15. System Integration

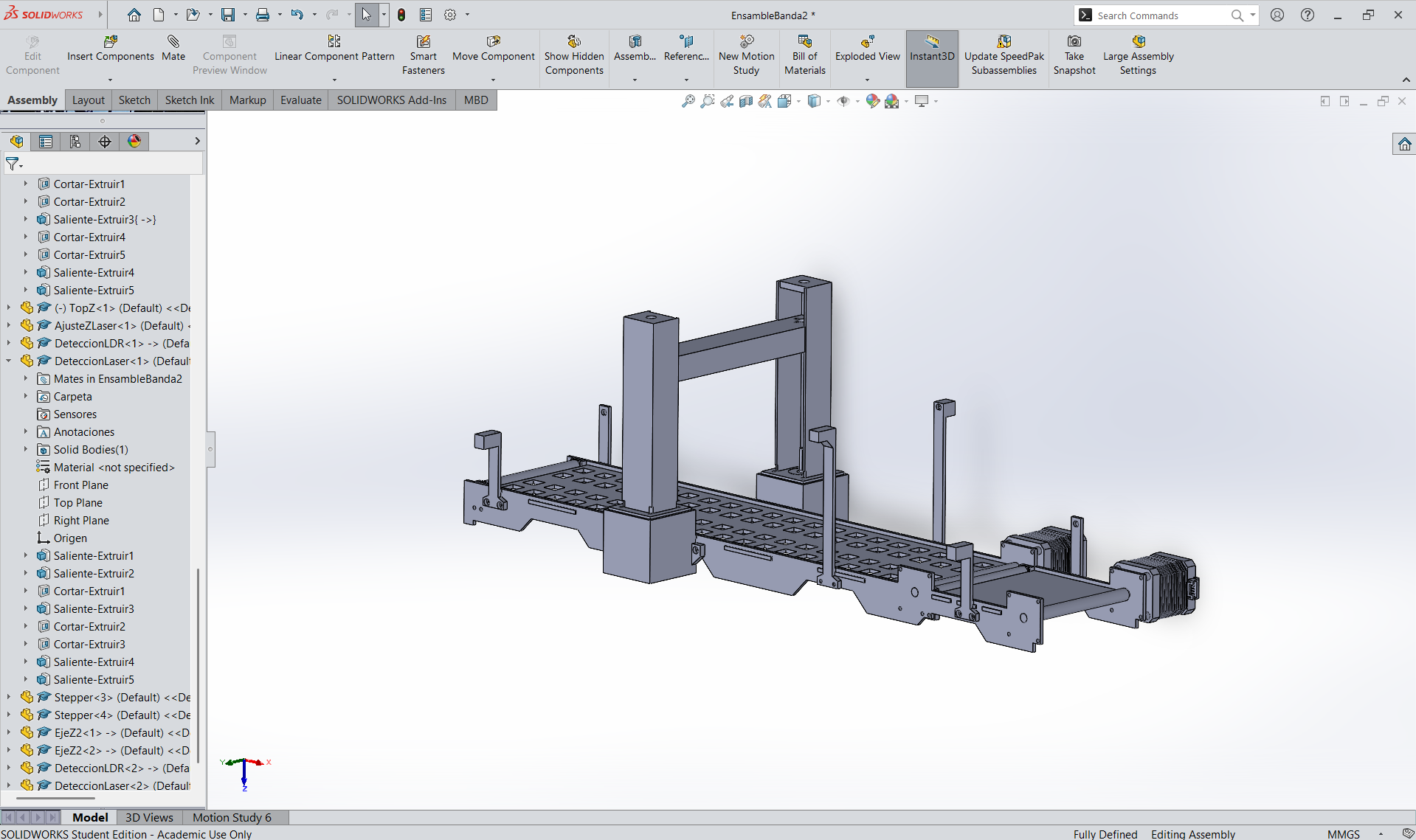

2D and 3D Modeling

After weeks of designing and testing I came up with my final design for my project. I took on consideration adding more sensors so it could work uninterrupted and without supervision.

Bill of Materials - Automated Conveyor System

| Component | Quantity | Notes / Specifications |

|---|---|---|

| Microcontroller | ||

| Seeed Studio Xiao RP2350 | 1 | |

| Motors and Drivers | ||

| Nema 17 | 3 | Stepper motors (Motor 1, 2, 3) |

| A4988 Driver | 3 | Stepper motor driver |

| 220μF / 50V Capacitor | 3 | |

| Sensors and Inputs | ||

| LDR (photoresistor) | 4 | Interruption sensors with laser |

| 5V Laser module | 4 | Laser emitter for LDR |

| LM393 Comparator | 2 | |

| Resistors | 10 | Voltage dividers for LDR & LM393 |

| 74HC165 (shift register) | 1 | For digital LDR states |

| Load Cell HX711 | 1 | For filling system |

| Limit switch (Z-axis) | 1 | Endstop for Z-axis |

| Actuators | ||

| 12V Peristaltic pump | 1 | For filling system |

| NPN Transistor (2N2222) or MOSFET (IRF540) | 1 | Pump control |

| Flyback diode (1N4007) | 1 | |

| Isolation & Protection | ||

| Optocoupler | 1–2 | Signal isolation |

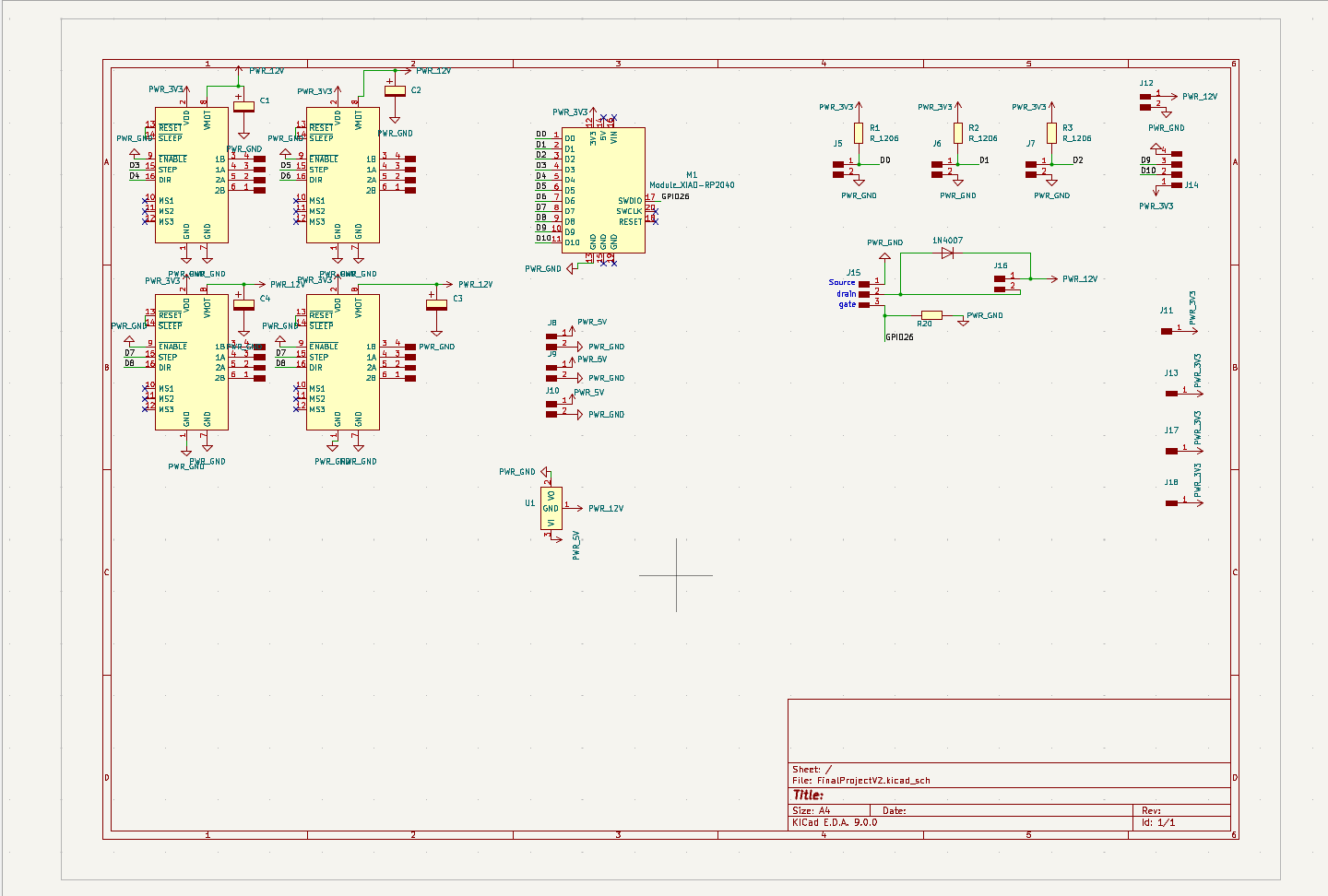

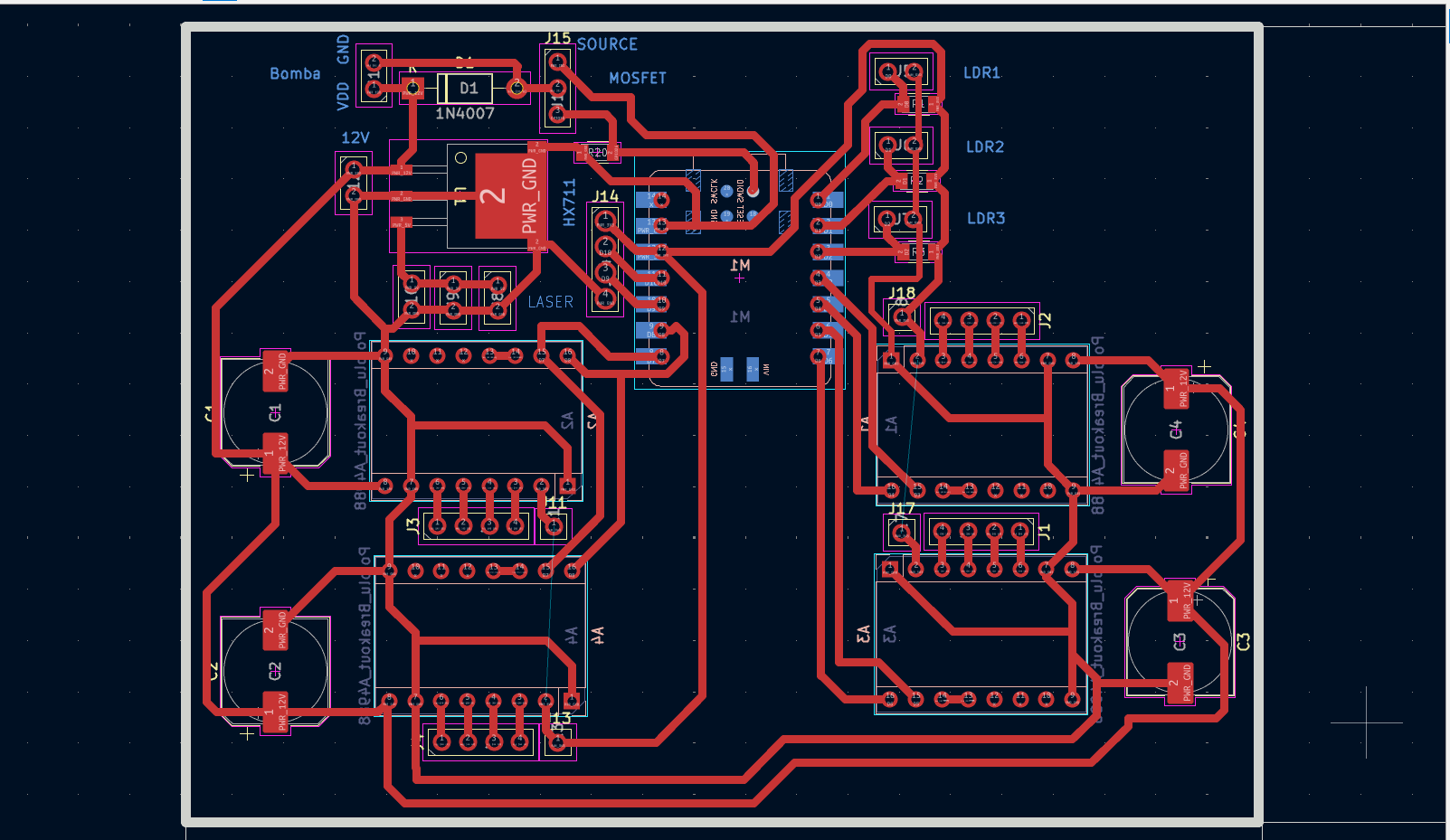

Electronics desing

For the electronics I used 4 driver A4988 one for each nema, 4 220 Capacitors one 7805 regulator, four 10K resistors, one mosfet, one Diode and lastly the brain of the operation a Xiao RP2350.