17. Applications & Implications, Project Development

Presentation Poster

Presentation Video

Objectives

- Individual Assignment

- Prepare drafts of your final project summary slide your final project summary slide (presentation.png, 1920x1080) and video clip (presentation.mp4, 1080p HTML5, < ~minute, < ~25 MB) put them in your root directory and check that they are linked in the final presentation schedule

- Propose a final project masterpiece that integrates the range of units covered, answering:

- What will it do?

- Who's done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

- Your project should incorporate 2D and 3D design,

- additive and subtractive fabrication processes,

- electronics design and production,

- embedded microcontroller interfacing and programming,

- system integration and packaging

- Where possible, you should make rather than buy the parts of your project

- Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Individual Assignment

Draft Slide & Video

First I made a render of my CAD design using Fusion 360

For cases where I do not have free graphics I can use, I generate them using ChatGPT.

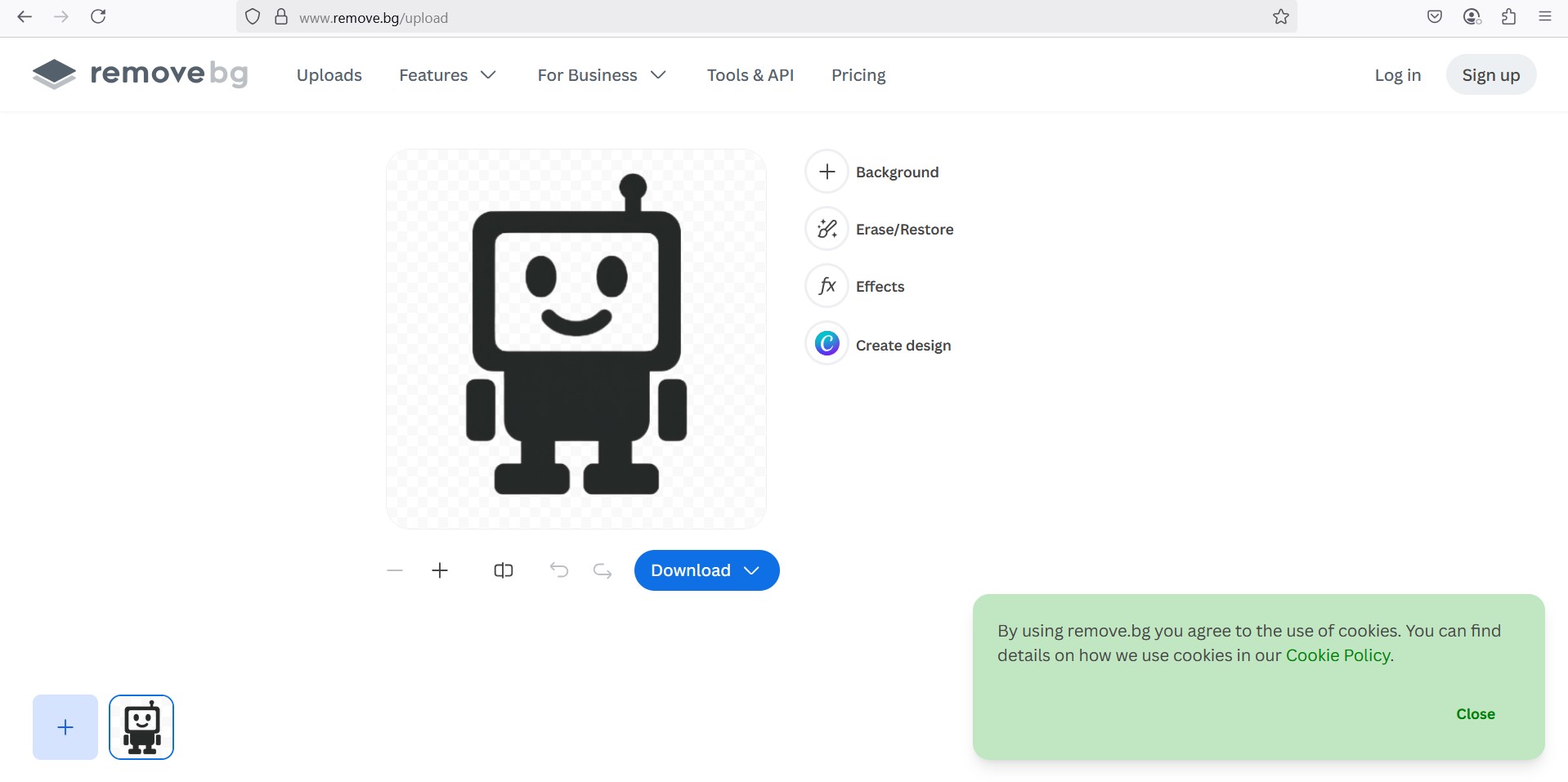

I removed the background of my graphics using remove.bg

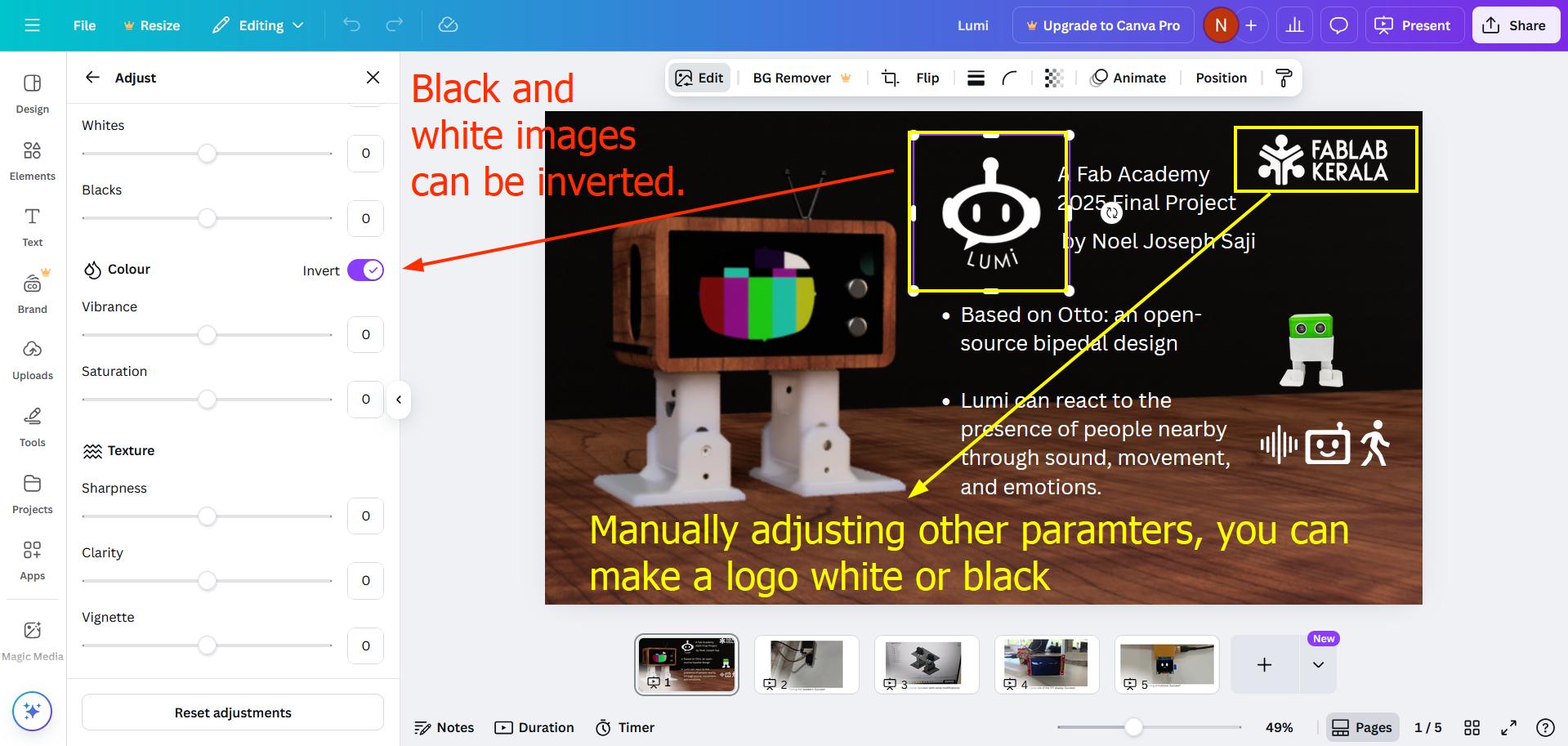

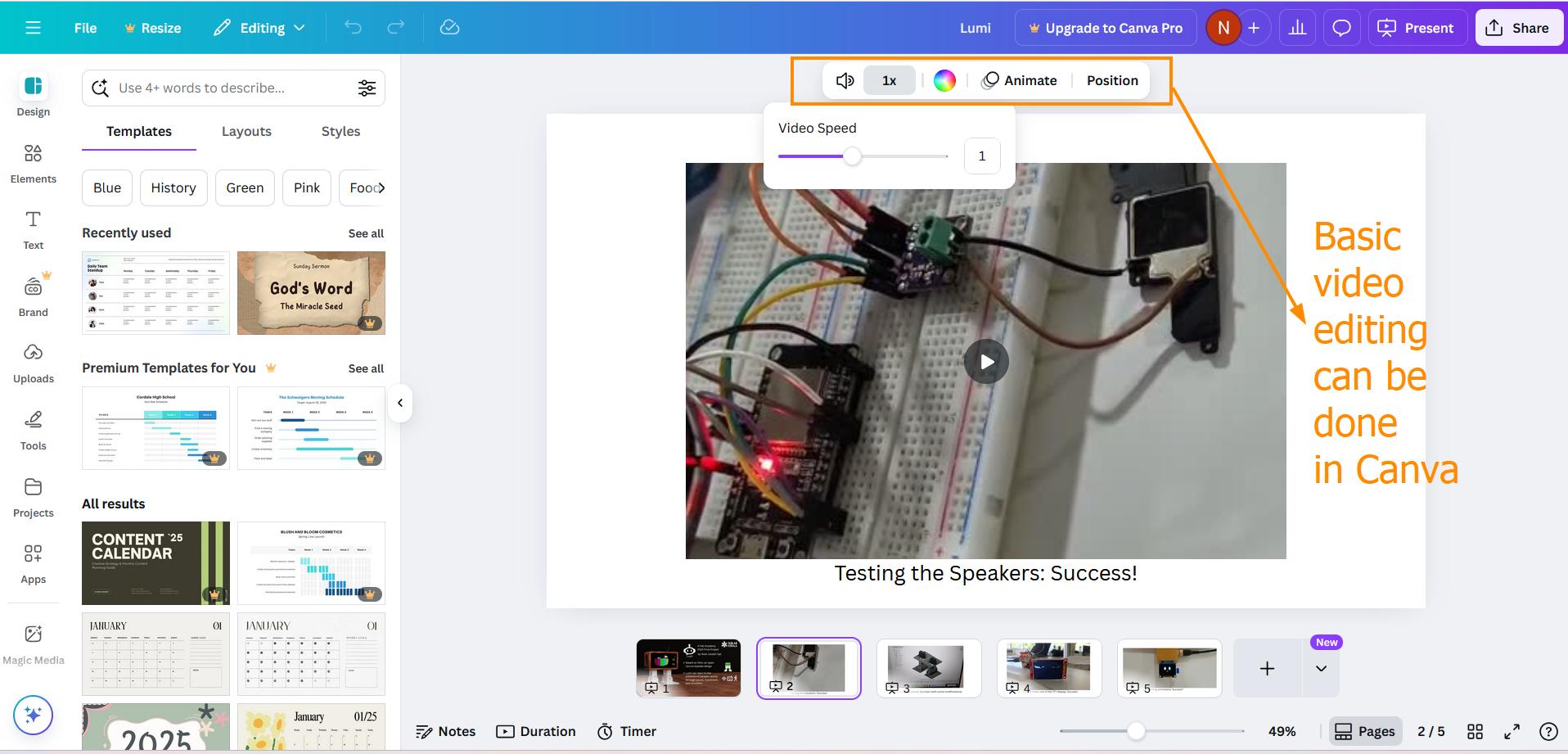

I used Canva both for making the poster and editing the video. Take care to follow the ratio of 1920x1080 for both poster and while making the video

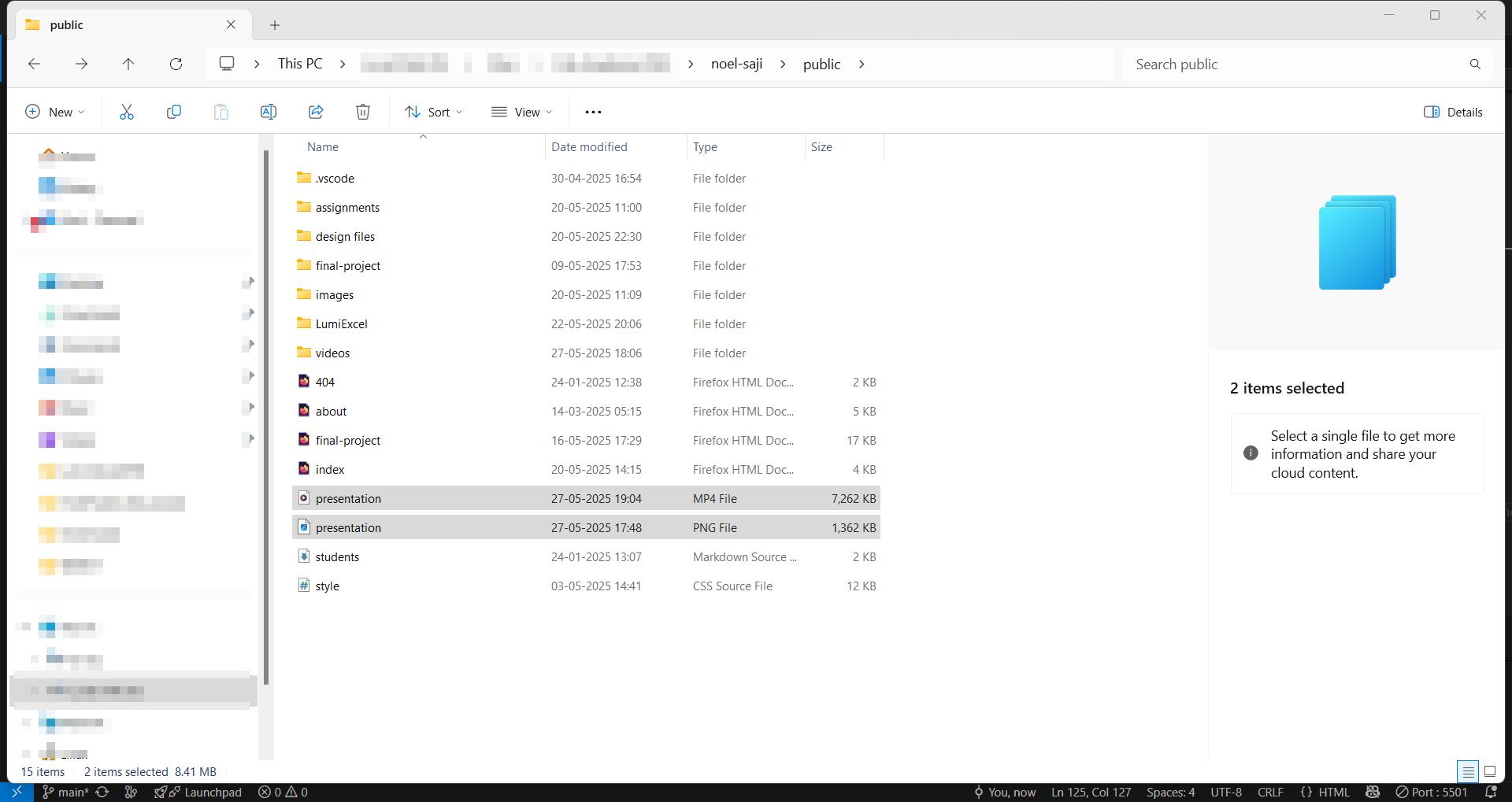

Then I renamed both the .png and .mp4 files as presentation.png and presentation.mp4 and added them in my root directory. I also confirmed that the video files are less than a minute and less than 25 MB.

Presentation Poster

Presentation Video

Applications & Implications

Propose a final project masterpiece that integrates the range of units covered, answering:

-

What will it do?

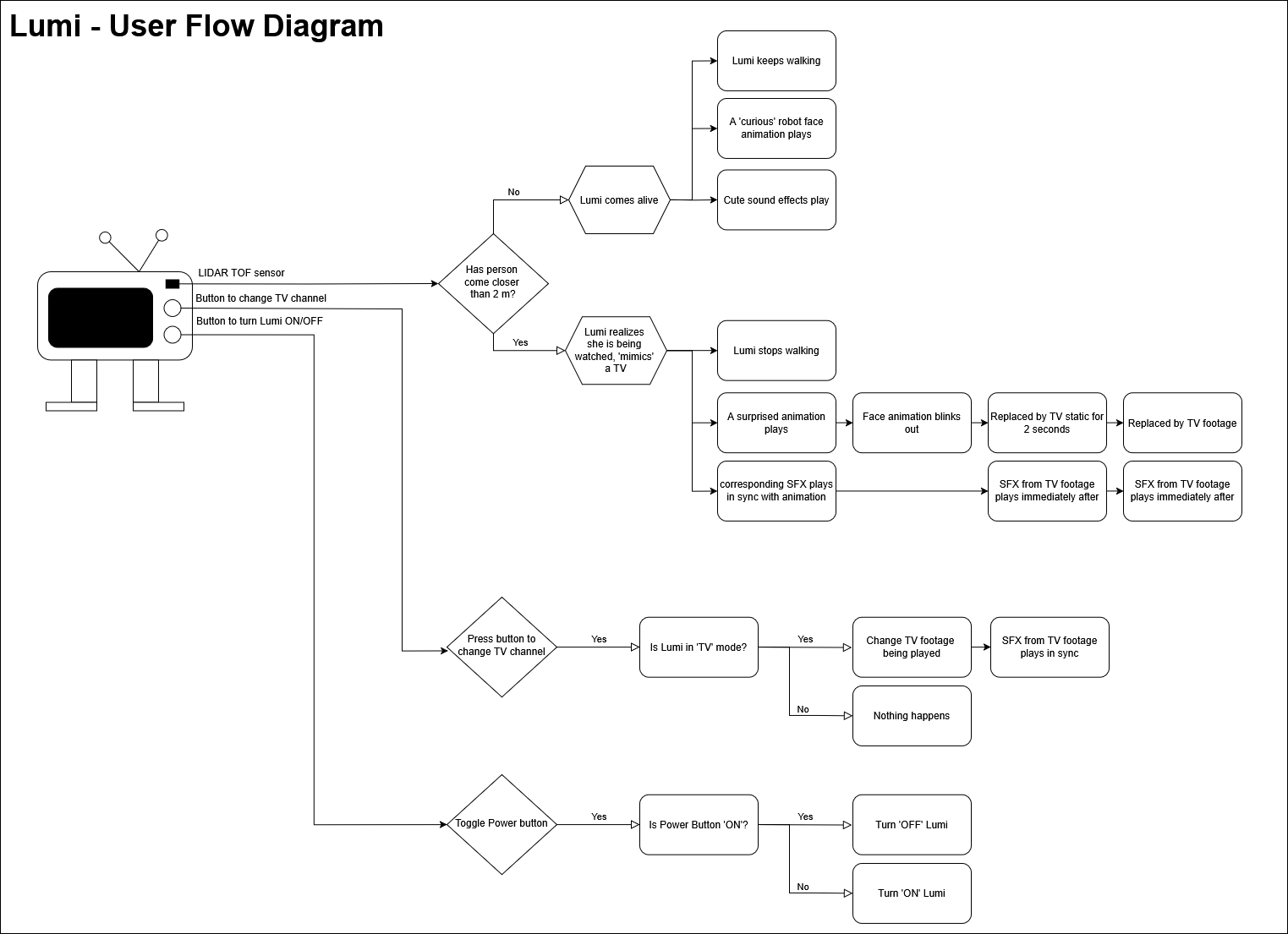

Lumi is a toy robot that resembles a TV on legs. It has the following key features:

- Lumi can detect if the user comes closer than 2m to it.

- When the user is farther than 2m, Lumi behaves like a living being

- Lumi 'shuffle' walks just like Otto

- Lumi plays facial animations randomly

- Sound effects corresponding to animations will also play

- When the user is closer than 2m, Lumi 'realizes' it is being watched, it then starts behaving like a regular TV

- Lumi stops moving

- It starts playing TV footage

- Accompaning sound effects will be playes from its speakers

The following user flow diagram answers this questions clearly:

Who's done what beforehand?

I will be using the following assets/files made by others to make my final project:

- There are multiple examples to make a mini TV display:

- How to Make a Retro Mini-TV! (by maker_soup, Instructables)The primary inspiration for the TV design

- ESP32 Mini TV Tutorial Build (Taylor Galbraith, Youtube): provided me a reference for playing TV video and audio

- Mini Retro TV(by 陳亮, Instructables): Provided extensive documentation for MicroSD card and MAX98357 audio requirements

- Working Miniature "Television" (By entomophile, Instructables): A twist on the original idea; convert an old media player into a miniature TV

- ESP32 Pinout Reference: Which GPIO pins should you use? (Randomnerdtutorials.com): Easy to follow documentation on ESP32 pinouts, which pins to avoid and which pins to use for different communication protocols

- Otto: The design of the legs that create the shuffle/dance are based off of an open source project called

- There are multiple examples to make a mini TV display:

What will you design?

- Integrating a TV into the Otto leg design

- PCB designing that uses an ESP32 chip instead of the DevKit

- The program logic that uses a TOF TOF LiDAR as an input and servos, TFT display and audio as the output

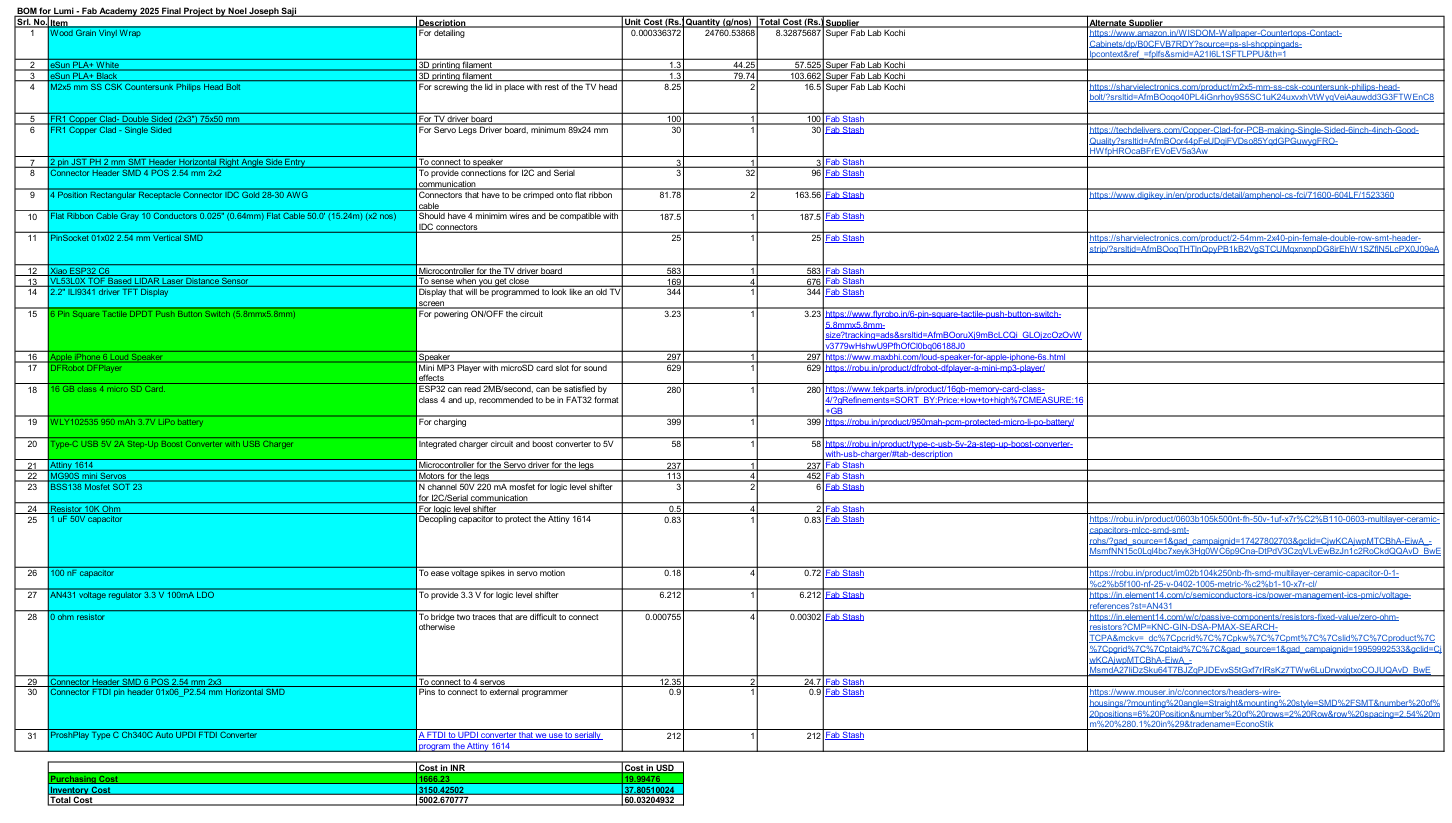

What materials and components will be used? Where will come from? How much will they cost?

All these questions have been answered in my BOM sheet

What parts and systems will be made?

- An easily assemblable and disaassemblable TV case

- Two PCBs holding different electronics and mounted behind the other using pin headers and pin sockets

- A modified leg design based on Otto's original design to accommodate the changed positioning of the servos

- A wood vinyl wrapper applied on top of the case to make the TV more realistic

What processes will be used?

I have used the following processes:

- Laser cutting - for initial prototyping in cardboard

- 3D printing - for making the outer body

- Vinyl cutting - to mimic a wood finish for the TV case

- Molding & casting - to make the buttons for the TV

- PCB Designing - in KiCAD

- Milling - To make the PCB

- Soldering - To make the PCB

- Programming - In Arduino IDE & VS Code

What questions need to be answered?

-

Can kerf bending be used to create a laser cut wood frame for my TV?

No, the radius needs to be at least 15 mm for 3mm birch wood. Will remove this idea, instead replacing it with vinyl cut wrapper to mimic a wood finish

- Library support for the ESP32?

- Can the audio and video play in sync?

- Does the entire animation flow make visual sense from an external user perspective?

- Since the TV will be more front heavy, that will affect the weight distribution. Will this cause the TV to fall? Will this issue be solved if the 'hip' servos are changed to offset the position of the legs

How will it be evaluated?

- Does Lumi respond in any way to input from the TOF TOF LiDAR sensor.

Your project should incorporate:

- 2D and 3D design ✔

- additive and subtractive fabrication processes ✔

- electronics design and production ✔

- embedded microcontroller interfacing and programming ✔

- system integration and packaging ✔

Where possible, you should make rather than buy the parts of your project

Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Project Development

To see my project development, click here

Conclusion

Notes for the Future

Add Mistakes only in Mistakes and Solutions section to avoid break in flow

References

References to help reader understand in detail

Look at previous year documentation