WEEK 10 - Machine design

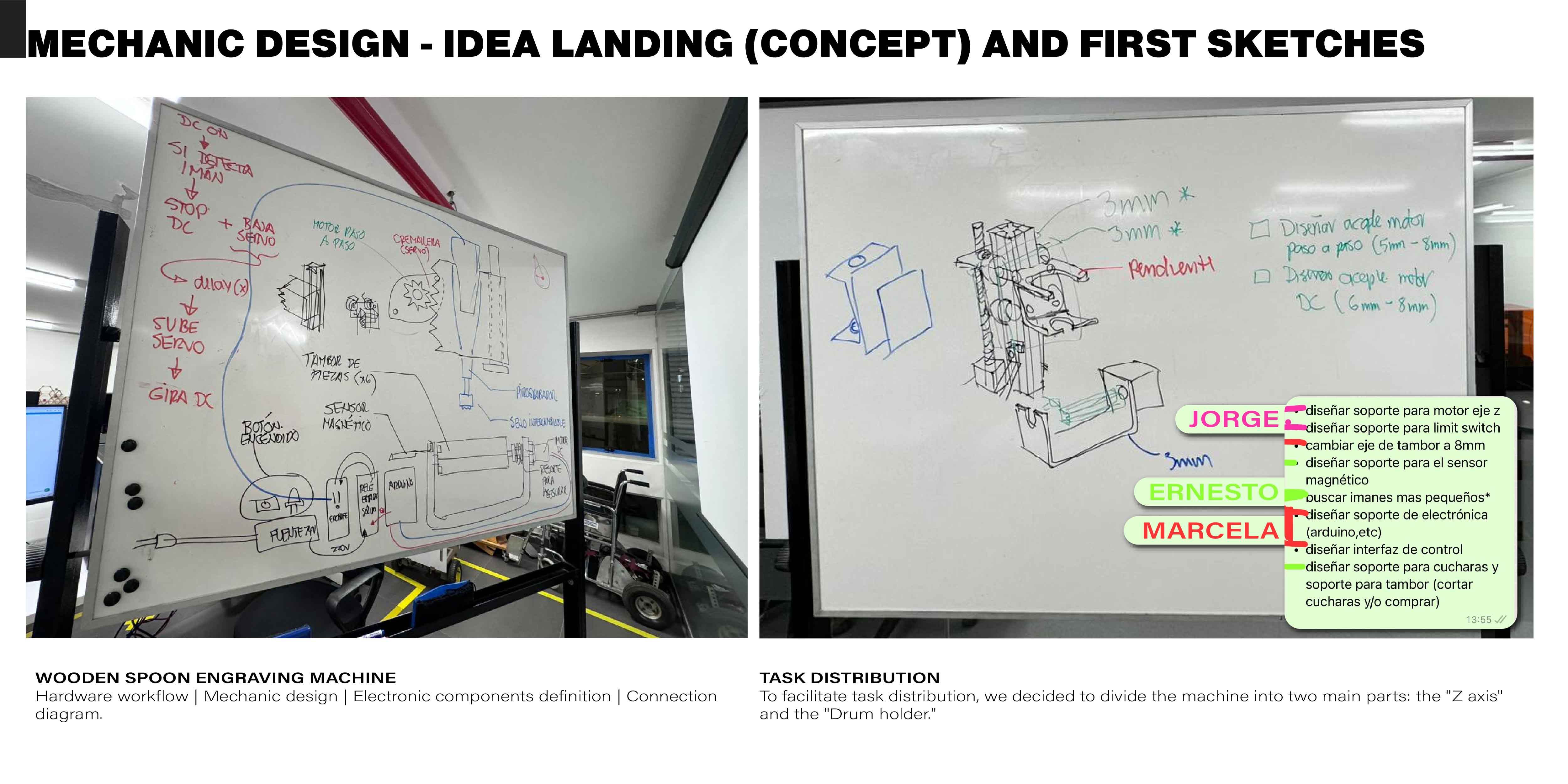

The Pyro Engraver is an automated engraving machine designed for wooden spoons or popsicle sticks. Its primary function is to automate the process of heat-engraving specific logos or designs onto these wooden items, making it ideal for small-scale productions and small businesses.

Main Components

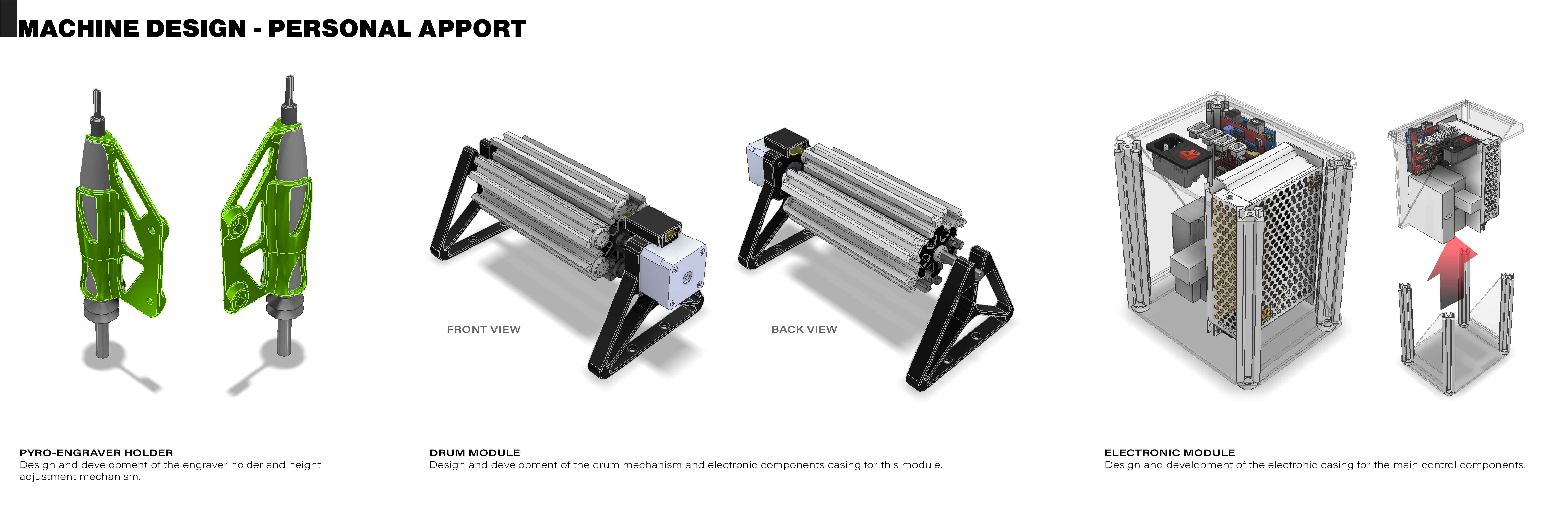

- Pyrographer: This is the actual engraving tool that uses heat to burn designs into the wood. It is mounted on a vertical axis (Z axis) that allows it to move up and down to engrave the wooden spoons positioned below.

- Material Drum Holder: This component holds the wooden spoons and rotates them to present the correct position for engraving. It includes a spoon holder, neodymium magnets for secure positioning, a stepper motor for rotation (drum), and a magnetic sensor for precise positioning.

- Control Panel and Electronics: The control system includes an Arduino Uno, a CNC Arduino shield, a 12V power supply, and a solid-state relay. The panel manages the machine's operations, including the movement of the stepper motors (for both the Z axis and the drum), and ensures precise control of the engraving process. It also features connection ports for the stepper motors, limit switches, and magnetic sensors.

Operation

- Setup: The wooden spoons are placed in the material drum holder. The control panel is connected, and the machine is powered on.

- Homing: The machine homes the Z axis and the drum to ensure they start from the correct positions using the limit switches and magnetic sensors.

- Engraving: The control panel receives commands, either manually or through a pre-programmed sequence. The Z axis moves the pyrographer to the designated starting height. The drum holder rotates to position each spoon under the pyrographer. The pyrographer engraves the design onto the spoon.

- Completion: After engraving, the drum rotates the next spoon into position, and the process repeats until all spoons are engraved. The machine can then be powered off, and the engraved spoons can be removed.

Checklist

- Document your individual contribution to the machine design.

Individual apport

In the group project, I was responsible for designing the drum mechanics, the pyroengraver holder, and the main electronic control case.

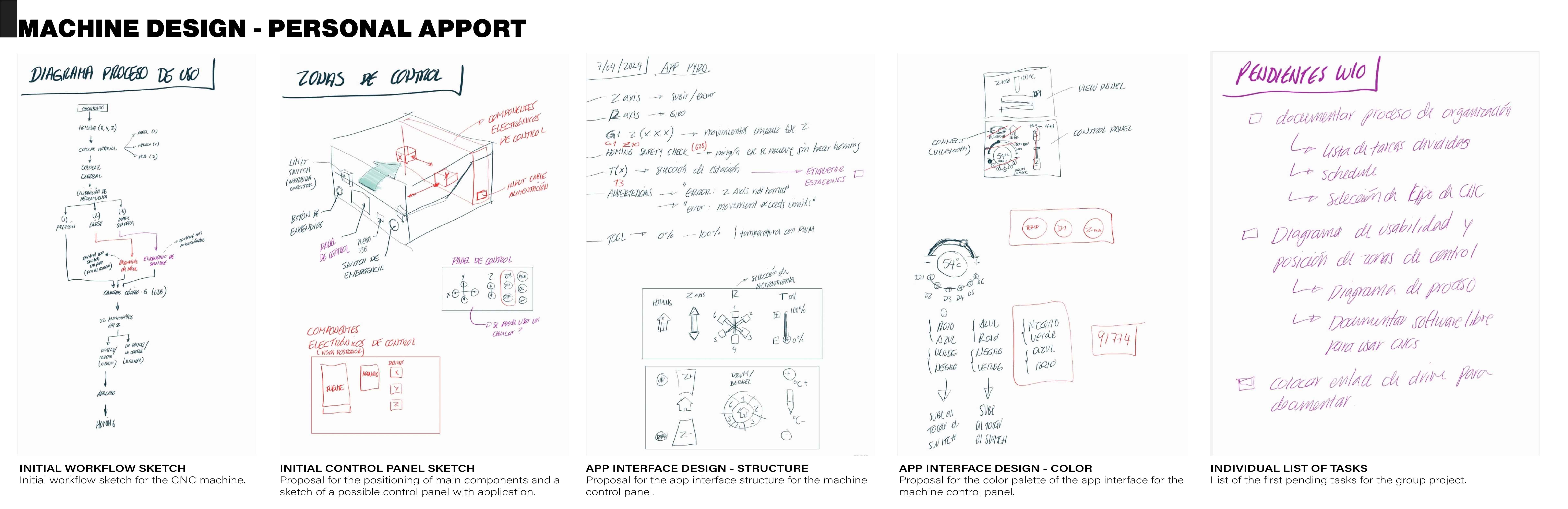

Sketching and planning

Design process

Concept

CAD

Electronic casing fabrication

In the group project, I was responsible for designing the drum mechanics, the pyroengraver holder, and the main electronic control case. For the fabrication of the electronic casing, I threaded aluminum profiles to attach 3d printed support levelers that provide stability to the main electronics module.

Laser cutting the electronic case pieces.

Interface design

Pyro app

Pyro app - Interface test

Download resources

Interface: App design

- Thunkable Pyro app design

- Thunkable project available at the web platform of the link.