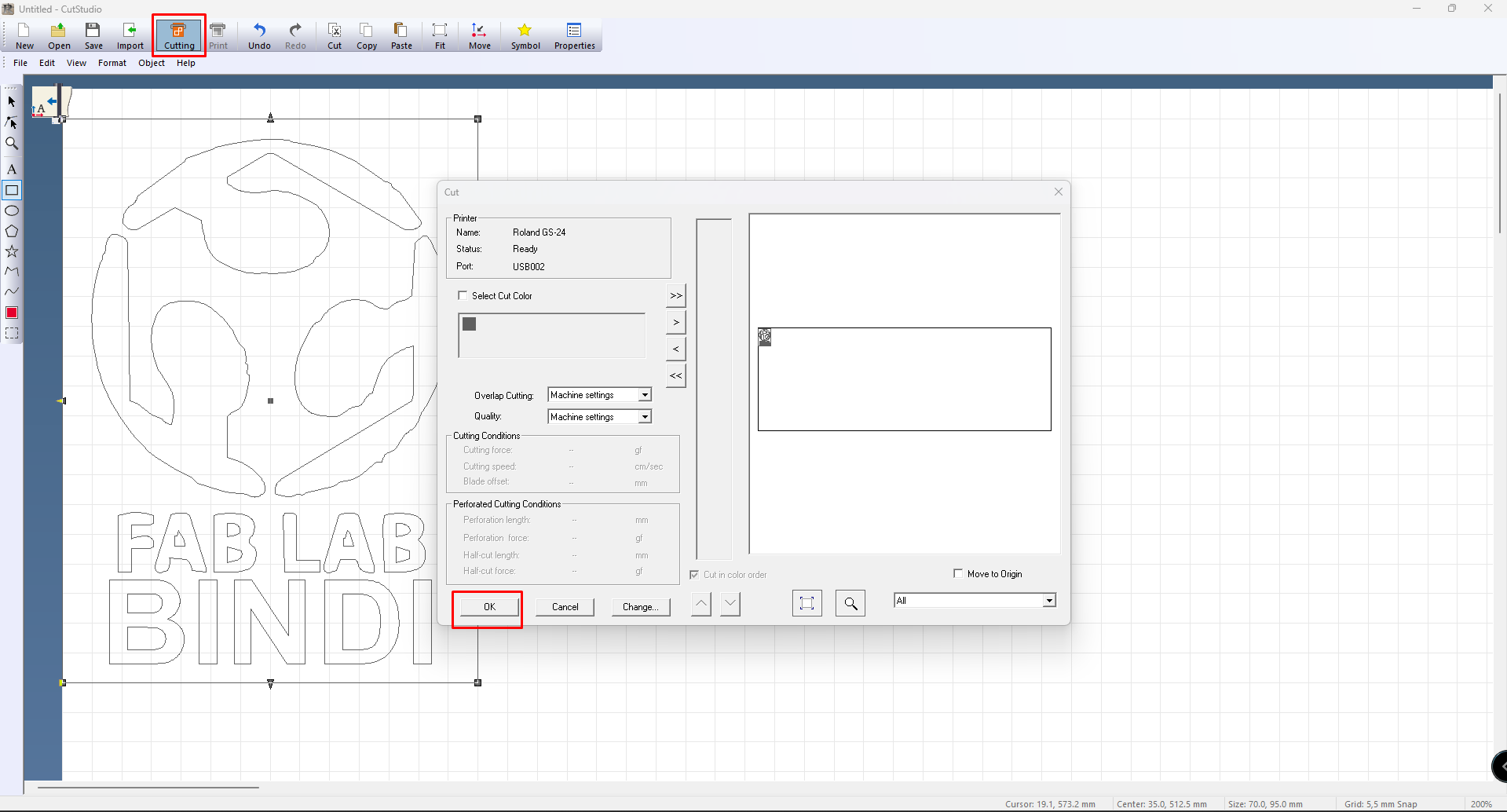

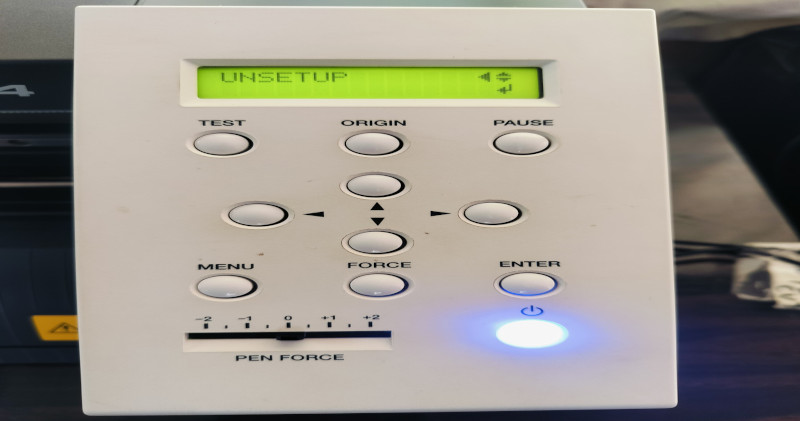

Desktop Vinyl Cutter CAMM-1 GS-24

The CAMM-1 GS-24 is a powerful desktop vinyl cutter, ideal for small and medium-sized businesses. Known for its accuracy and user-friendliness, it supports a wide range of materials, including paper, vinyl, and heat transfer materials. The GS-24 operates efficiently and delivers high-quality results, making it perfect for creating custom signage, decals, and heat transfer designs for clothing. Designed for both intricate designs and large-scale projects, it provides a versatile and reliable solution for various cutting needs.

.png)

.png)