7. Computer-Controlled Machining

Group assigment

- Complete your lab’s safety training

- Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine

- Document your work to the group work page and reflect on your individual page what you learned

Link to Group page: Computer-Controlled Machining

Individual assigment

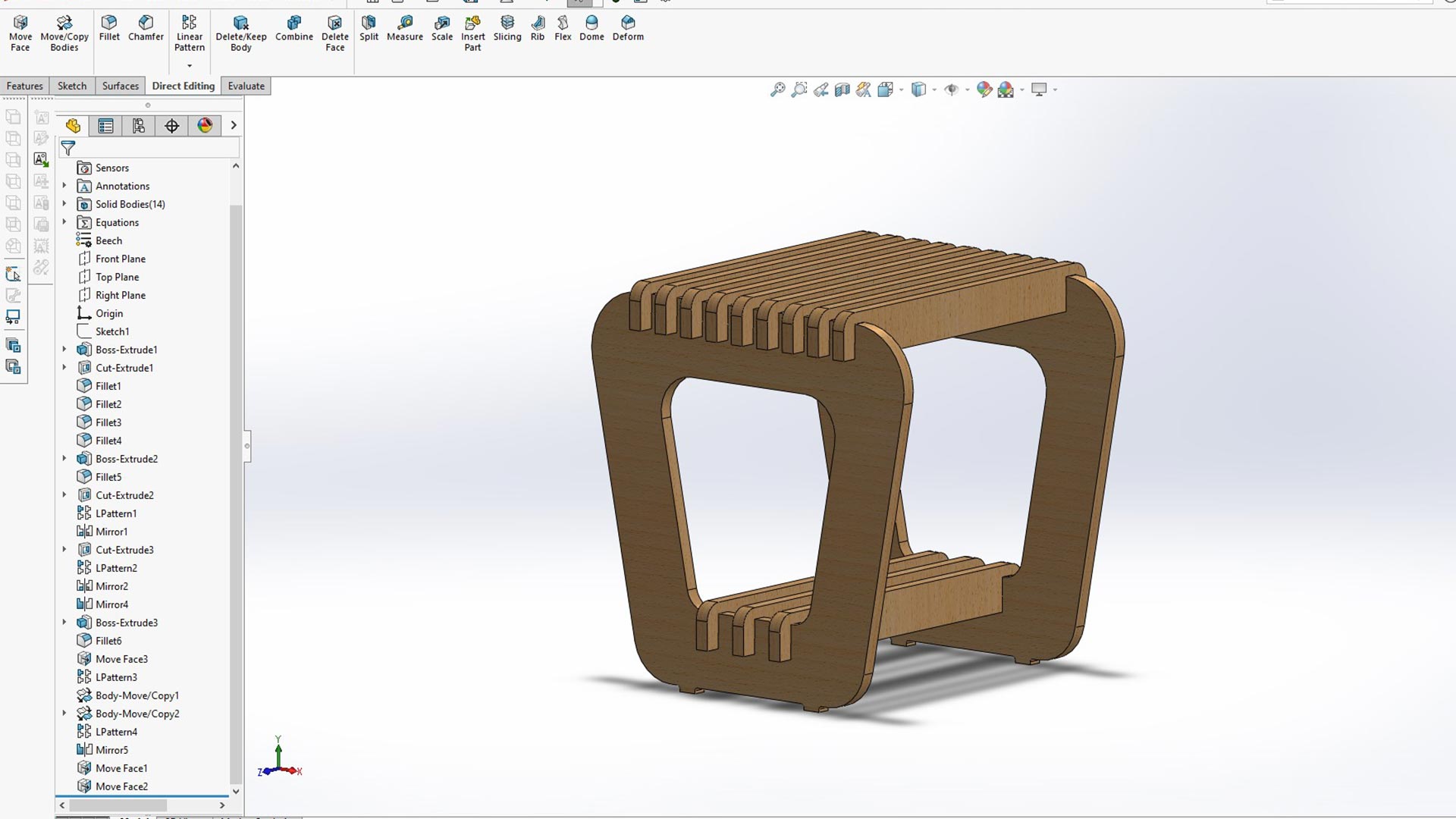

- Make (design+mill+assemble) something big. For this assigment, I designed and fabricated a stool table . I used cnc machine to cutt all the parts.

Design process in SolidWorks

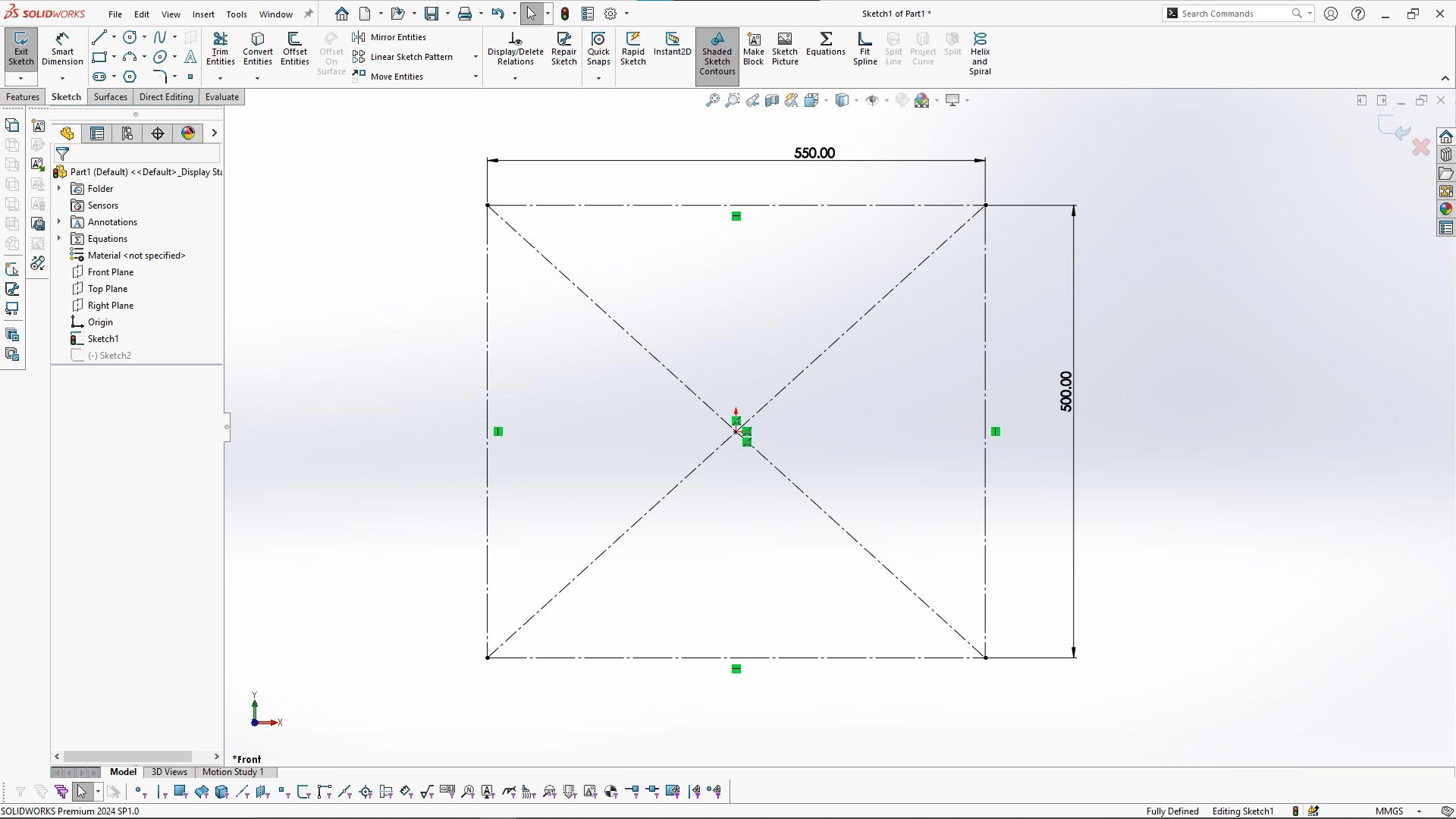

I began by creating a center rectangle to define the stool's base dimensions. I used construction center rectangle.

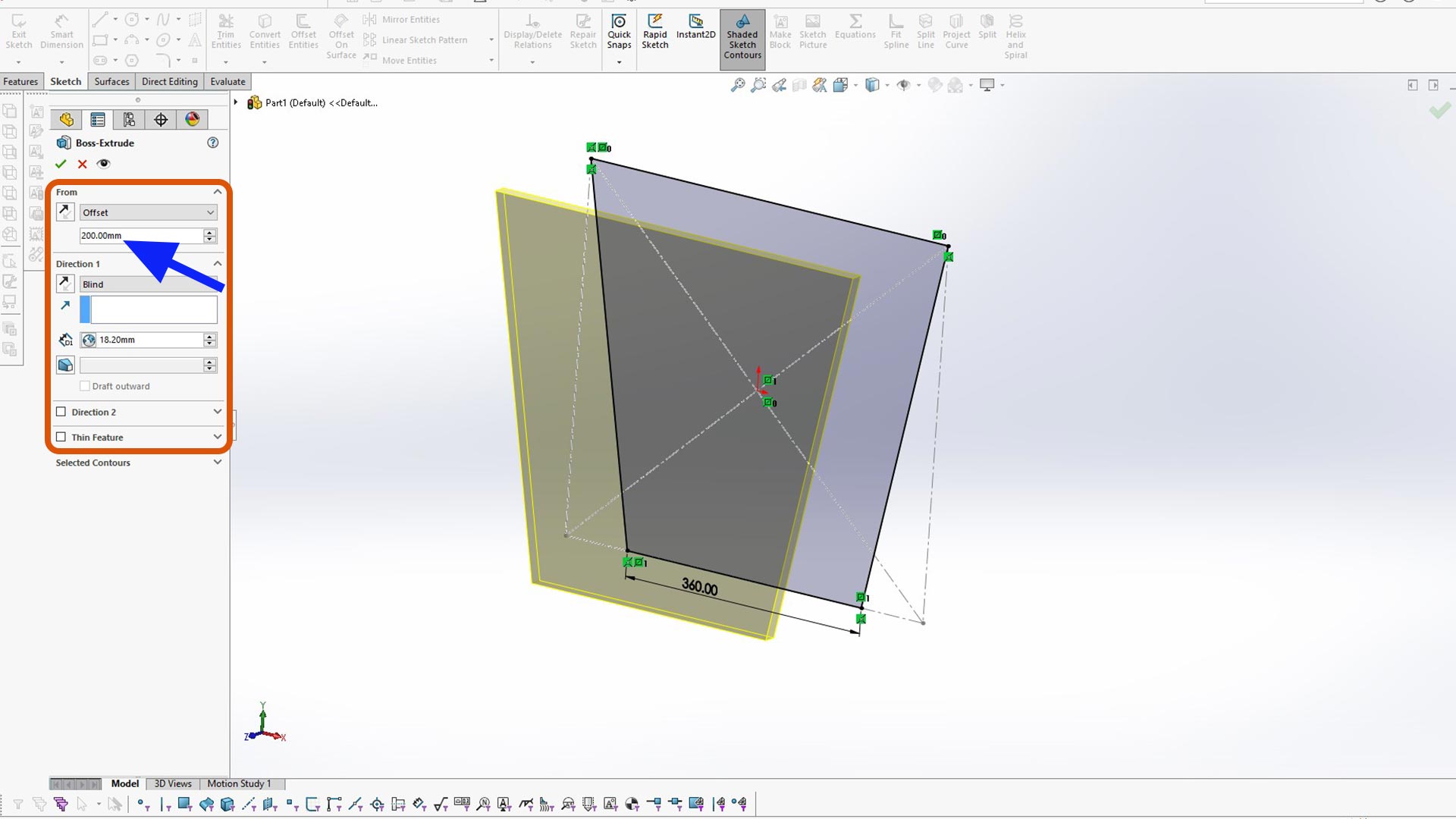

Then I created trapezoid sketch. The shape of the stool. With extrude tool, I added a 200mm offset to establish the stool's height. This approach facilitated the creation of a mirror part later. You can use center plane instead of creating new plane.

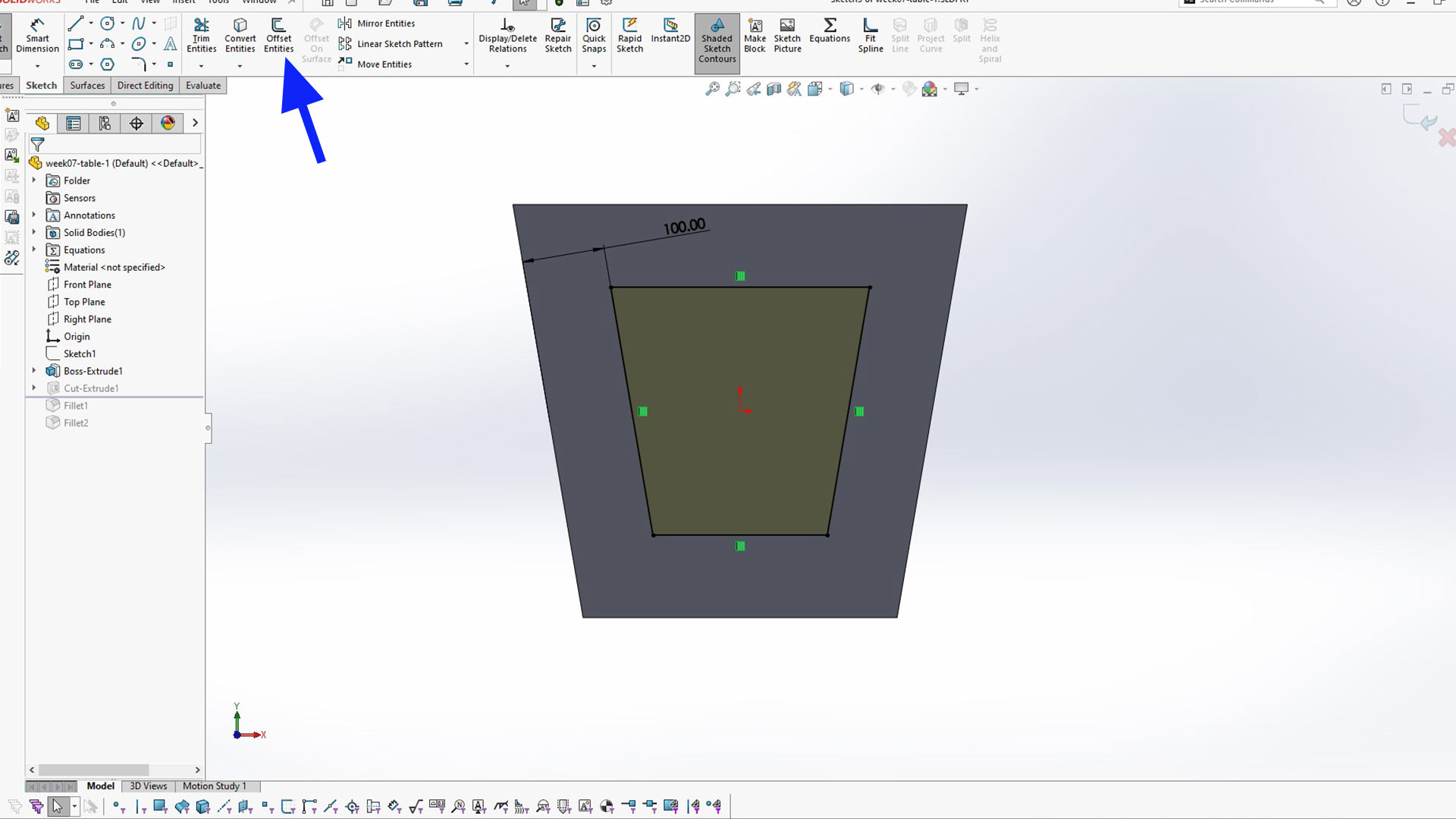

With the Offset Entities tool, I crafted the inner contours sketch, maintaining a 100mm distance from the outer edges.

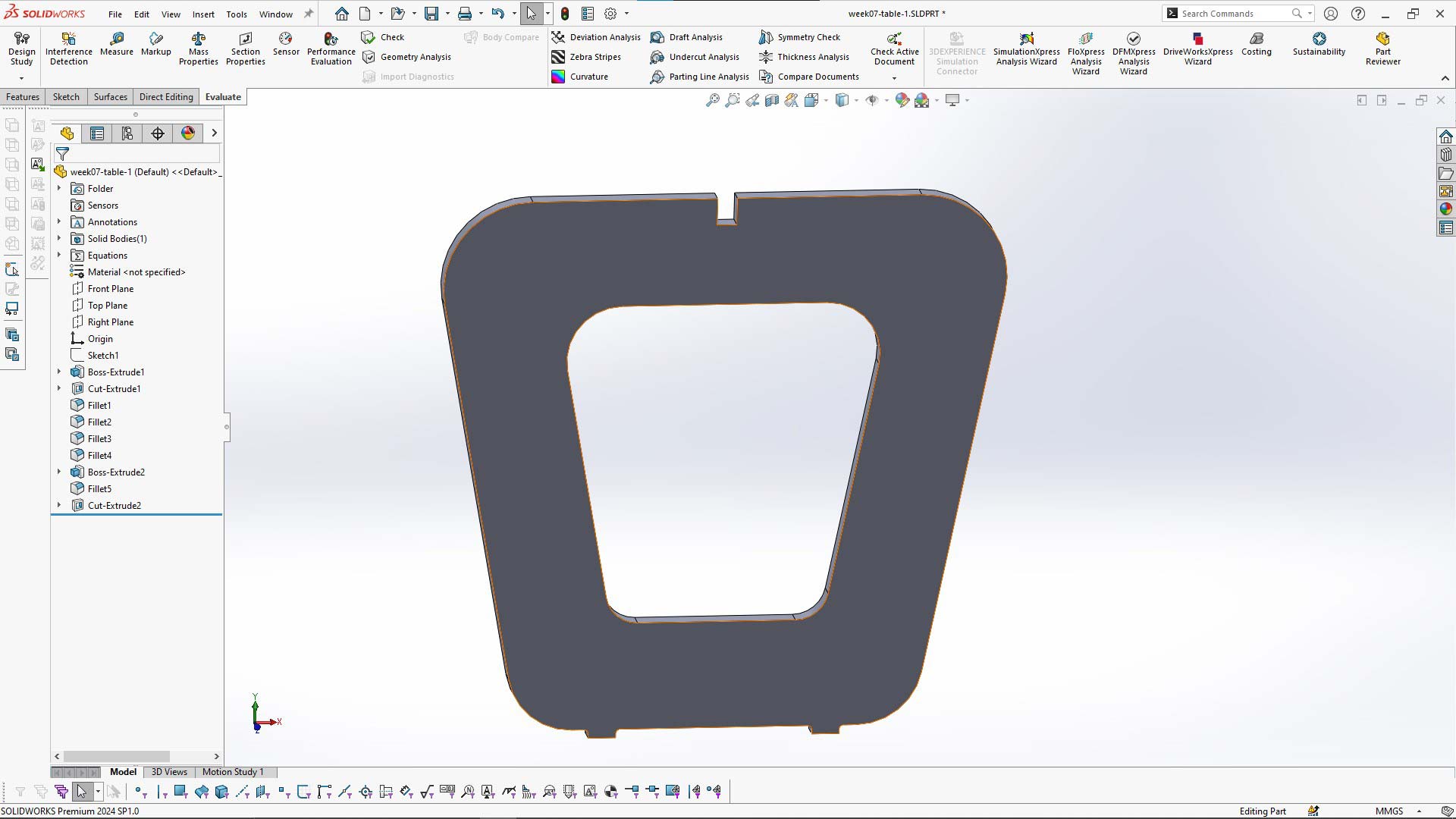

I then added fillet to smooth the edges and designed tabs for the crossbars.

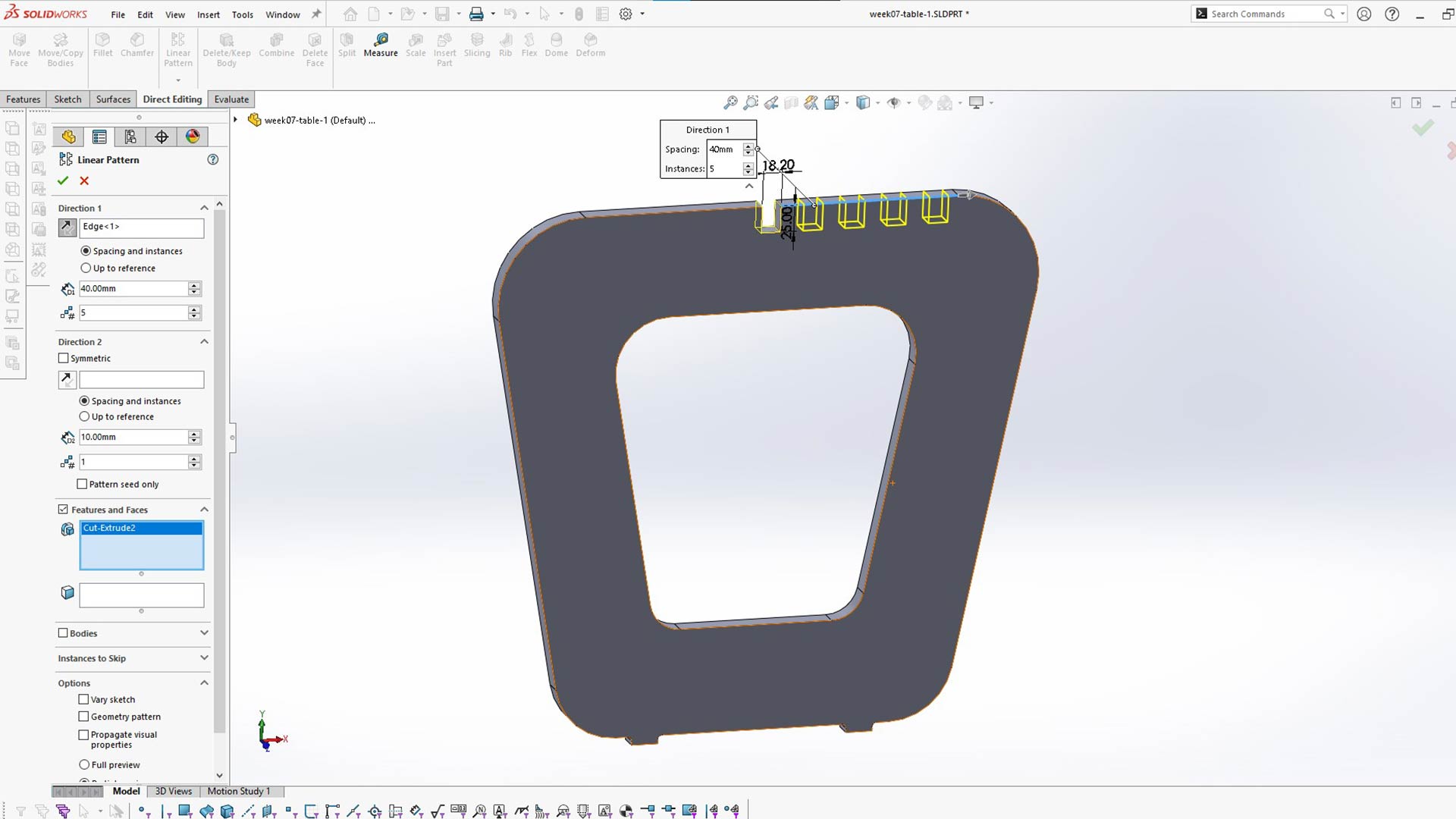

With the Linear Pattern feature, I duplicated the tabs across the design.

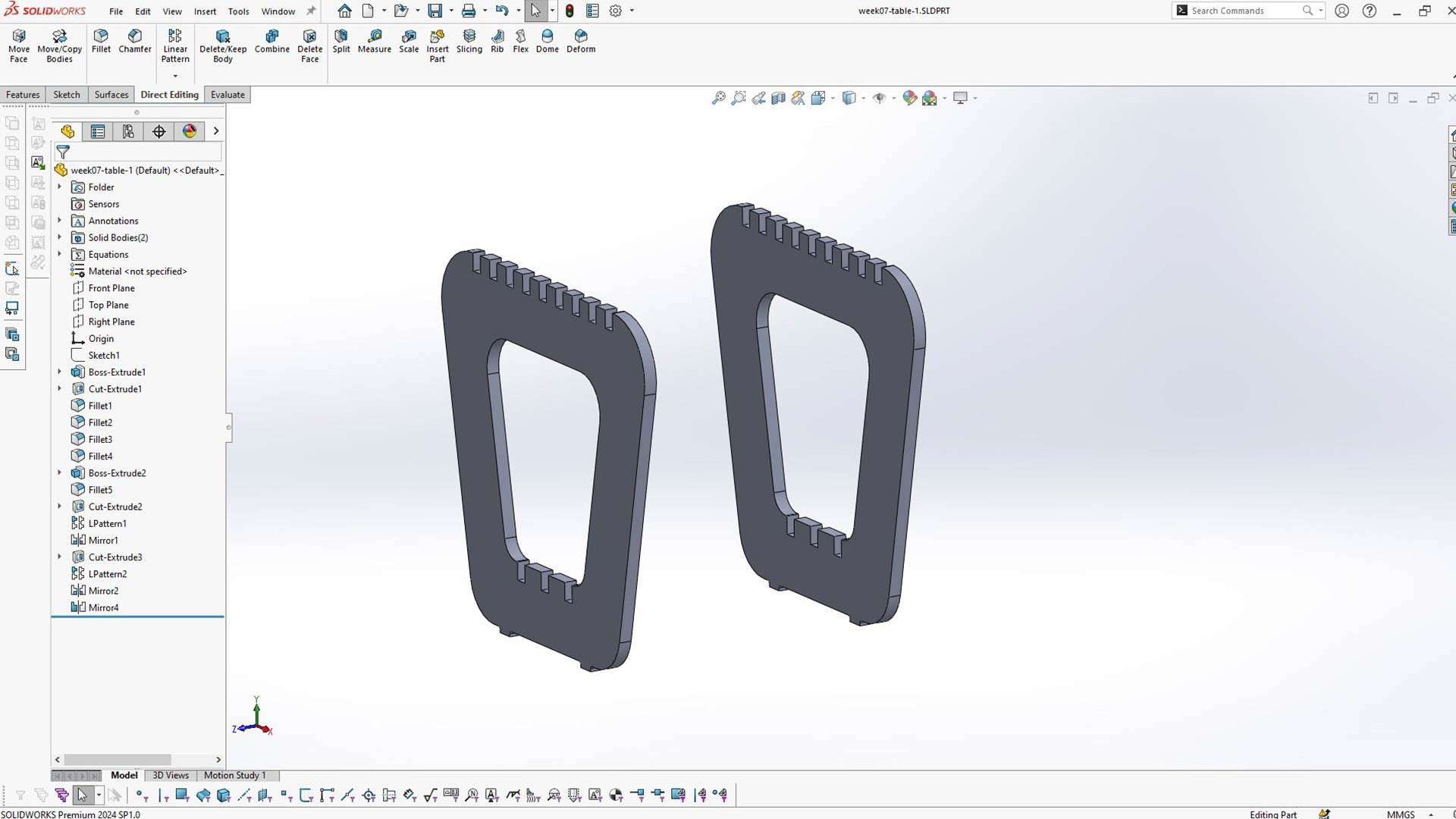

To complete the symmetry of the design, I mirrored the entire body on the other side using plane.

Note: Mirroring body is more efficient in this case since it has quite many features, it is recommended to mirror body instead of feature(s).

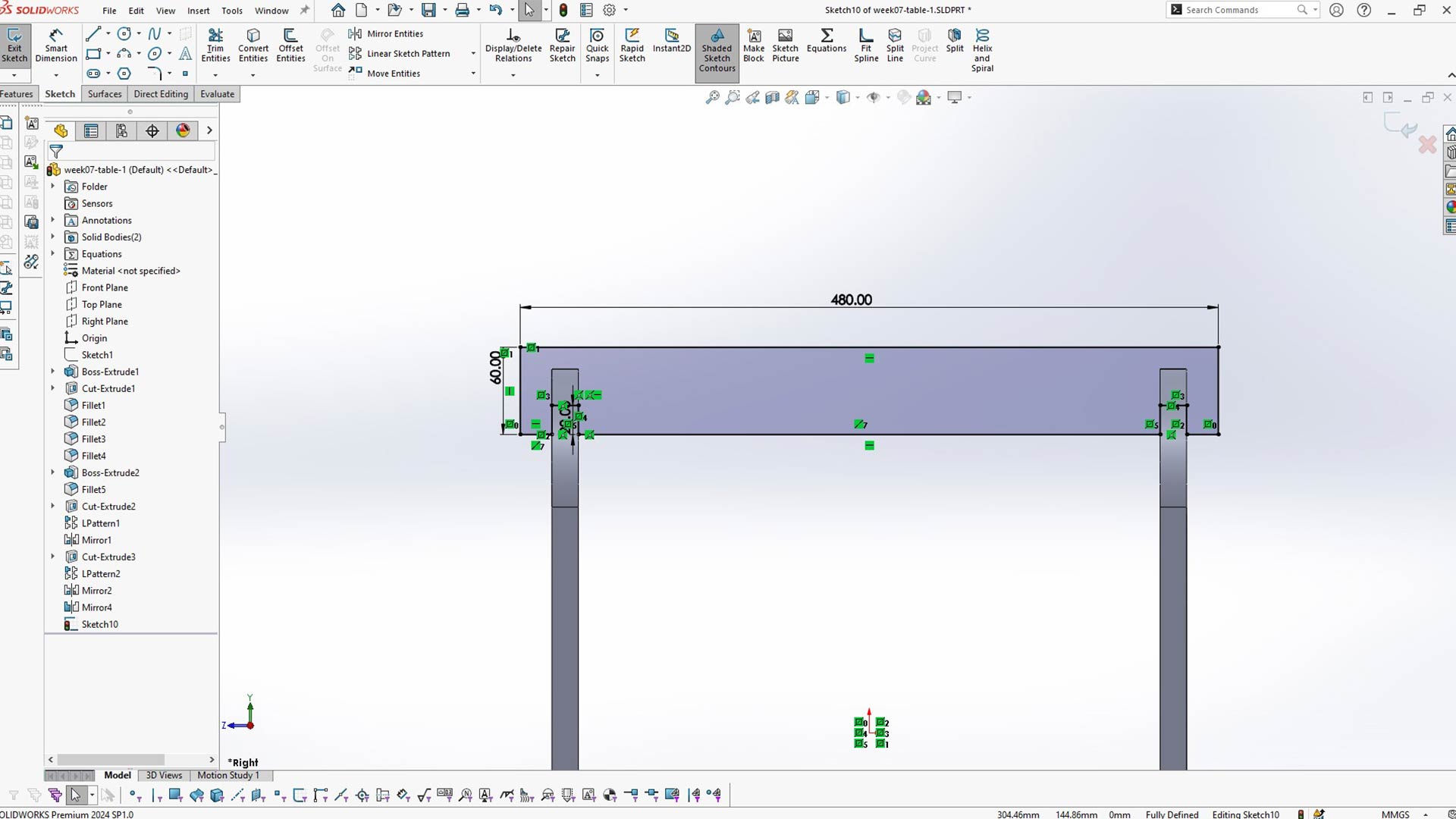

I then designed the crossbars

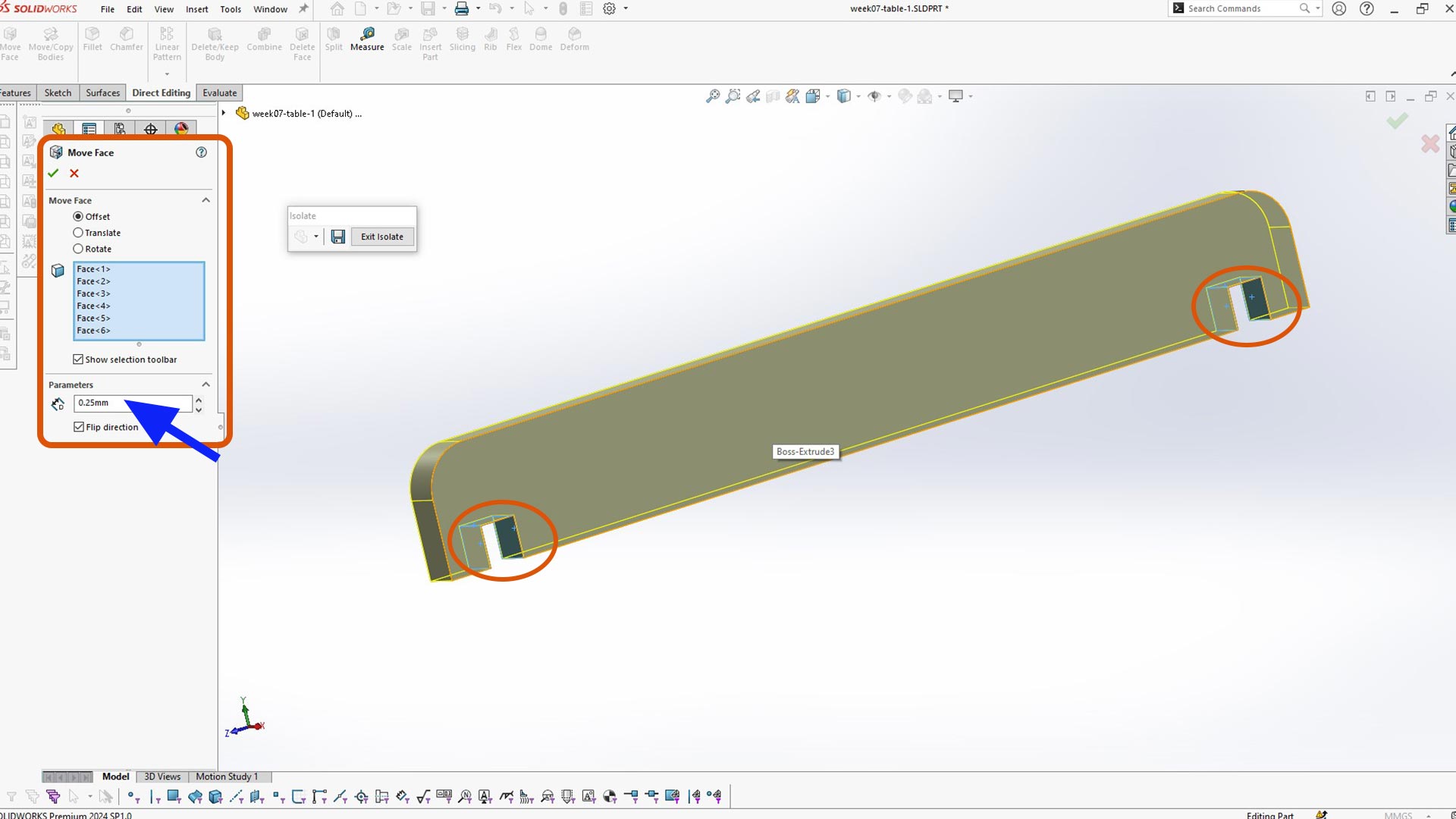

With move face tool, I added 0.25mm clearance, ensuring ease of assembly. This clearance value may vary depending on the material used.Therfore it is best practive the test it before cutting all pieces.

Finally, I used the Linear Pattern tool to replicate all the necessary crossbars.

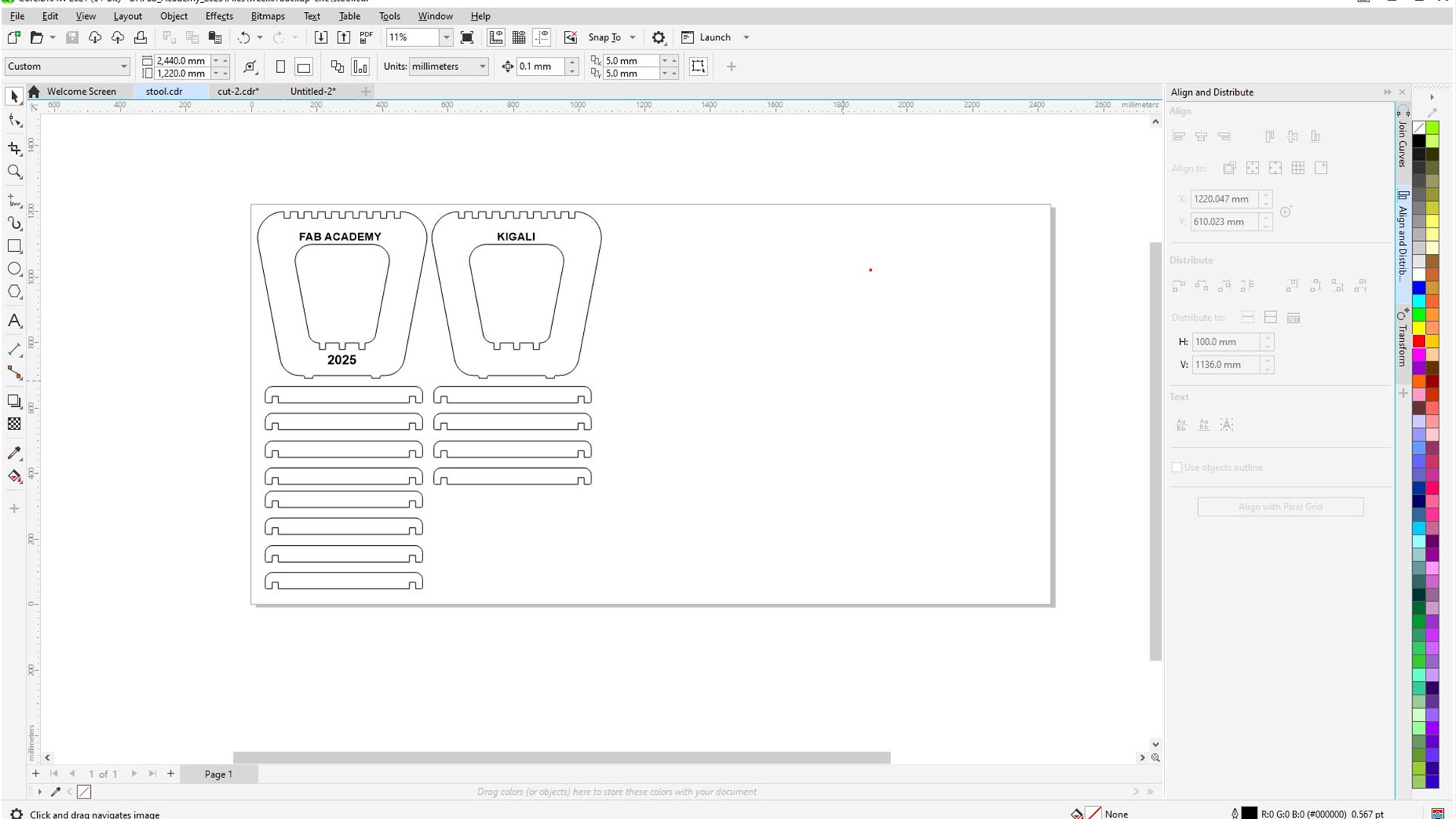

Preparing Files in CorelDRAW

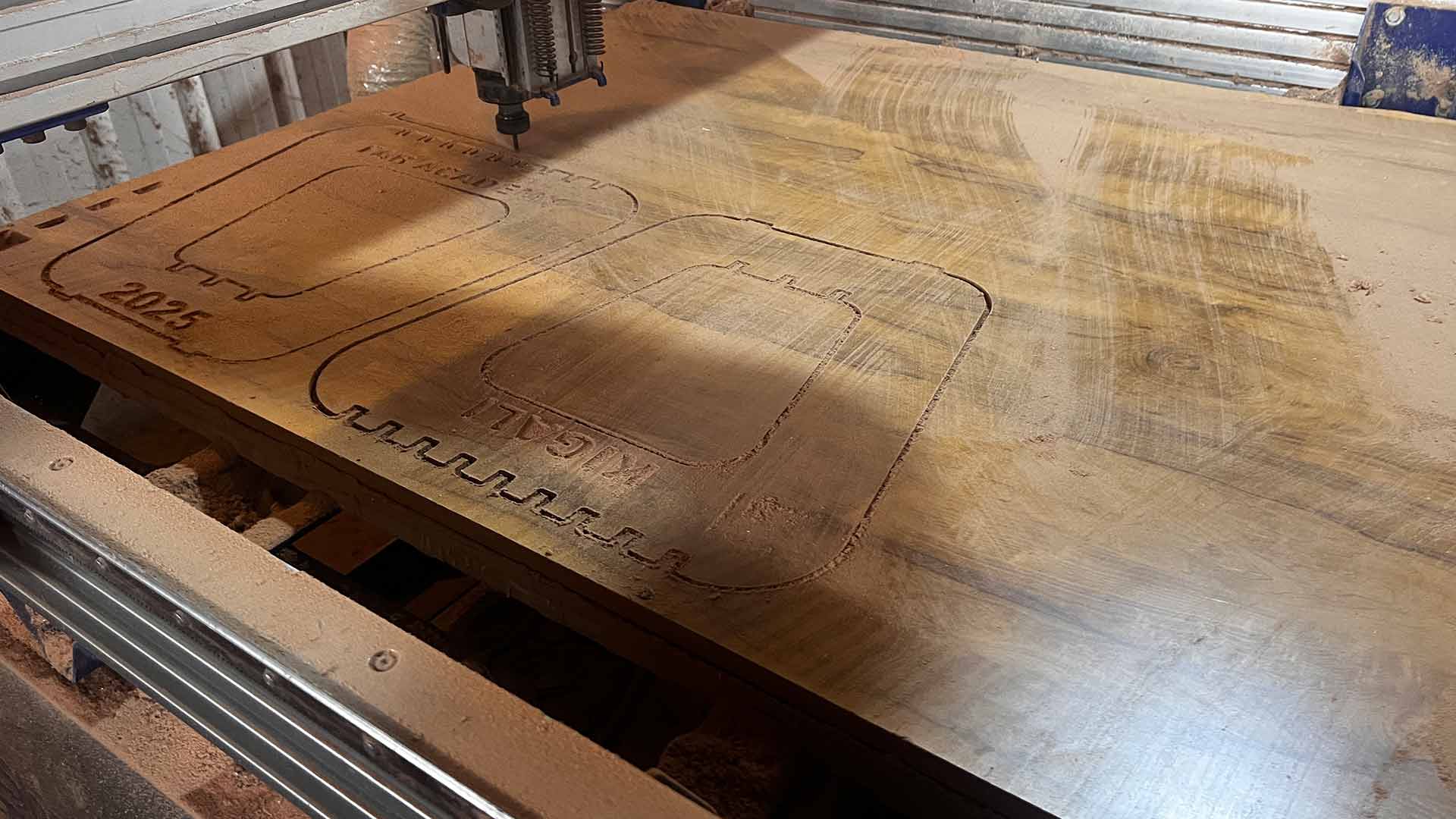

After completing the design, I exported the parts as DXF files and arranged them in CorelDRAW. This step helped me to visualize the material required and then I added text annotations for engraving.

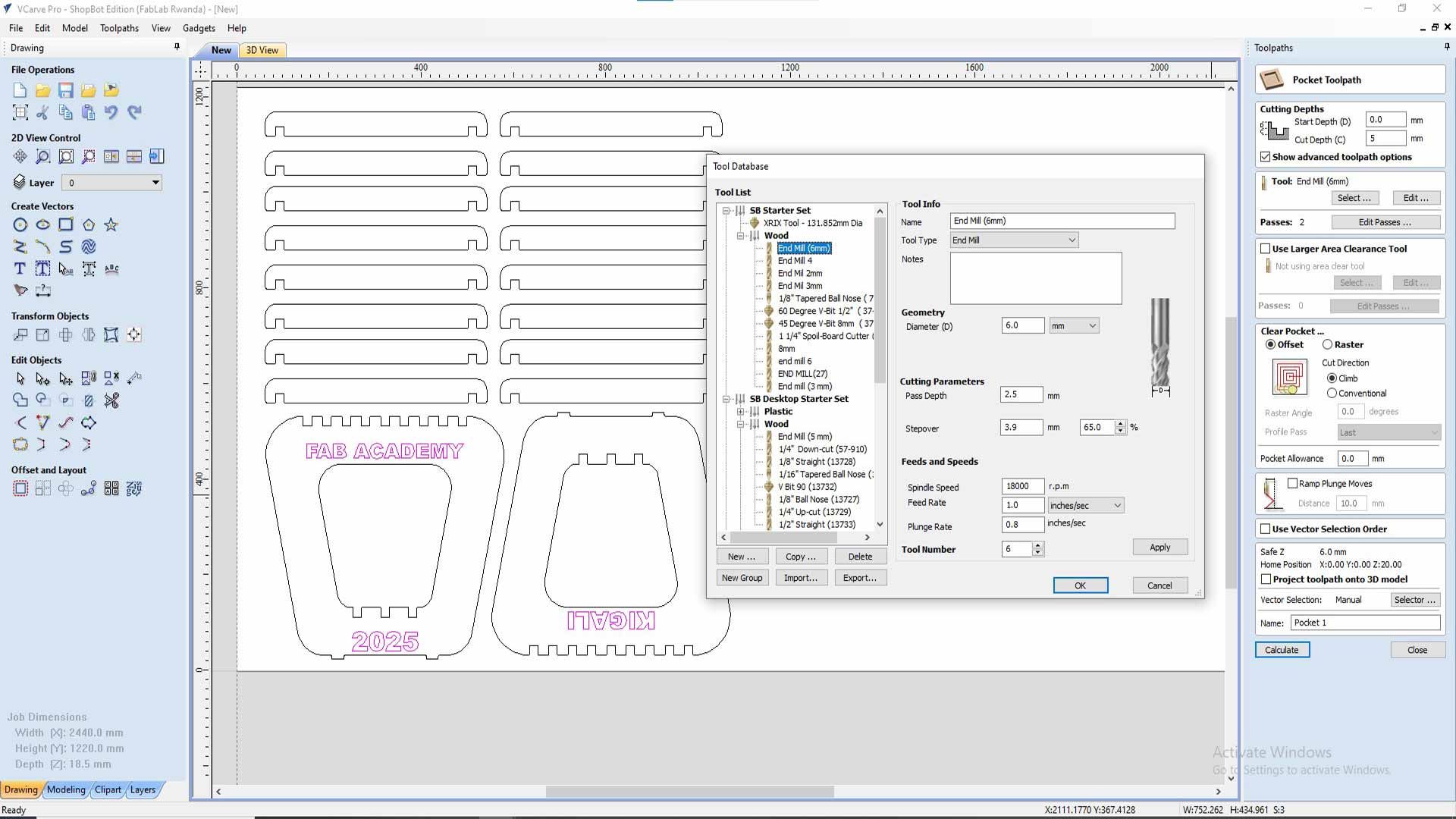

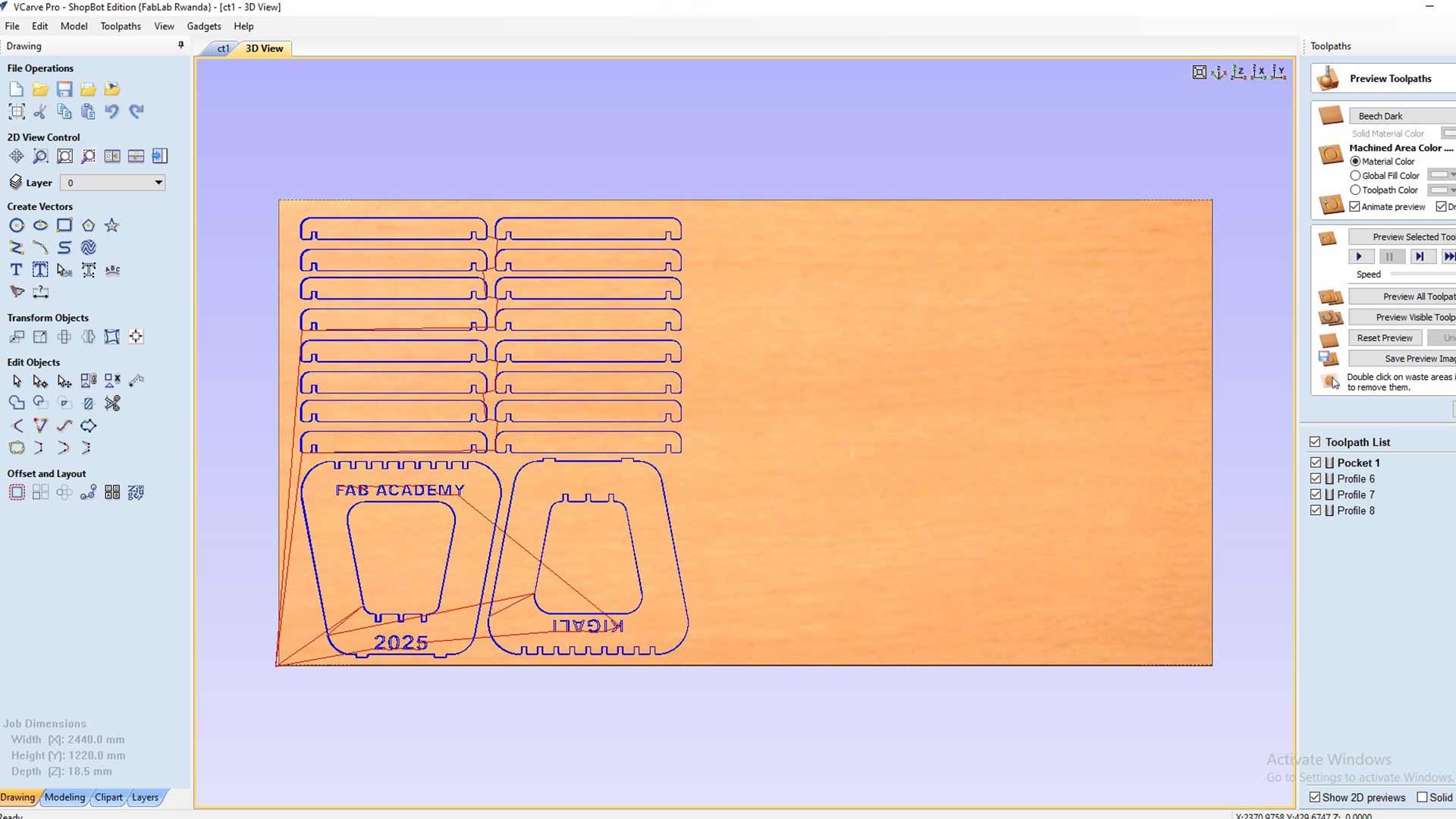

Generating Toolpath in VCarve Pro

I imported the file in VCurve pro to calclate tool path. I started with text to be engraved first. I used 6mm diameter tool and engraved 5mm deep with two passes.

I then added the other toolpath. All other parts will cut profile.

CNC Machining

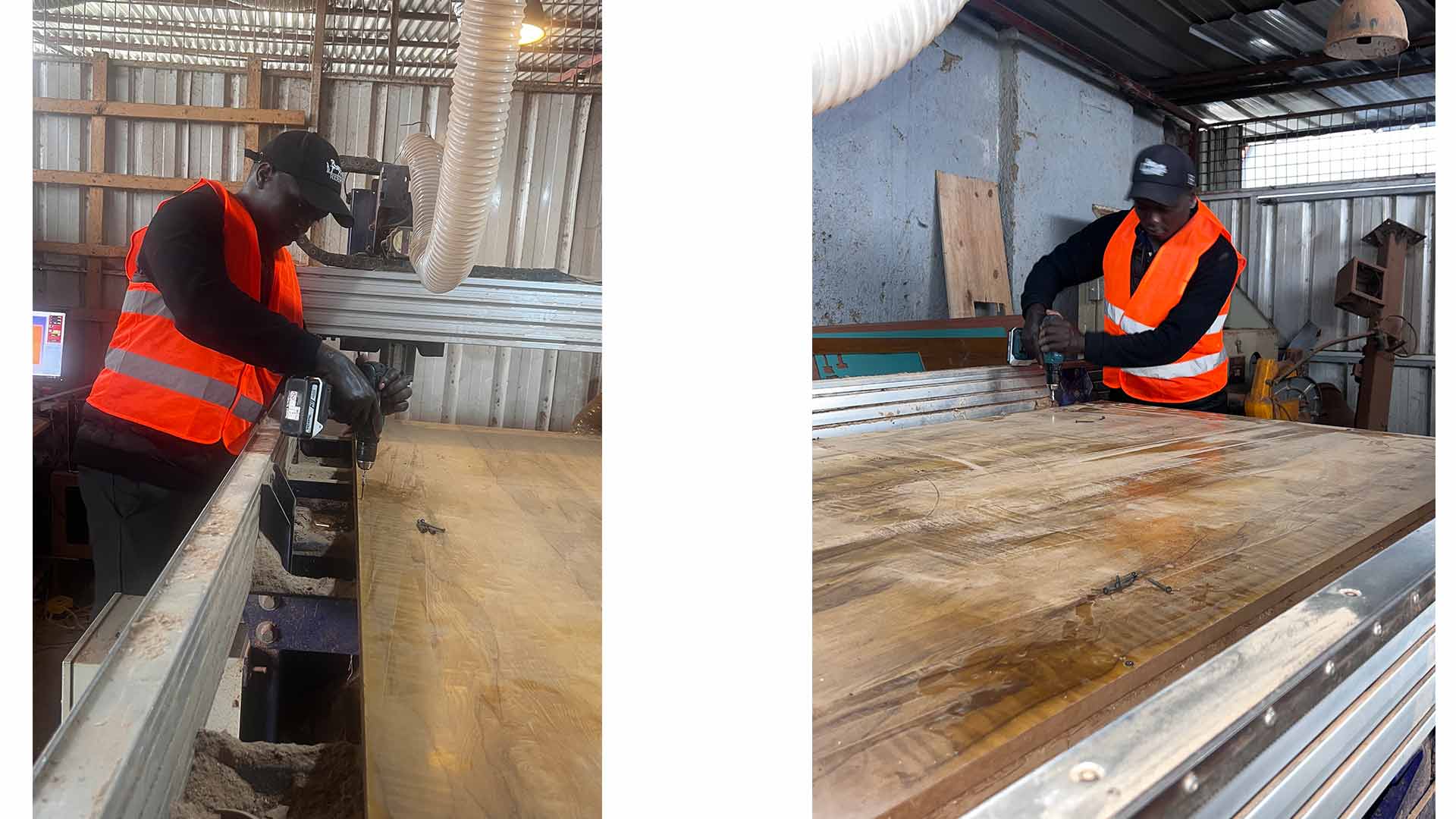

I placed MDF board on cnc machine and then secured it with screws to prevent movement during cutting.

I began by engraving text and followed by cutting out the stool components.

After machining is done, I cleaned all the pieces to prepare them for assembly.

Assembling process

I started by aligning side stands vertically and connected them with one horizontal crossbar.

I then added the top crossbar panel onto the assembled to make base frame.

Finally, I installed the remaining crossbars to complete the stool structure.

Download files

Here you will find the original files I designed

SolidWorks Design File DXF Files for CNC Machining