W5 | 3D Scanning and Printing

INDIVIDUAL ASSIGNMENT

- Design and 3D print an object (small, few cm3, limited by printer time) that could not be easily made subtractively.

- 3D scan an object. (and optionally print it)

1. Design and 3D Print

Small Gyroscope

For this week's individual assignment, I took on the challenge of designing and 3D printing an

object that would not be easy to make using traditional subtractive methods. After

brainstorming ideas, I decided to create a small gyroscope

—a fascinating mechanism made up of multiple concentric rings that can rotate freely within each other.

I designed the model in Fusion 360, carefully ensuring that each ring had enough clearance to move smoothly once printed.

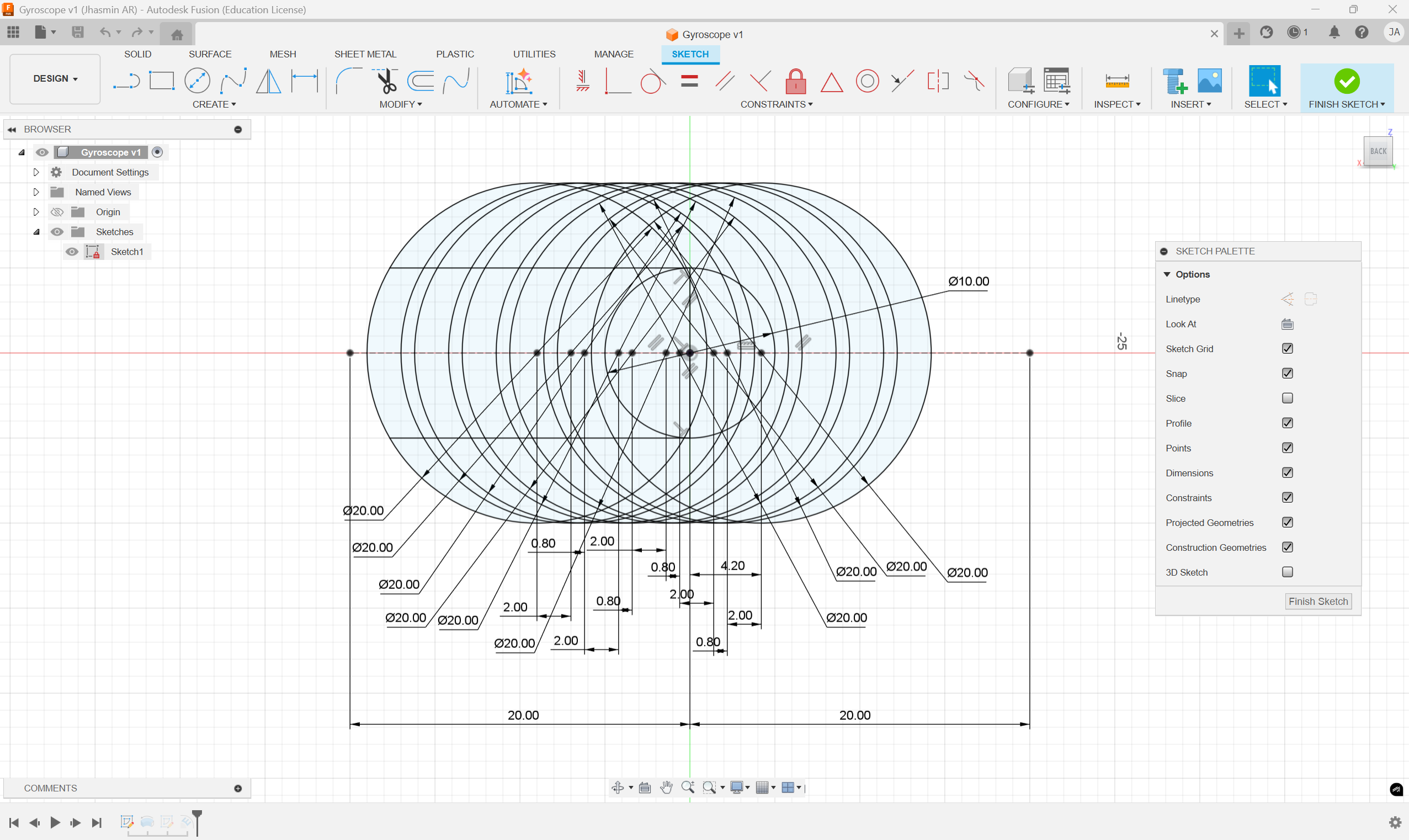

This is the sketch in Fusion 360

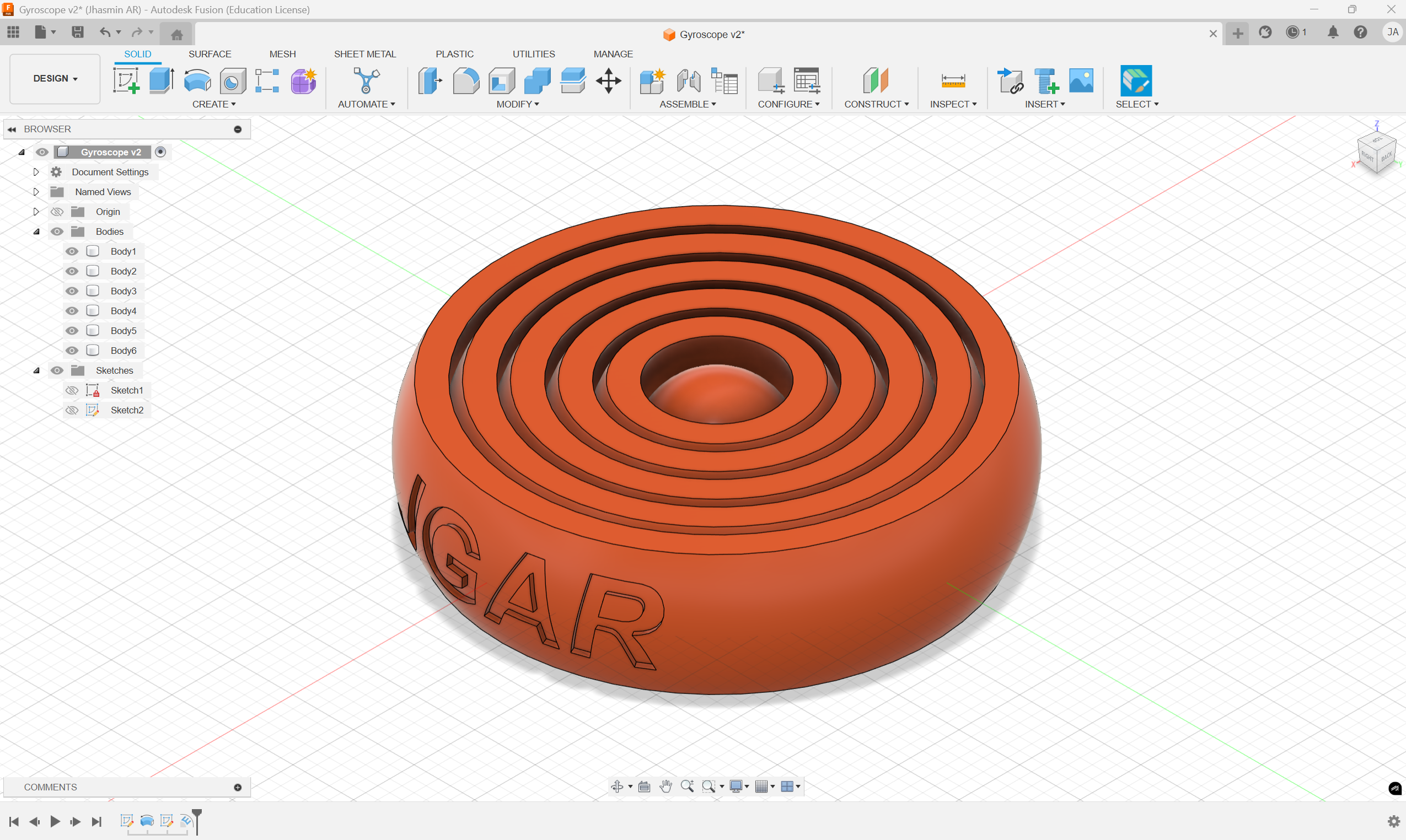

These are the bodies

What makes this design special is that it is impossible to fabricate as a single piece using subtractive manufacturing. The only way to achieve this conventionality would be by manufacturing the rings separately and then assembling them, which adds complexity and potential inaccuracies.With 3D printing, however, I was able to produce the entire gyroscope in one go, eliminating the need for assembly.

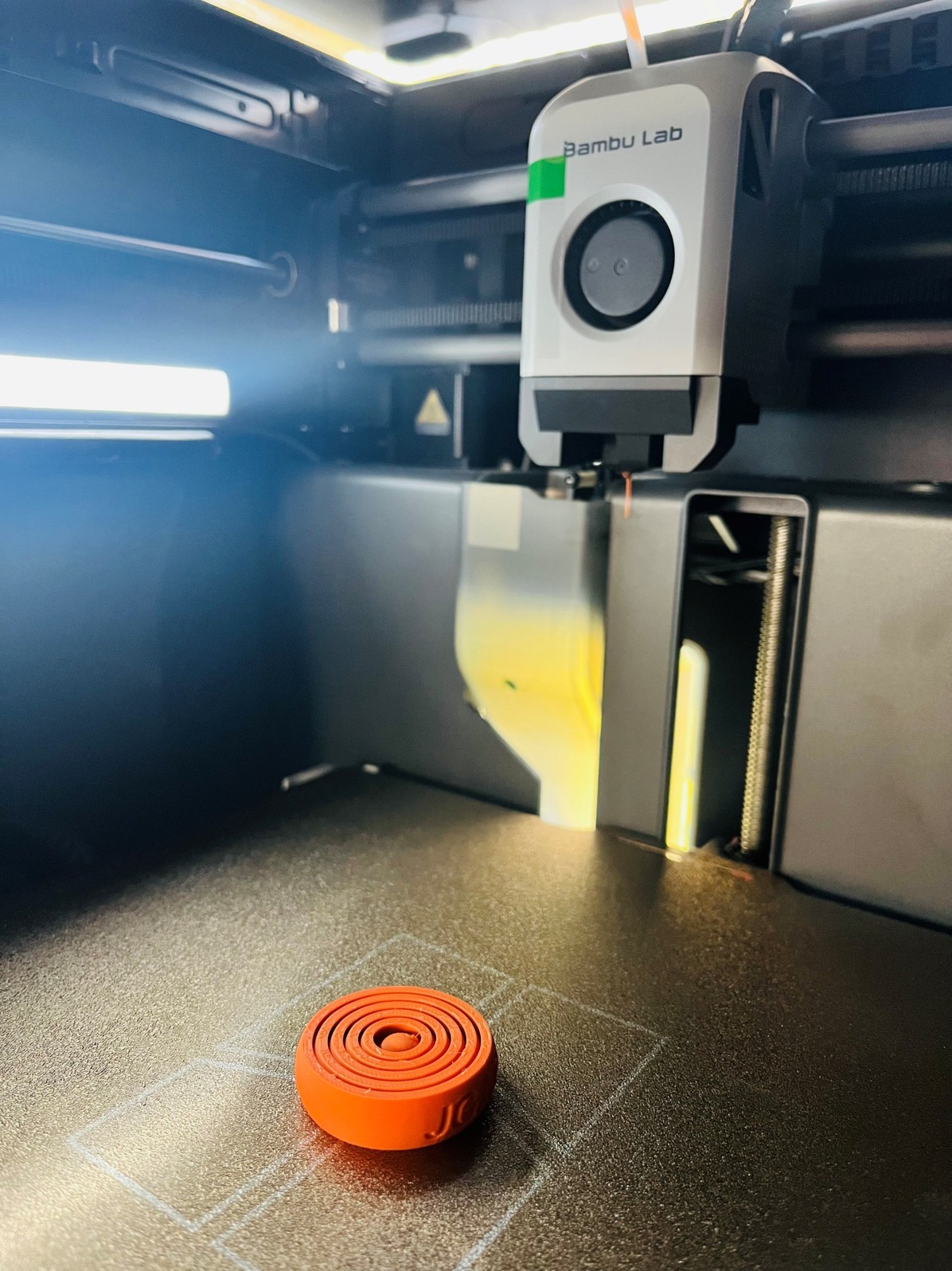

Printed in the Bambu Lab P1S

The result?A fully functional, smoothly rotating gyroscope straight off the print bed!