Learning about Electronics Design

To do:

Group assignment: I worked with my colleague Jhasmin Ayala

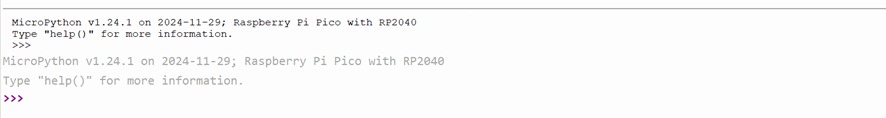

1. Use the test equipment in your lab to observe the operation of a microcontroller circuit board (as a minimum, you should demonstrate the use of a multimeter and oscilloscope)

2. Document your work on the group work page and reflect what you learned on your individual page

Individual assignment:

1. Use an EDA tool to design a development board that uses parts from the inventory to interact and communicate with an embedded microcontroller

WHAT I ALREADY KNOW BEFOREHAND?

• I approached this task by understanding that designing a circuit is like designing an office workflow. You must carefully identify the routes (traces) through which electricity (information/energy) must flow to complete a task.

• I also related the process of selecting standard components (like microcontrollers) and adding custom modules (inputs/outputs) to using APIs or cloud services in a business model, where you integrate pre-built functionalities to create a unique operational system.

Group assignment:

Check this link

Individual assignment:

1. Designing and 3D Printing a Hinge

• Concept: Designing a hinge that cannot be made subtractively is a great choice because hinges often require interconnected parts that are challenging to create through traditional machining methods.

• Tools: I experimented with Fusion 360 and Blender, ultimately choosing Blender, although I had to design using approximations. Blender is excellent for organic and complex shapes, while Fusion 360 is better for parametric and mechanical designs. For a hinge, Fusion 360 might have been more straightforward due to its precision tools.

• Challenges:

o Ensuring the hinge parts fit together properly.

o Designing for 3D printing constraints (e.g., overhangs, tolerances).

Reference video: this link

REFLECTIONS

• KiCad is a relatively straightforward tool to use. However, the main challenge lies in the careful placement of components during the design phase. If components are not positioned correctly, you encounter issues during routing, such as trace crossings or the inability to connect to the necessary power and ground. Furthermore, without a preliminary sketch on paper or a whiteboard outlining the schematic, it is difficult to map everything needed in the software, which can lead to missing components mistakes you might only discover after the board is already milled.

• Achieving a fully routed board with no unconnected lines was a challenging but highly engaging and entertaining process.