W9 | Input Devices 🦠

INDIVIDUAL ASSIGNMENT

- Measure something: add a sensor to a microcontroller board that you have designed and read it.

Adding an Input Sensor to My Microcontroller Board 📡

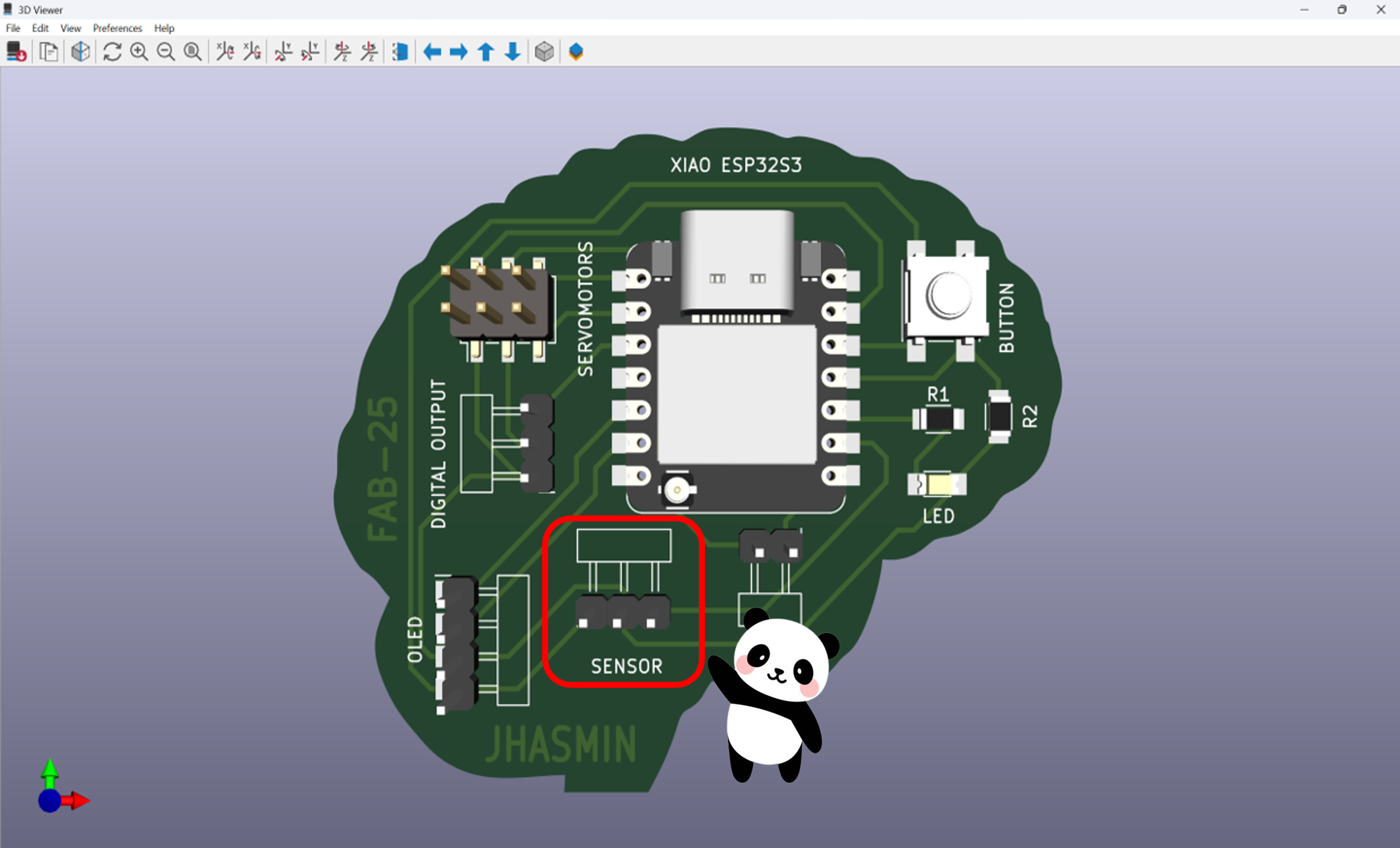

During Electronic Design, I designed the main board for my microcontroller. Later, in Electronics Production Week, I brought it to life by milling the PCB, soldering all the components, and testing it. Now, with some hands-on experience in PCB design and fabrication, it's time for the next challenge, designing the input board for my sensor!Let's see how this goes! 🚀

For my final project, I'm using the XIAO ESP32S3 Sense as my microcontroller, and one of the key inputs I need is a sensor. My little robot needs to detect movement to wake up and start performing actions. But that left me with a big question: which sensor should I use to make that happen? 🤔

Input

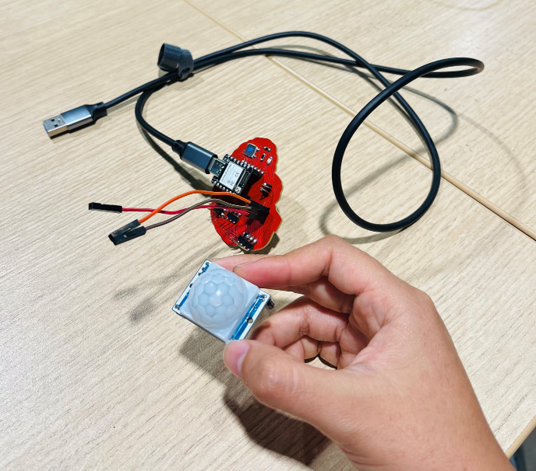

So, to achieve this, I needed to choose the right sensor. While exploring the lab, I found these options:- Pyroelectric sensor (Motion sensor)

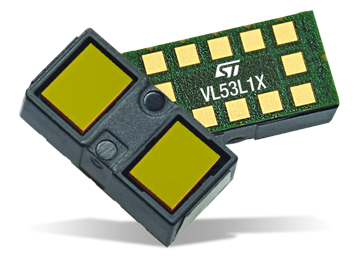

- VL53L1X (Distance Sensor)

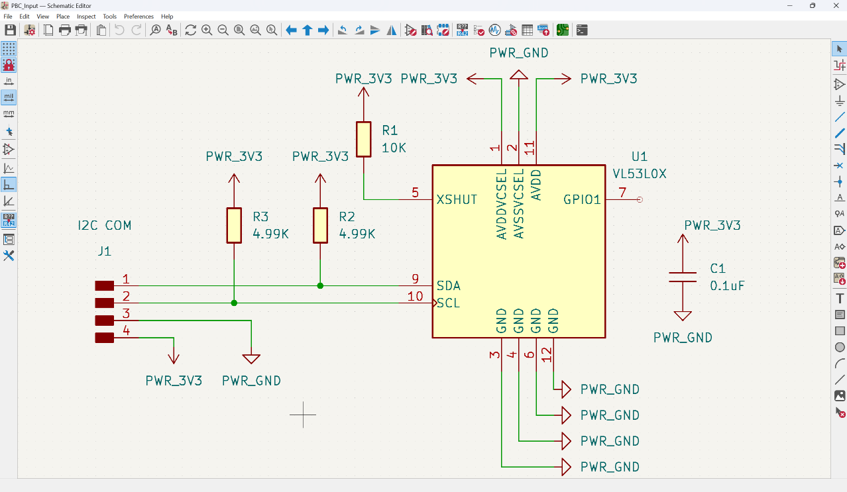

- A 0.1 µF capacitor

- Two 4.99K resistors

- One 10K resistor

- VL53L1X (Temperature Sensor)

- One 10K resistor

- One PinHeader 01x03

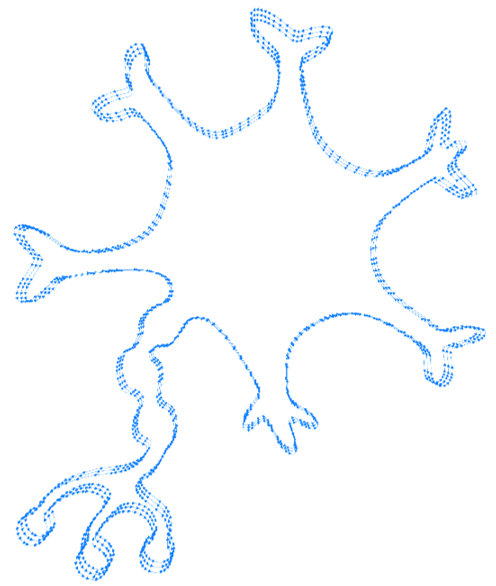

Traces toolpaths Cut toolpaths

A pyroelectric sensor is perfect for motion detection because it reacts to changes in infrared radiation (heat).

Basically, if something warm—like a person—moves in front of it, the sensor picks up the change and sends a signal.

For my project, this means my little robot will be able to detect movement and wake up when someone is nearby.

But...Looks like I hit a little roadblock 😔. The pyroelectric sensor I found already comes with its own board,

meaning I can just plug it straight into my main board using the pin headers I had set up for the sensor on digital port D8.

However, I ran some tests to check if it was working properly, and good news—it is! 🎉 But here's the problem: I didn't design

the board for this sensor, which means it doesn't really meet the assignment's requirements.

Let's see how it goes! 🚀

Here's the test I tried out!:

So… back to the storage room! Time to find a motion sensor that lets me create the input board myself. Let's see what other options I have! 🤔

After searching, I found the VL53L1X sensor, a distance sensor based on Time-of-Flight (ToF) technology. It works by

emitting an invisible infrared laser pulse and measuring the time it takes for the light to bounce back from an object.

With this data, it calculates the distance with high precision.

It's not a motion sensor like a PIR (which detects changes

in infrared radiation), but it can still be used to determine if an object or person is approaching or moving away—making it a

great fit for my robot! With the right settings, I can program it to activate my robot when something enters a specific range.

Schematic

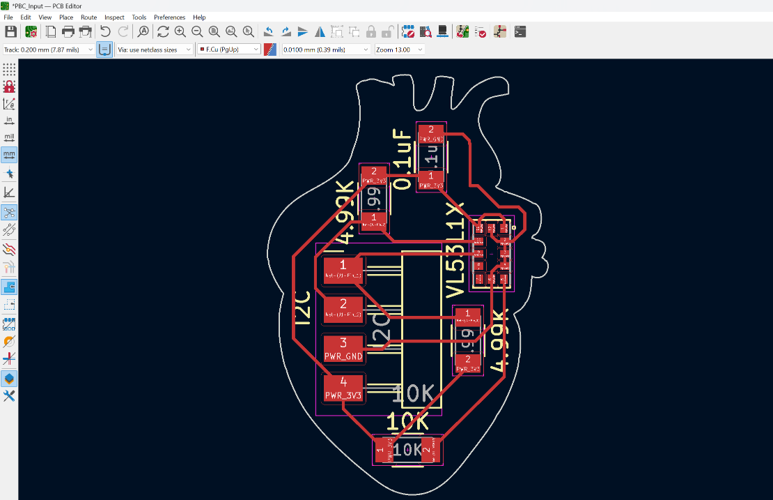

PCB Editor

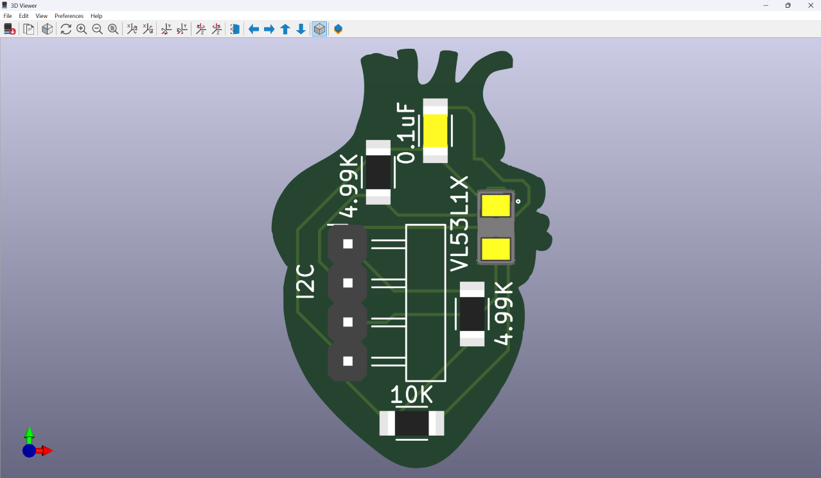

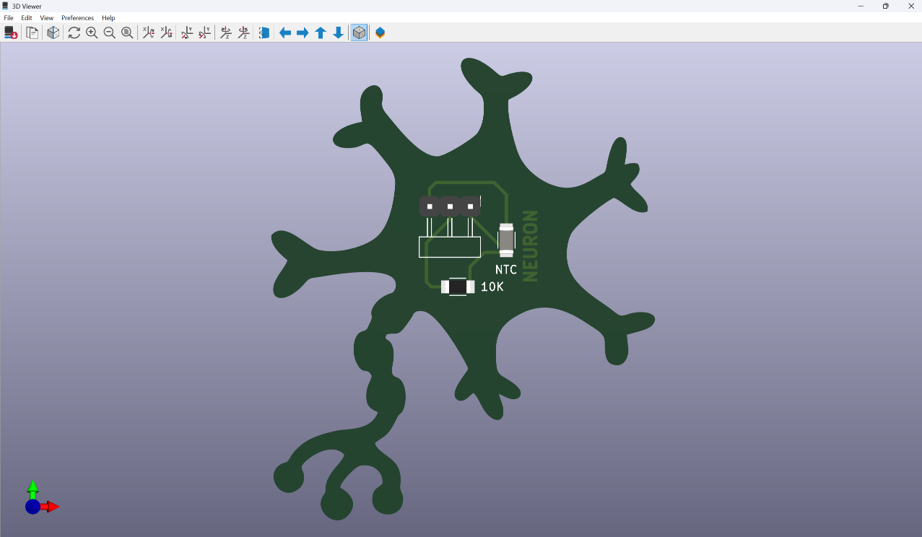

And...Finally, this is the KiCad's 3D Viewer! So, the PCB is ready to be fabricated.

KiCad's 3D Viewer

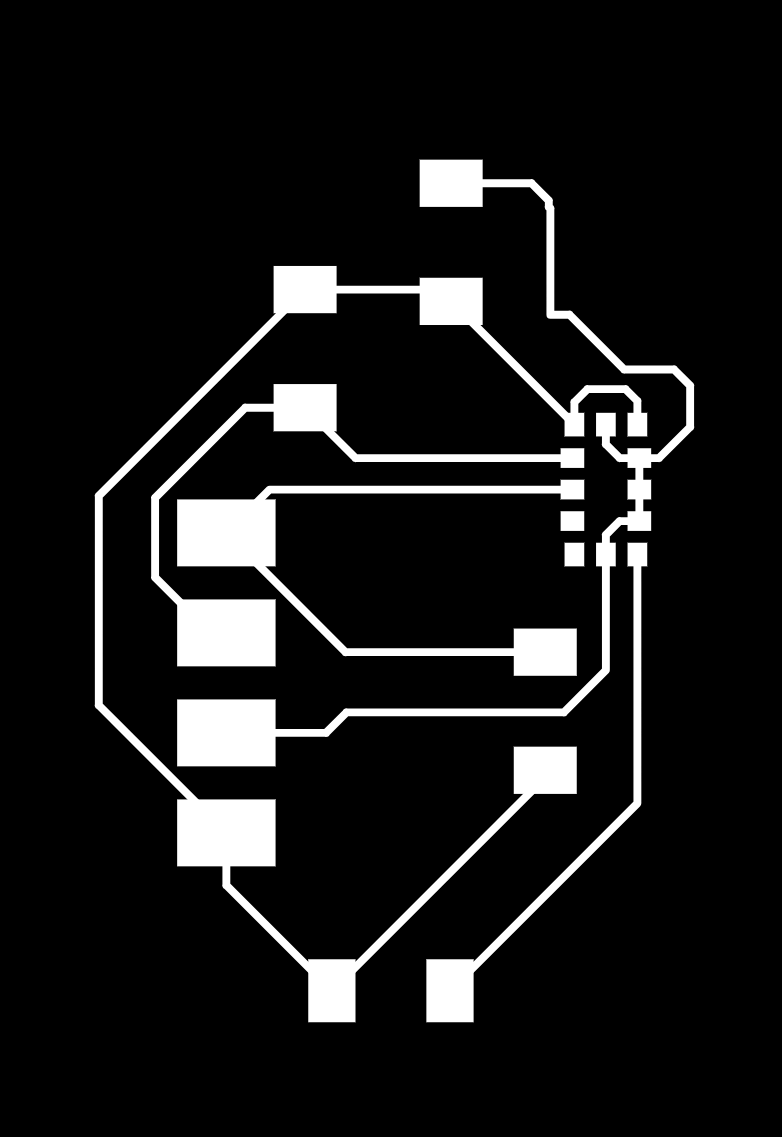

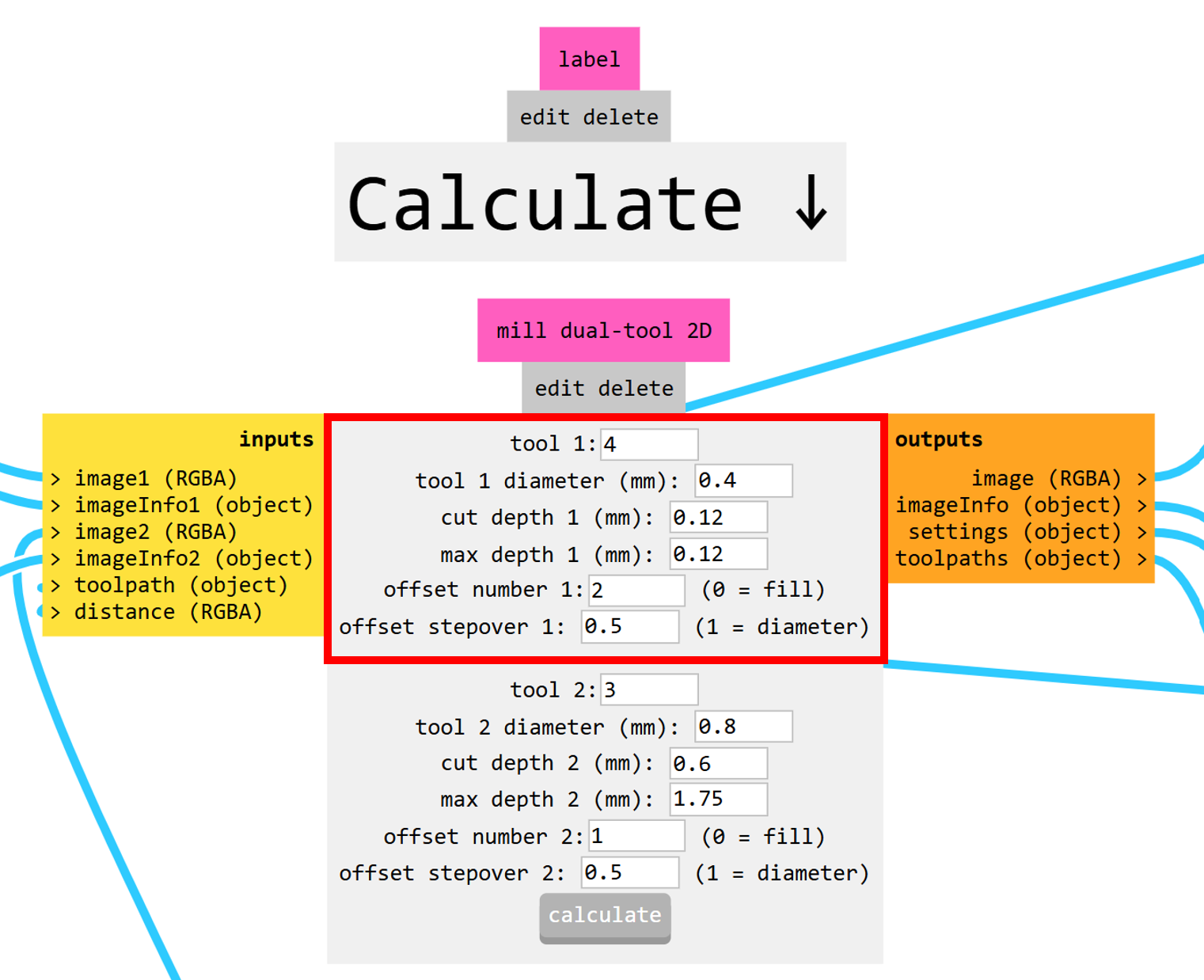

Once the design was ready, I needed to generate the toolpaths to fabricate the PCB. Just like last week, I exported the Gerber files and converted them into PNG format using Gerber2PNG—one for the traces and another for the outline cut. Then, to generate the toolpaths, I used ModsProject.

Traces

External Cut

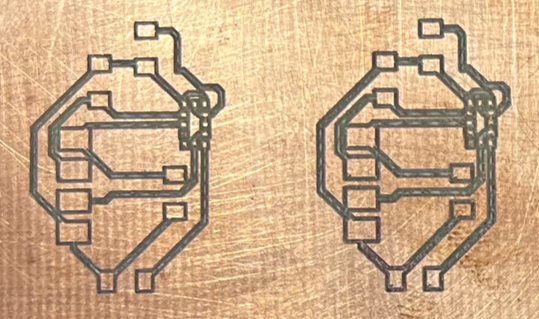

Since the sensor is really tiny, I needed the traces to be 2 mm wide. I kept this in mind while generating the toolpaths for milling. Everything seemed fine—the toolpaths were generated without issues and looked good in the preview. But when it came time to mill the board... things didn't go as planned 😔. The end mill was cutting through the traces! I tried different tool sizes and adjusted the settings, but no matter what, the traces kept getting cut off.

First attempts

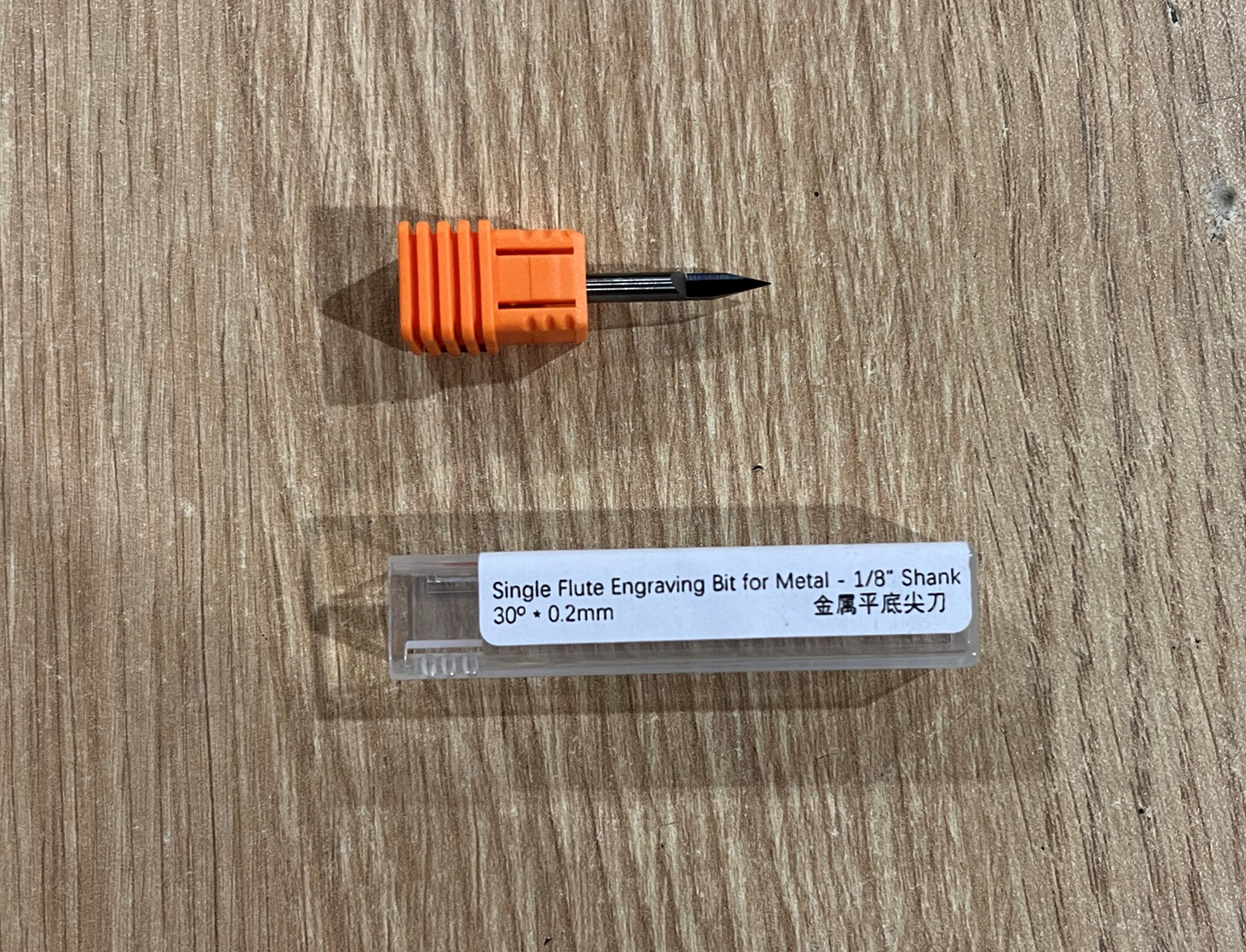

After several failed attempts, I figured the issue might be with the settings or the milling bit itself. In the lab, we only have V-bits, which might be the cause of the issue. These are the milling bits I tried:

60° * 0.1 mm

30° * 0.2 mm

This is the result I got after milling the traces:

Testing the traces milling

Note: Despite the challenges I faced while fabricating the PCB for my sensor, I'm not giving up! Every mistake is a chance to learn and improve. I'll keep experimenting and adjusting until I find the right solution.In the meantime, to keep moving forward with input devices, I decided to fabricate the board for the next sensor:

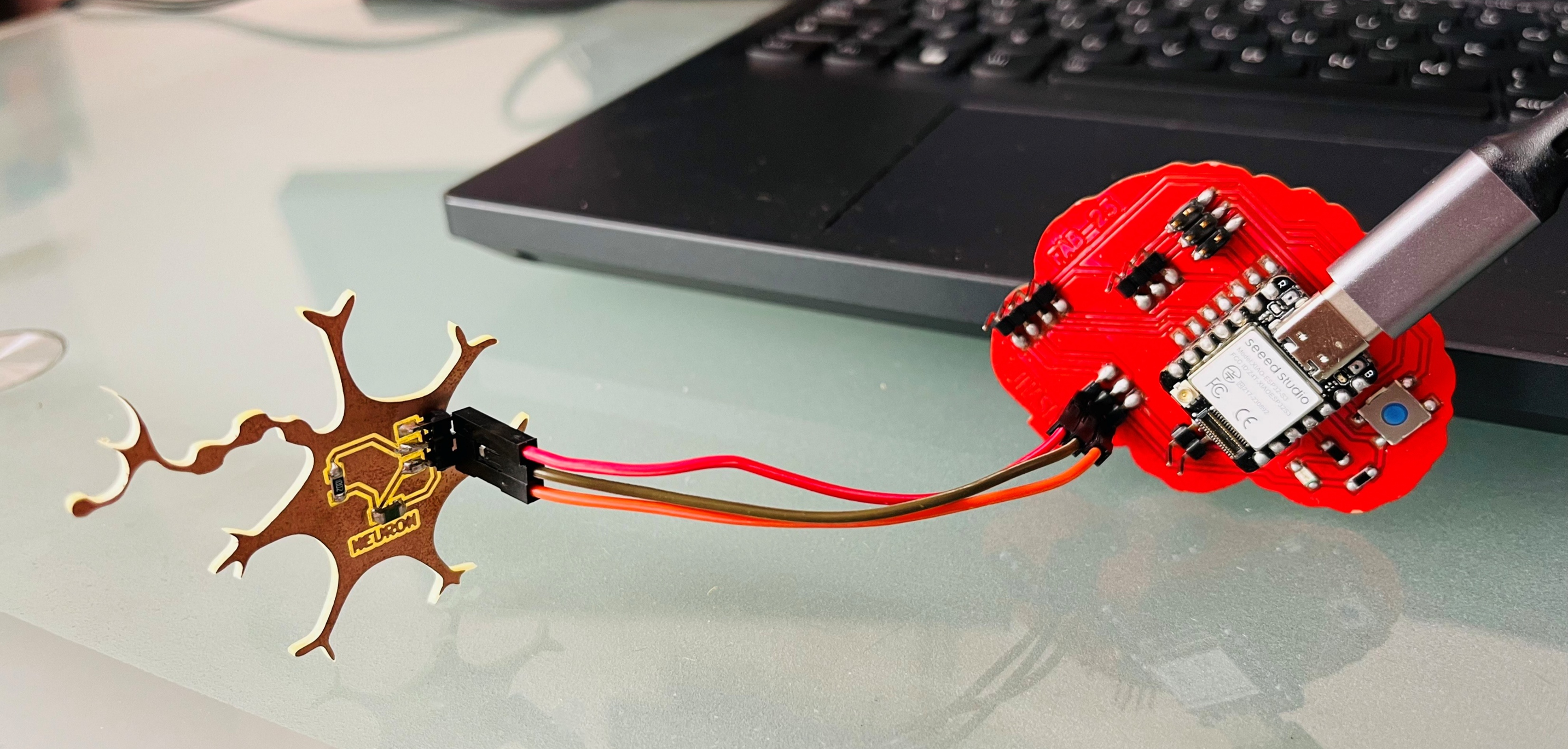

To test the input with my custom-designed board, I created a dedicated PCB for the NTC sensor and connected it to my main board.

The NTC (Negative Temperature Coefficient) sensor is a type of thermistor that decreases its resistance as temperature increases.

This makes it ideal for measuring temperature changes with high sensitivity. By integrating it into my project, I can collect temperature data

and use it for various applications.

This sensor wasn't originally planned for my project, but hey… maybe it could be useful! I'll think about it. 🤔

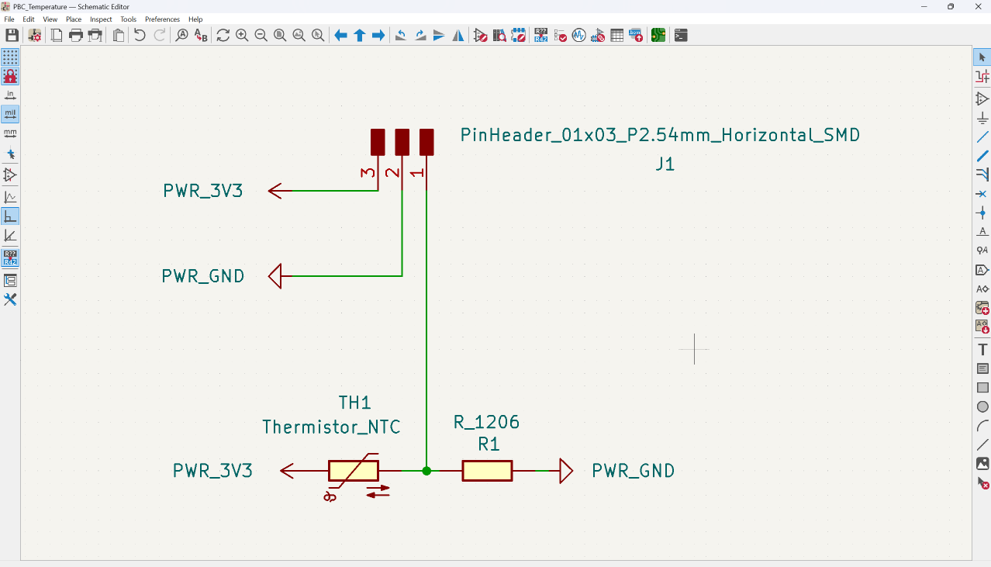

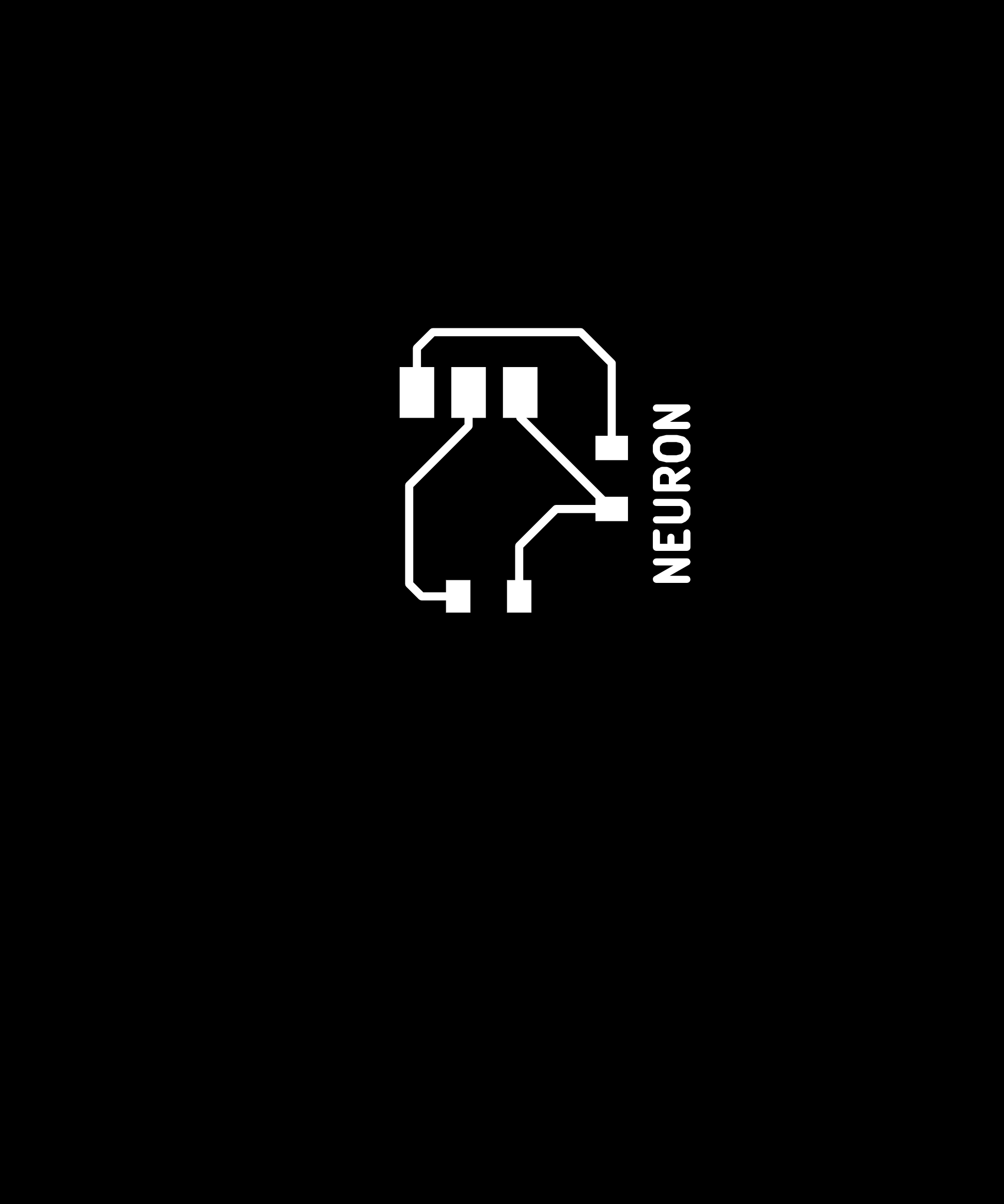

So...I started designing the input board with the NTC sensor 🛠️

Schematic

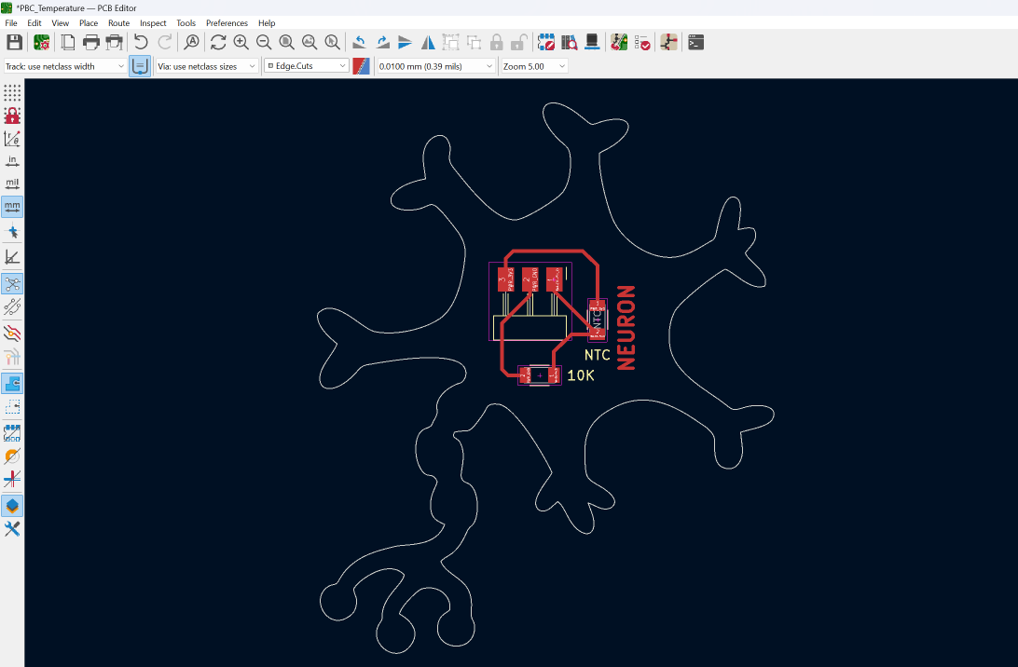

PCB Editor

And...Finally, this is the KiCad's 3D Viewer! So, the PCB is ready to be fabricated.

KiCad's 3D Viewer

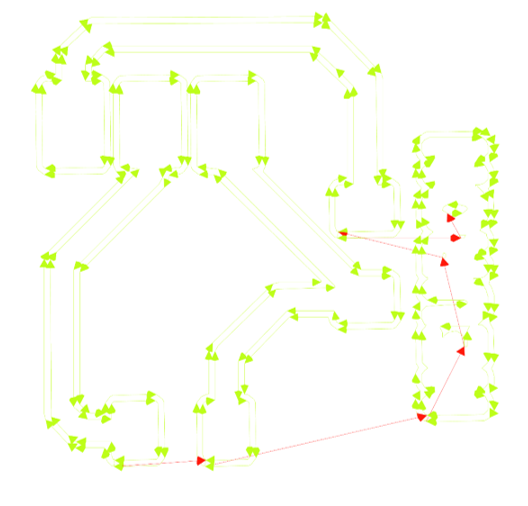

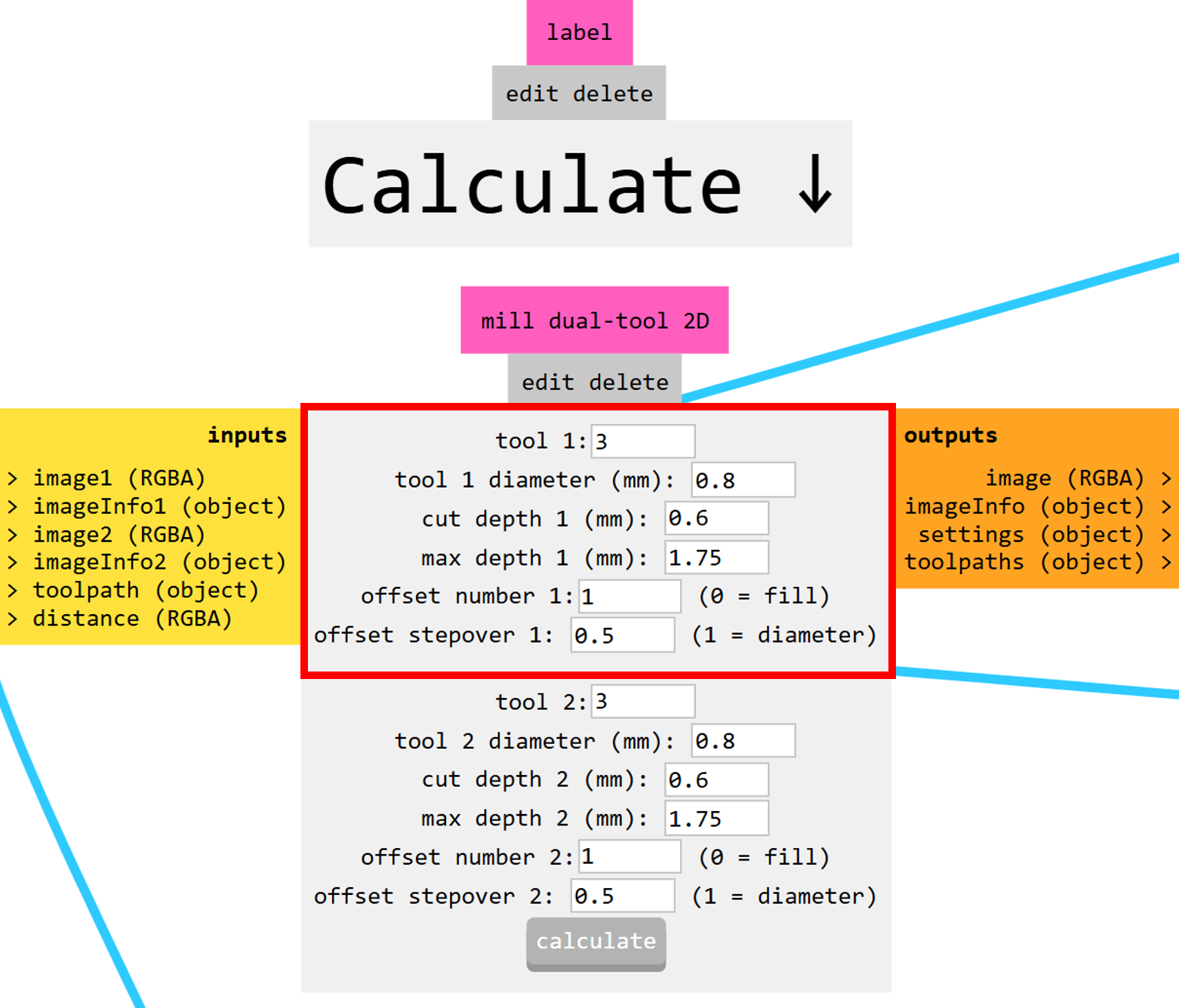

Once the design was ready, I needed to generate the toolpaths to fabricate the PCB. Just like last week, I exported the Gerber files and converted them into PNG format using Gerber2PNG—one for the traces and another for the outline cut. Then, to generate the toolpaths, I used ModsProject.

Traces

External Cut

Here are the toolpaths generated by ModsProject.

Toolpaths ModsProject

Settings

60° * 0.1 mm

Toolpaths ModsProject

Settings

0.8 * 5.5 mm

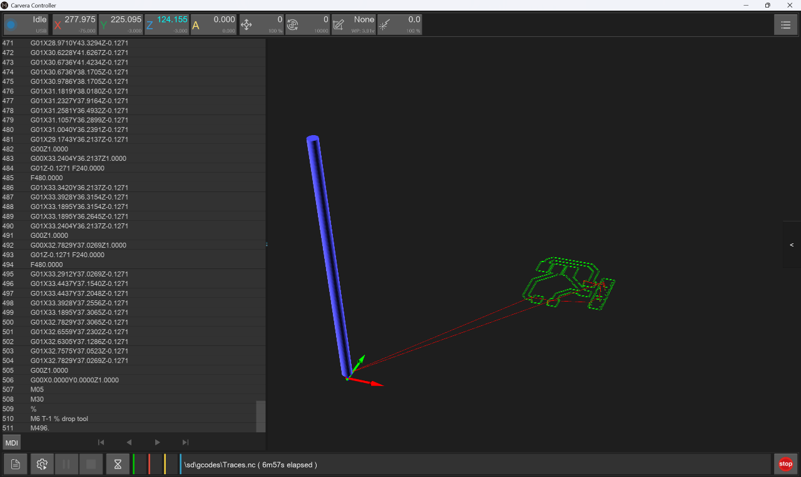

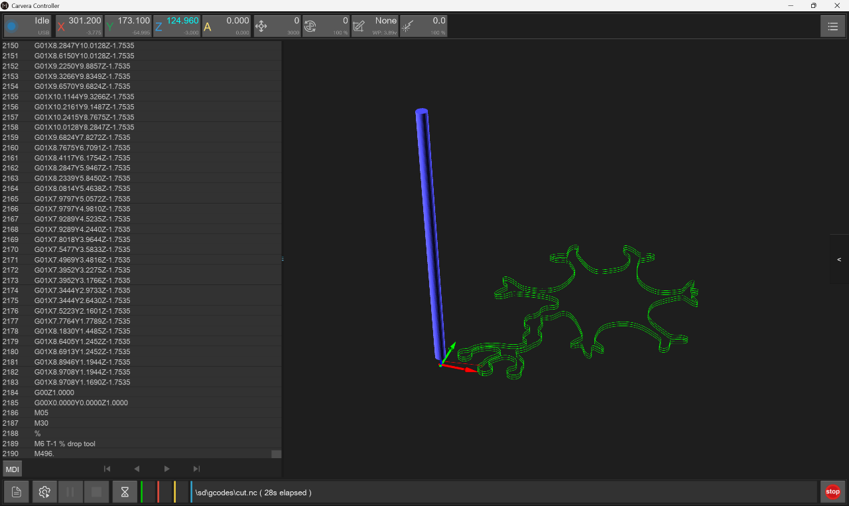

It's time to mill the PCB! For that, I used the Carvera Controller with the same settings as the previous week. The only change I made was adjusting the starting point, since I had to mill it twice. In the first attempt, the outer contour was too small, but on the second try, everything turned out just right.

Traces Carvera Controller

External Cut Carvera Controller

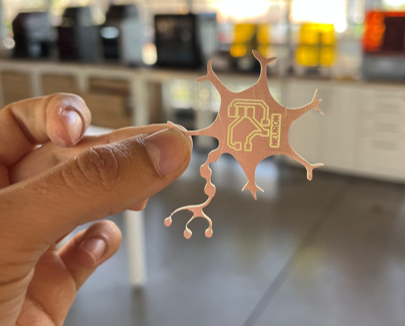

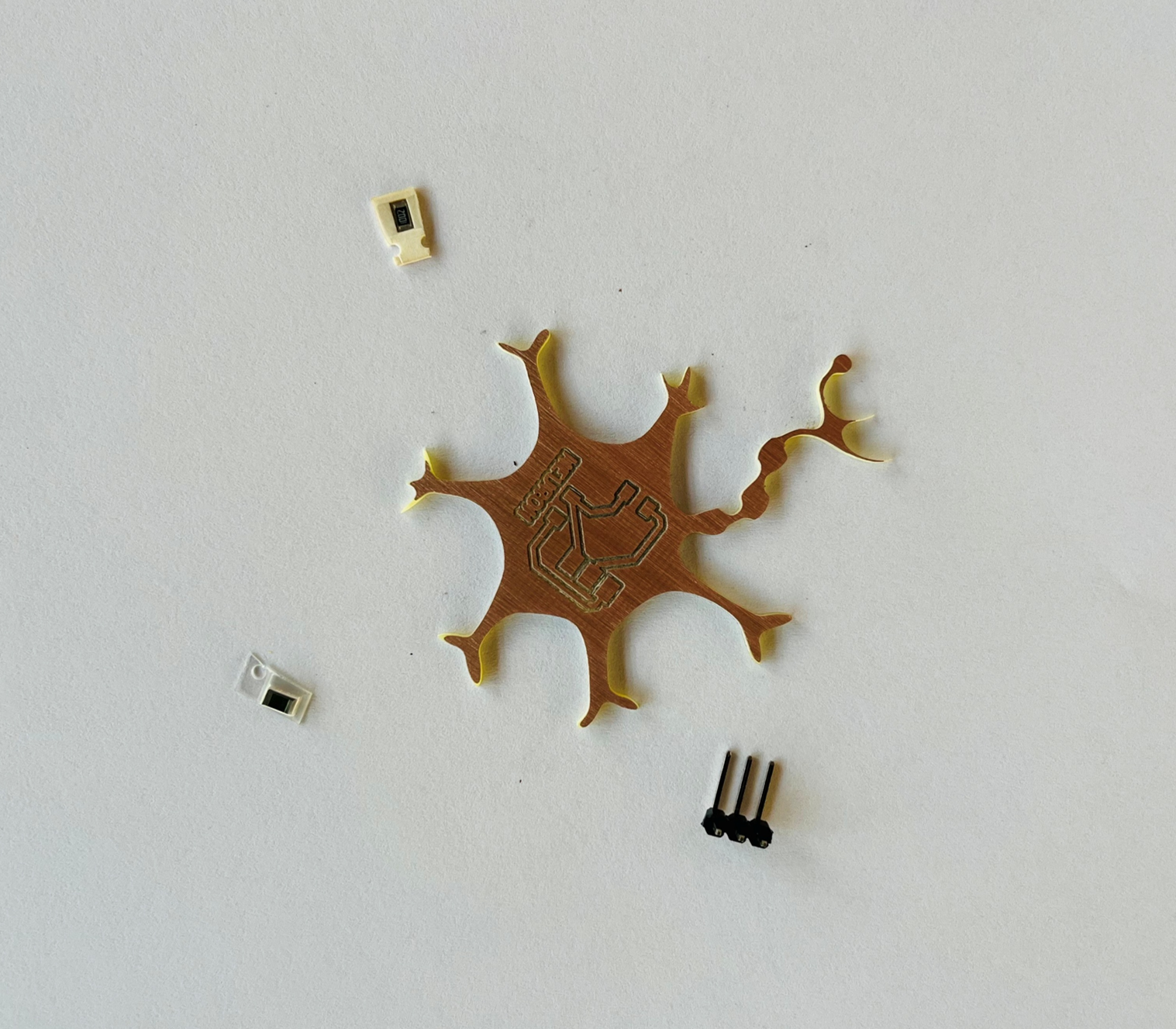

This is the result I got after milling the PCB:

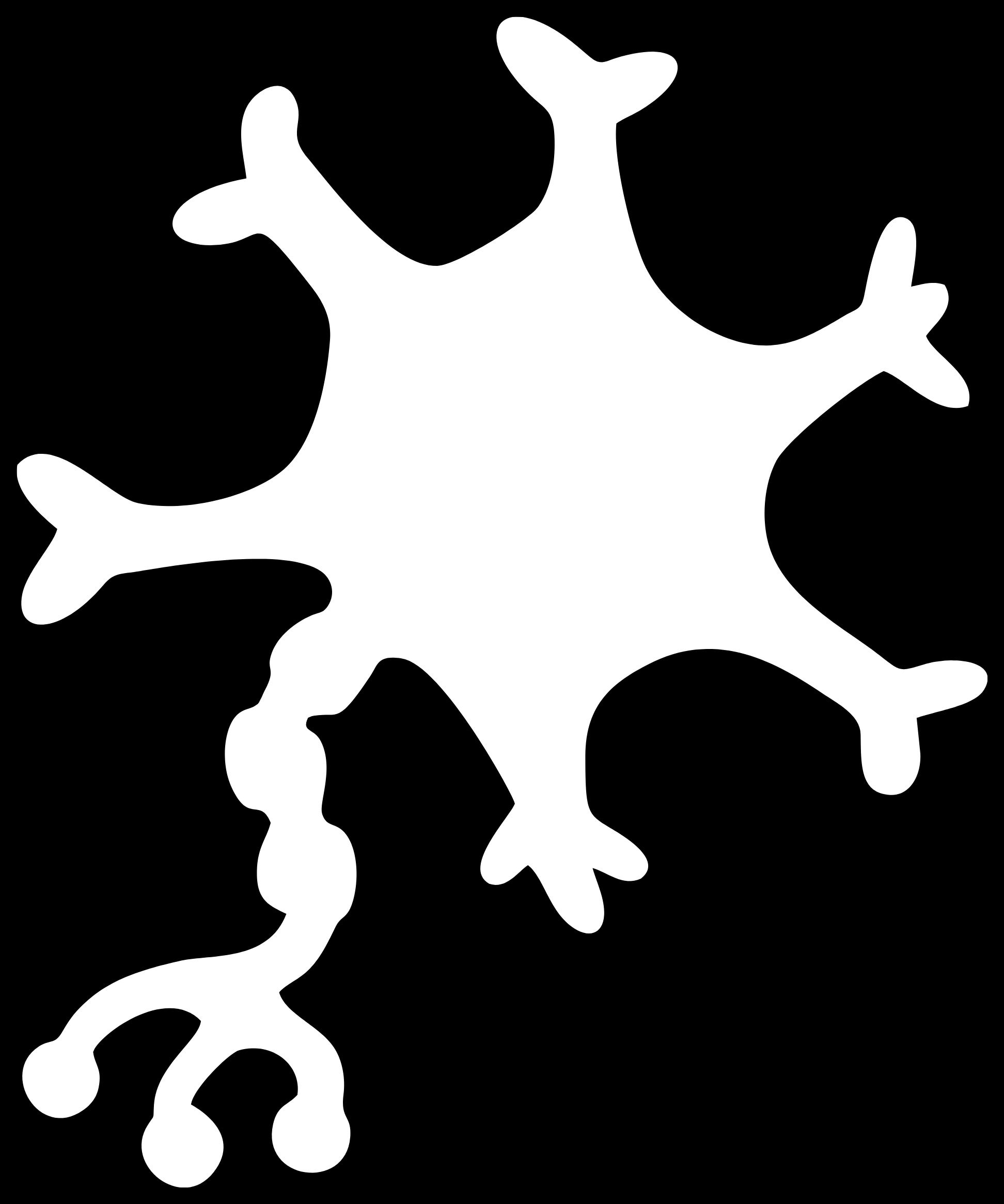

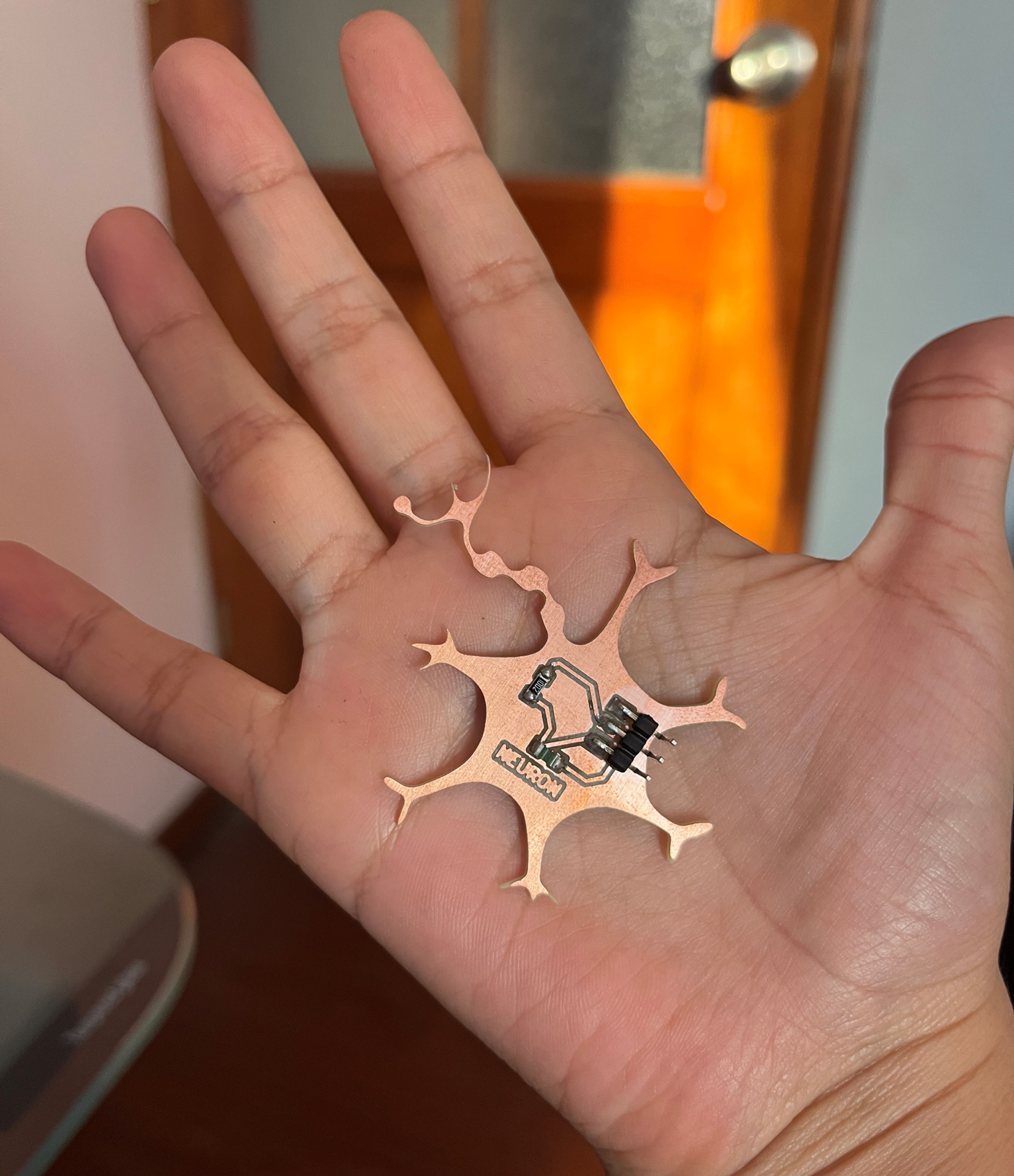

Neuron PCB

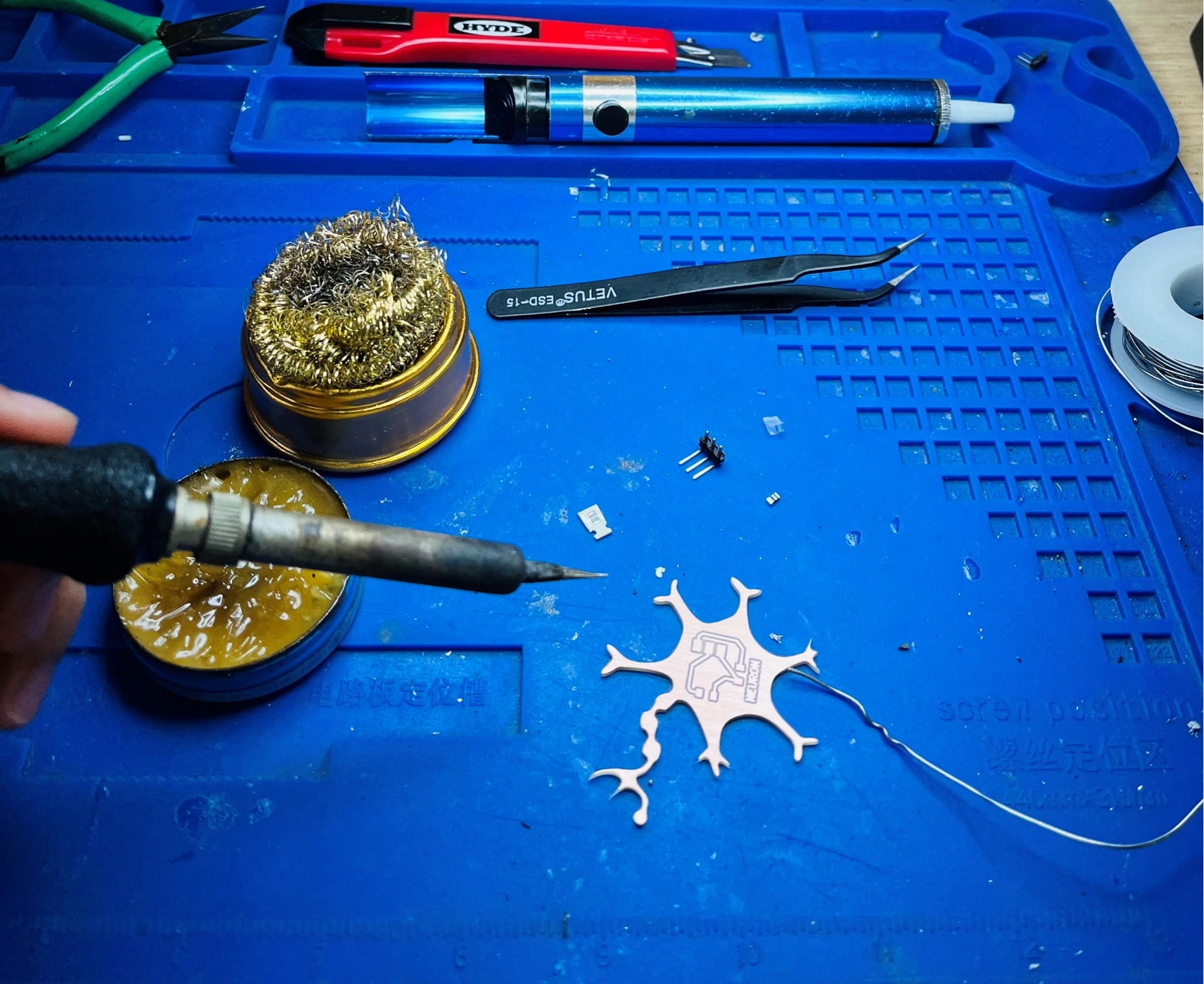

Next, I soldered the components, and the board was ready to use.

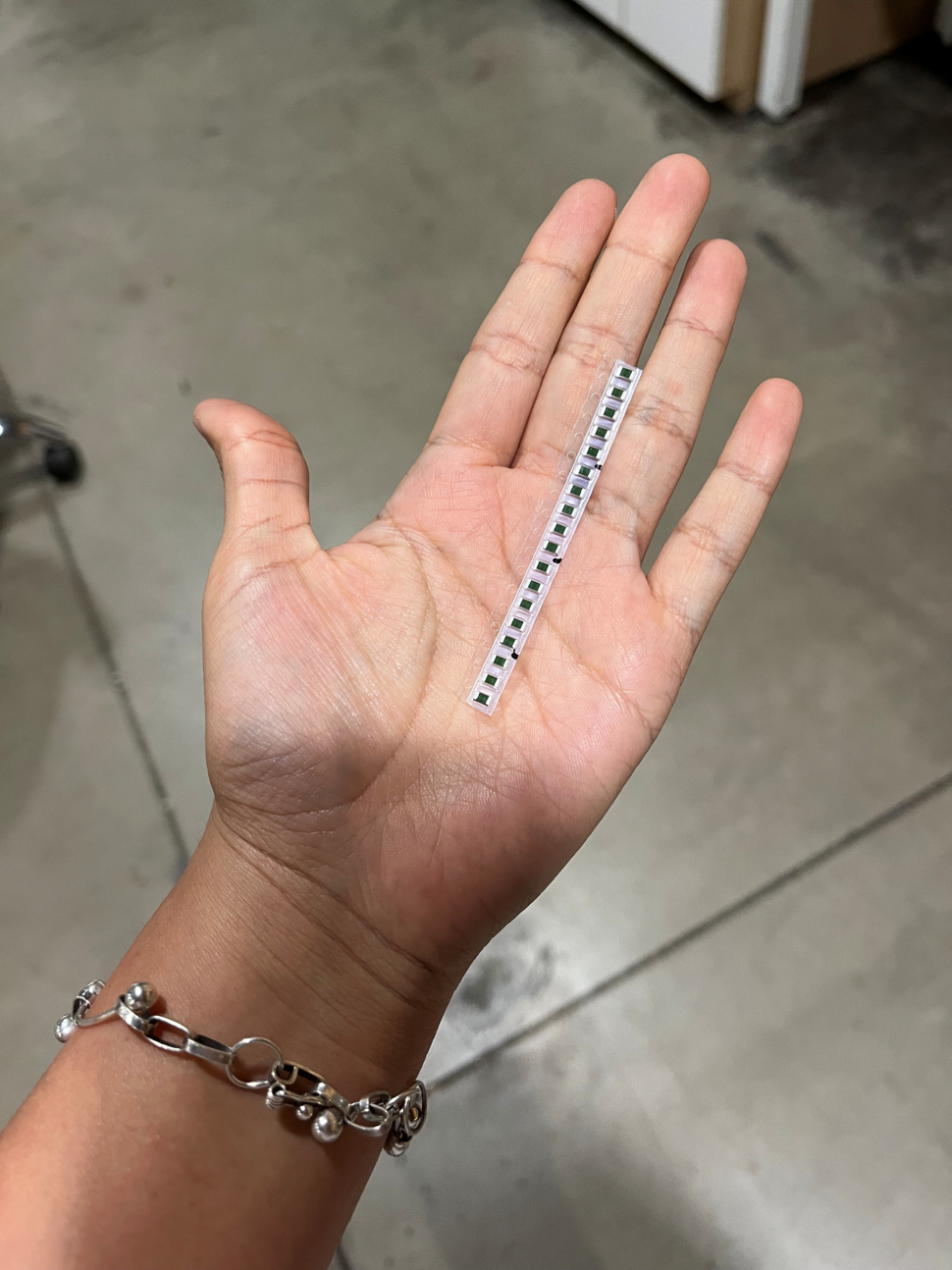

Choosing the correct components

Soldering

This is the FINAL RESULT! 😁

Neuron PCB

Then, I wrote the code in Arduino IDE, which is as follows, and obtained the following result:

Brain - Neuron PCB

Test Video: