Learning about Electronics Production

To do:

Group assignment: I worked with my colleague Jhasmin Ayala.

1. Characterize the design rules for your in-house PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

2. Document the workflow for sending a PCB to a boardhouse

3. Document your work to the group work page and reflect on your individual page what you learned

Individual assignment:

1. Make and test a microcontroller development board that you designed

WHAT I ALREADY KNOW BEFOREHAND?

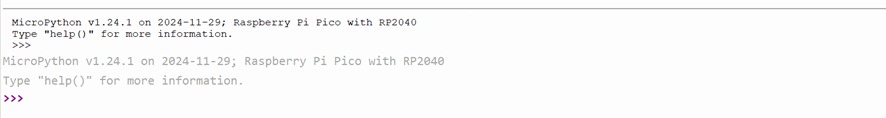

This week was particularly challenging for me, as I had never used a soldering iron before. A new revelation was discovering that microcontrollers are not only inexpensive but also increasingly versatile, allowing for highly flexible project development.

From an economic perspective, I immediately related this task to supply chain considerations. The design dictates the required components, which directly impacts cost and availability.

Group assignment:

Check this link

Individual assignment:

1. Designing and 3D Printing a Hinge

• Concept: Designing a hinge that cannot be made subtractively is a great choice because hinges often require interconnected parts that are challenging to create through traditional machining methods.

• Tools: I experimented with Fusion 360 and Blender, ultimately choosing Blender, although I had to design using approximations. Blender is excellent for organic and complex shapes, while Fusion 360 is better for parametric and mechanical designs. For a hinge, Fusion 360 might have been more straightforward due to its precision tools.

• Challenges:

o Ensuring the hinge parts fit together properly.

o Designing for 3D printing constraints (e.g., overhangs, tolerances).

Reference video: this link

REFLECTIONS

• I learned that soldering is a critical process where safety is paramount. Furthermore, any flaw—such as a cold joint or a solder bridge—can lead to short circuits or non-functional components, generating rework and additional costs.

• The end-to-end process of creating a board—from conceptualizing its function and identifying components, to designing it in KiCad, milling it, and finally soldering it—was enlightening. It showed me how to integrate displays, lights, buttons, and buzzers. A feature I particularly enjoyed was the ability to fully customize the board's design, not just the components, but also its physical shape by defining the milling outline.

• I believe that transitioning from a digital design (a .png file) to a functional physical object (the PCB) is the very essence of "digital fabrication." It is the materialization of a concept, similar to how a business plan is transformed into an operational project or company.

• Today, microcontrollers enable automation and IoT applications that can accelerate the digital transformation of businesses, especially for small and medium-sized enterprises with limited budgets. This makes advanced technology more accessible and affordable.