Individual Machine Build Part

Summary

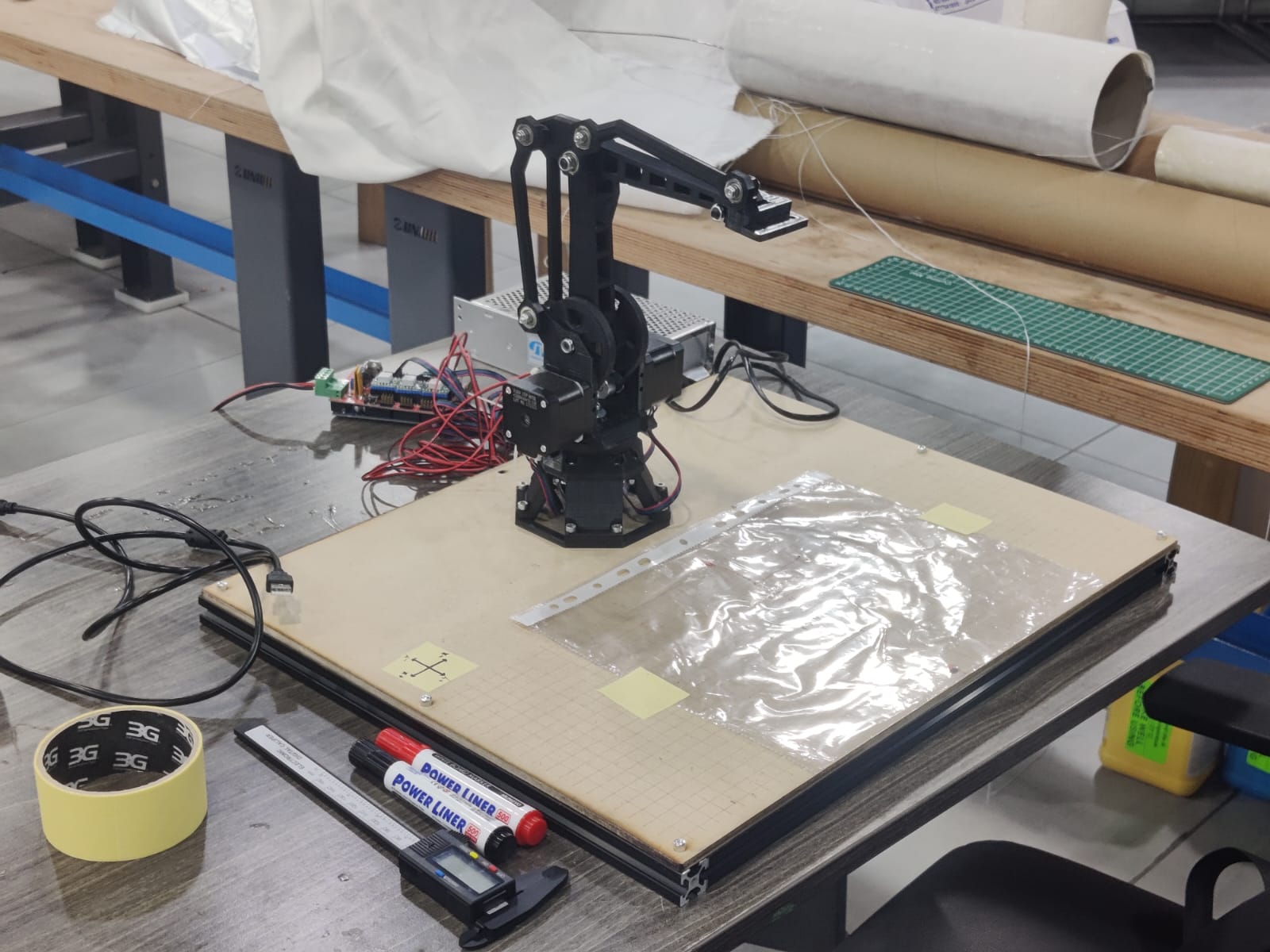

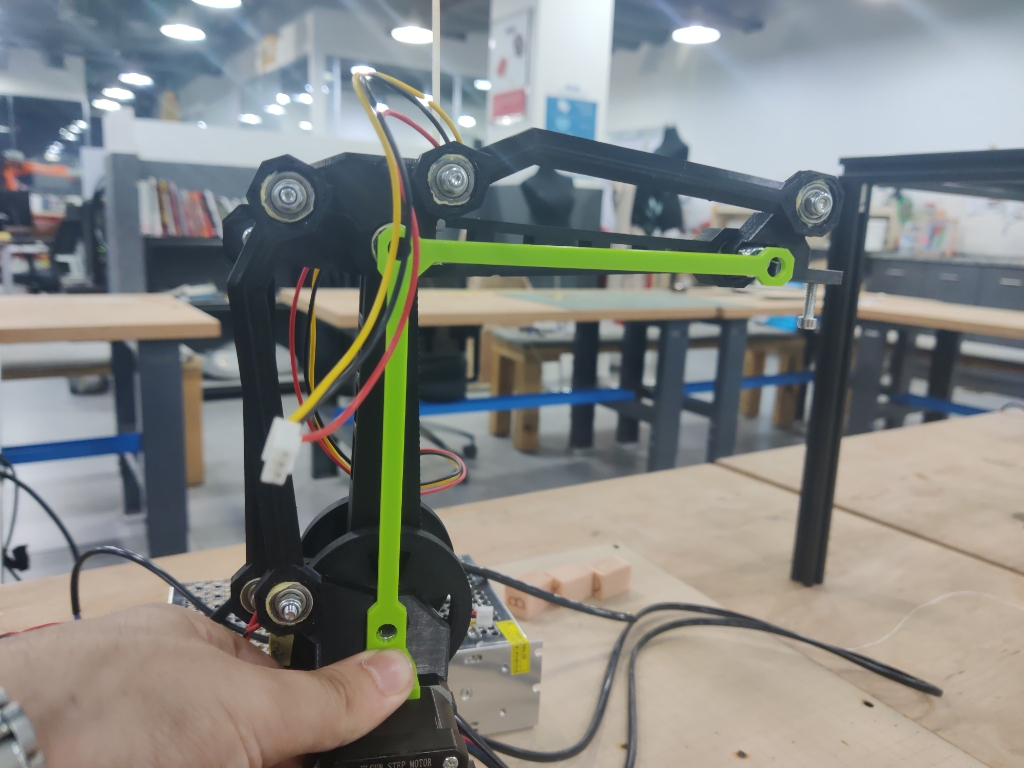

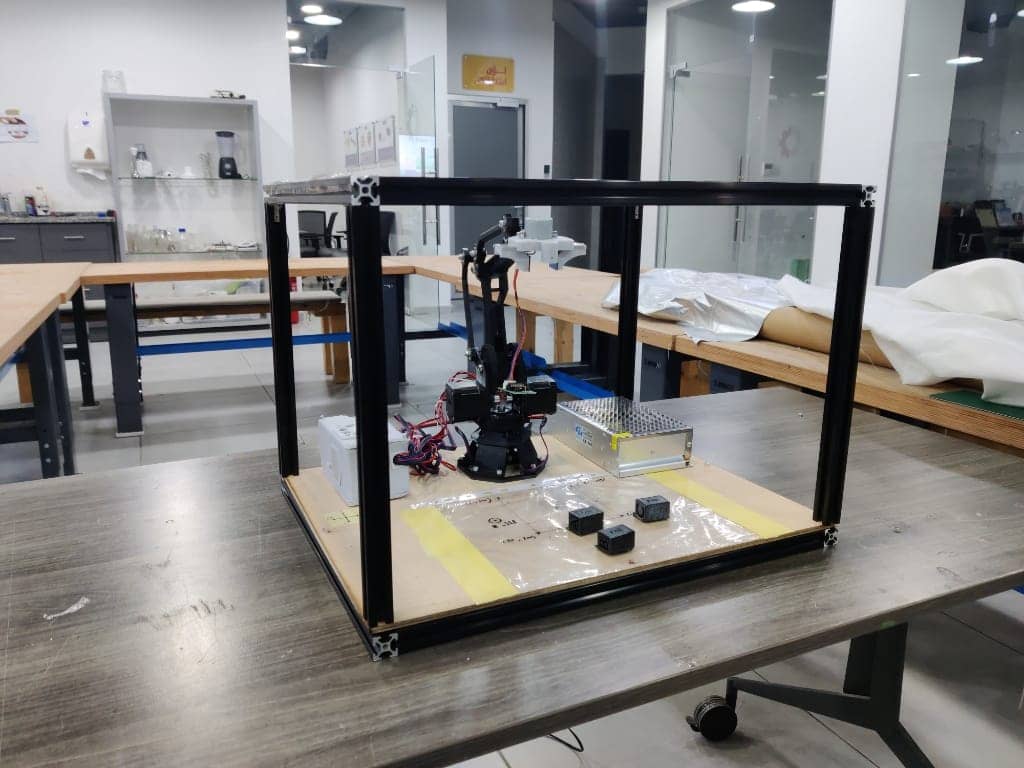

Throughout Machine Week, I took primary responsibility for the mechanical design and construction of our articulated robotic arm project, FabLab in a Box. My role spanned from analyzing CAD files and identifying required parts, to 3D printing components, sourcing materials from local markets, and assembling the full mechanical structure. I also contributed significantly to system alignment, gripper integration, structural mounting, and preparing the arm for its multi-functional tasks like gripping, plotting, and engraving.

The group assignment Page :

Work Process Detail

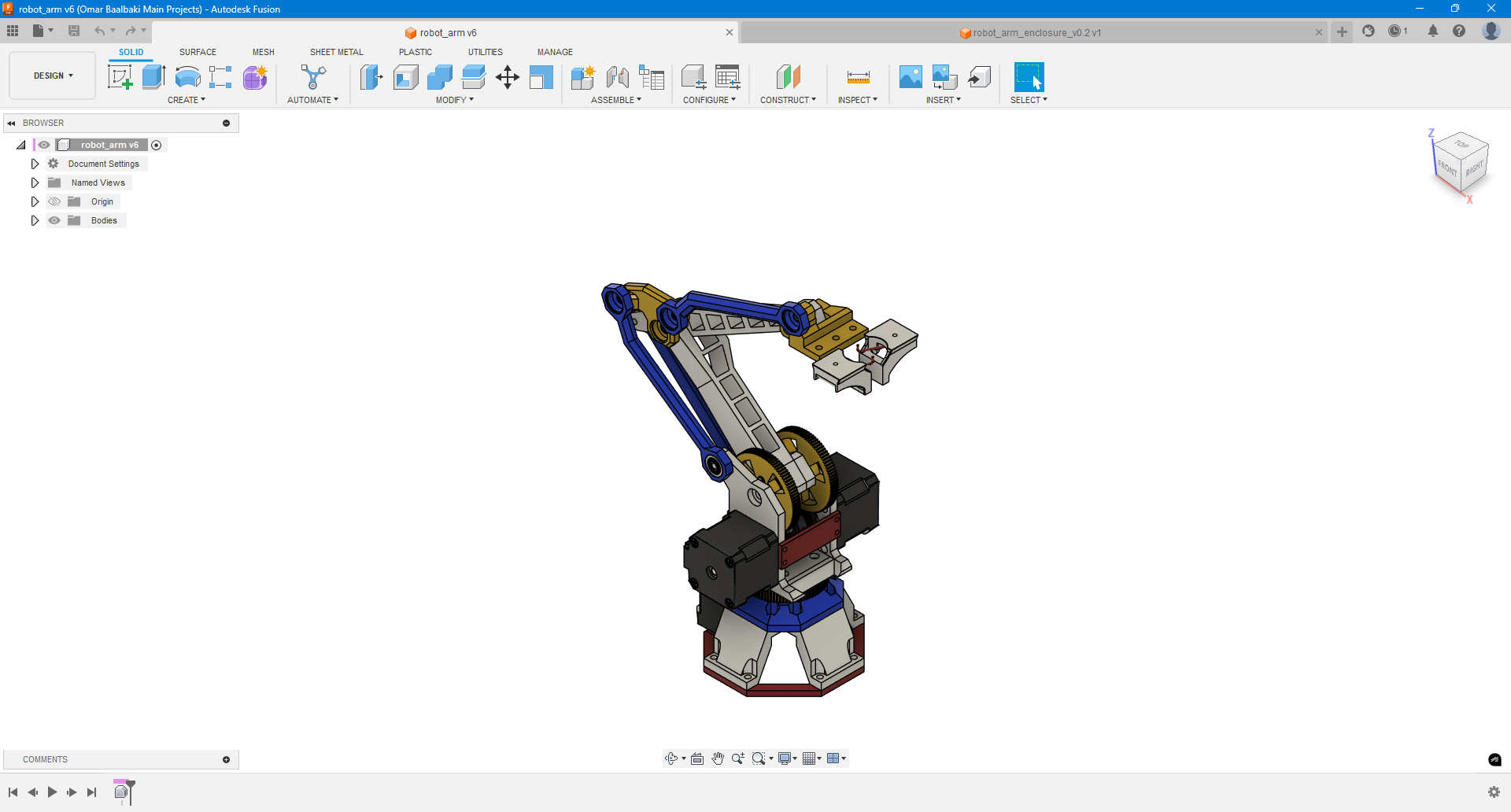

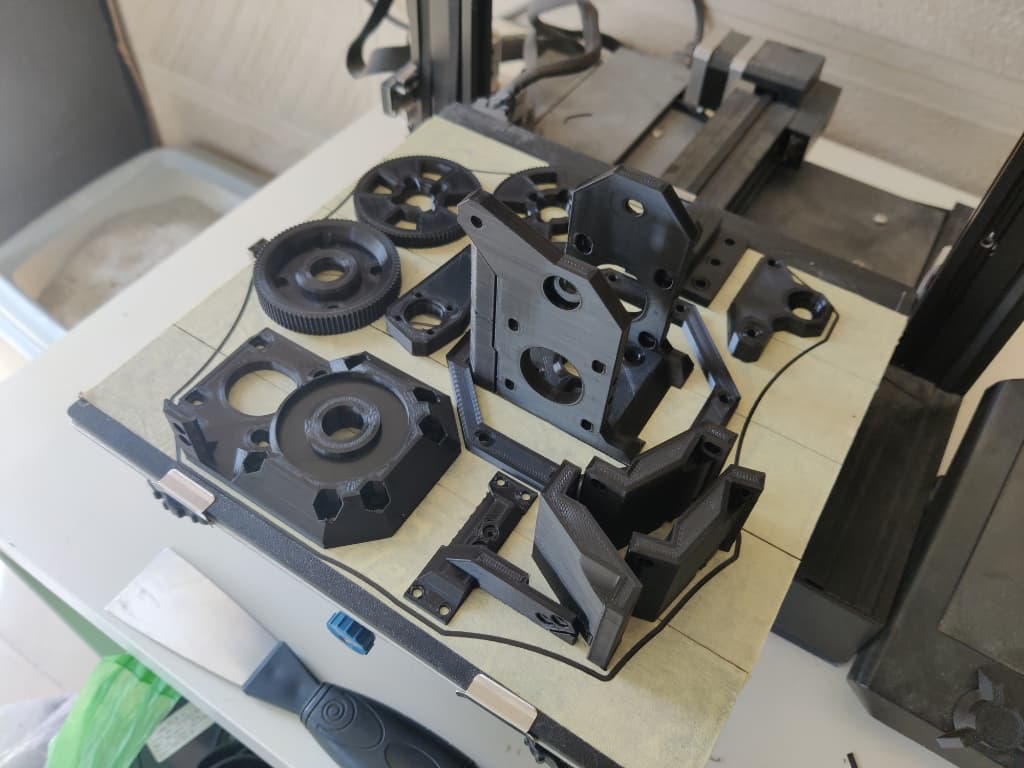

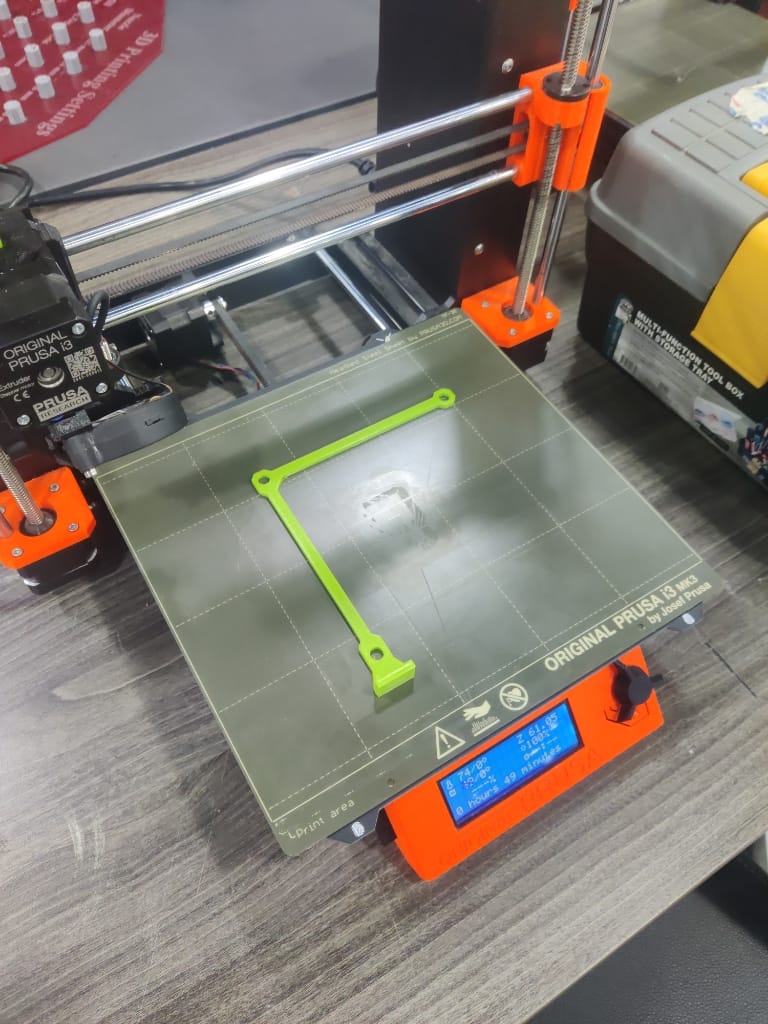

1. 3D Modeling & Printing

- Designed components in Fusion 360 and printed structural parts using PLA.

- Utilized available printer settings for strong infill and quality finish.

2. Local Sourcing & Salvage

- Purchased missing mechanical parts: bearings, screws, nuts, washers.

- Recycled parts from old 3D printer kits (stepper motors, belts, etc.) with instructor approval.

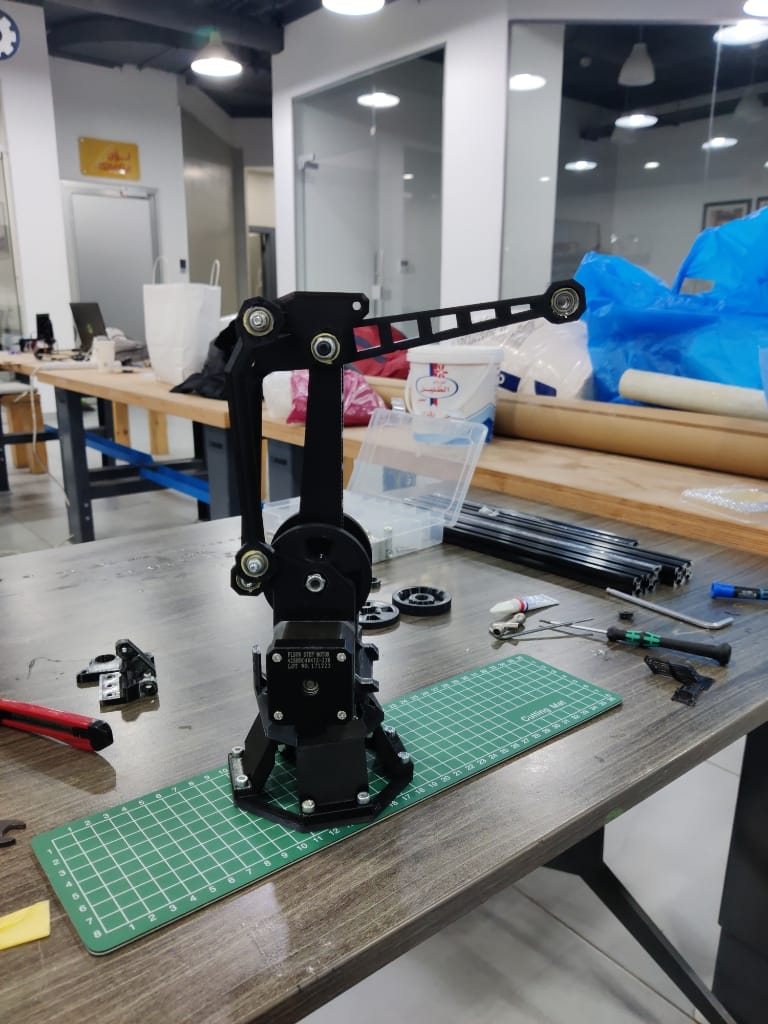

3. Mechanical Assembly

- Organized all parts and created a labeled parts kit.

- Assembled the robot arm over two days following the plan and adapting where needed.

- Solved bearing compatibility issues by micro-adjusting diameters with tape shimming.

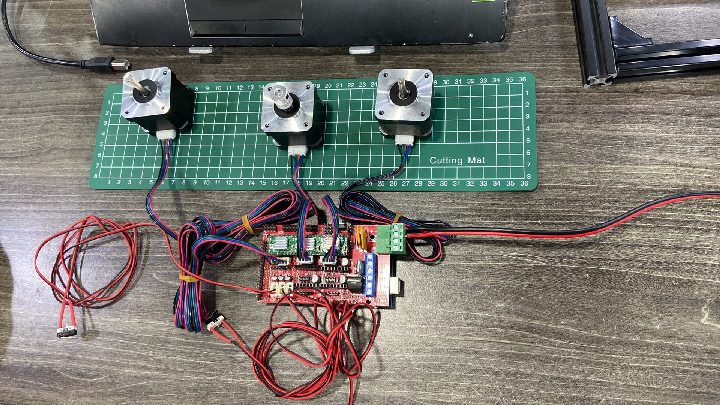

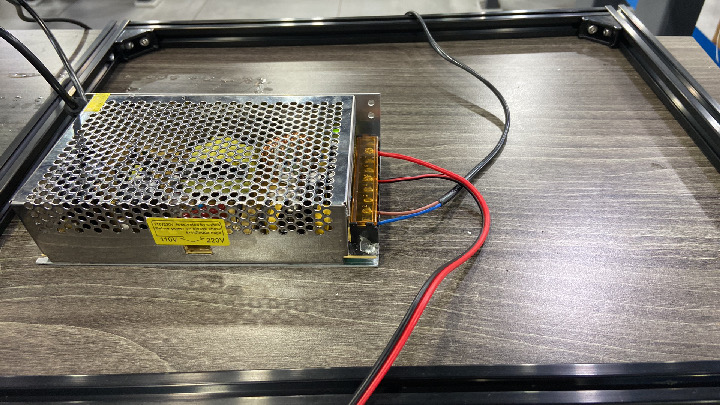

4. Electronics Setup & Testing

- Used RAMPS 1.4 board with A4988 drivers and a 12V power supply.

- Checked all voltages and current limits using a multimeter and proper safety protocols.

- Tested motors and limit switches individually before integrating into the frame.

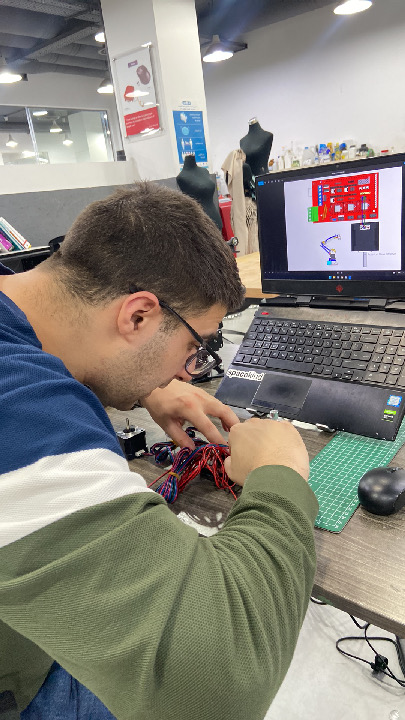

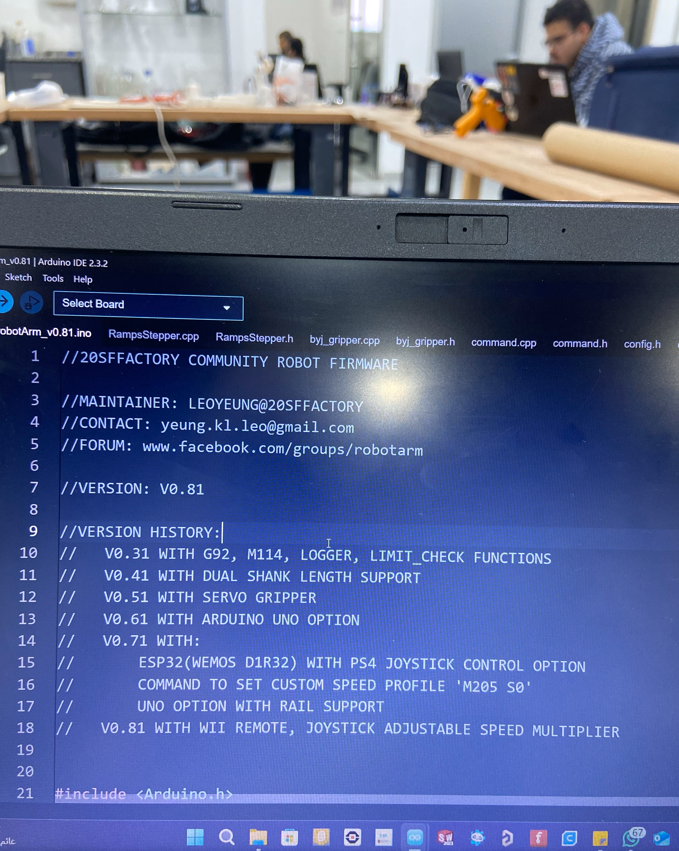

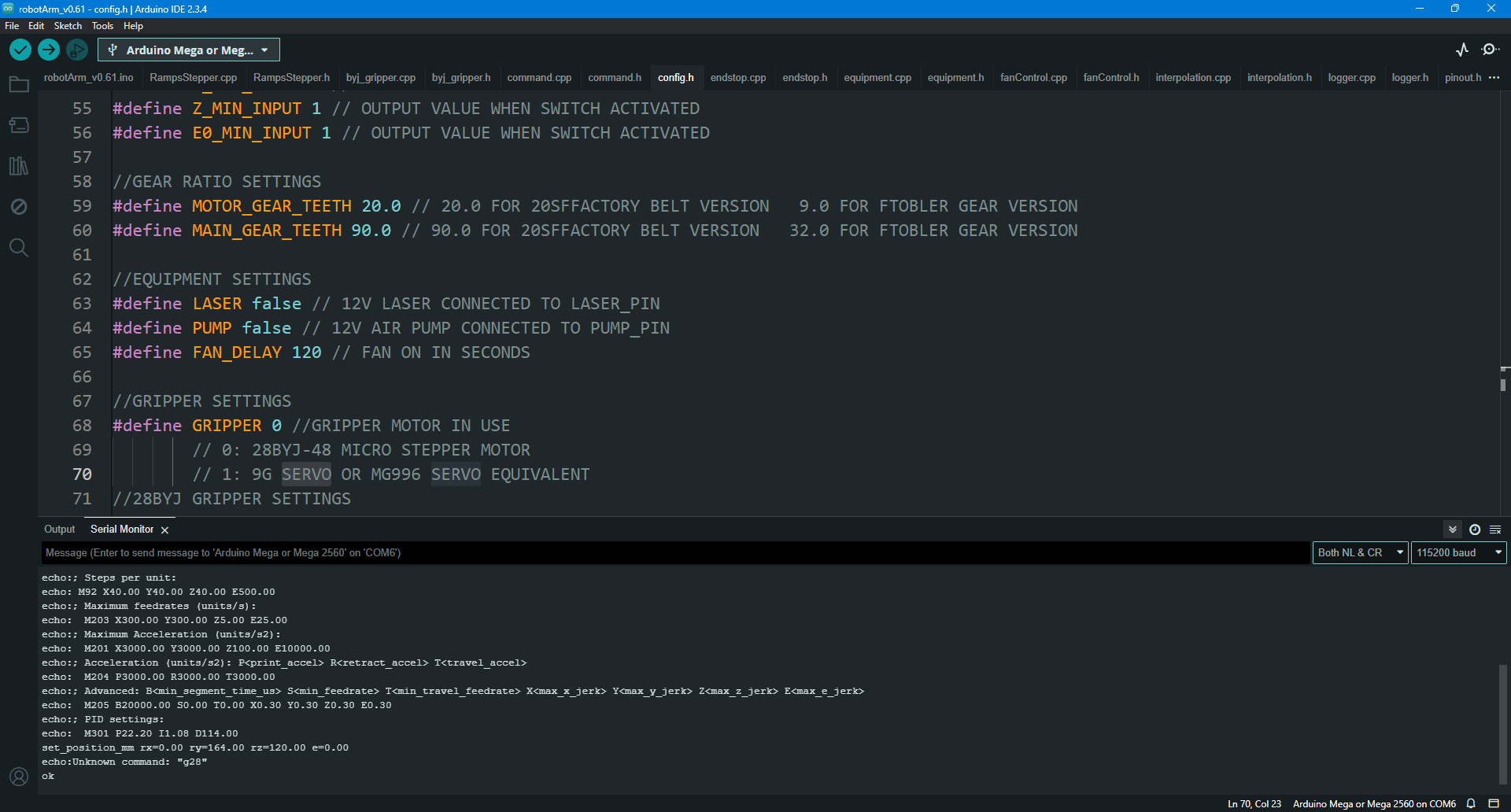

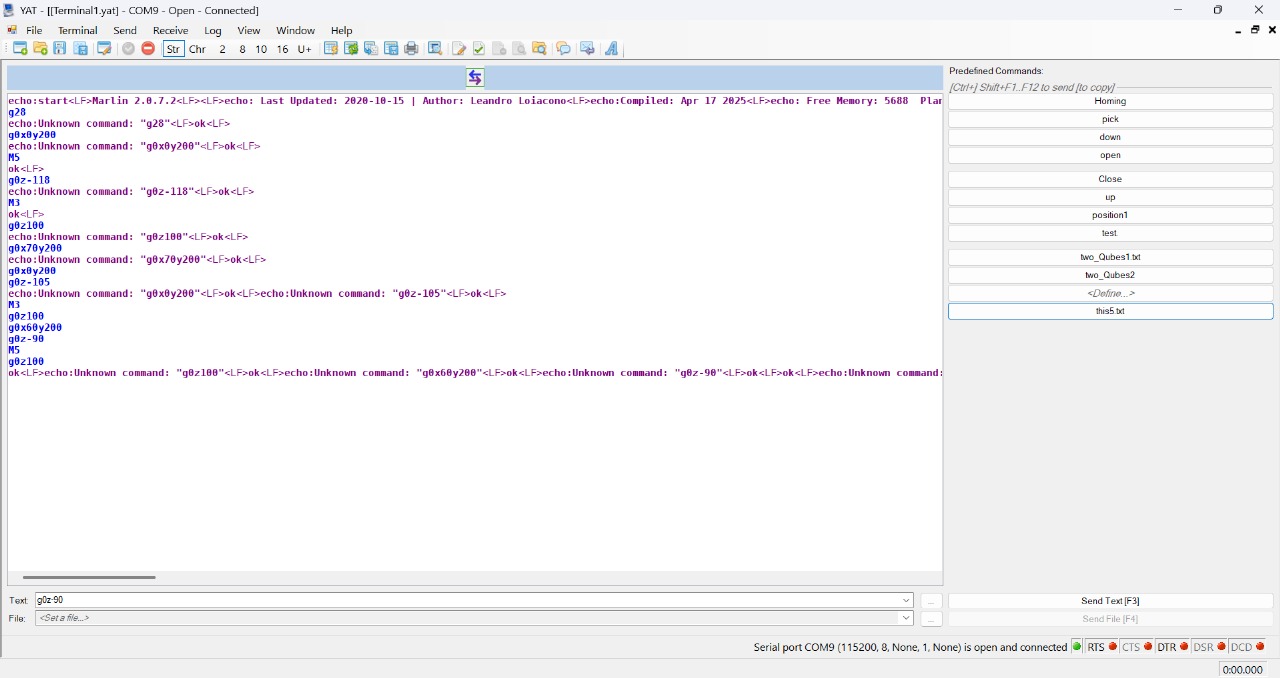

5. Firmware & Serial Communication

- Uploaded Arduino firmware to control motion using G-code commands.

- Tested homing and serial interaction via Serial Monitor and YAT (Yet Another Terminal).

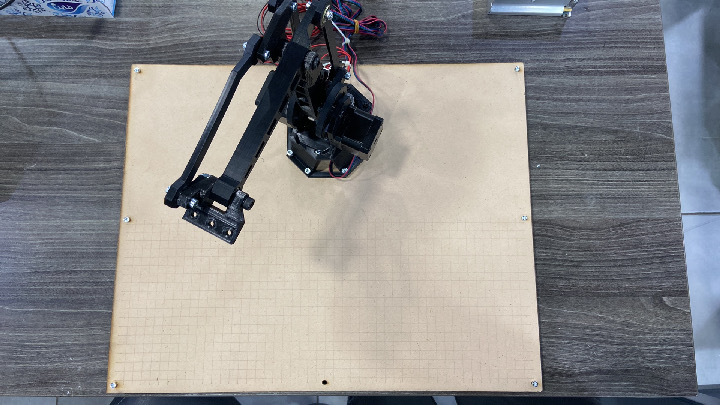

6. Calibration & Base Setup

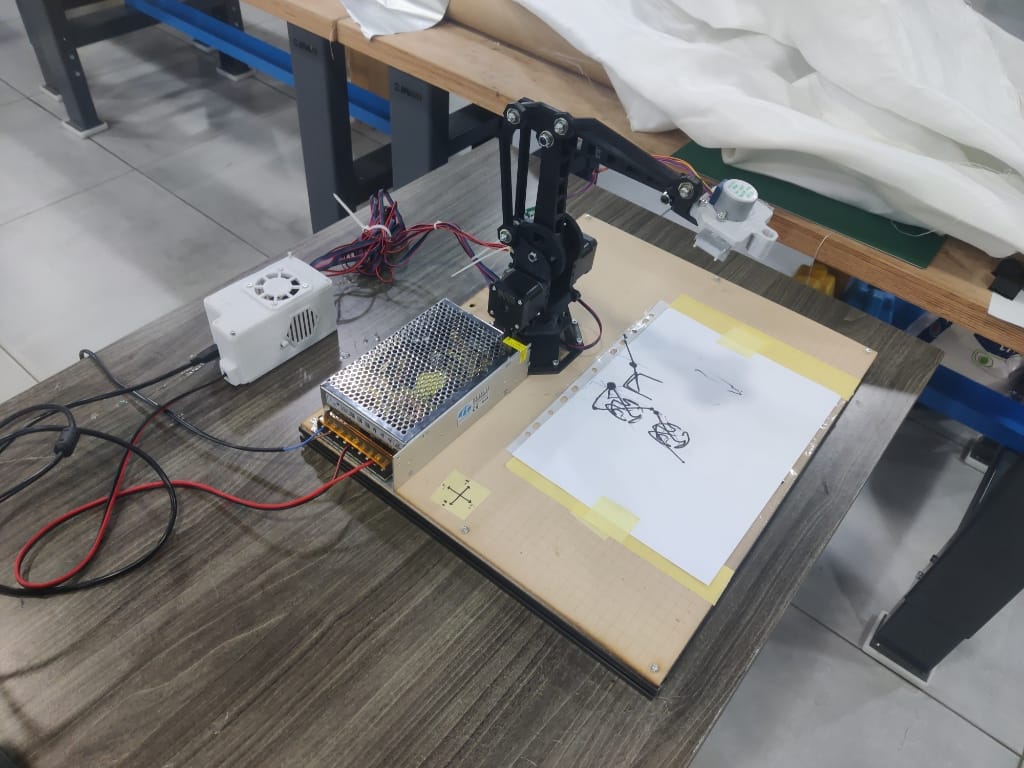

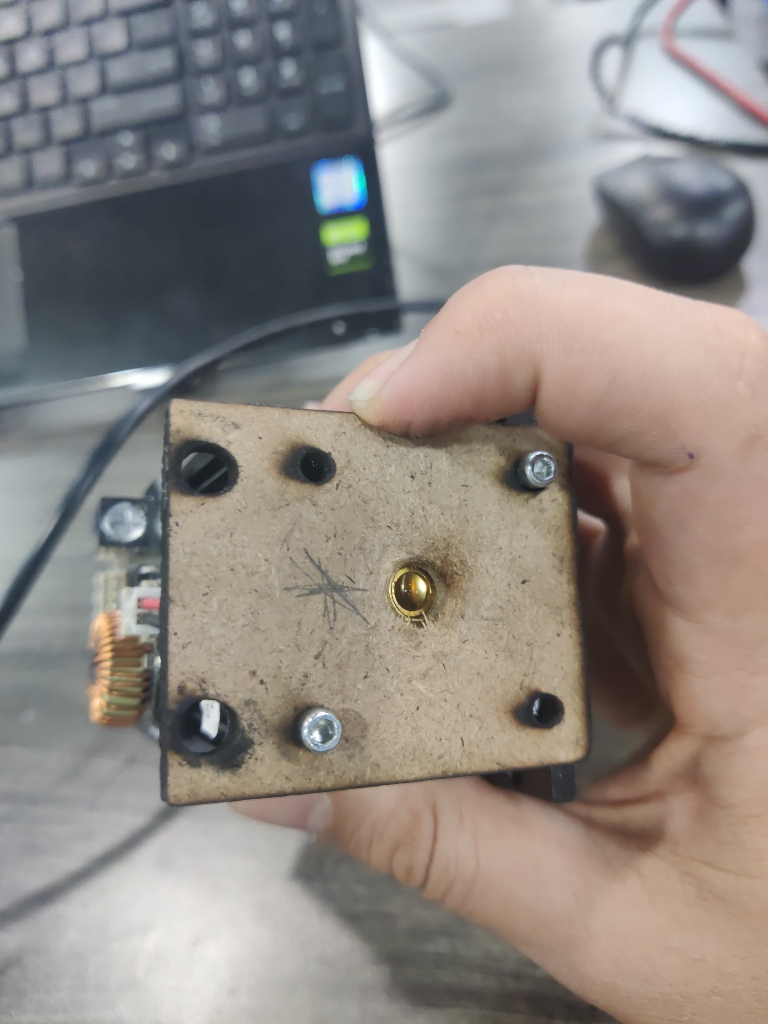

- Built a custom MDF base plate with a coordinate grid to ensure repeatable motion.

- Added aluminum profiles for rigidity and smoothed the surface with sanding tools.

- Printed calibration tools to align motor positions and joints, then updated kinematic values in code.

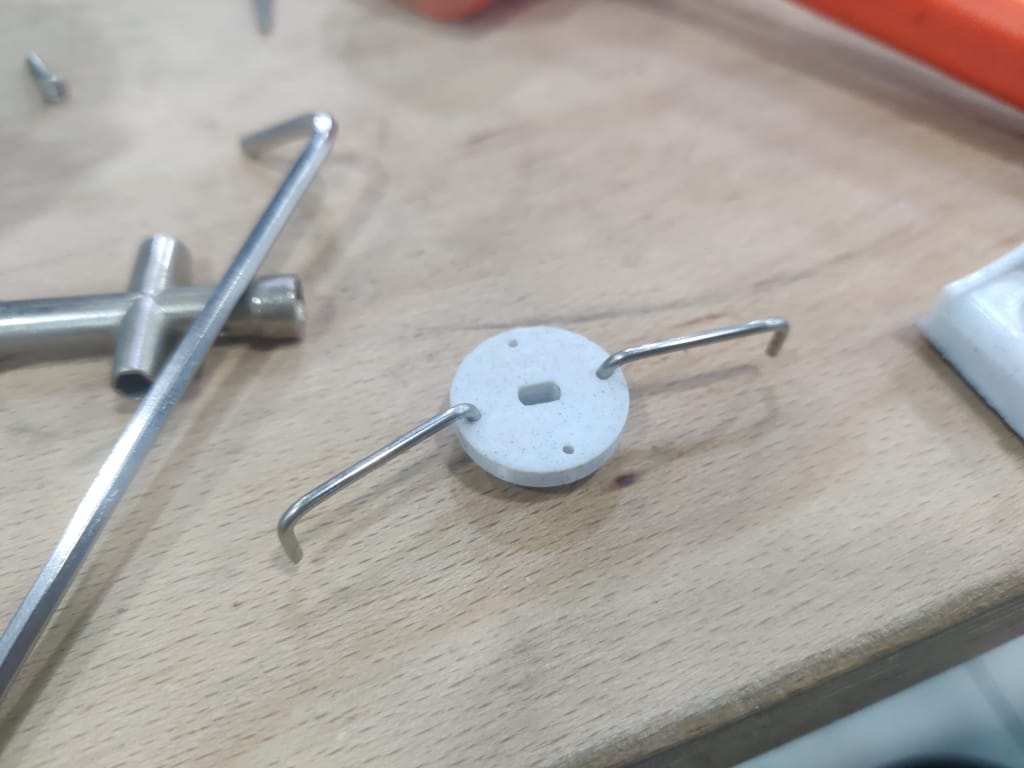

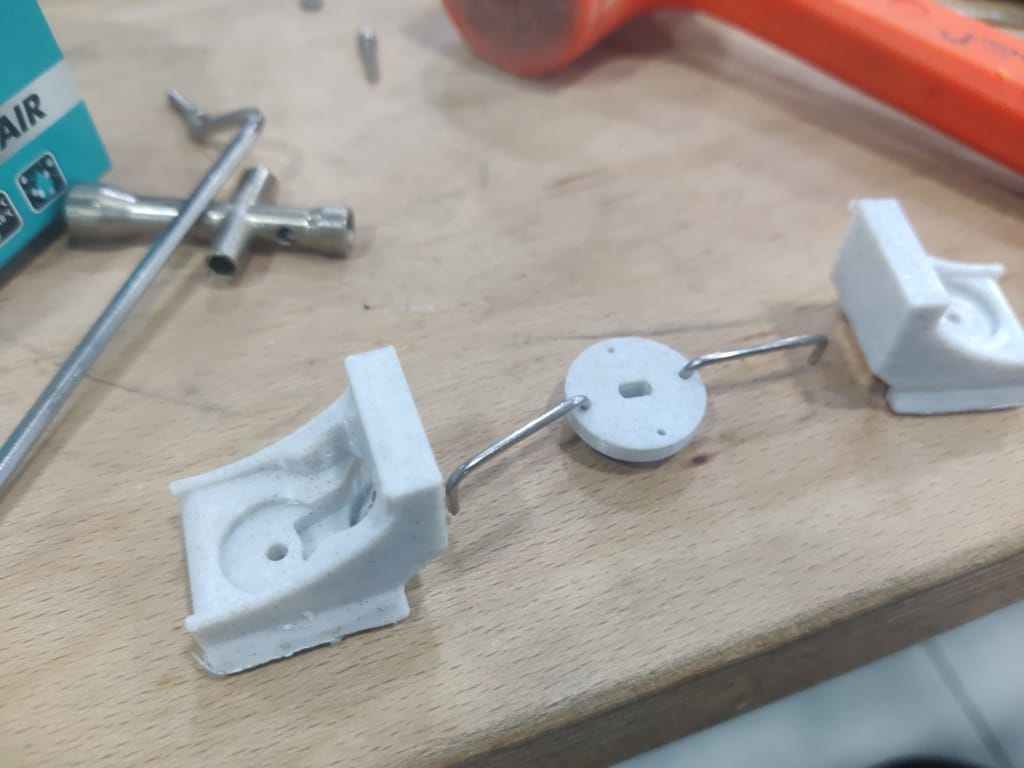

7. Gripper Design & Pick-and-Place Test

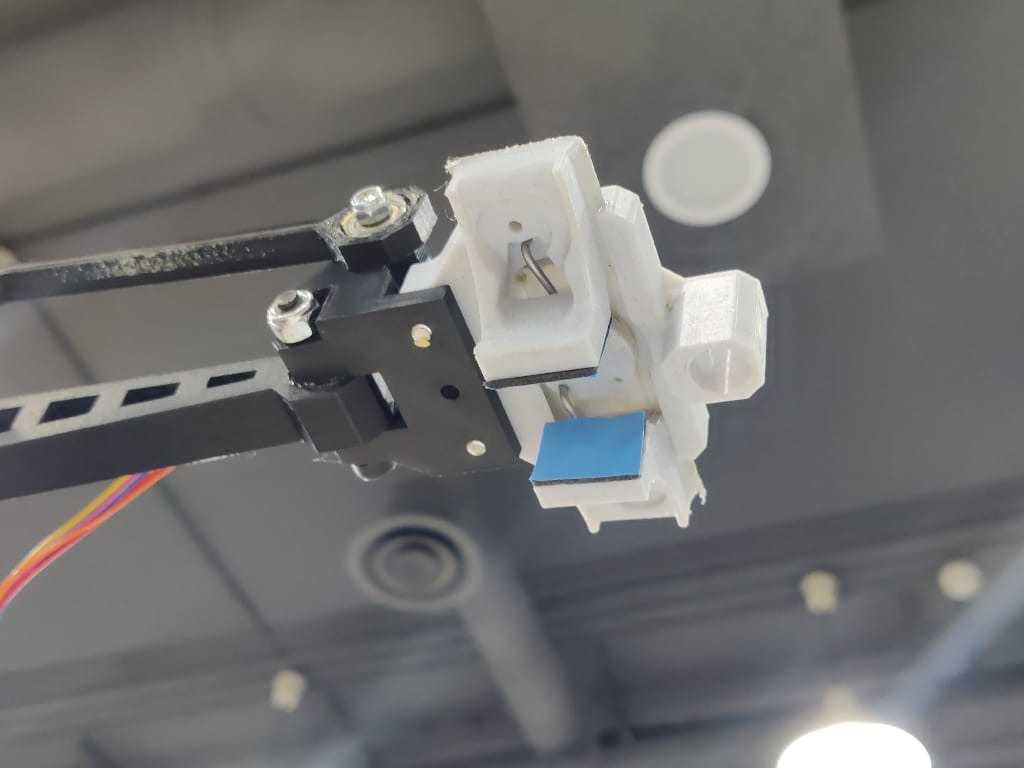

- Modeled and fabricated a two-finger gripper using rods, 3D-printed sliders, and a stepper motor.

- Wired and configured the gripper motor zero position.

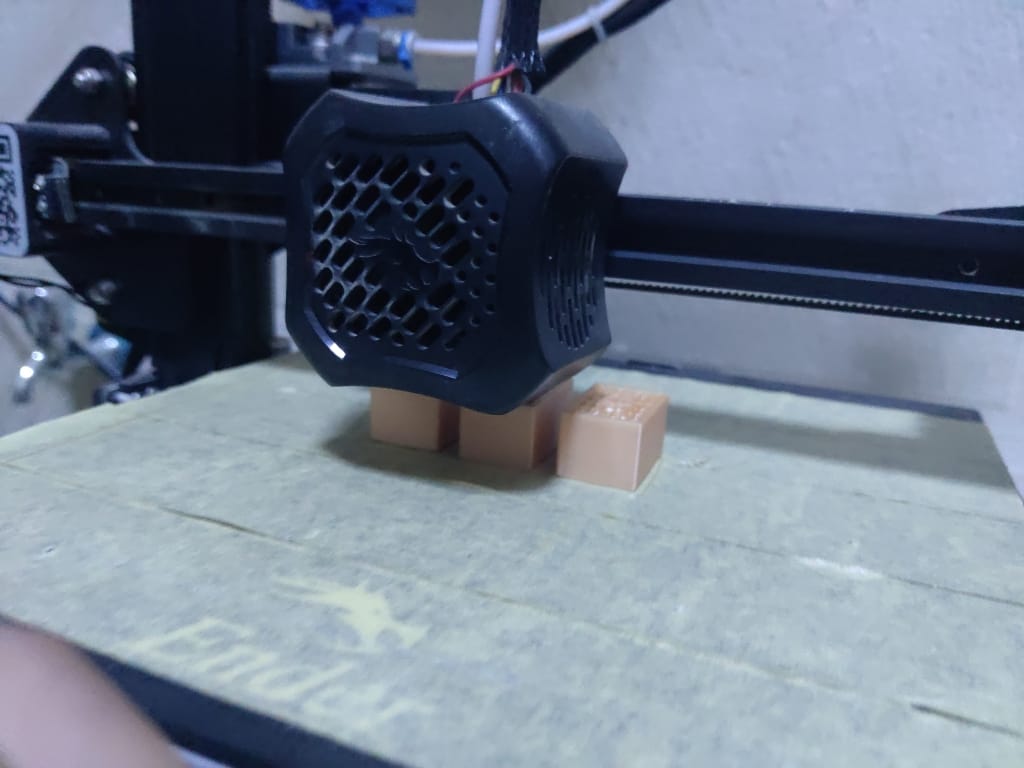

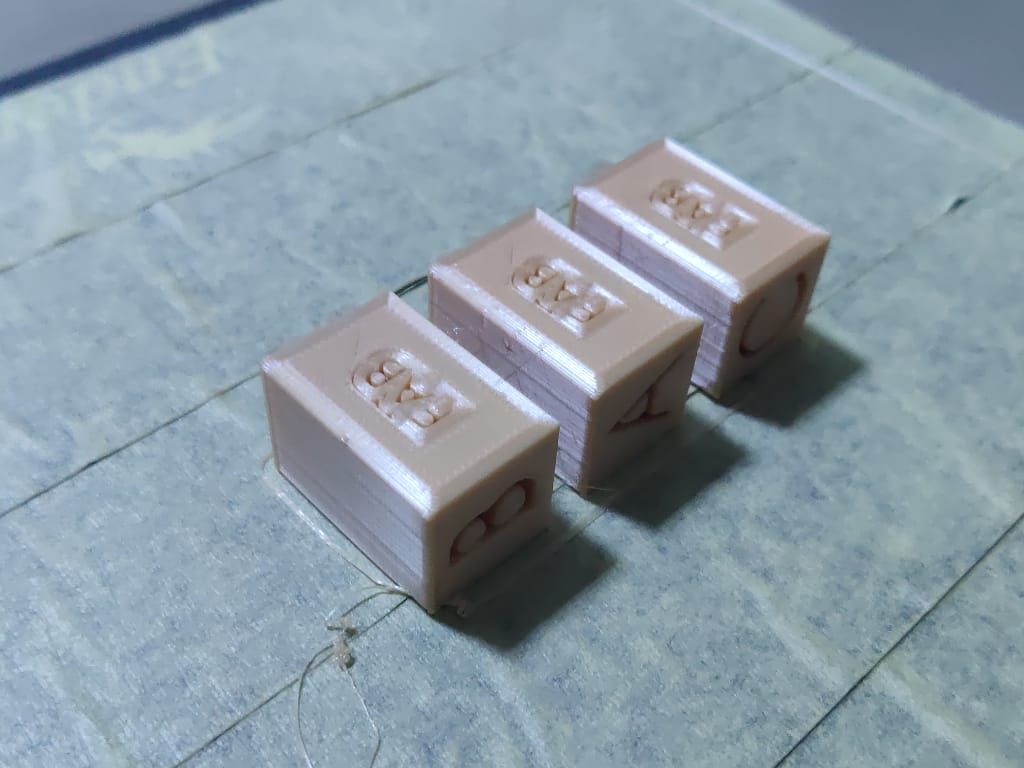

- Printed labeled blocks (A, B, C) and successfully stacked them via scripted motion sequences using YAT.

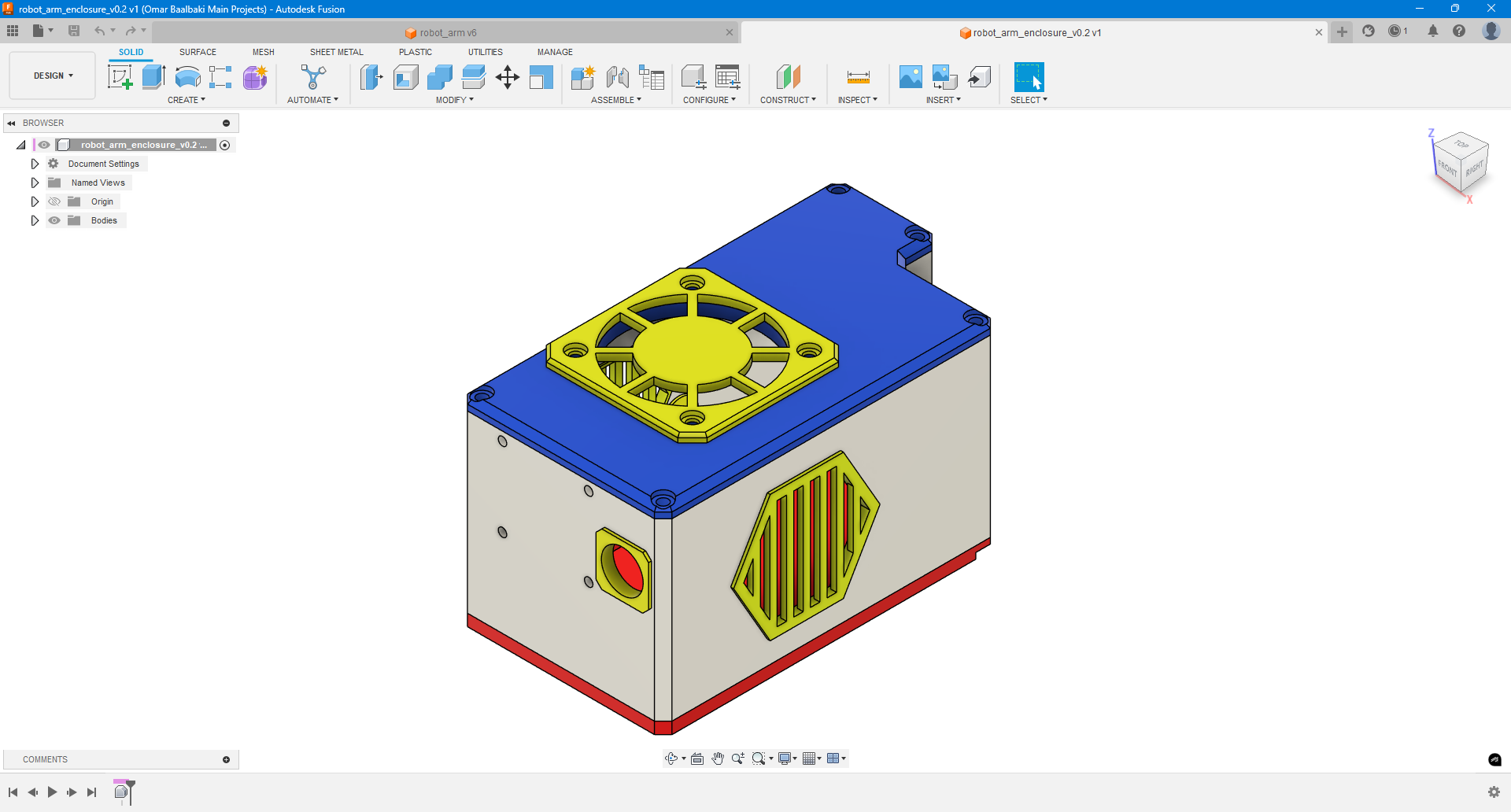

8. Frame Enclosure Build

- Built a protective cubic aluminum frame for stability and future enclosure with acrylic.

- Ensured modularity for thermal insulation during 3D printing operations.

9. Laser Engraving Setup

- Designed and laser-cut a custom laser mount for the robot head.

- Calibrated Z-offset and focus using a test paper and alignment jig.

- Engraved the Fab Academy logo using paper as a medium.

10. Final Testing & Evaluation

- Demonstrated full plotting and pick-and-place operation.

- Validated inverse kinematics functionality and motion precision.

Learning Outcome

This experience deepened my skills in mechanical problem-solving, hardware-software integration, and collaborative prototyping. I learned how to adapt real-world designs to local constraints, troubleshoot fitment issues under time pressure, and optimize mechanical stability for multi-functional use cases. Moreover, I strengthened my ability to coordinate between digital fabrication (3D printing, laser cutting) and electronics wiring, turning a collection of parts into a functional robotic system.

Resources:

https://www.thingiverse.com/thing:3846234