Week 13: Molding and Casting.

Review the safety data sheets for each of your molding and casting materials

Make and compare test casts with each of them

Compare printing vs milling molds

Safety Data Sheet(SDS) Review

SILOCZEST Liquid Silicone Rubber (LSR 110)

We used SILOCZEST Liquid Silicone Rubber (LSR 110) for molding and casting.

Here are key points from its Safety Data Sheet (SDS):

Type: Two-part silicone rubber (Part A: Base, Part B: Catalyst)

Mix Ratio: 1:1 by weight or volume

Hazards: Generally non-toxic and skin-safe, but prolonged exposure may cause skin or eye irritation

PPE Required: Gloves, safety goggles, lab coat or apron

Ventilation: Use in a well-ventilated area, especially in enclosed spaces

Storage: Store in a cool, dry place, tightly sealed

Disposal: Follow local regulations. Do not pour uncured silicone down the drain. Cured silicone can typically be discarded with solid waste.

NOTE: We wore gloves and worked in a ventilated area while mixing and pouring the silicone.

Smooth-Cast 305

Here are the important findings from its Data Sheet.

Type: Low-viscosity urethane resin

Mix ratio: 1A:1B by volume

Pot life: ~7 minutes

Cure time: ~30 minutes

Key precautions:

Always wear gloves, safety glasses, and work in a well-ventilated space

Avoid contact with skin and eyes

Harmful if inhaled – avoid breathing vapors

- Advantages:

Very fast cure

Rigid, durable cast

Good for fast prototypes

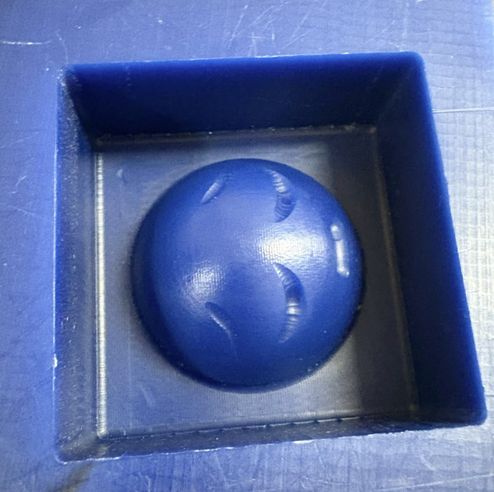

Test Cast Summary

Unfortunately, we only have one cast material in our lab which is the Smooth-Cast 305. That's why, we were only able to test that one.

This is how it turned out:

Here are some of the important findings we made.

Surface Detail: accurate(since our design was very simple, we could not make a very strong stand whether it was very accurate or not.)

Strength: Rigid and durable once fully cured.

Flexibility: Not flexible.

Ease of Use: Easy to mix (1A:1B by volume) and pour.

Finish: Slightly glossy white finish with minimal air bubbles when poured correctly.

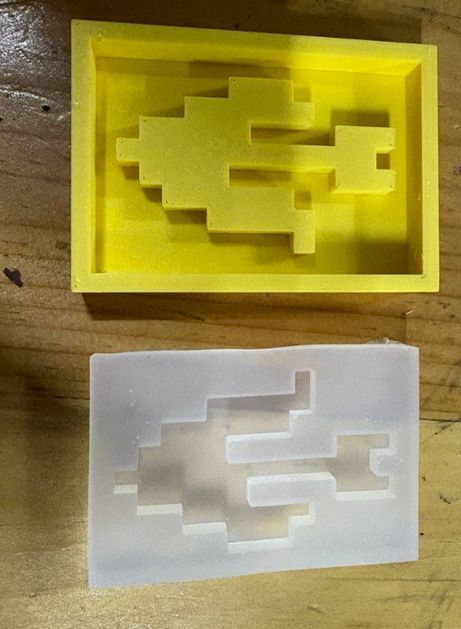

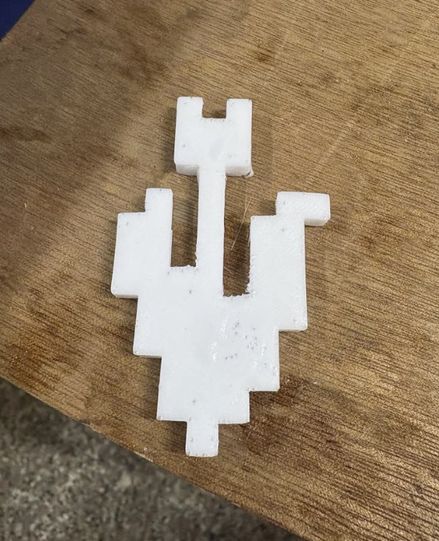

Printing vs Milling molds

This is the result of milling molds.

This is the result printing molds.

Findings

Since our designs are very VERY simple, we were not able to make a lot of definite findings. However, we did come to notice that 3D printing molds are quite durable, but it can deform with heat, whereas milling wax is fragile but quite precise. Milling also provides us with a higher level of details with a very smooth finish. 3D printing was easier for all of us since we already learnt how to do it in the earlier weeks. With milling, we had to learn how to create the toolpaths and all from the very beginning.

Thank You!