Learning about 3D Mechanical Design, Machine Designg

To do:

Group assignment: I worked with my colleague Jhasmin Ayala

1. Design a machine that includes mechanism + actuation + automation + application

2. Build the mechanical parts and operate it manually

3. Actuate and automate your machine

4. Document the group project

Individual assignment:

1. Document your individual contribution

WHAT I ALREADY KNOW BEFOREHAND?

This is my first time modeling in 2D and 3D, it looks very interesting, I'm interested in trying AI tools for 3D modeling.

Group assignment:

Check this link

Individual assignment:

1. Designing and 3D Printing a Hinge

• Concept: Designing a hinge that cannot be made subtractively is a great choice because hinges often require interconnected parts that are challenging to create through traditional machining methods.

• Tools: I experimented with Fusion 360 and Blender, ultimately choosing Blender, although I had to design using approximations. Blender is excellent for organic and complex shapes, while Fusion 360 is better for parametric and mechanical designs. For a hinge, Fusion 360 might have been more straightforward due to its precision tools.

• Challenges:

o Ensuring the hinge parts fit together properly.

o Designing for 3D printing constraints (e.g., overhangs, tolerances).

Reference video: this link

REFLECTIONS

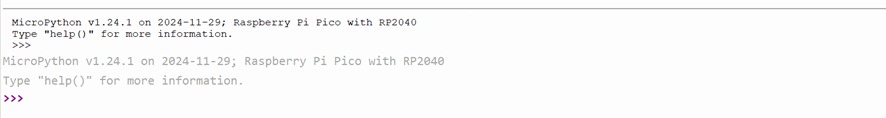

It was a challenging week; it was the first time I'd ever seen any code. It took me a while to understand it, and then it became repetitive. I learned to design web pages, edit a template, upload code to a repository, among other things.

If I had to do it again, I might look for a simpler template or work with the base template and Markdown.