3D Scanning and Printing

Home ← →

Objective of this Week

- To test design rules of our 3D Printer

- Safety Precaution while using machine

Our Fablab has two 3D printers

1.CR-10 S Pro V2 -3D Printer

2.Creator 3 Pro 3D Printer

CR-10 S Pro V2 -3D Printer

- The Creality CR-10S Pro V2 is a high-precision FDM 3D printer with a large build volume of 300 x 300 x 400 mm. It features an auto bed leveling system with a BLTouch sensor for accurate first-layer adhesion. The printer has a dual-gear filament extruder for smooth and reliable filament feeding. Equipped with a MeanWell power supply, it ensures stable performance and quick heating. A resume printing function allows it to continue after power loss. The touchscreen interface makes navigation user-friendly. Its sturdy aluminum frame improves stability and print quality.

- It cost comes around Rs. 43K

Specification:

| | |

| Printing Technology | Fused Deposition Modeling (FDM) |

| Build Volume | 300 x 300 x 400 mm |

| Layer Resolution | 0.1 - 0.4 mm |

| Nozzle Diameter | 0.4 mm (Standard) |

| Printing Speed | ≤ 180 mm/s (Recommended: 60 mm/s) |

| Filament Diameter | 1.75 mm |

| Compatible Materials | PLA, ABS, PETG, TPU, Wood, Carbon Fiber |

| Extruder Type | Direct Drive Dual Gear |

| Heated Bed | Yes (Max Temp: 110°C) |

| Nozzle Temperature | Max 260°C |

| Connectivity | SD Card, USB |

| Power Supply | 24V / 350W |

| Display | 4.3-inch Touchscreen |

| Filament Sensor | Yes |

| Weight | 13.7 kg |

| Supported File Formats | STL, OBJ, G-code |

| Compatible Software | Cura, Repetier-Host, Simplify3D |

Creator 3 Pro 3D Printer

- The FlashForge Creator 3 Pro is a professional IDEX (Independent Dual Extruder) 3D printer, allowing dual-material and multi-color printing. It has a 300°C high-temperature extruder, enabling compatibility with a wide range of filaments like PLA, ABS, PETG, PC, and Nylon. The heated flexible build plate improves adhesion and makes print removal easy. With an enclosed chamber, it maintains stable temperatures for better print quality. The active leveling system ensures precise calibration. It features Wi-Fi, USB, and Ethernet connectivity for remote operation.

- It cost comes around Rs. 2L

Specification:

| | |

| Printing Technology | Fused Filament Fabrication (FFF) |

| Build Volume | 300 x 250 x 200 mm |

| Layer Resolution | 0.05 - 0.4 mm |

| Nozzle Diameter | 0.4 mm (Standard) |

| Printing Speed | ≤ 150 mm/s |

| Filament Diameter | 1.75 mm |

| Extruder Type | Independent Dual Extruders (IDEX) |

| Compatible Materials | PLA, ABS, PETG, TPU, PVA, Nylon, Carbon Fiber |

| Heated Bed | Yes (Max Temp: 120°C) |

| Nozzle Temperature | Max 320°C |

| Enclosure | Fully enclosed for temperature stability |

| Connectivity | USB, Wi-Fi, Ethernet |

| Power Supply | 24V / 500W |

| Display | 4.3-inch Touchscreen |

| Supported File Formats | STL, OBJ, 3MF, G-code |

| Compatible Software | FlashPrint, Simplify3D, Cura |

| Weight | 40 kg |

Safety Precautions

| | |

| Ventilation | Use in a well-ventilated area to prevent harmful fume exposure. |

| Stable Surface | Place on a stable, heat-resistant surface to avoid tipping. |

| Electrical Safety | Use the original power supply and avoid overloading sockets. |

| Heated Components | Do not touch the hotend (260°C) or heated bed (110°C) to prevent burns. |

| Fire Safety | Never leave the printer unattended; keep a fire extinguisher nearby. |

| Filament Handling | Store filaments in a dry, cool place to prevent moisture absorption. |

| Nozzle Cleaning | Use proper tools for cleaning; avoid touching the nozzle when hot. |

| Bed Leveling | Carefully use auto-leveling or manually level to prevent damage. |

| Cooling Period | Let the printer cool before performing maintenance or moving it. |

Slicing Process

Uthaya took the design model to test our 3D printer in Thingiverse

Then Gayathri did the slicing for our 3D printer testing,

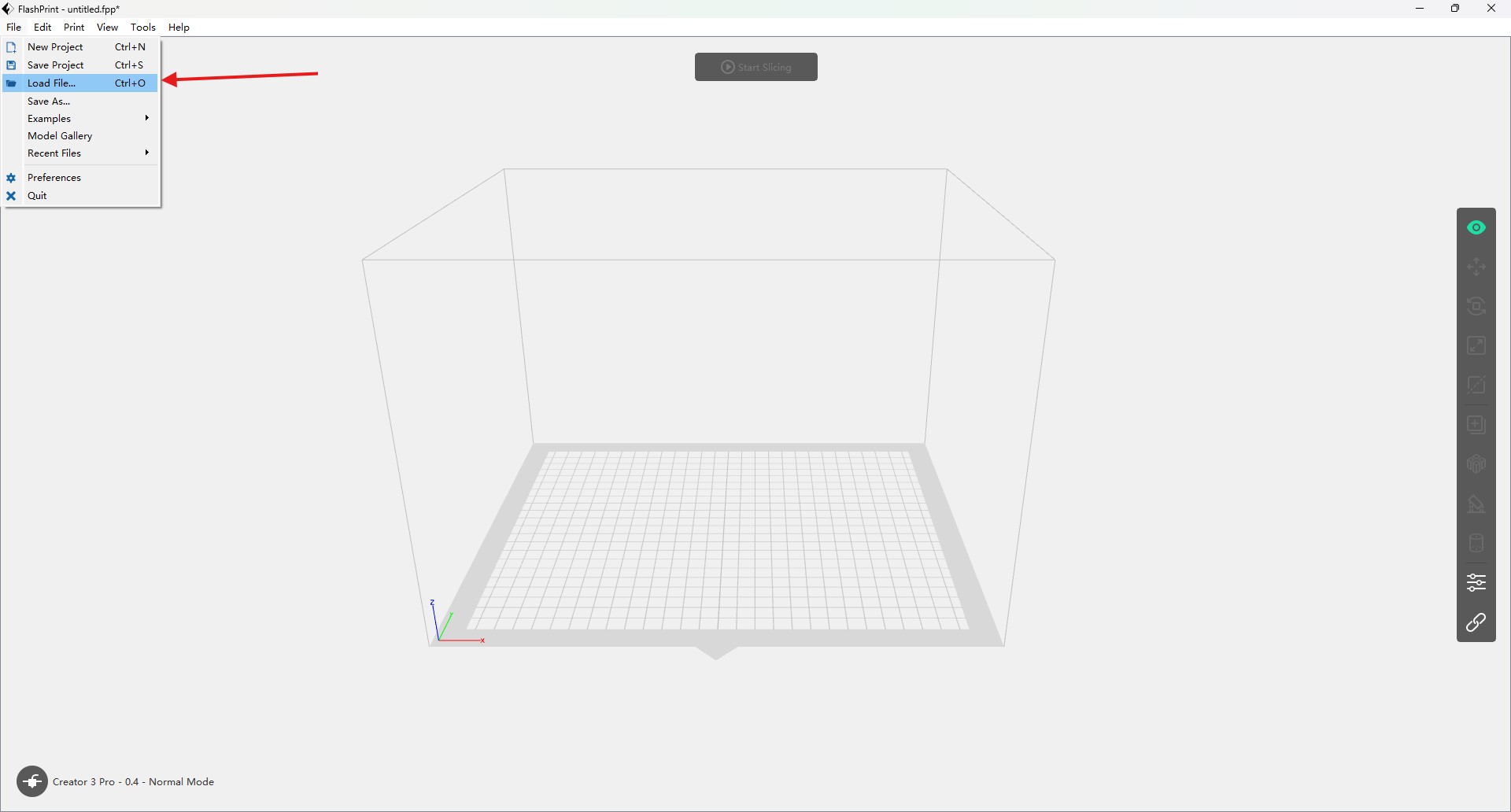

After downloading the STL file he load it into the flash print software because of our 3D printer only support it.

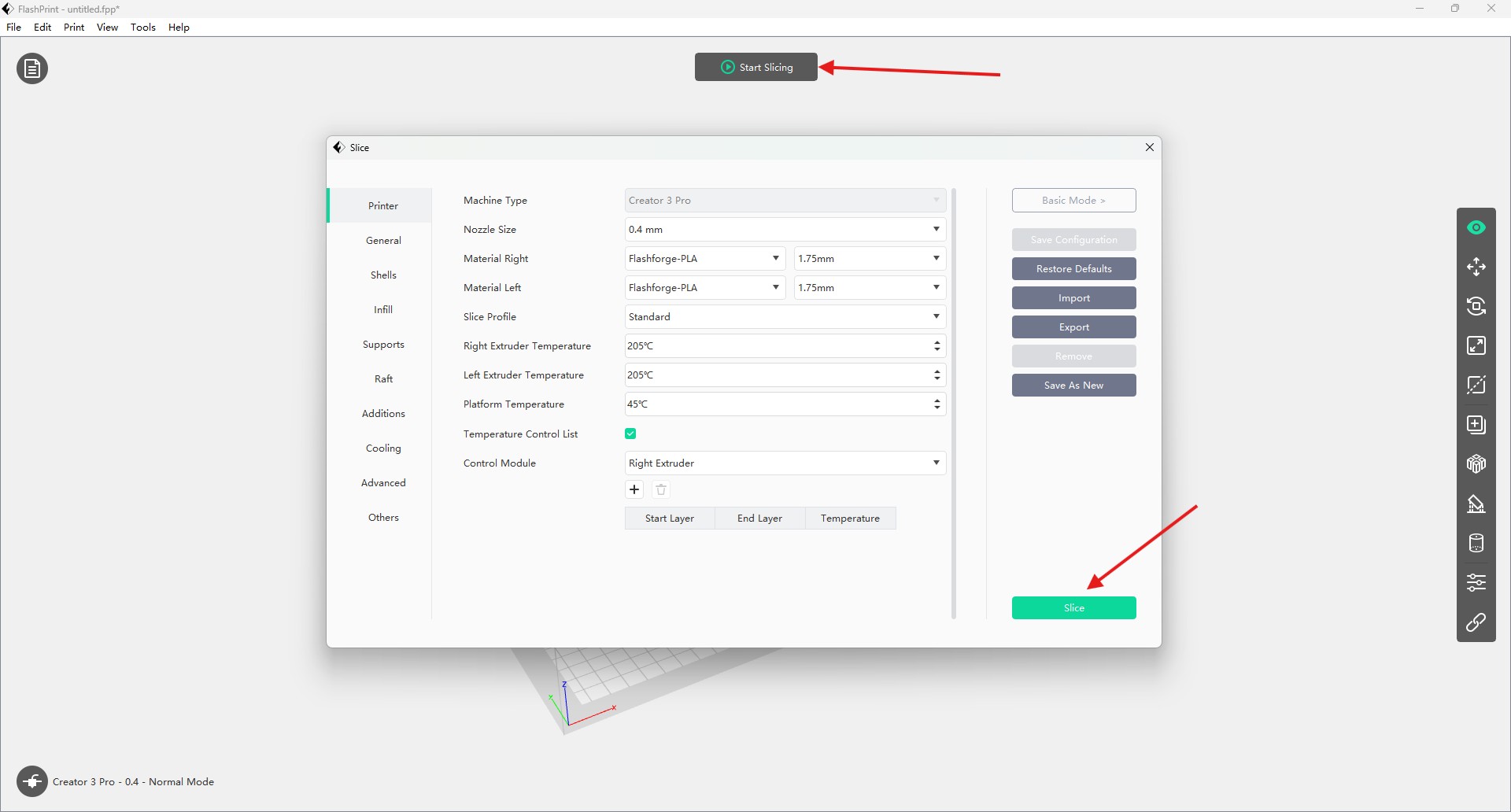

Then start the slicing process, he uses the PLA material for this assignment

Infill pattern - Hexagon

Infill density - 30%

Nozzle temp - 205 degree celcius

Bed temp - 55 degree celcius

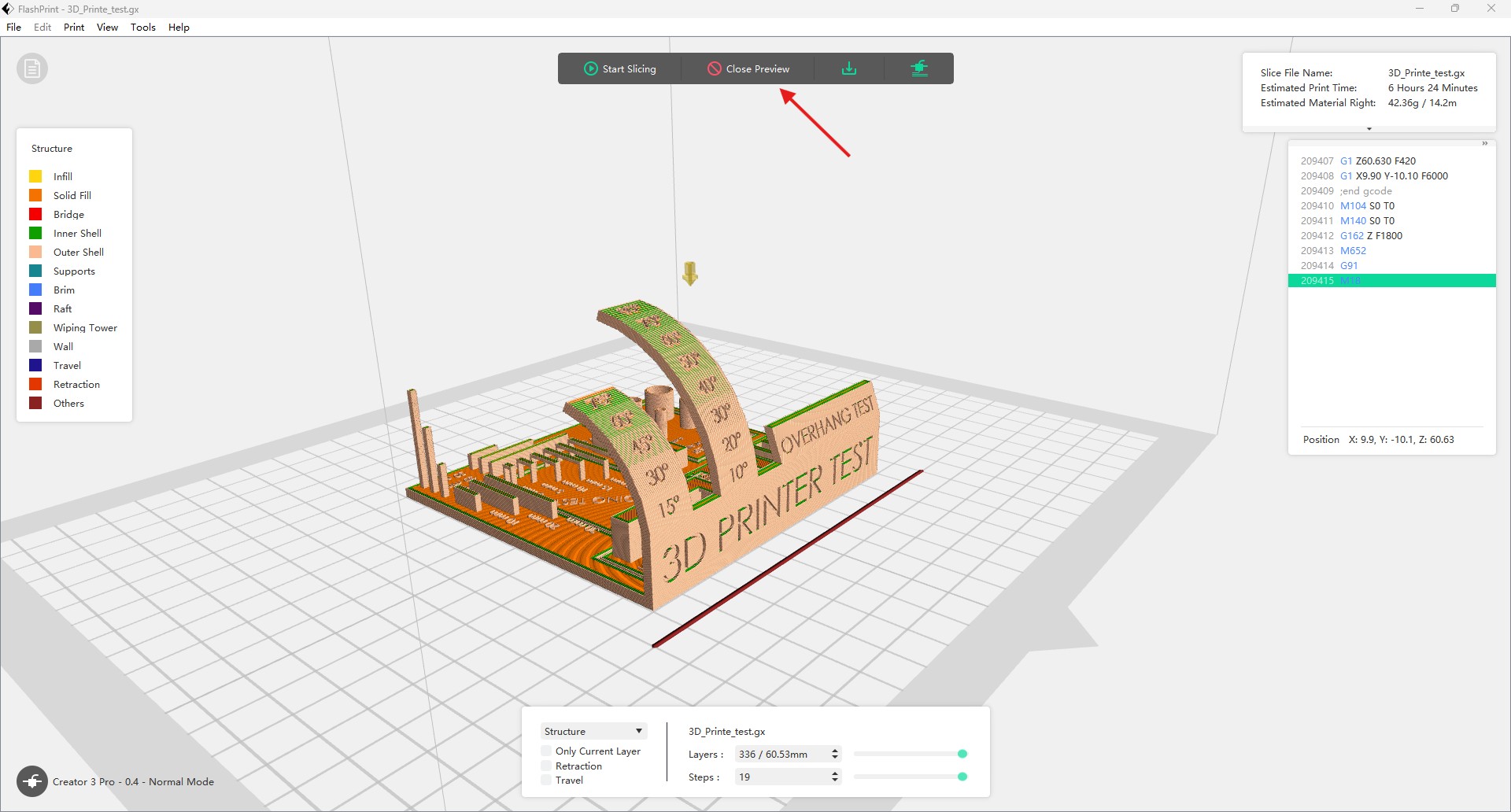

After set everything he click the slicing and open the preview tap

Now we can see the printing times in hrs, filament usage in grams, gcode

Then he download it into the gcode format and give me to print it.

Design Test

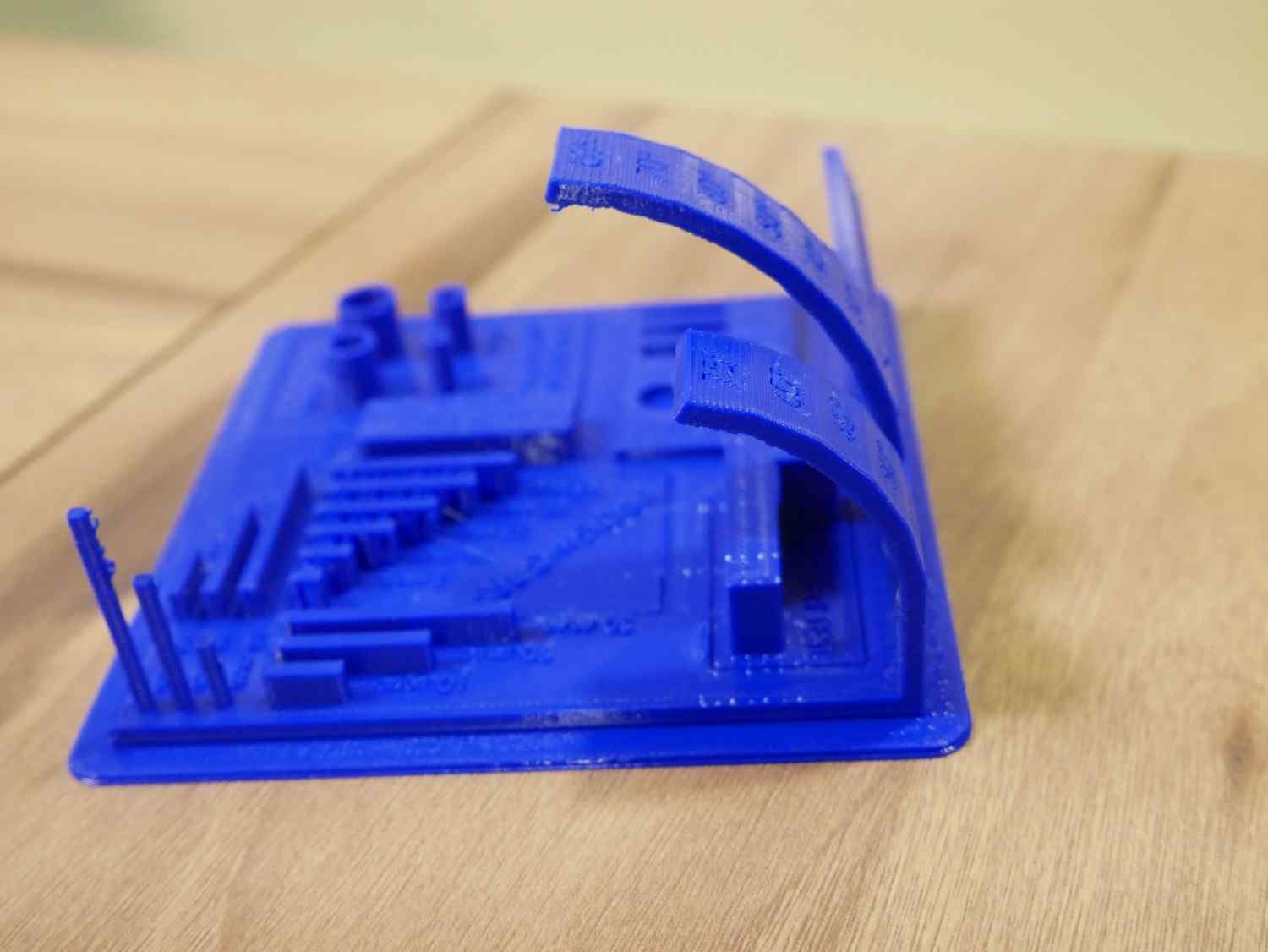

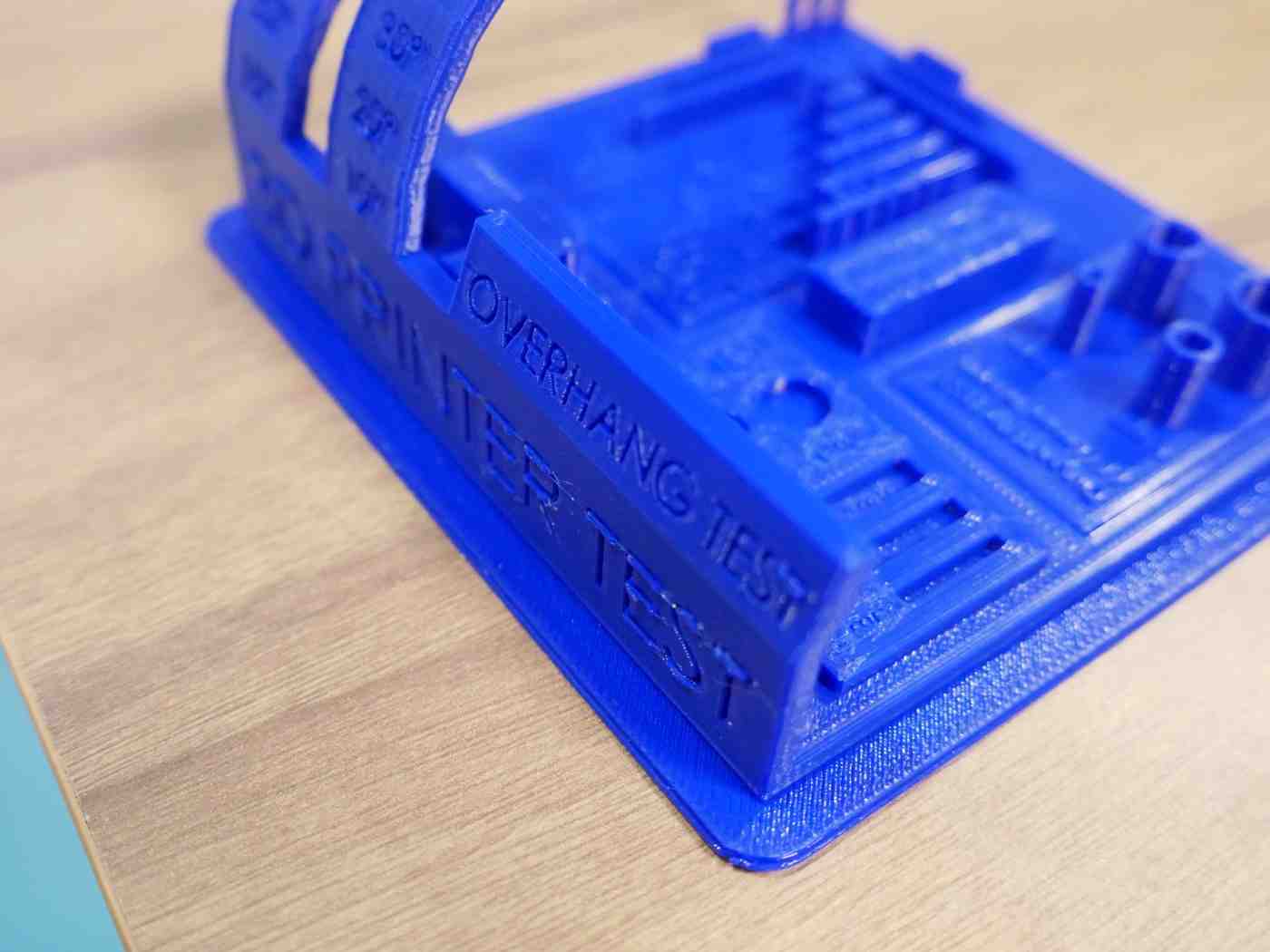

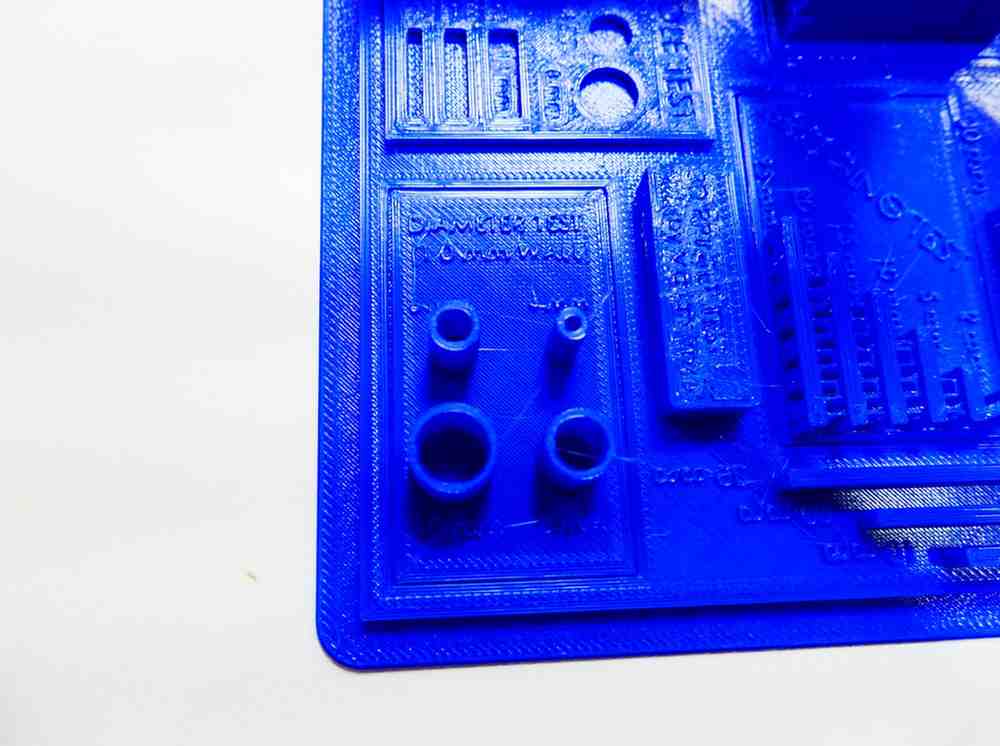

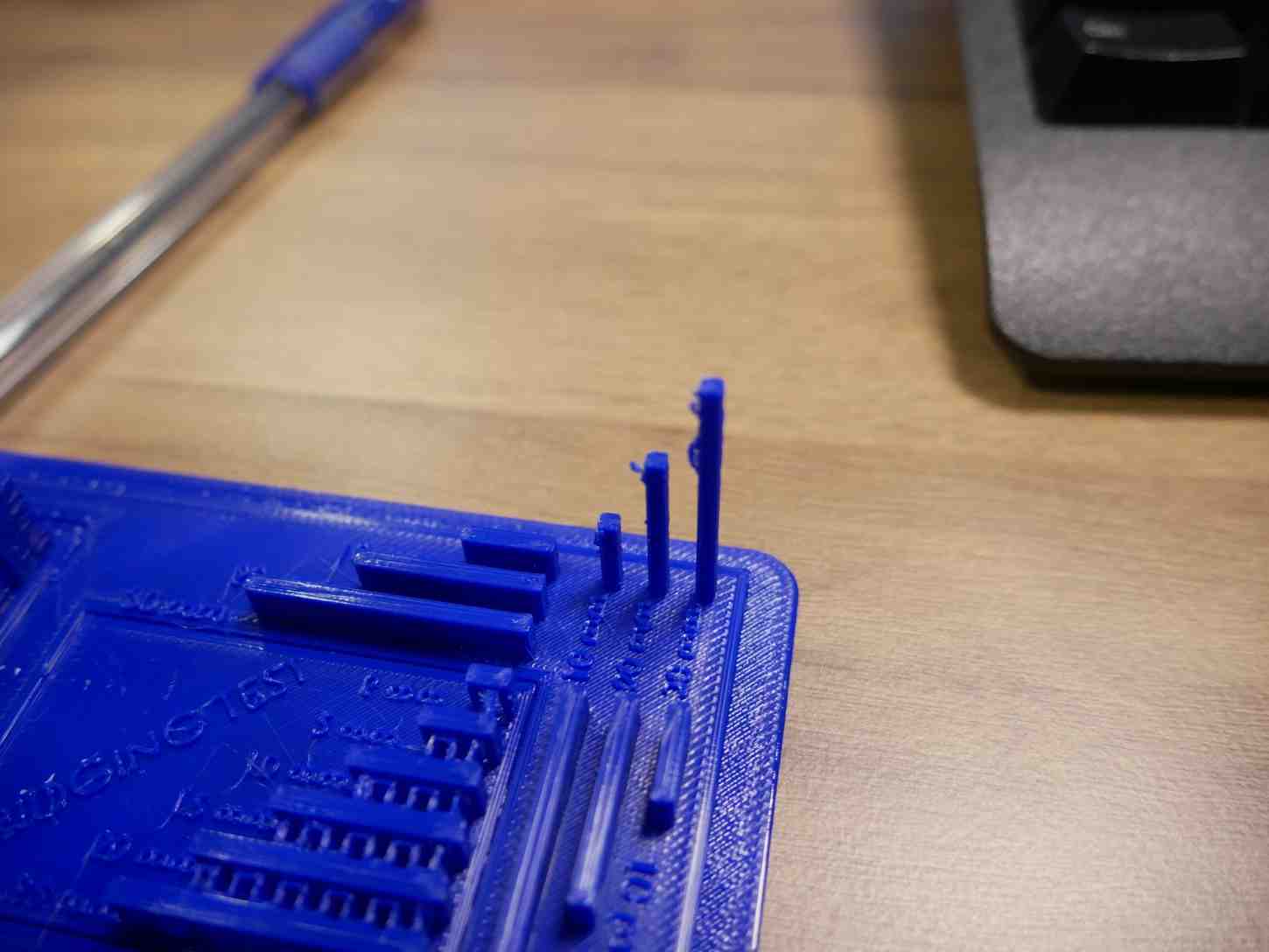

After the slicing I start print it and wait for the final output

Then take out the printed part from the 3D printer and inspect the printing parts

Challenges

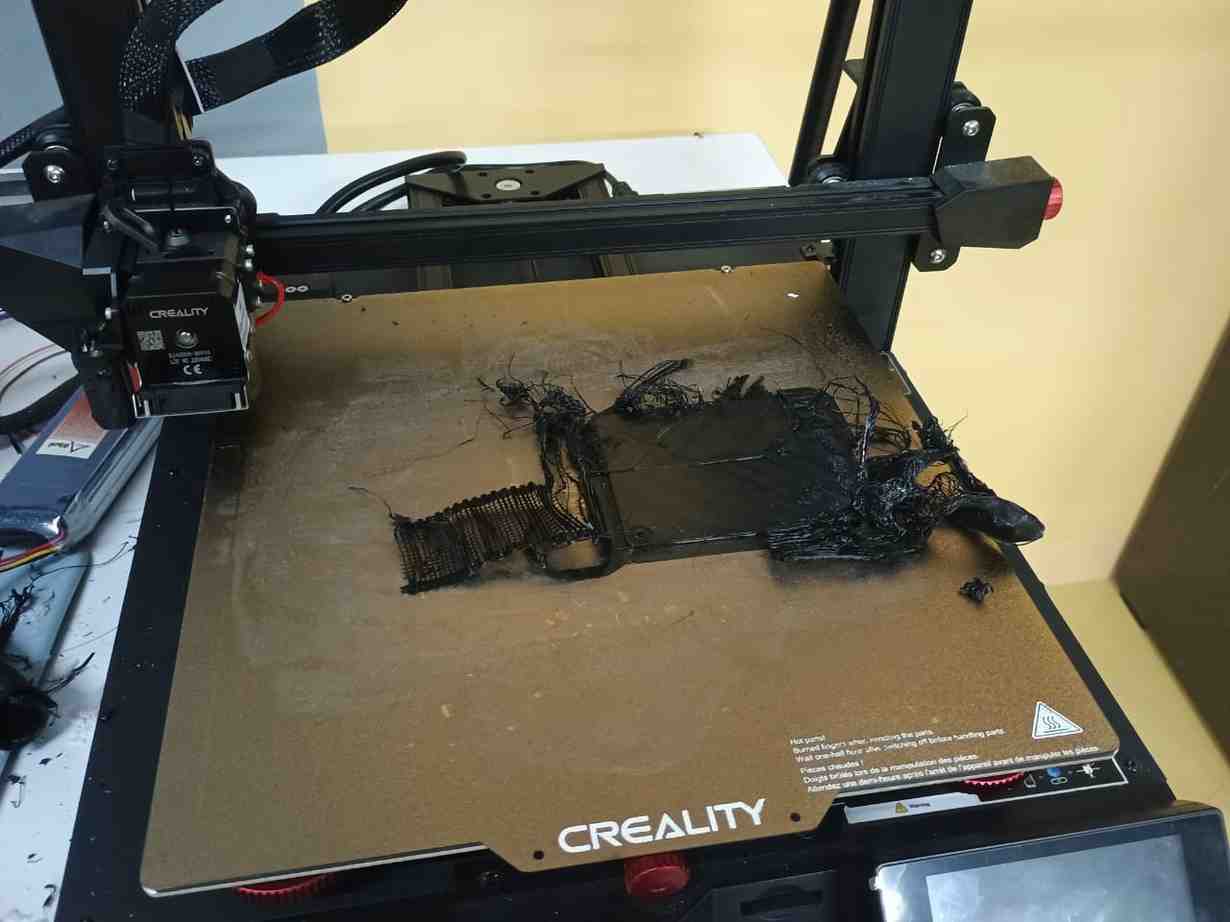

In our lab CR-10 S Pro V2 -3D Printer has some issues in printing, so we have decided to rectify that.

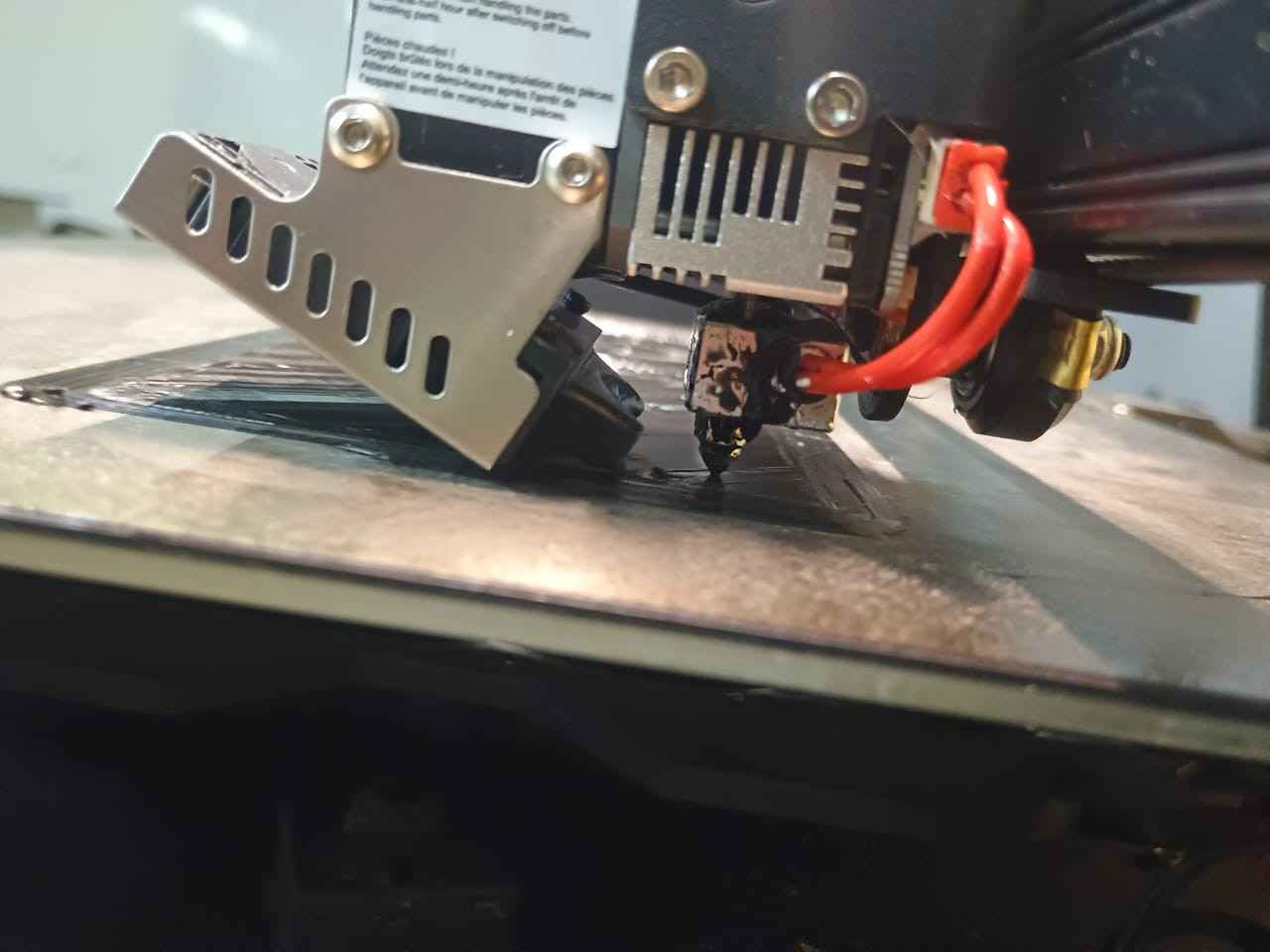

We check that 3D printer by import one design to test it, the printing goes sucessfully only the first half hour, after that it has seems into one problem, so we check that out.

The block of the nozzle has some leaking issues we diagnosed it

Therefore we started to troubleshooting that what the probelm cause.

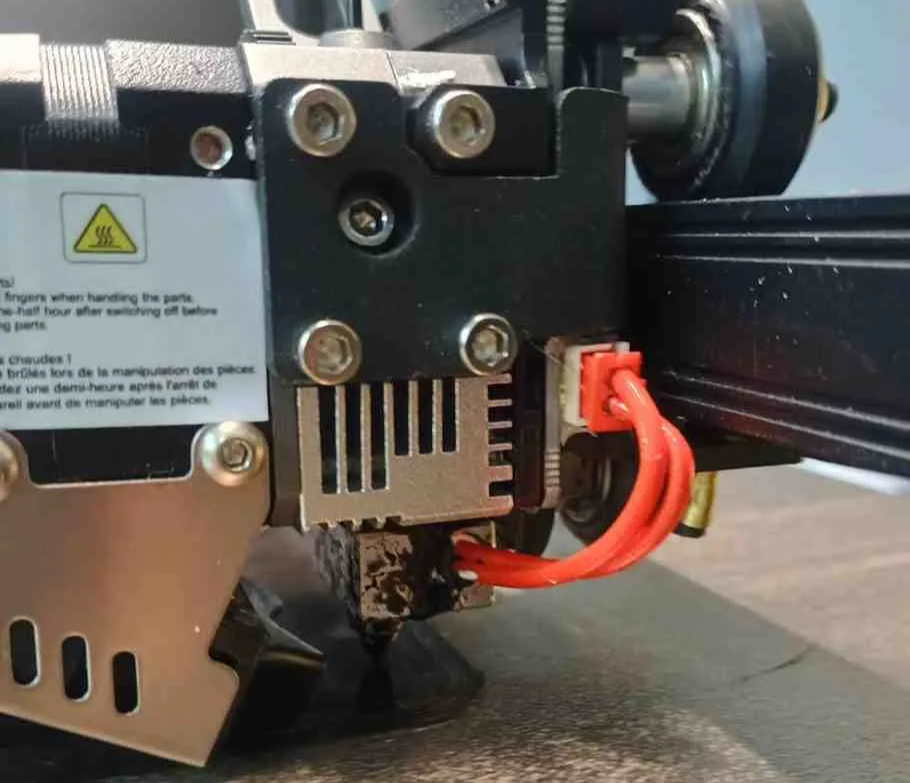

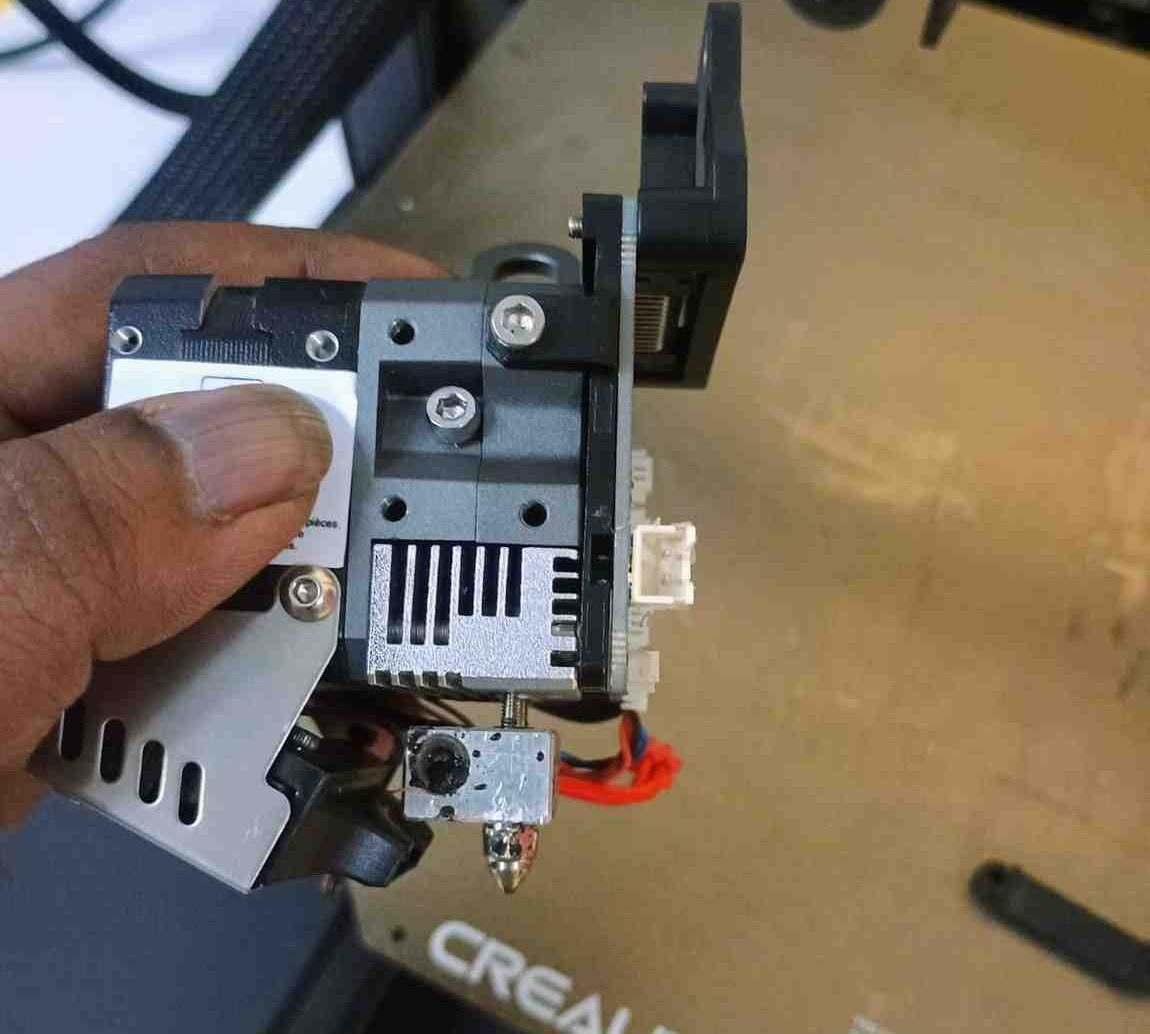

We first remove the Filament part from that head and completely removed the head from the 3D printer

Then we removed the nozzle and clean it by using the heat gun to heat the filament material which is stick it in the nozzle block because it didn’t comes that much easily.

We figure out the block is not tightly closed when it was troublshooted at last time for the temperature issued .

We fix it up by tightening tools and then again fixing into the 3D printer.

Then again we run the test print but this time it cames good without leaking the filament from the nozzle block.