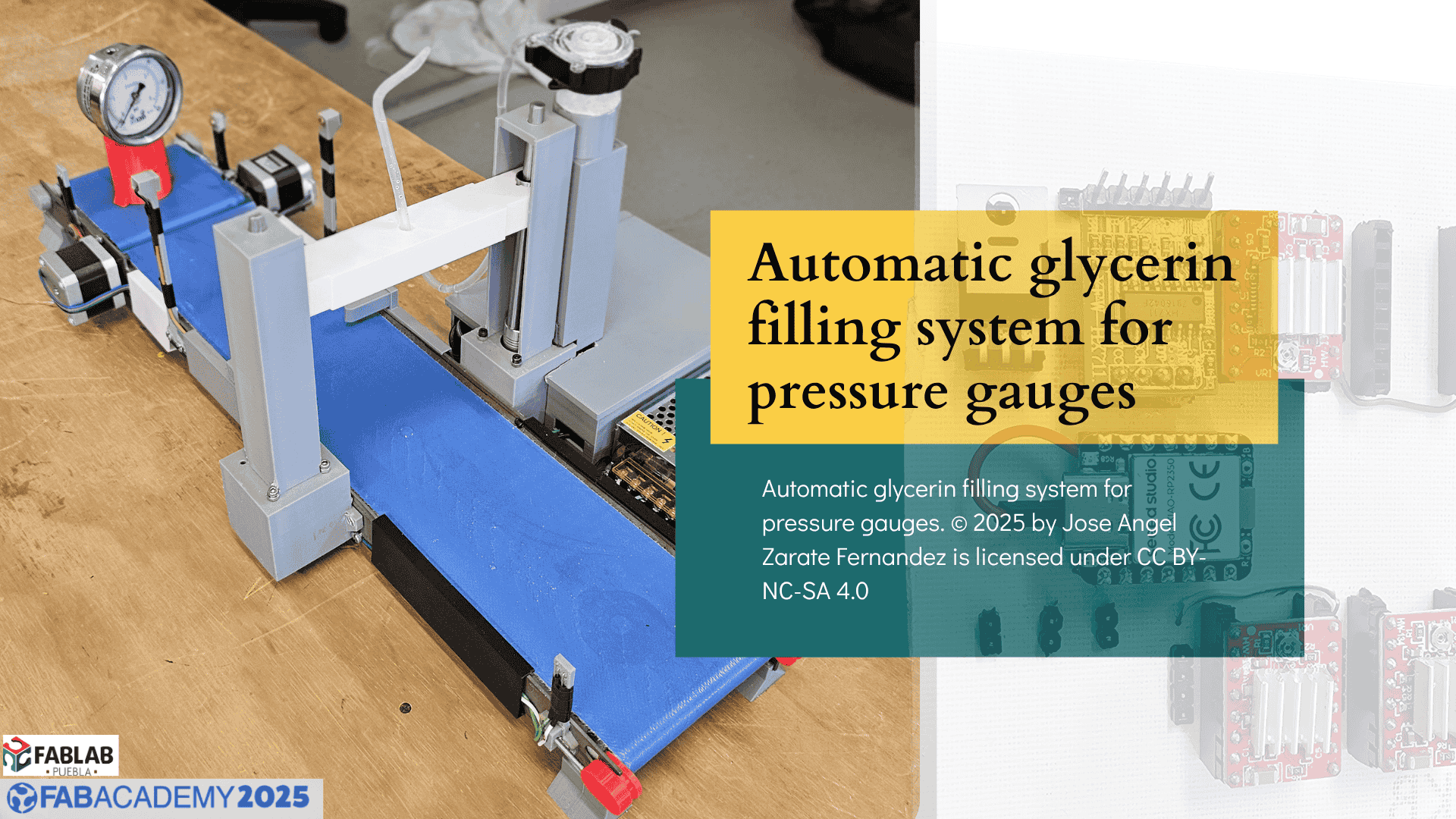

My Final Project- Automatic glycerin filling system for pressure gauges.

Research

For my final project I will resume a prototype that still is a work in progress. An Automatic glycerin filling system for pressure gauges.

In the pressure gauges business is important that some of them are filled with glycerin, this to ensure the accuracy of the measurements, avoid spikes on the indicator and absorb the movements to which the pressure gauge may be exposed. Some companies still fill the pressure gauge manually resulting in high human error which contributes to the waste of glycerin and time. The purpose of this project is to make the process 100% automatic to save time and glycerin, resulting in potentials savings to the company.

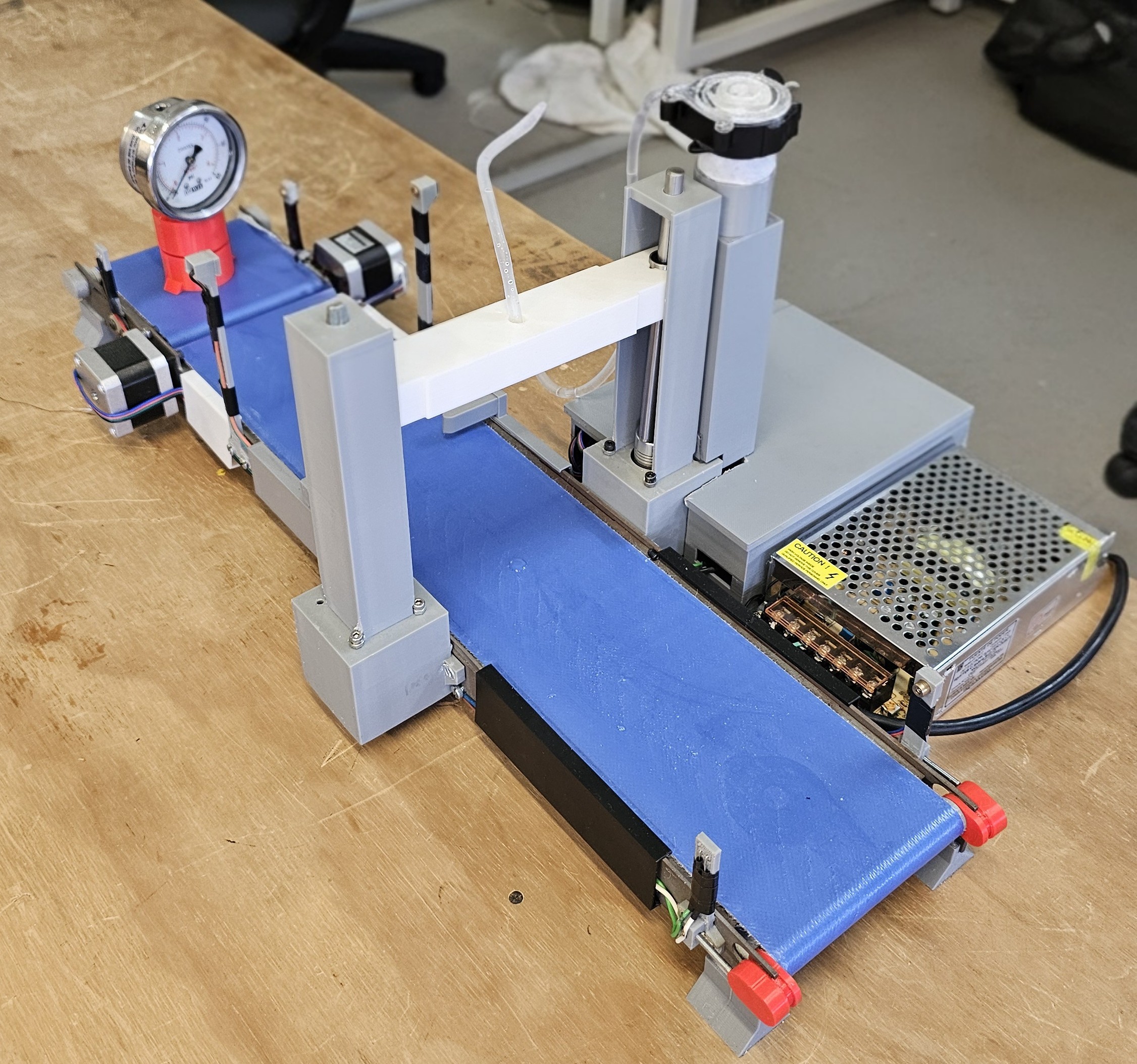

Currently this is my prototype, which I want to upgrade in the next 5 months of hard work.

Improvements to make:

- Faster filling process.

- Expand the band to have more pressure gauges in the system.

- Have a stop/start system.

- Add a Storage/collection area.

- Adapt the height of the filling system to accommodate the size of the pressure gauges.

- Use a laser detection system.

- Use of stronger materials.

Fabrication Processes Used

- Waterjet Cutting: Used to create the metal base and structural components of the conveyor system with precision and durability.

- 3D Printing: Applied for designing and producing custom brackets, nozzle holders, and sensor supports for the system.

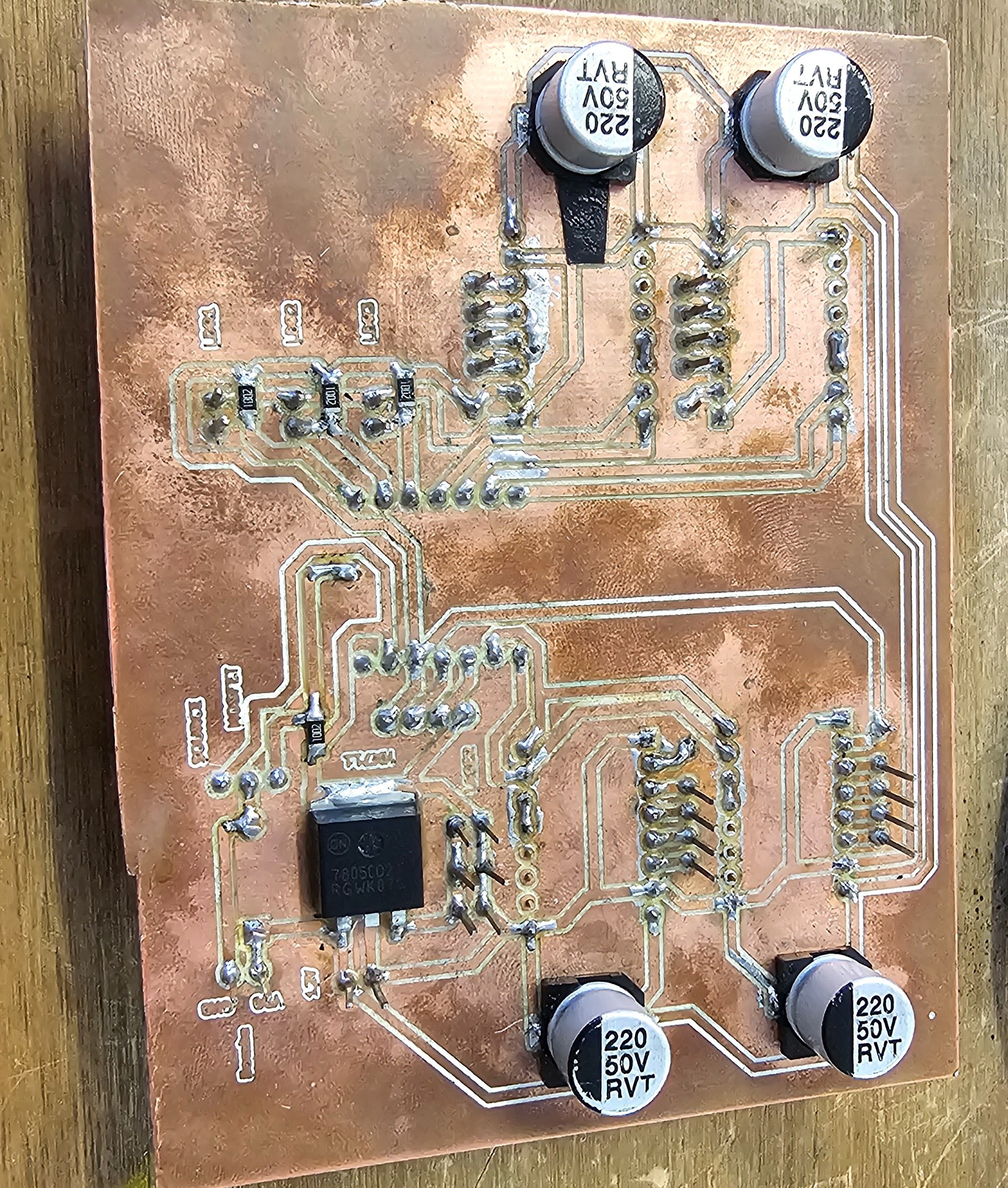

- PCB Fabrication: Designed and manufactured a custom printed circuit board to control the motors, sensors, and pump.

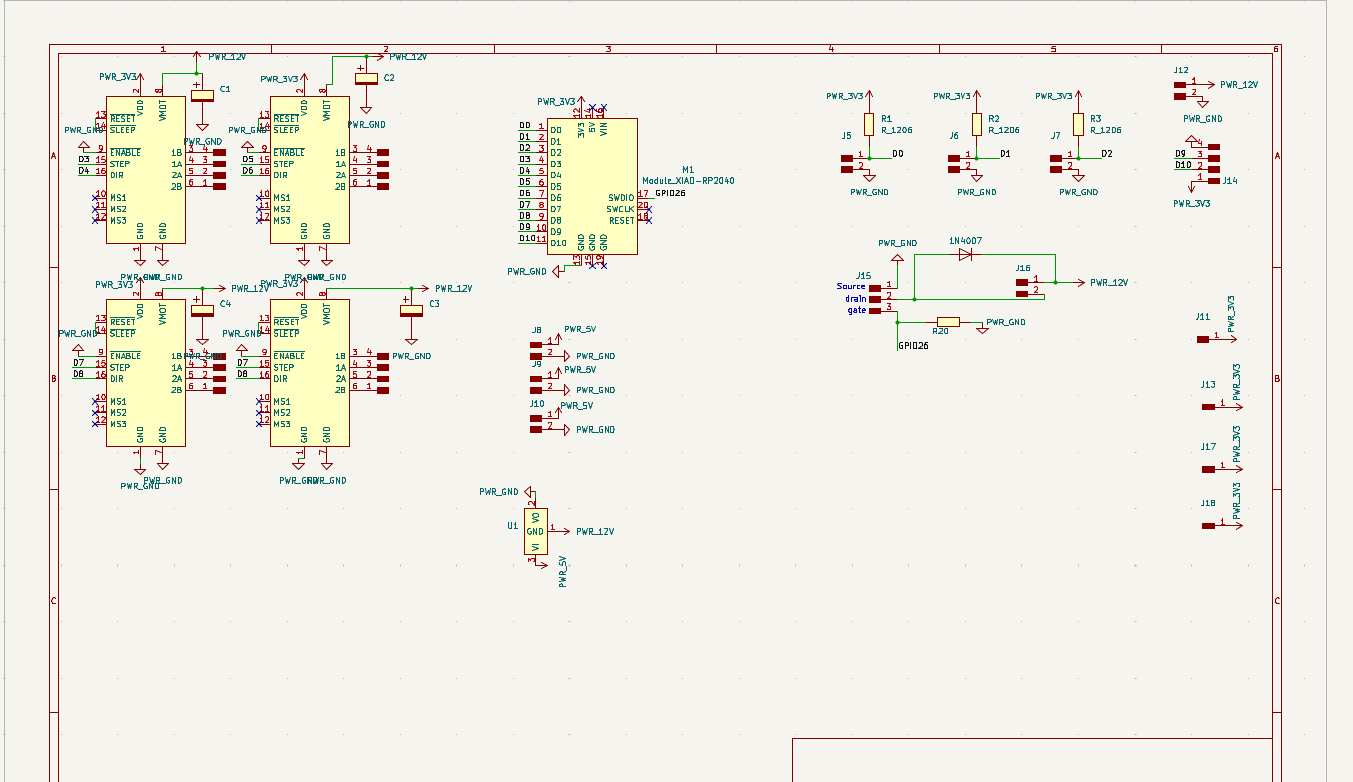

Electronics Description

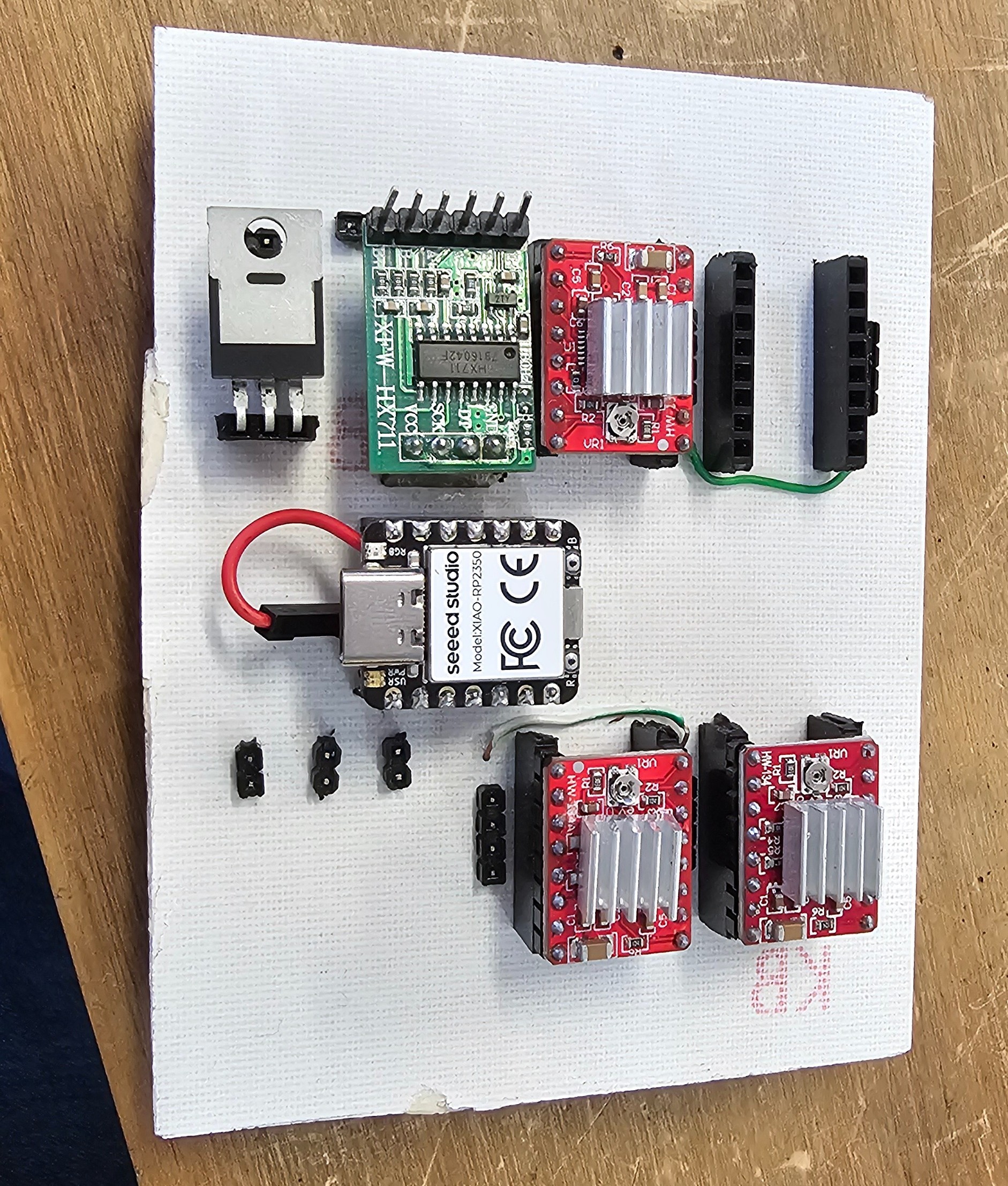

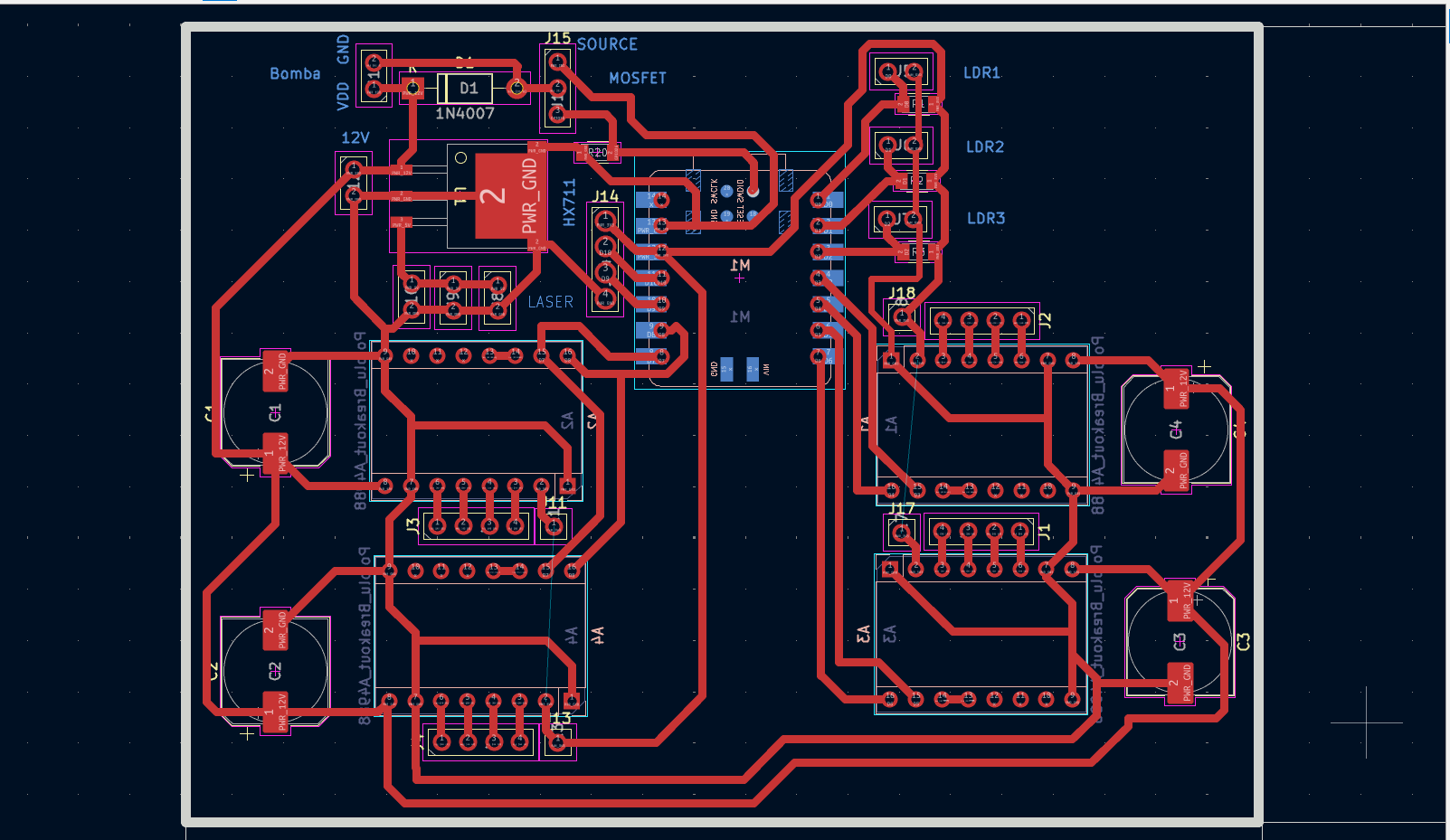

The electronic system is built around a Seeed Studio XIAO RP2350 microcontroller. It controls three stepper motors via A4988 drivers to move the conveyor, adjust the Z-axis, and position the filling station. The system also integrates three LDR sensors with laser interruptions for object detection, and an HX711 module connected to a load cell for precise weight measurement. A small pump is activated based on the weight detected. All components are powered with 12V and regulated appropriately for logic levels and current demands.

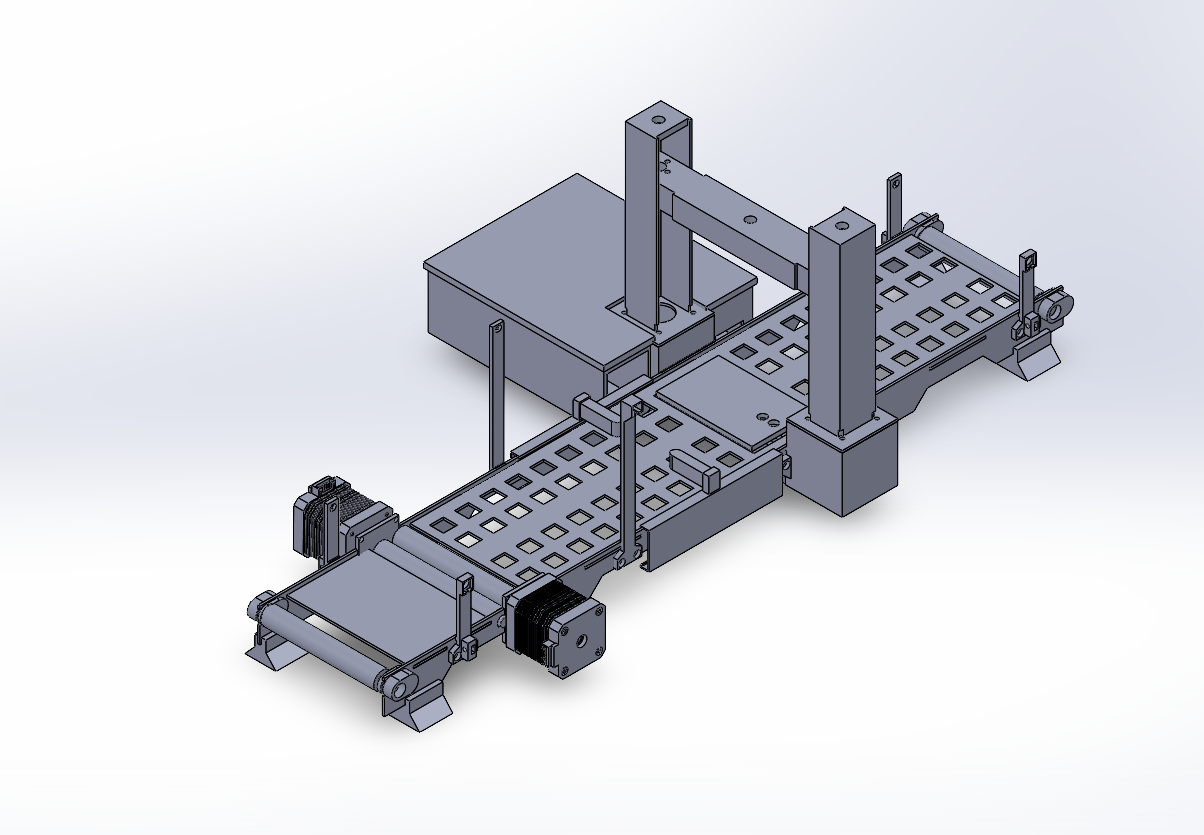

3D Design

The 3D-printed parts were modeled using SolidWorks and include the mounting structure for the LDR sensors, the bracket for the pump nozzle, and the support for the Z-axis adjustment. PLA was used as the primary material for ease of printing and good mechanical resistance under light loads. These components were strategically positioned to align precisely with the conveyor belt and manometers.

PCB Design

A custom PCB was created to simplify the wiring and improve the robustness of the system. The board integrates headers for the XIAO RP2350, sockets for the A4988 drivers, connectors for the HX711 module and LDR sensors, and screw terminals for power input. The design was made using KiCad and fabricated by myself. The PCB reduces the chance of loose connections and allows for easy maintenance and future upgrades.