Week 17 Assignment

We needed to answer all the quiestion related to the final project planning and development.

These questions are:

- What will it do?

- Who has done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will they come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

- What tasks have been completed?

- What tasks remain?

- What has worked? What hasn’t?

- What questions need to be resolved?

- What will happen when?

- What have you learned?

What will it do?

my minimum goal is to draw basic shapes like circles, squares rectangles and triandles. and for complete feature I want it to understand gcode and receive files from the PC GUI and for the nice to have features I want it to do live drawing through out the GUI like the GUI will have a canvas that the user can draw in and the hand will move accordingly in real time.

Who has done what beforehand?

There are many people through out the internet explored making this robotic arm using a 4 link mechanism or a scara robot arm like mechanism like:

- Arduino Controlled Drawing Robot.

- Sketching Robot Arm

- Lukas, Tanjas, Peters and Jimenas Drawbot (2018)

What will you design?

- I designed in fusion a 3d and laser cut parts

- I fabricated 3D parts and laser cut parts out of plywood.

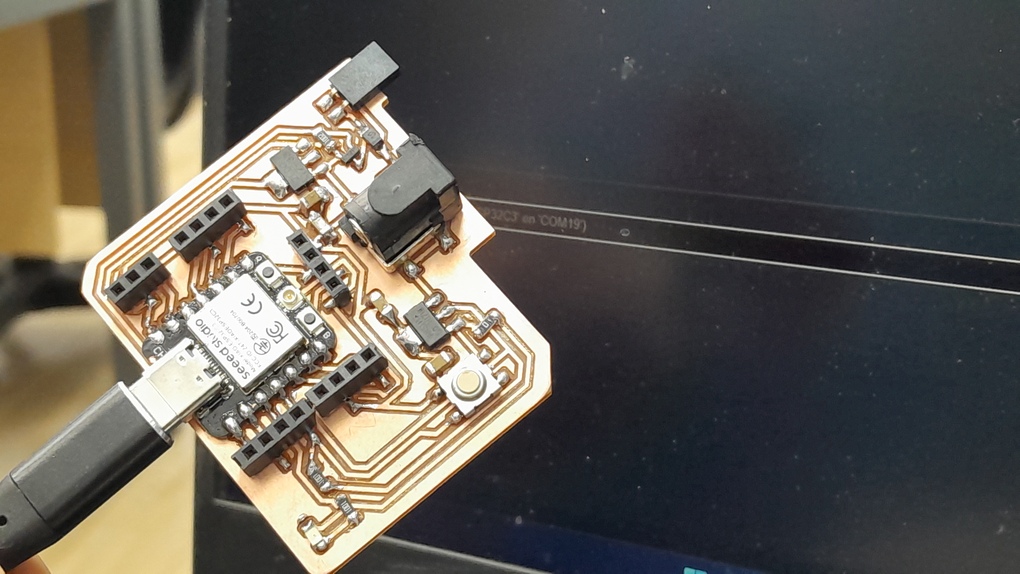

- For the PCB and electronics I will design a PCB to control the Motors but I will use my own Xiao ESp32 board I made back in week 6 and fabricated it in week 8

.png)

What materials and components will be used?Where will they come from? How much will they cost?

| Components | Quantity | Links | Cost |

|---|---|---|---|

| Stepper motor | 2 | Stepper motor Nema 17 | 900EGP |

| Servo motor | 1 | Servo motor SG90. | 100EGP |

| GT2 timing belt | 2 | Timing belt 1m 6mm | 60EGP |

| Stepper motor pulley | 2 | Pulleys 20 teeth 5mm bore | 100EGP |

| Stepper motor pulley | 2 | Pulleys 36 teeth 5mm bore | 150EGP |

| Limit switch | 2 | Limit Switches | 15EGP |

| Stepper motor driver | 2 | Stepper motor driver A4988 | 170EGP |

| Arduino Uno/Nano/Xiao ESP32 C3 | 1 | Xioa ESP32 C3 | 750EGP |

| LCD with I2C interface/ OLED | 1 | 20x4 LCD display | 350EGP |

| Materials | Quantity | Notes | Cost |

| Acrylic 6mm/Plywood 6mm | Inventory | ||

| 3D printing filament | Inventory |

What parts and systems will be made?

- I will make the mechanical design and this will be fabricated out of 3d printed parts and plywood cut parts.

- I will make the Motor control PCB.

- I will make the limit switches PCB.

- I will make the GUI where I can control the robot arm.

What processes will be used?

- 3D printing of course for the complicated parts.

- Laser cutting for the arms and the base of the robot arm.

- PCB milling for the limit switches PCB and motor control PCB.

- Sanding for the plywood.

What questions need to be answered?

- First, it the math right? I am using a general inverse kinematics equation to get the angles out of the x and y.

- Is the material choose right?

- The driver I am using will it do the job.

- Do I have to change the design?

How will it be evaluated?

- The robot arm should move smoothly.

- It should be have some precision in the movement.

- I can go to points in x and y plane.

- Draw something.

- Draw line, circle and rectangle

- Draw something out of the GUI.

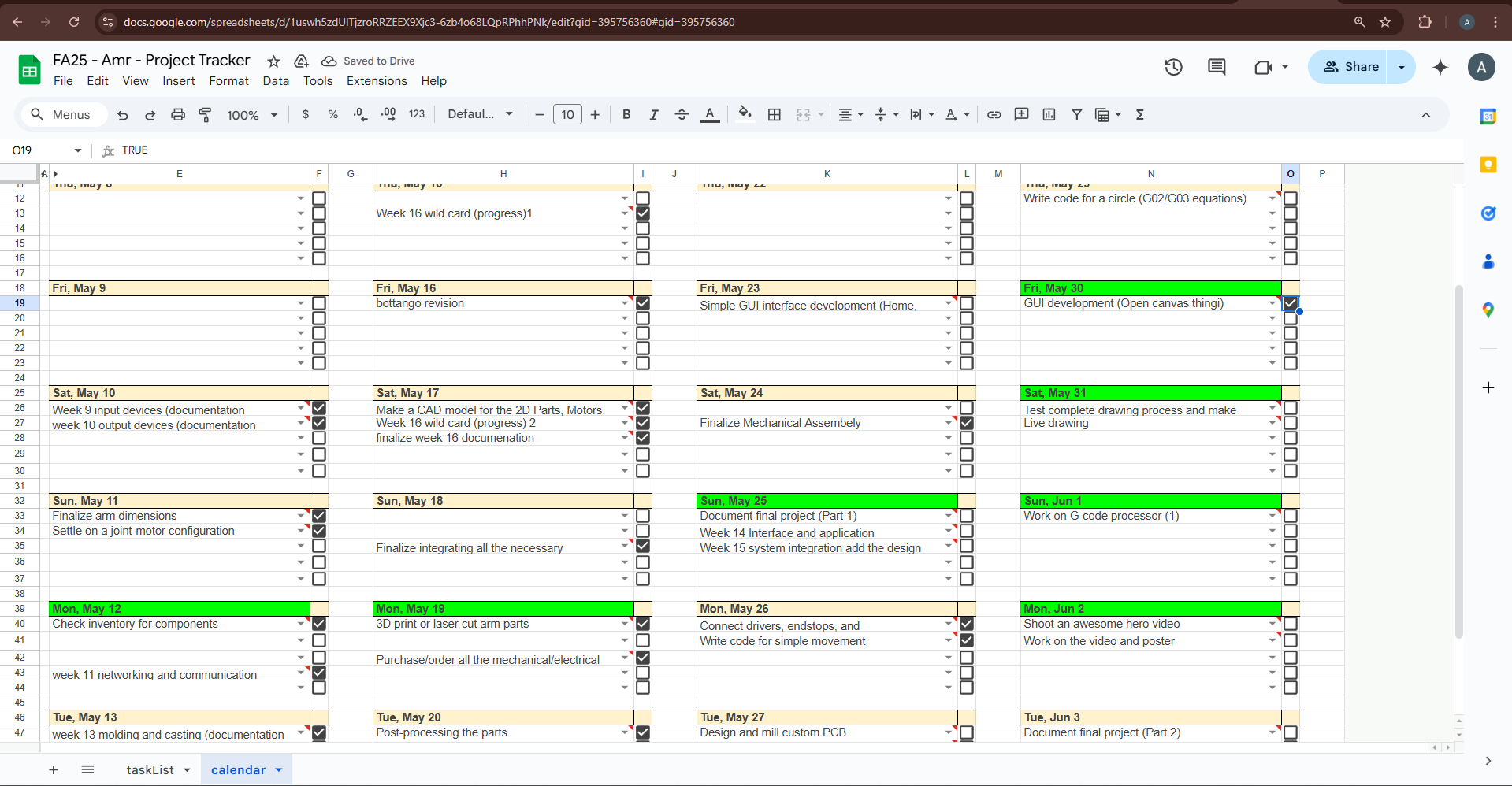

What tasks have been completed?What tasks remain?What will happen when?

Tasks I have completed are the checked ones:

What has worked? What hasn’t?

- ًWhat has worked..

- Motors worked fine.

- The GUI is done and the communication is great.

- Mechanical design and assemble I think it went quite good but it could be much better but I am running out of time.

- What hasn't worked?

- The math and calculations in paper it should work but I still hasn't figure out what is the problem.

What have you learned?

- This is a great opportunity to work on a real life robot arm and I liked this.

- I learned about inverse kinematics.

- Used thrust bearing and ordinary bearing for the first time for a project I only work on it.

- Using Tkinter and pyserial

- Learned how Scara robot arms work mechanically.