16. Wildcard week

Waterjet Cutting

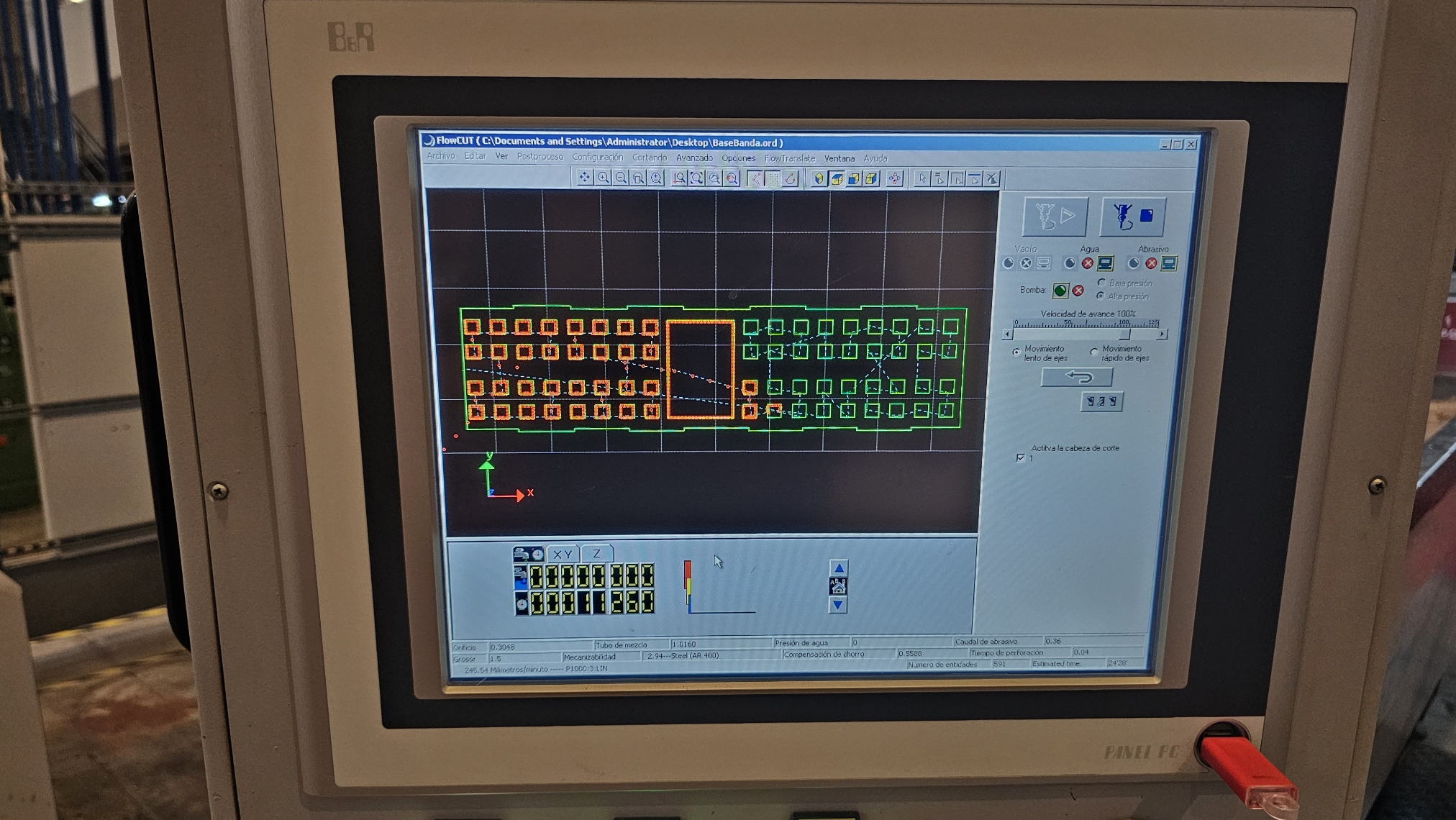

During Wildcard Week, I explored fabrication using a waterjet cutter for the base of my project. I worked with the Flow Mach 2 1313B, a precision waterjet cutting machine that uses a high-pressure stream of water mixed with abrasive material to cut through a wide range of materials such as metal, stone, composites, and glass.

The Flow Mach 2 1313B offers a cutting area of approximately 1.3m x 1.3m and is controlled via Flow software (FlowPath and FlowCut), providing reliable CNC precision and flexibility for custom fabrication projects.

Steps to Use the Flow Mach 2 1313B

- Design the Part: Create a 2D design using CAD software like AutoCAD or Fusion 360. Export the drawing in

.dxfformat for compatibility with the machine software. - Import and Configure in FlowPath:

- Open FlowPath and import the DXF file.

- Select the material type and thickness (e.g., mild steel, 6 mm).

- Set the cut quality level (typically ranges from 1 to 5, where 5 is the highest precision but slowest cut).

- Define the lead-in and lead-out points to avoid cutting into critical edges of your part.

- Generate Toolpath and Export: After reviewing and simulating the path, generate the cutting file and export it for use in FlowCut.

- Prepare the Machine:

- Clean the tank area and remove any debris or leftover material.

- Place the raw material flat on the cutting grid inside the tank.

- Secure the material with clamps or heavy weights to prevent shifting during cutting.

- Load File and Set Zeros:

- On the FlowCut interface, load the toolpath file.

- Manually jog the cutting head to the desired origin point (X0, Y0) and set the zero coordinates.

- Perform a touch-off or zeroing for the Z-axis height.

- Check Machine Readiness:

- Confirm that the abrasive hopper is filled with garnet.

- Ensure water pressure is optimal (usually around 60,000 psi).

- Verify that all safety covers are closed and emergency stop buttons are operational.

- Start the Cut: Initiate the cut and monitor for consistent water stream, proper following of the path, and absence of clogging or deviation.

- Finish and Clean: Once the cut is complete, turn off the high-pressure pump, remove the part carefully, and rinse it with water to remove residual abrasive particles.

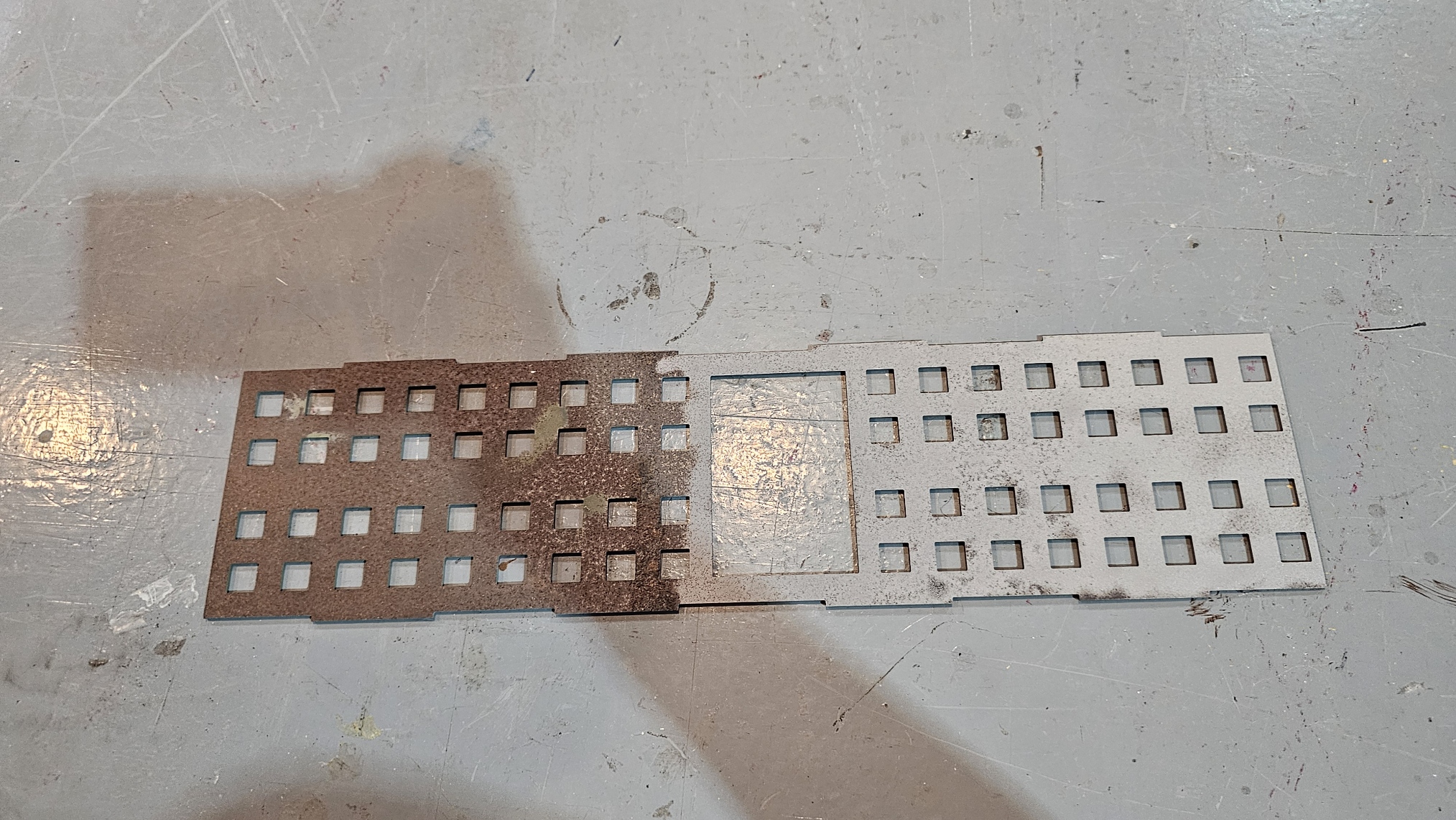

Post-Cutting: Sandblasting

After removing the part from the waterjet table, The metal was covered with a lot of rust. To clean the surface and improve the finish, I used a sandblasting machine. This process involves propelling fine abrasive material at high speed to remove rust, oxide layers, and minor imperfections from the metal surface.

Sandblasting not only restored the clean appearance of the cut part but also prepared it for further post-processing.

Conclusion

Working with the Flow Mach 2 1313B waterjet cutter was an insightful experience into industrial-grade manufacturing. I learned how to plan a toolpath, operate high-pressure equipment safely, and use post-processing techniques like sandblasting to refine the final product.