1. Group assignment:

- design a machine that includes mechanism + actuation + automation + application

- build the mechanical parts and operate it manually

- document the group project and your individual contribution

2. Individual assignment:

- document your individual contribution of the project.

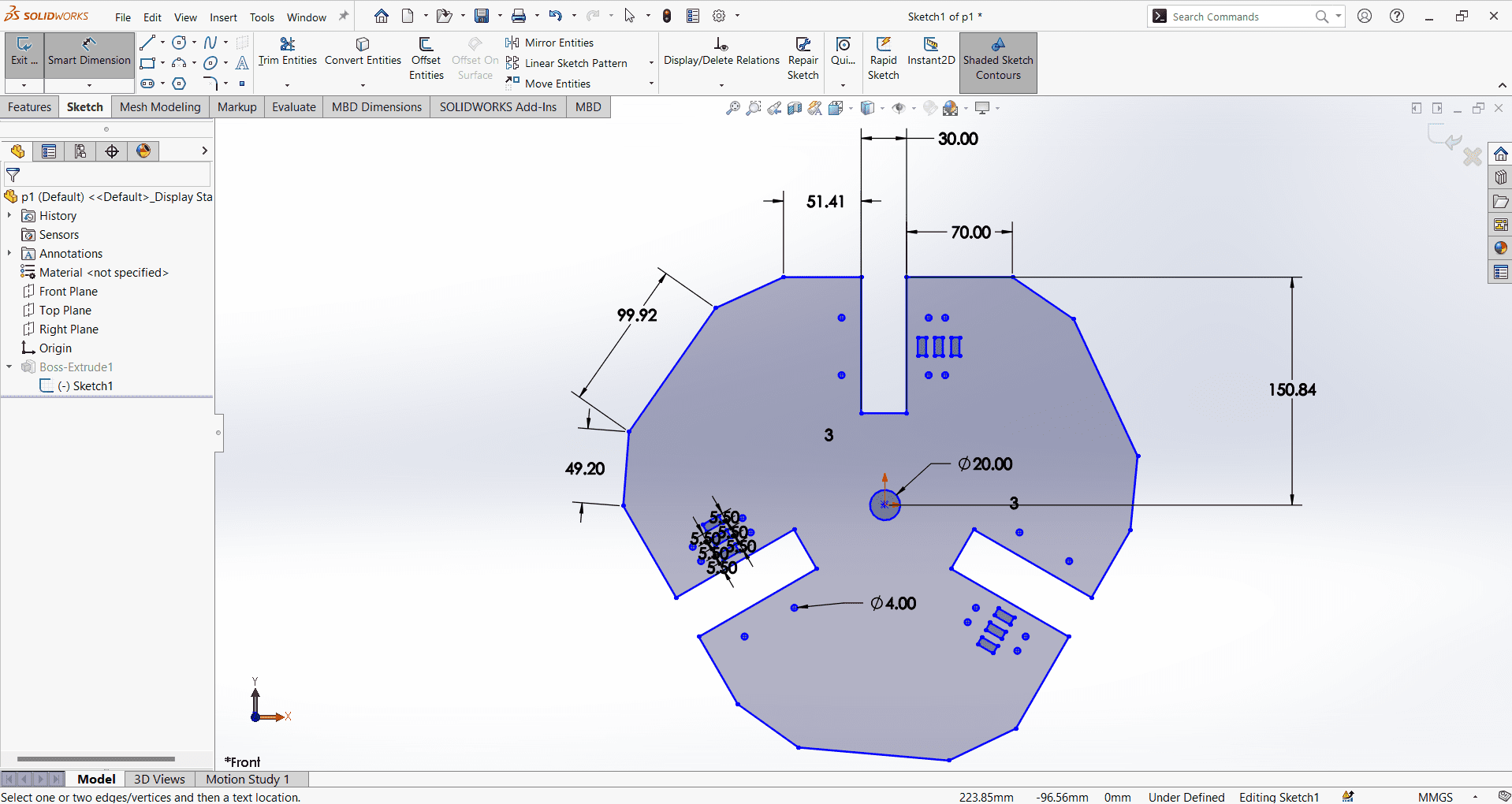

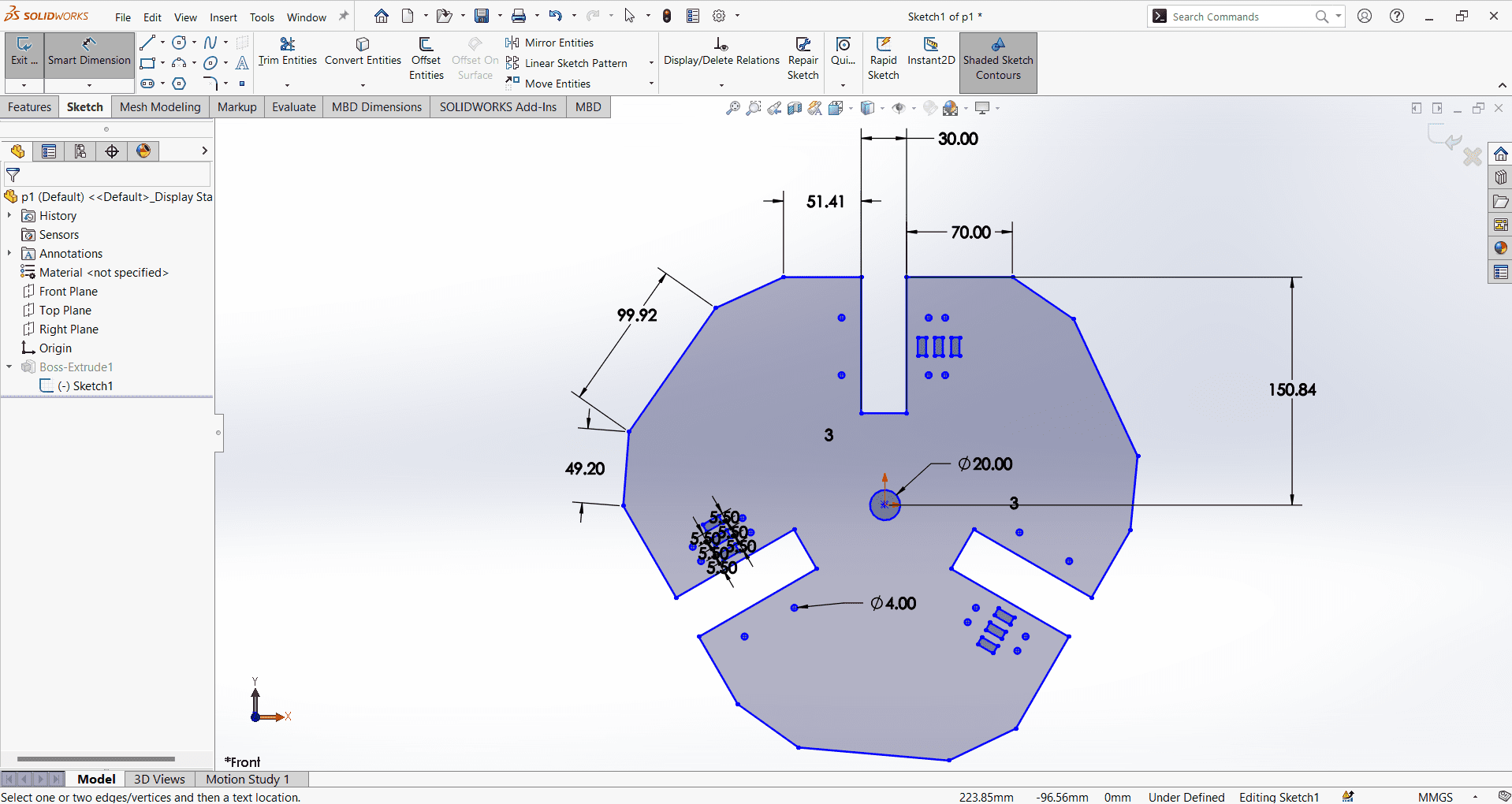

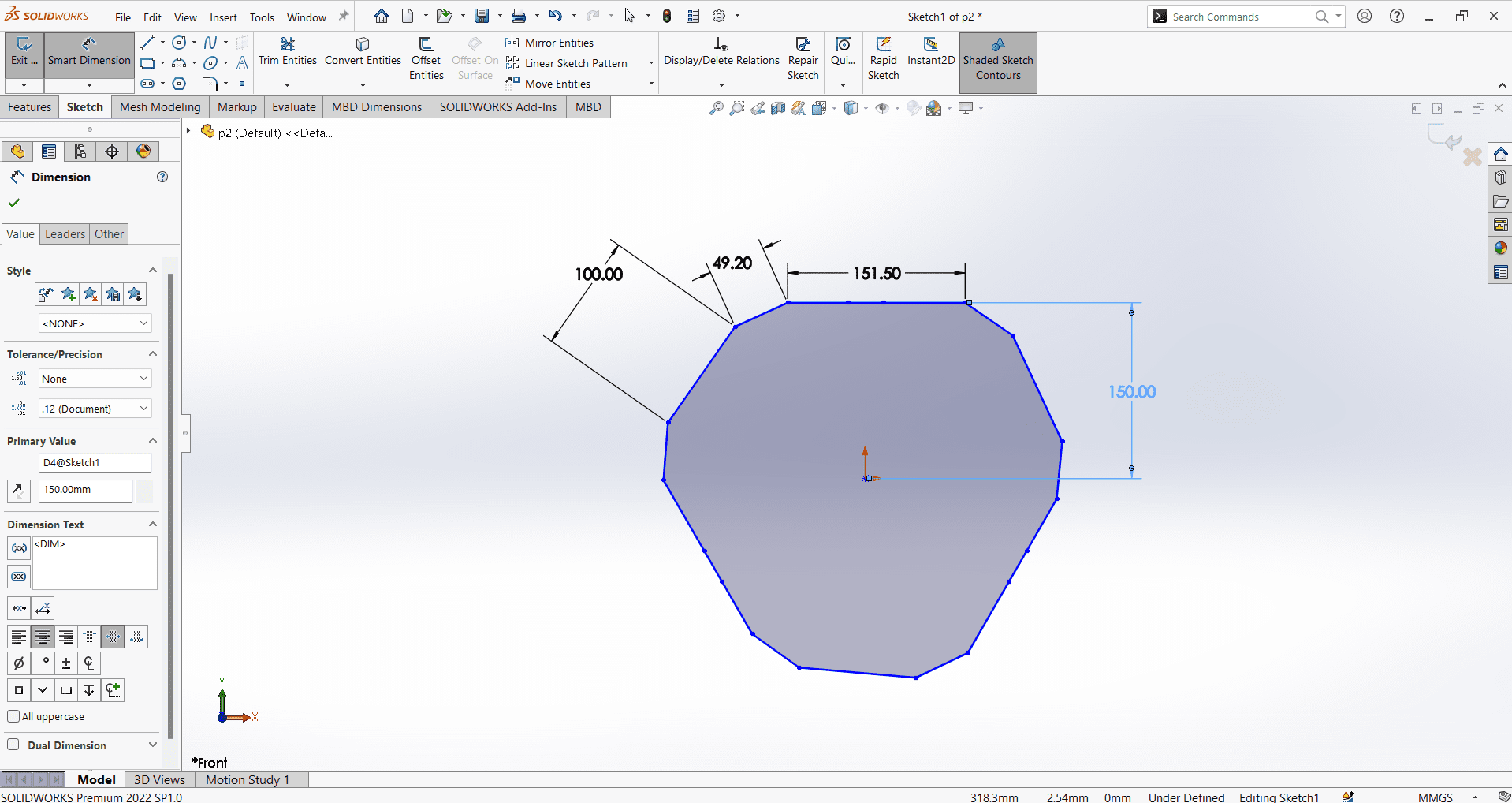

I used the SolidWorks for 3d modeling of the robot.

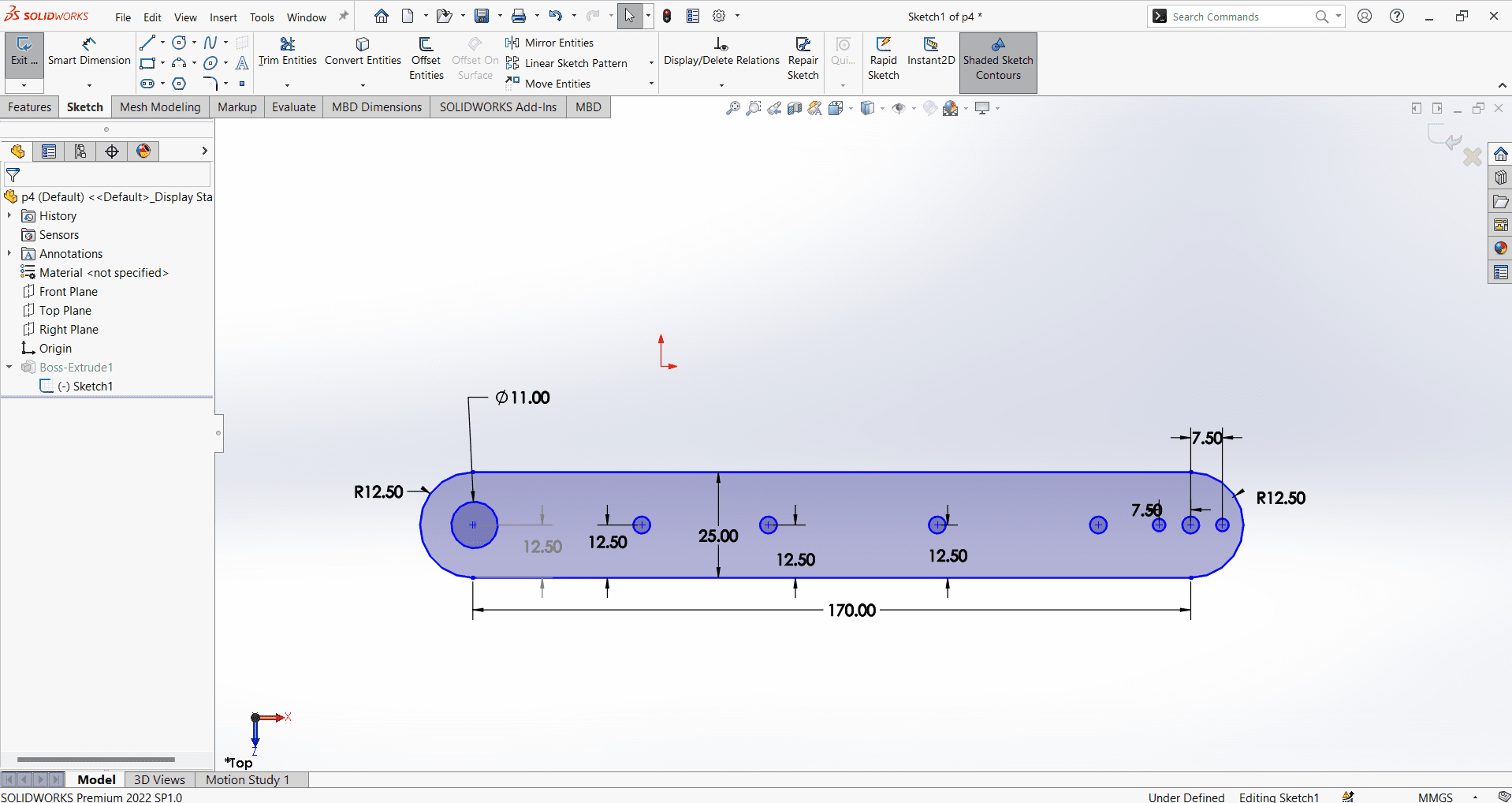

This is the upper face of the robot where we will going to fix the stepper motors.

I made the slots & holes on the face for the motor mountings.

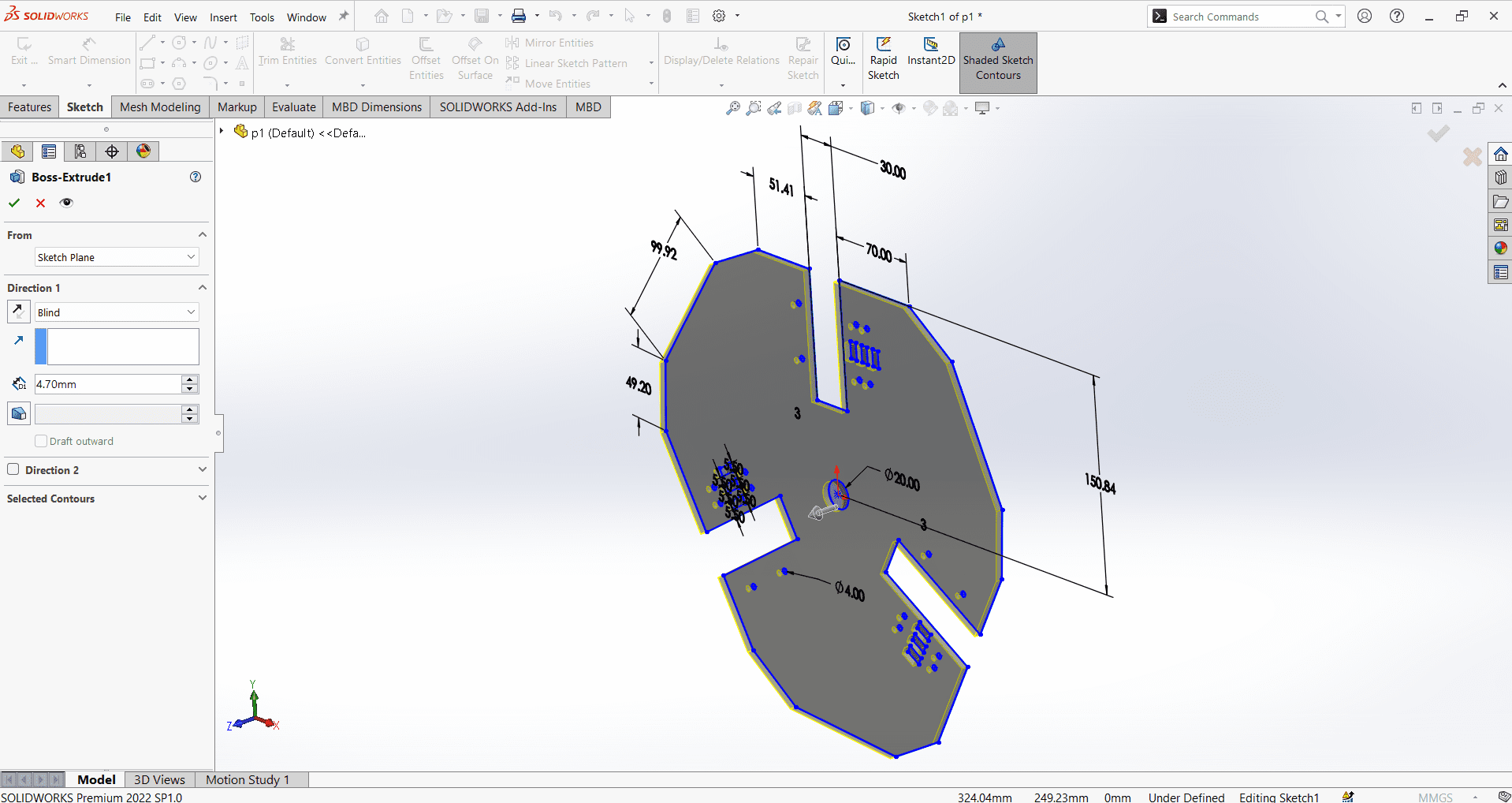

I extruded the face by 4.70mm thickness using extrude command in features section.

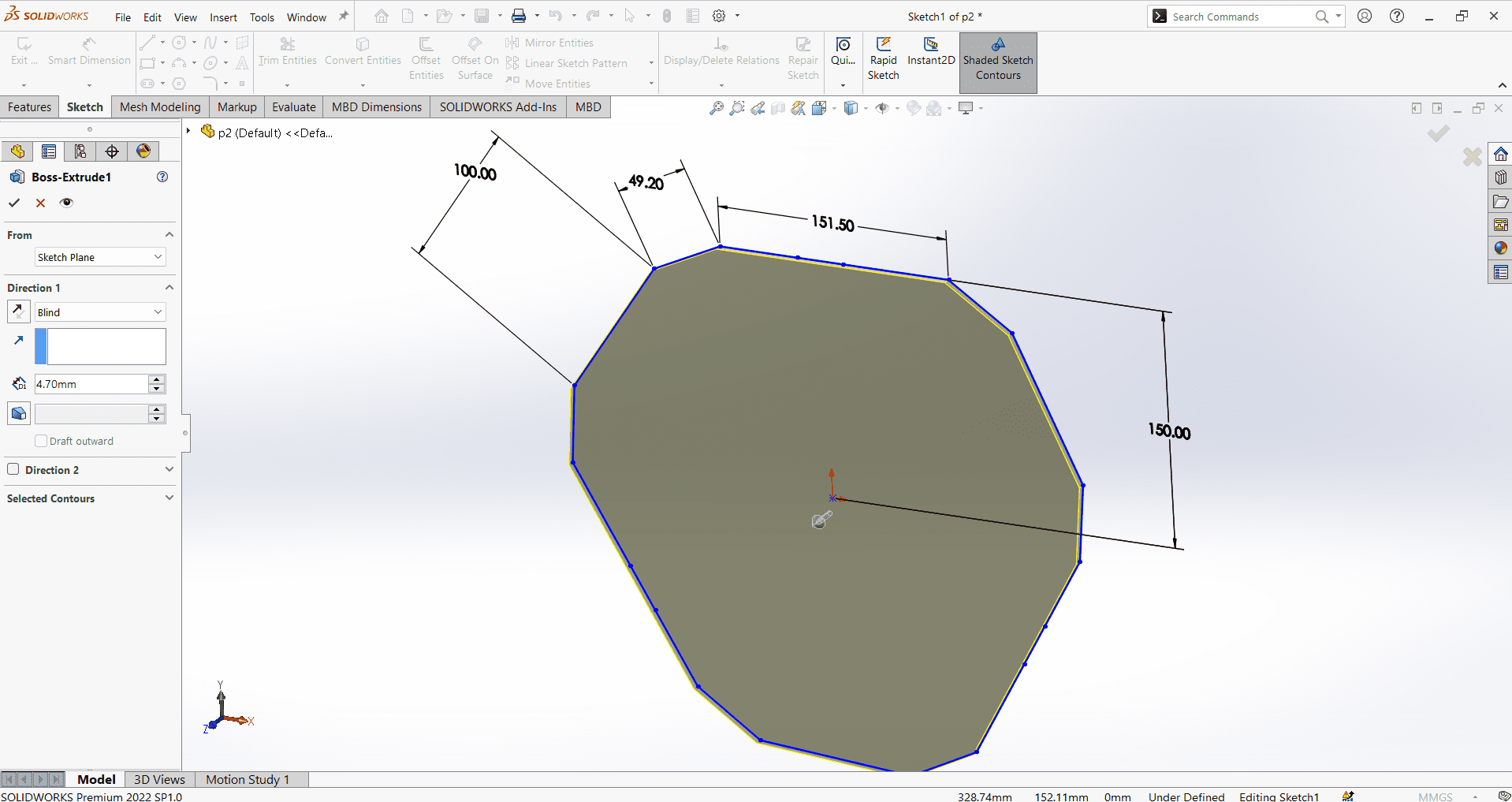

This is the lower face of the delta robot.

After that I extruded the lower face by the same thickness as that of upper face.

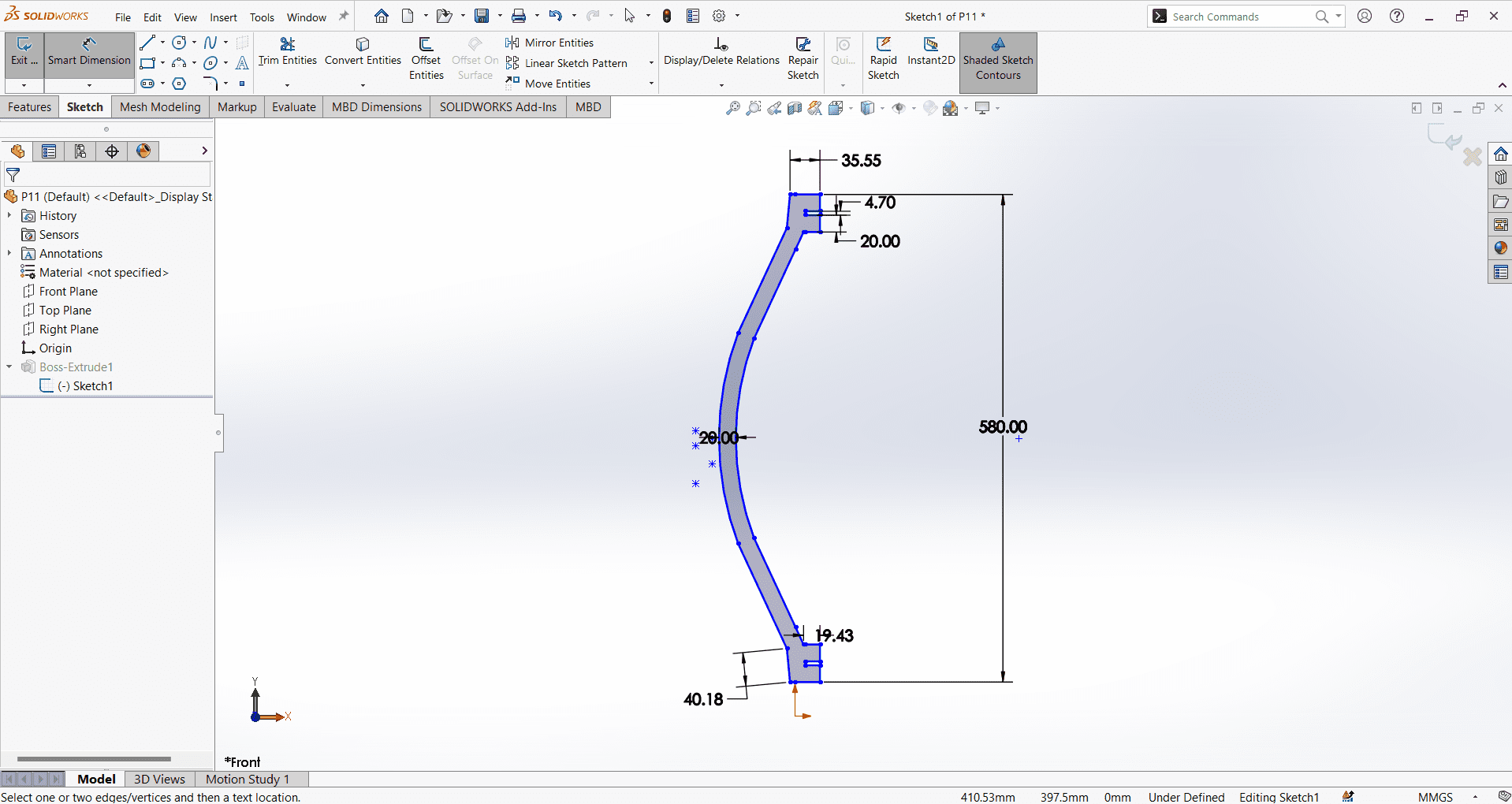

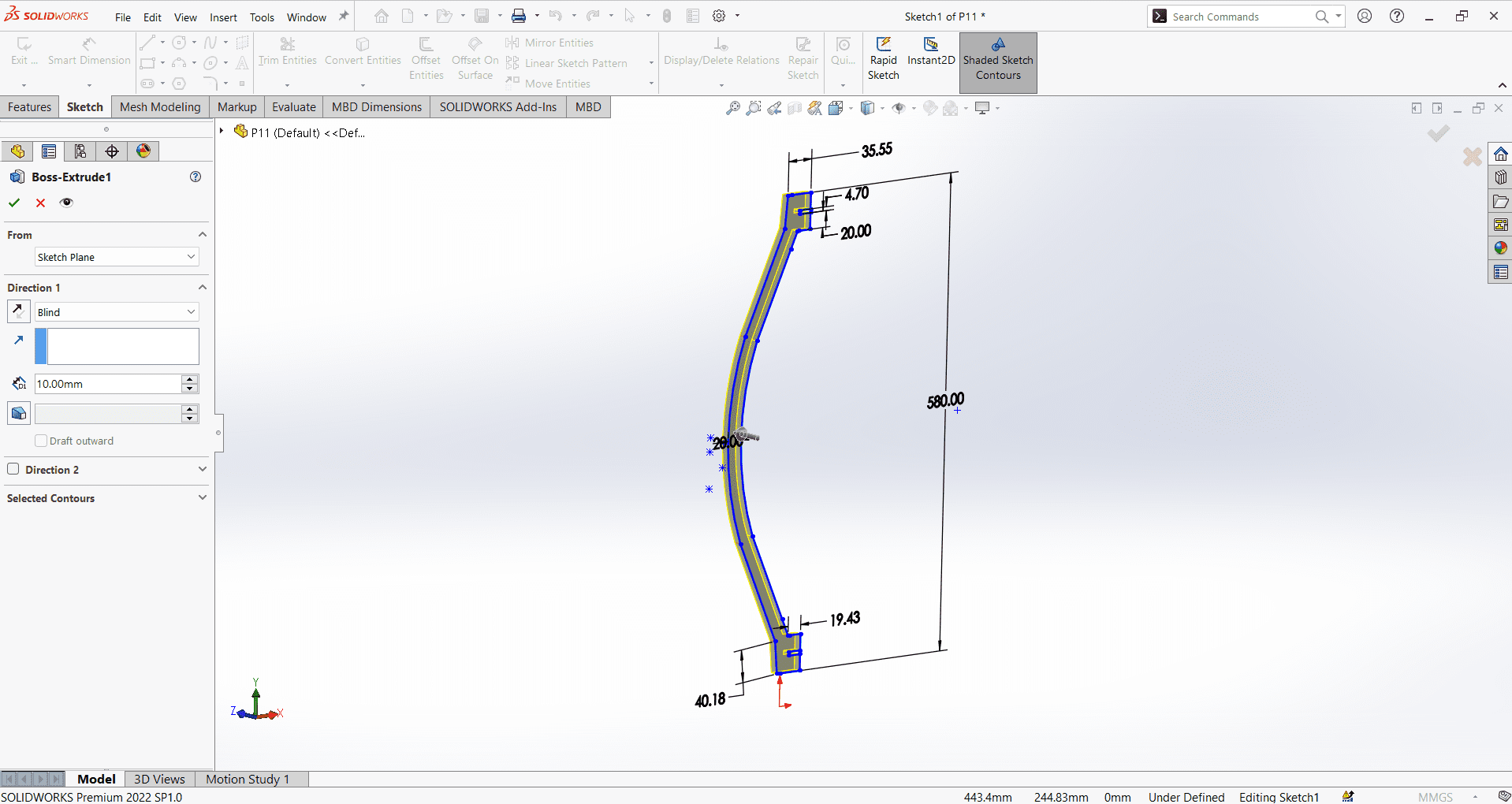

I designed the vertical supports of the robot using the various commends such as 3 point arc, line, and spline command.

I extruded the sketch using the extrude command which is present in features option.

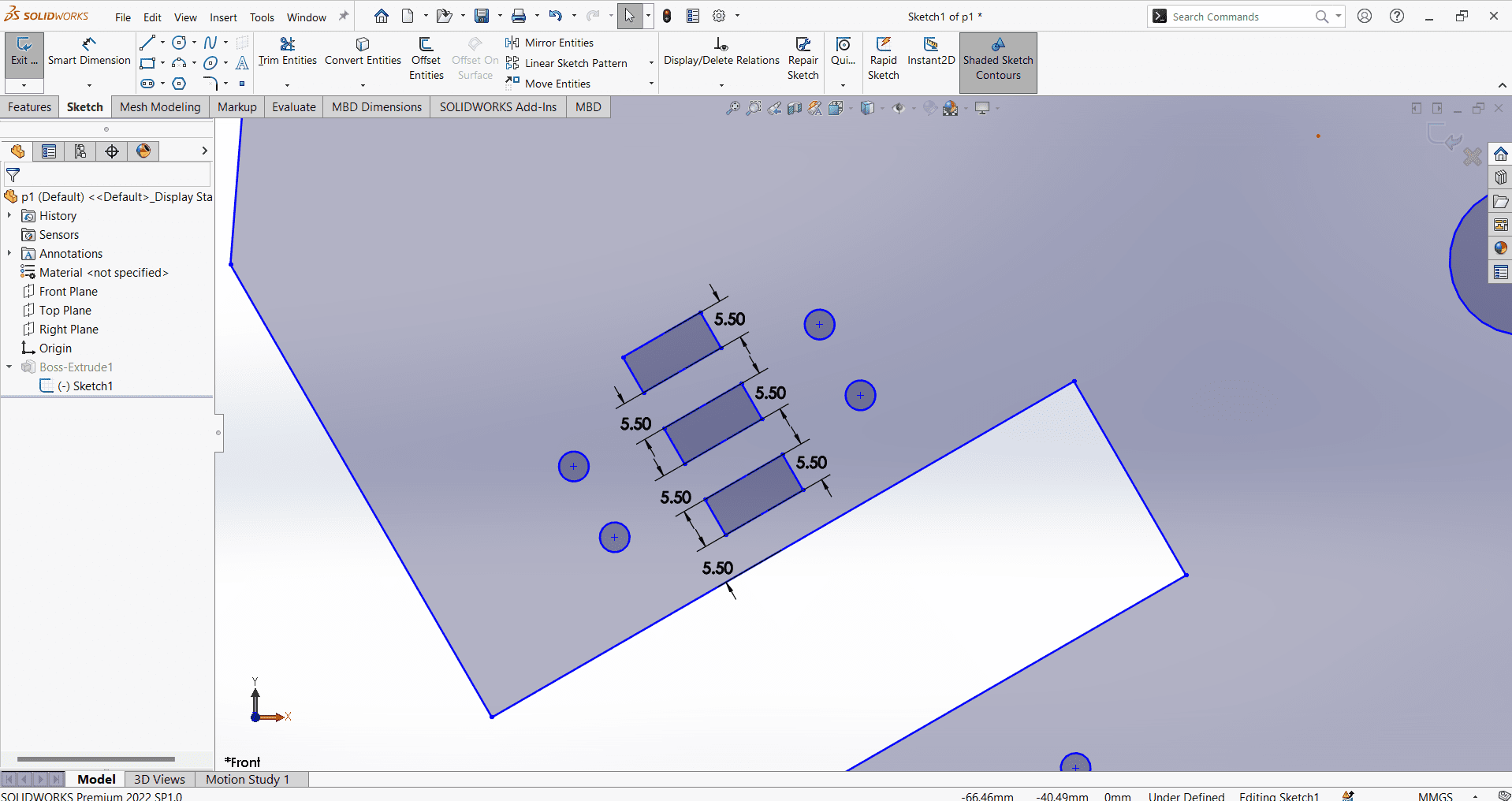

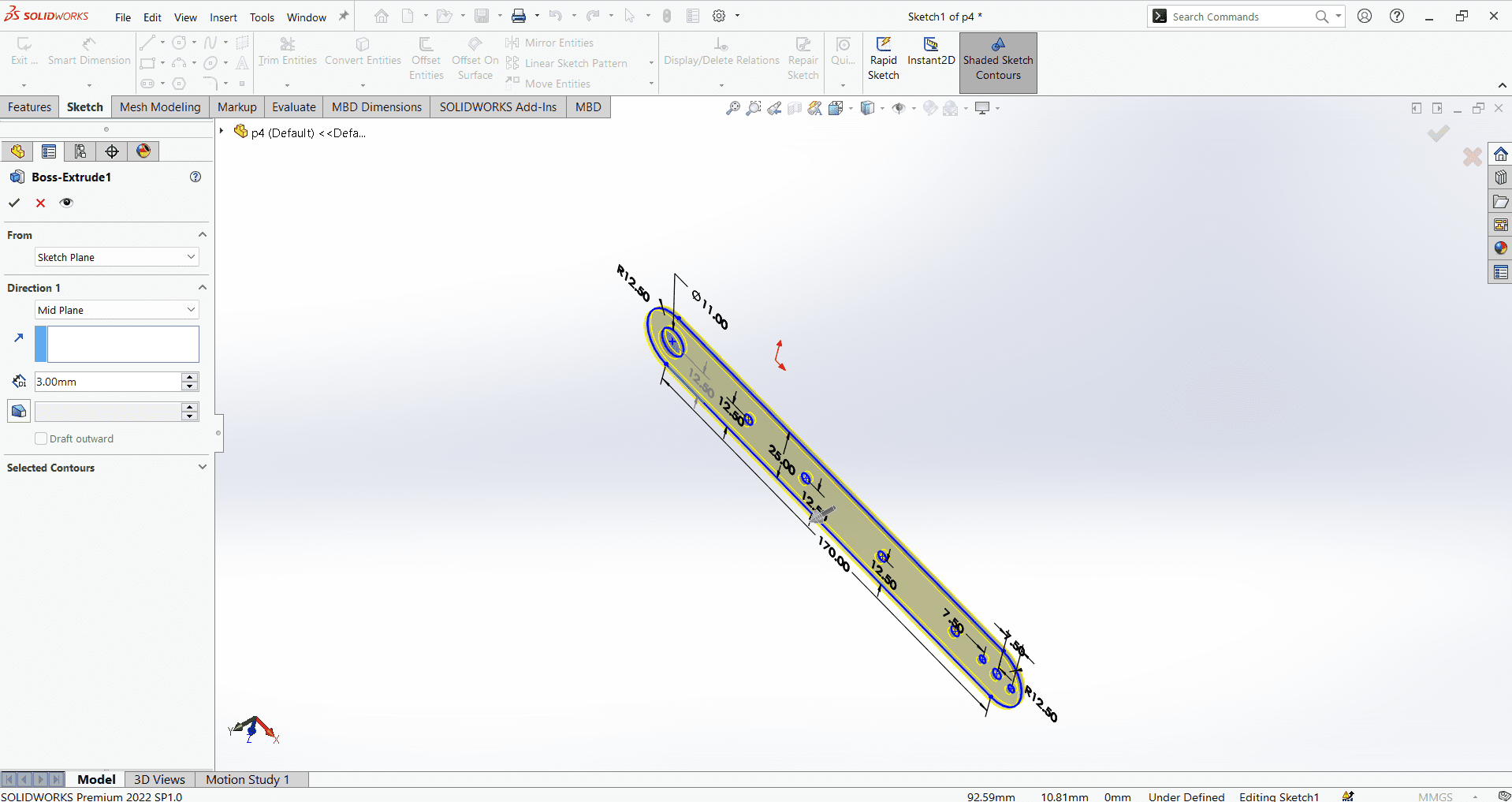

This is the sketch of upper 3 links.

I extruded the upper links using extrude command.

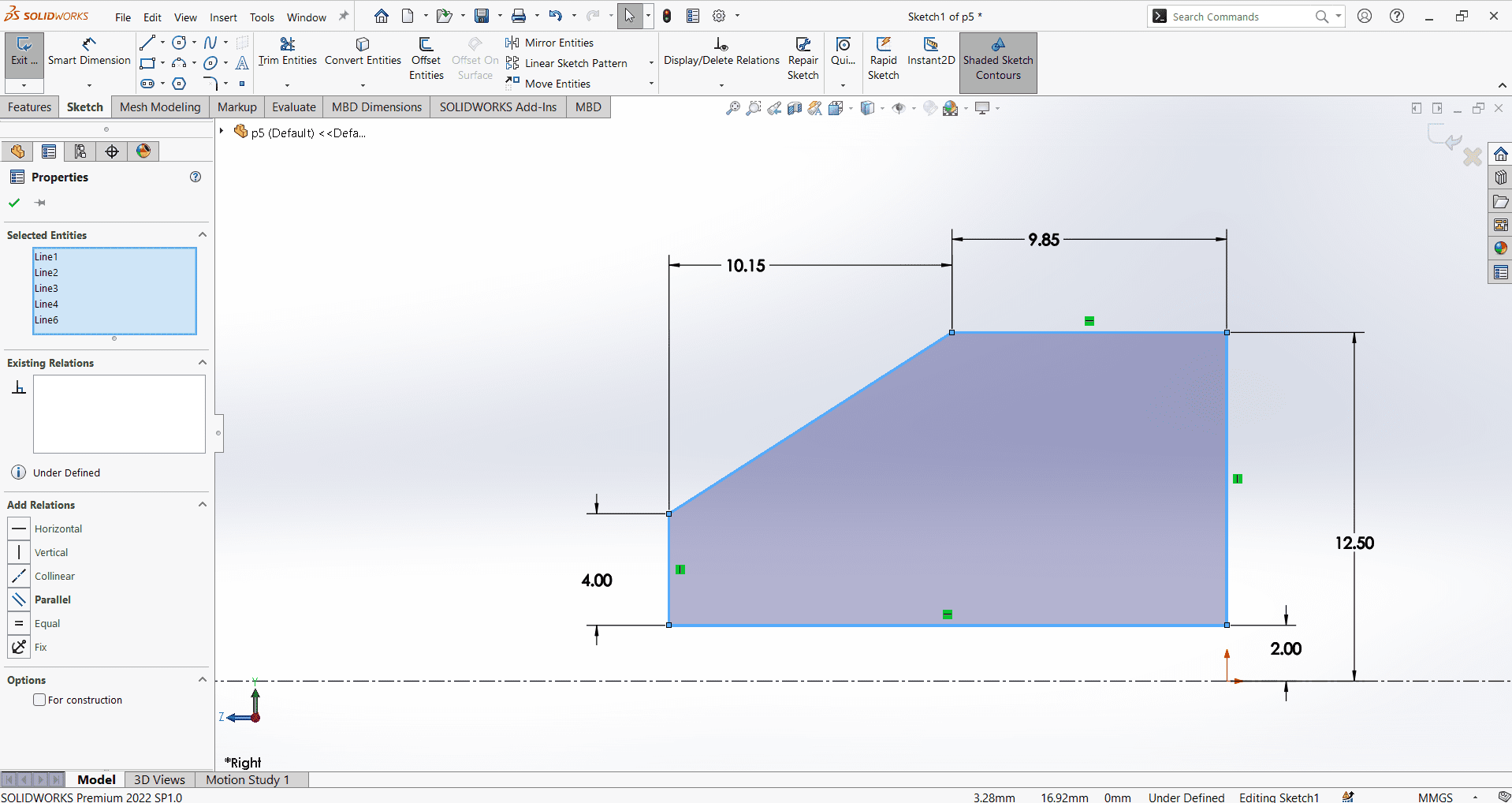

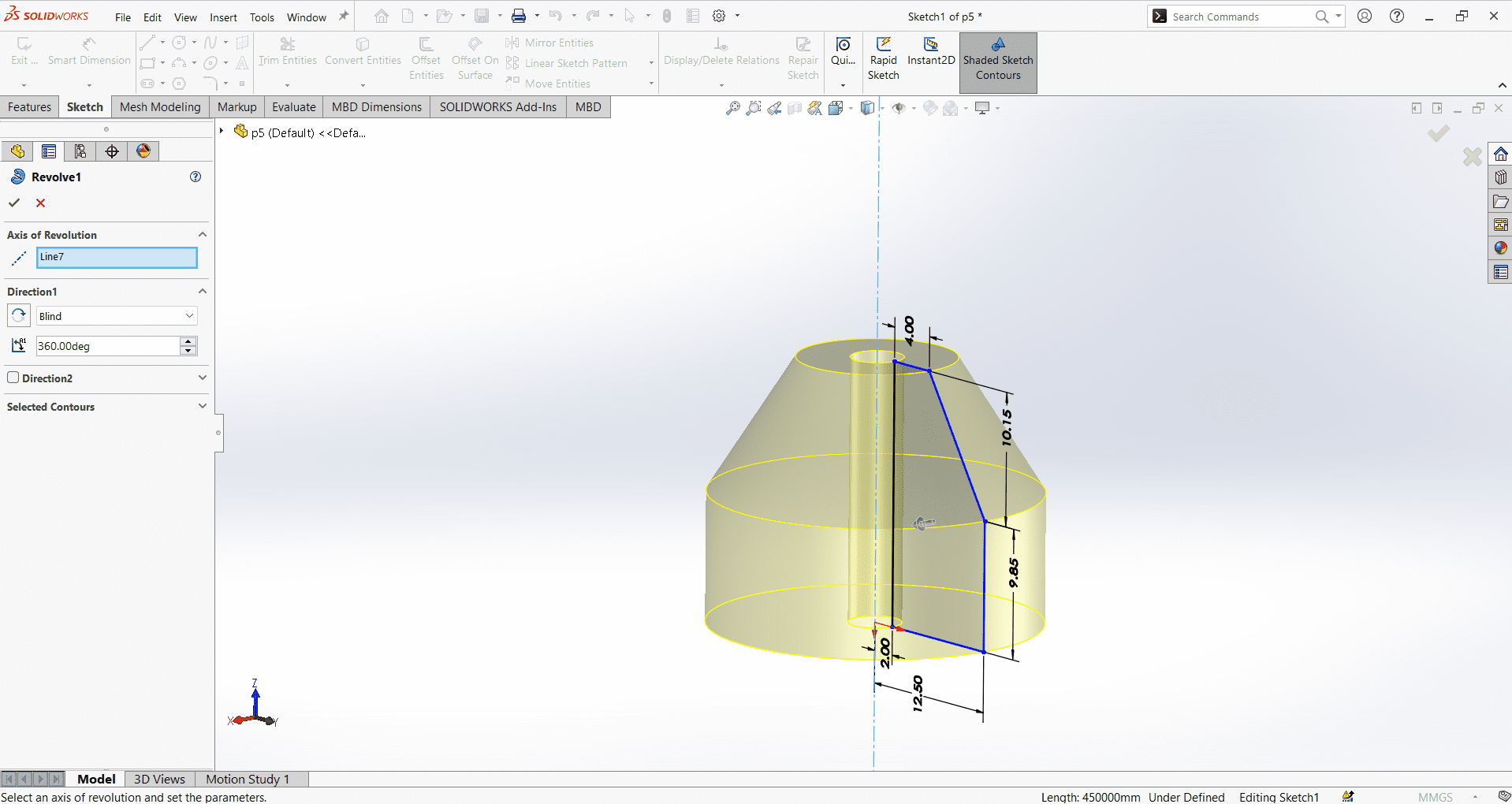

This is the part used for link join.

I used the revolve command for making this part.

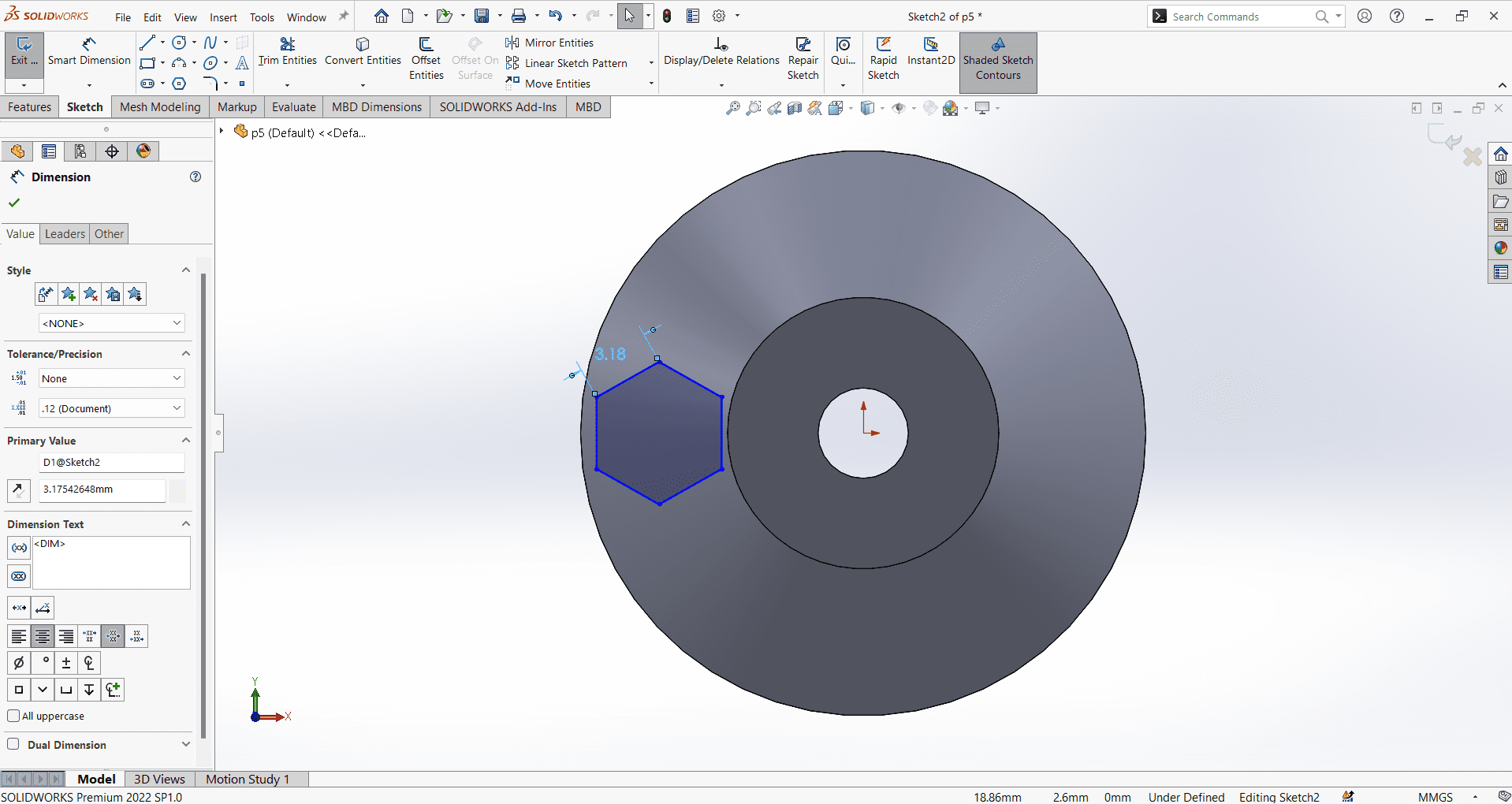

then draw the hexagon on the part.

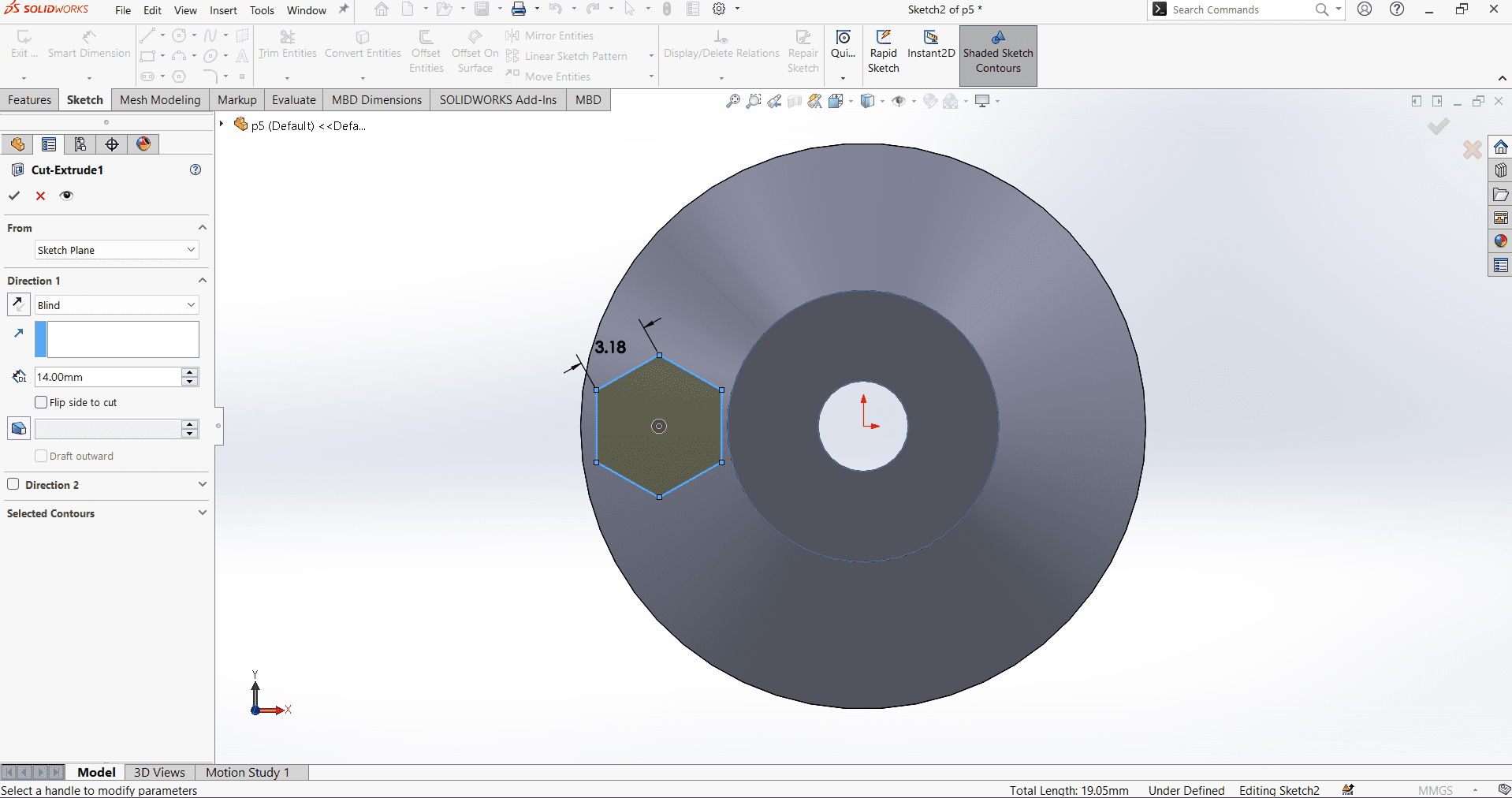

Extrude it.

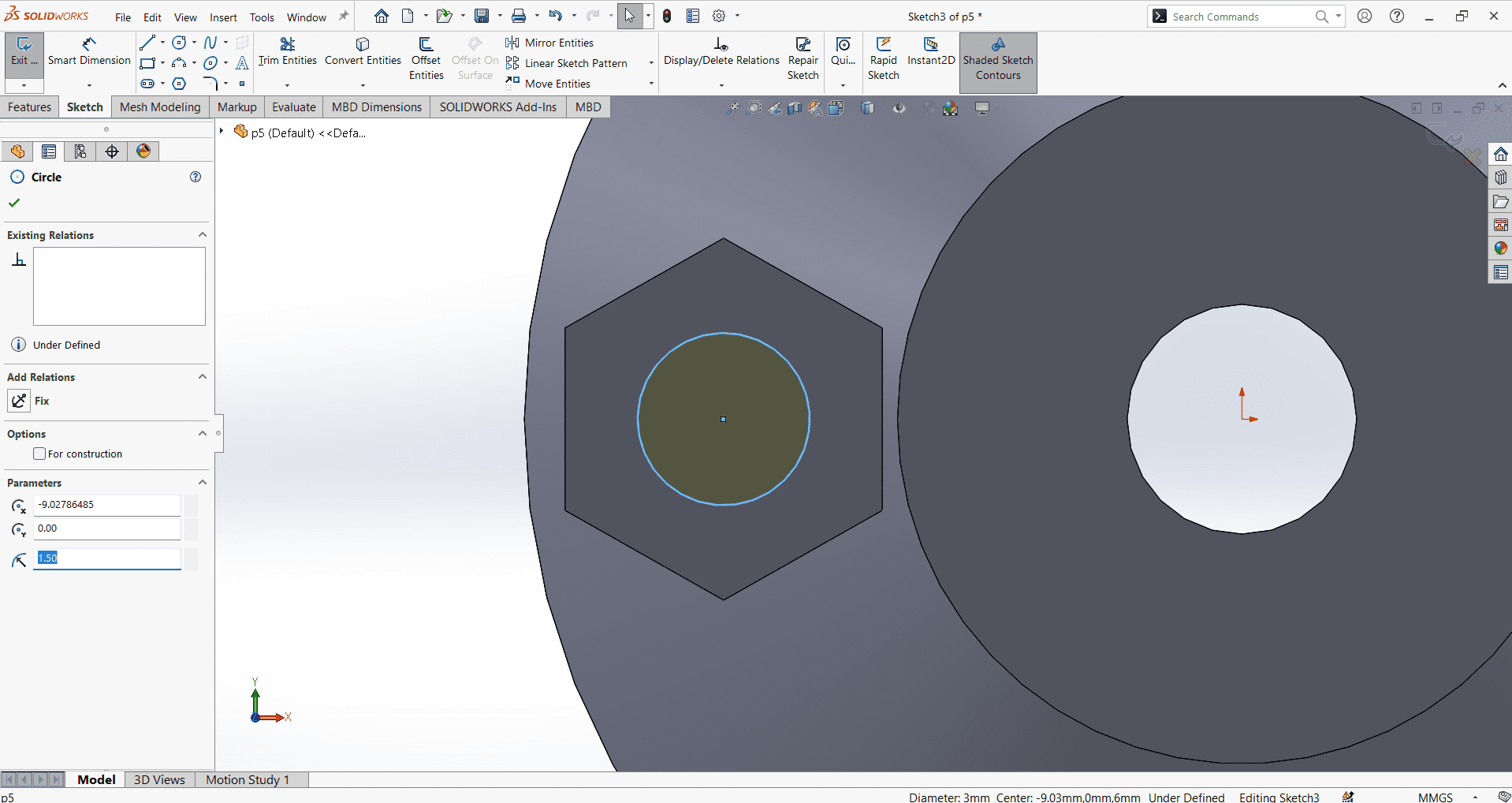

For malking hole draw a circle in hexagon.

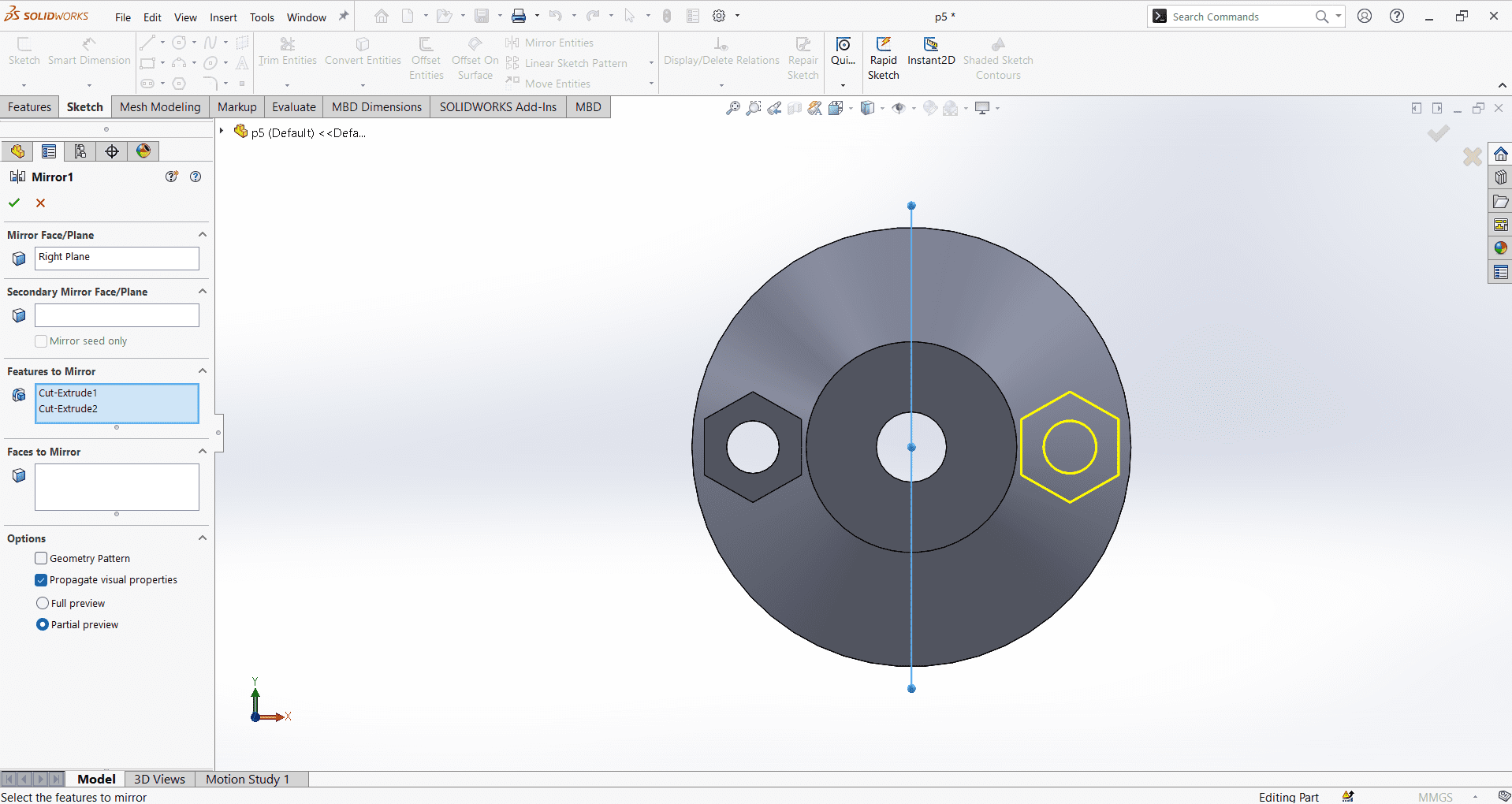

after that i used the mirror command from features option.

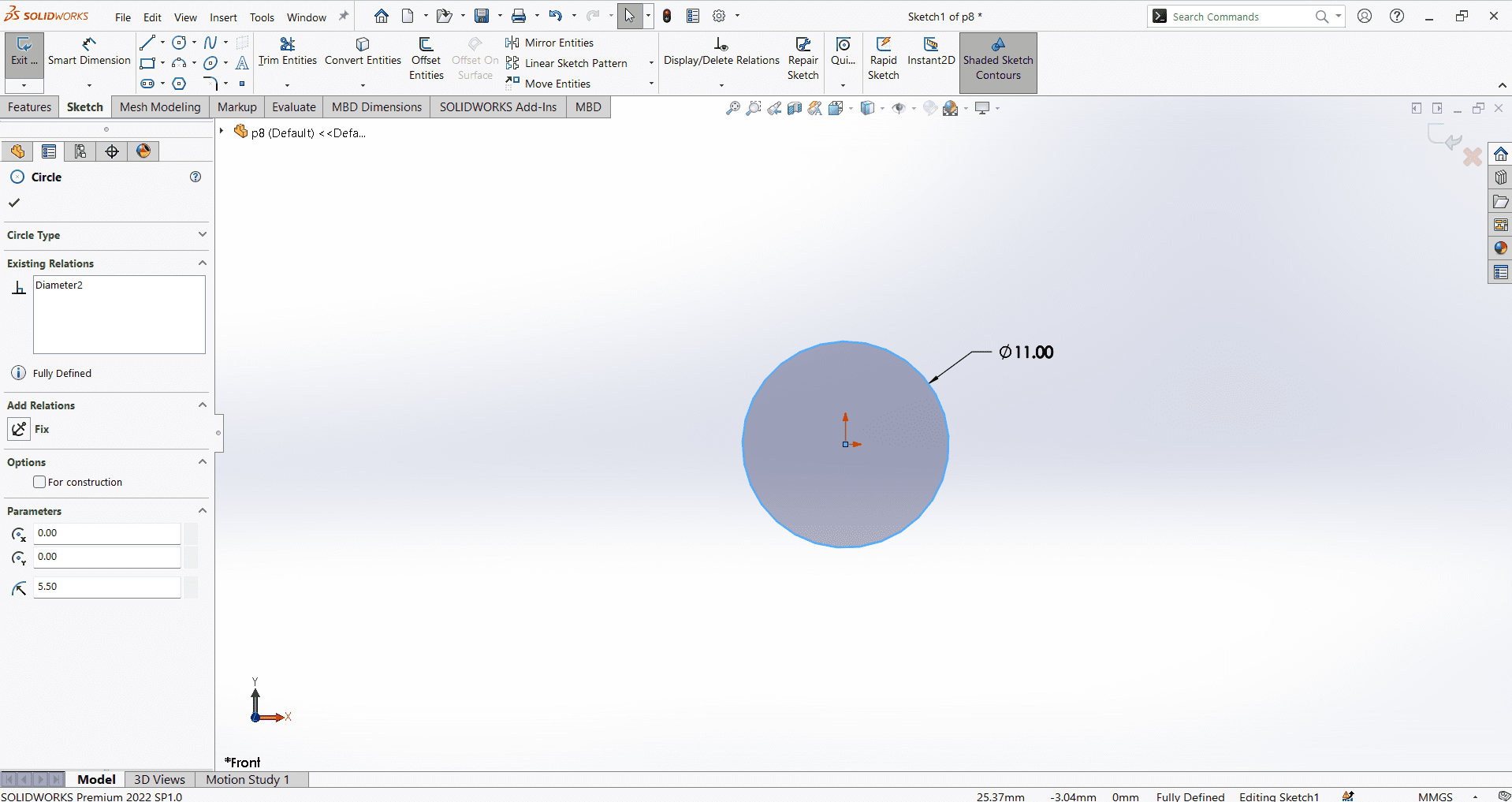

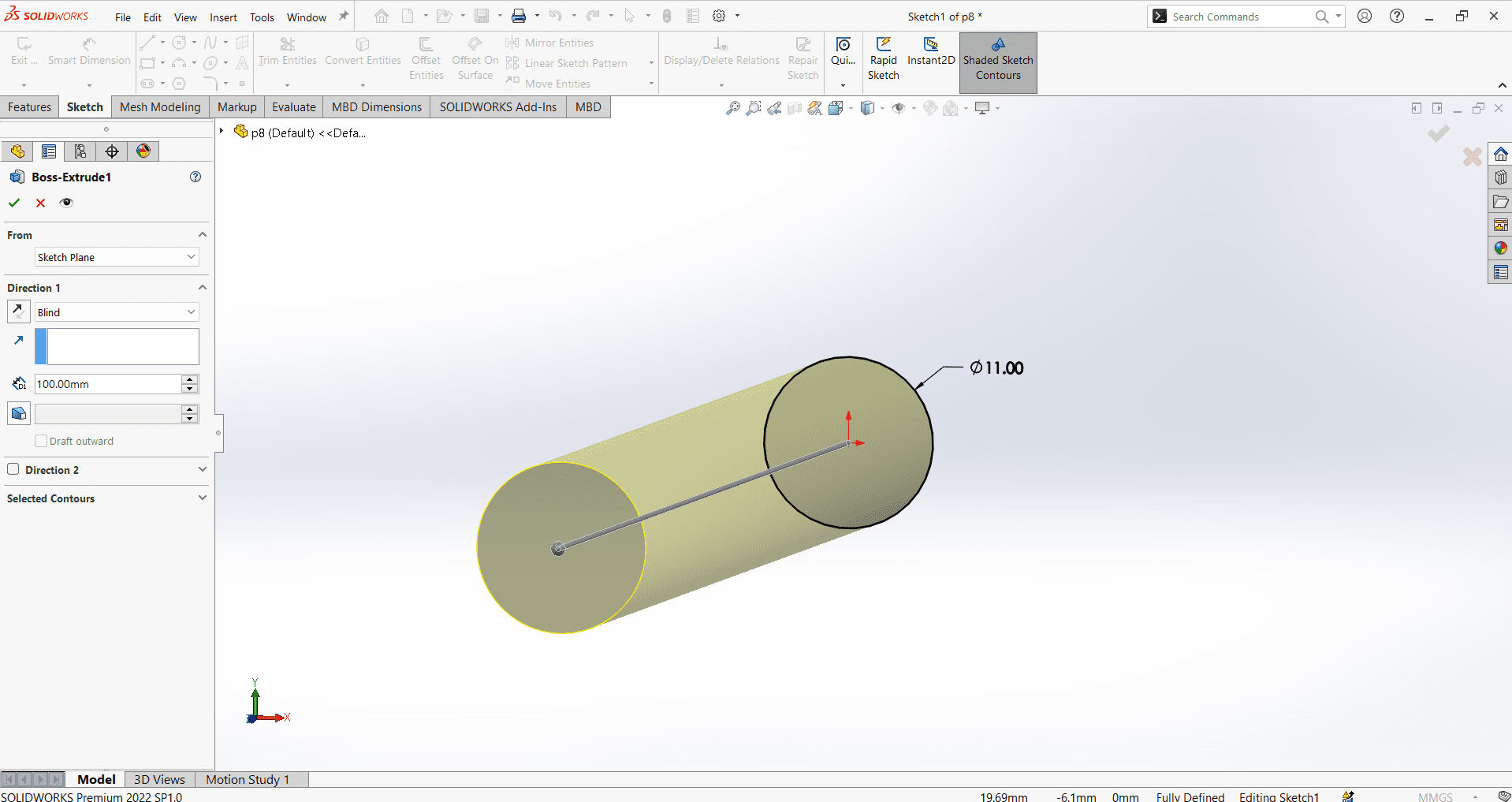

I Drawn a circle for making a small rod.

Extruded it.

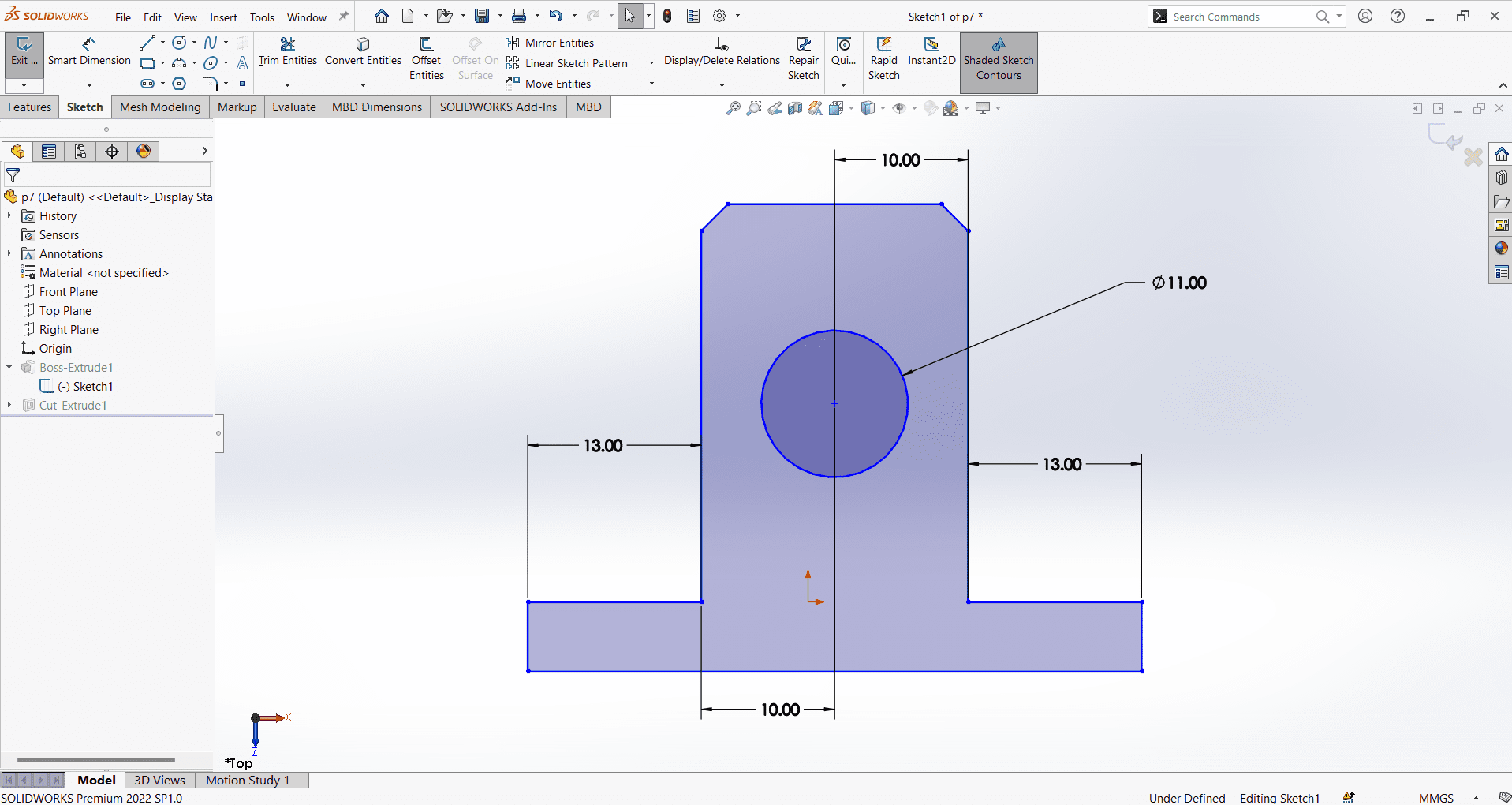

For holding that rod below the upper face of the robot I made a rod holder.

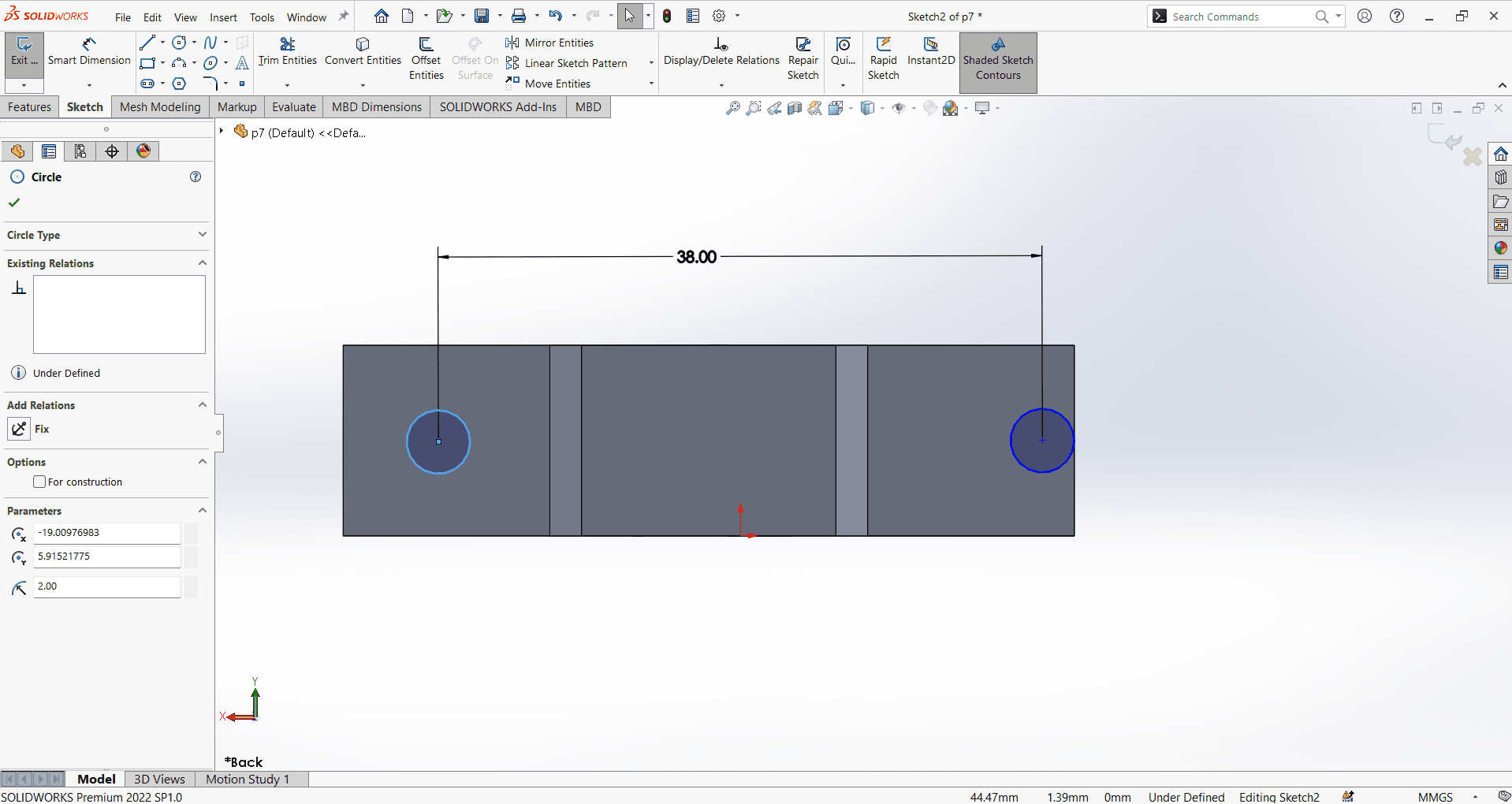

Extruded it, and drawn the circles on it for fixing this on upper face.

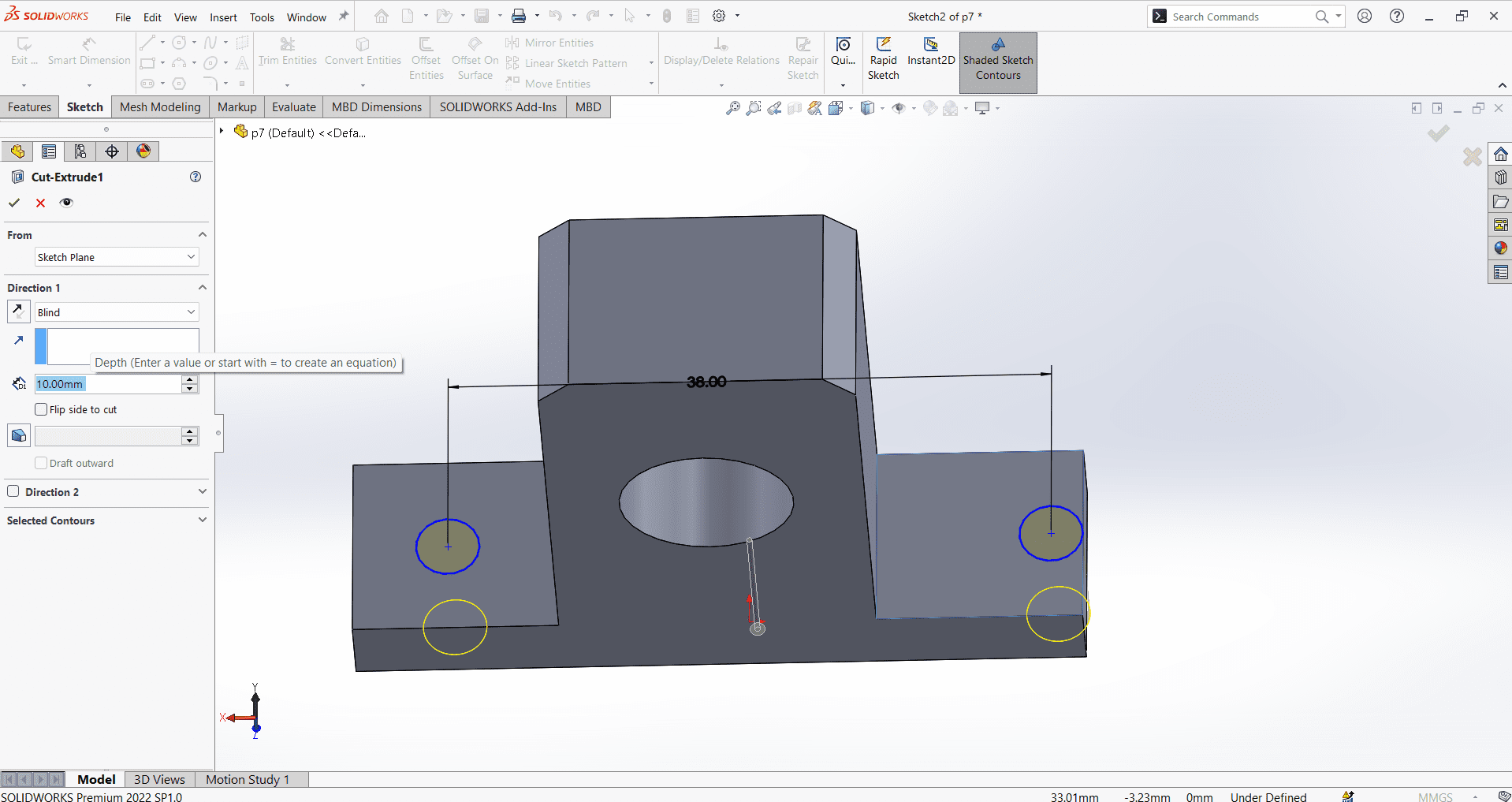

I used the cut extrude command from features option.

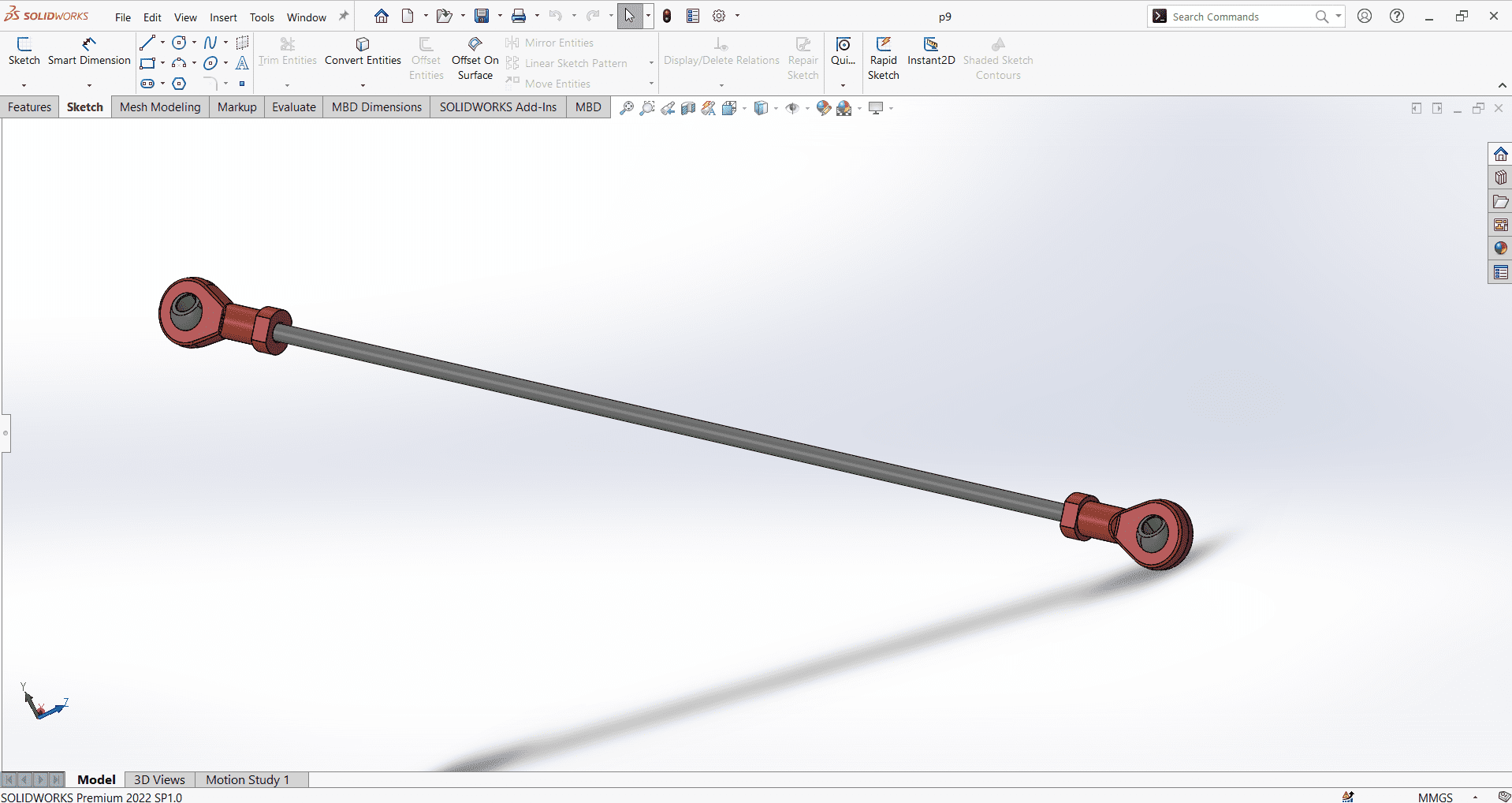

I have assembled the lower link of the delta robot.

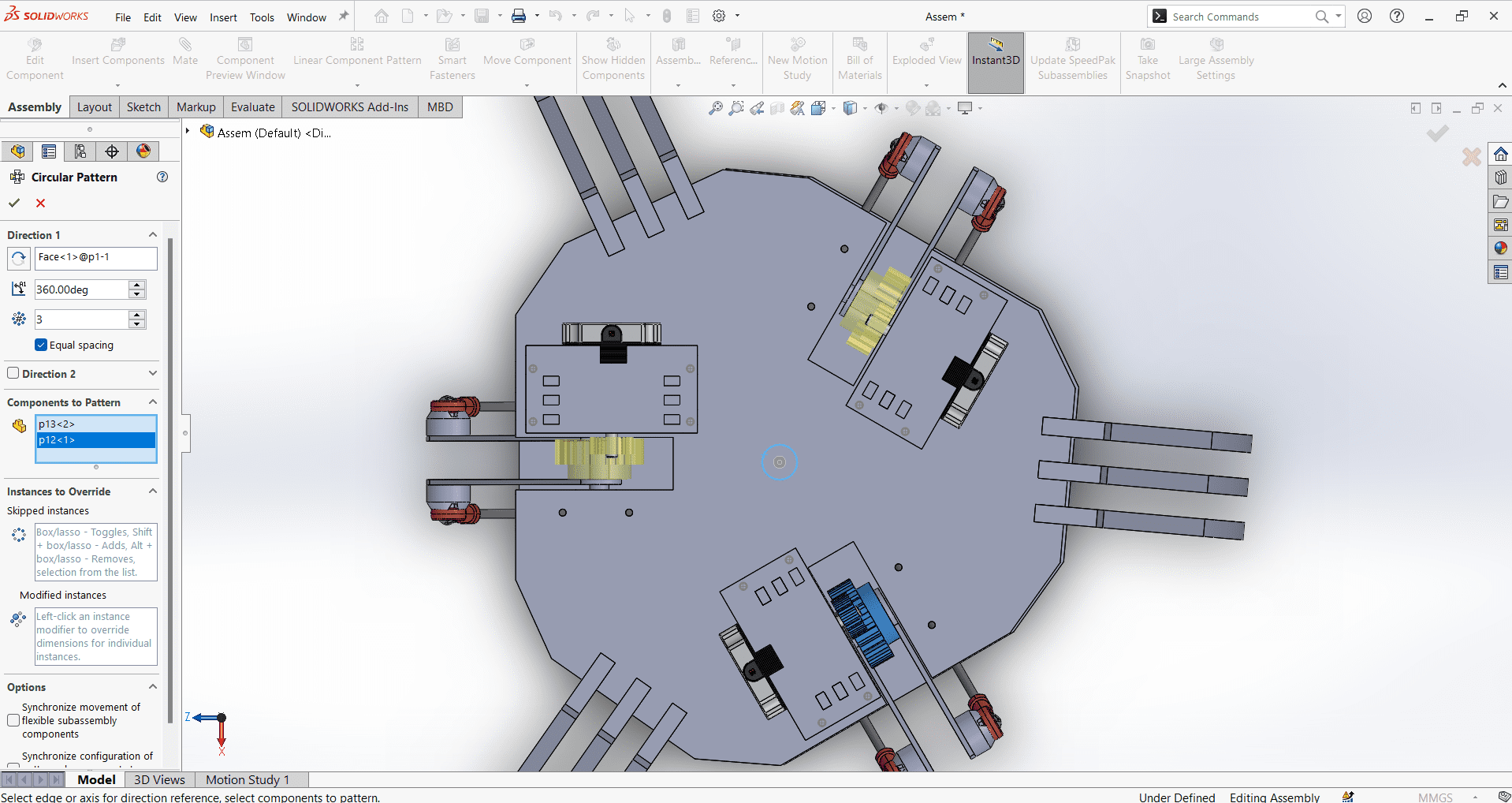

I have taken the 3D model of stepper motor from internet and assembled all the parts using assembly option in Solidworks, I used different mates to join all the parts such as coincident, parallel, concentric, etc.

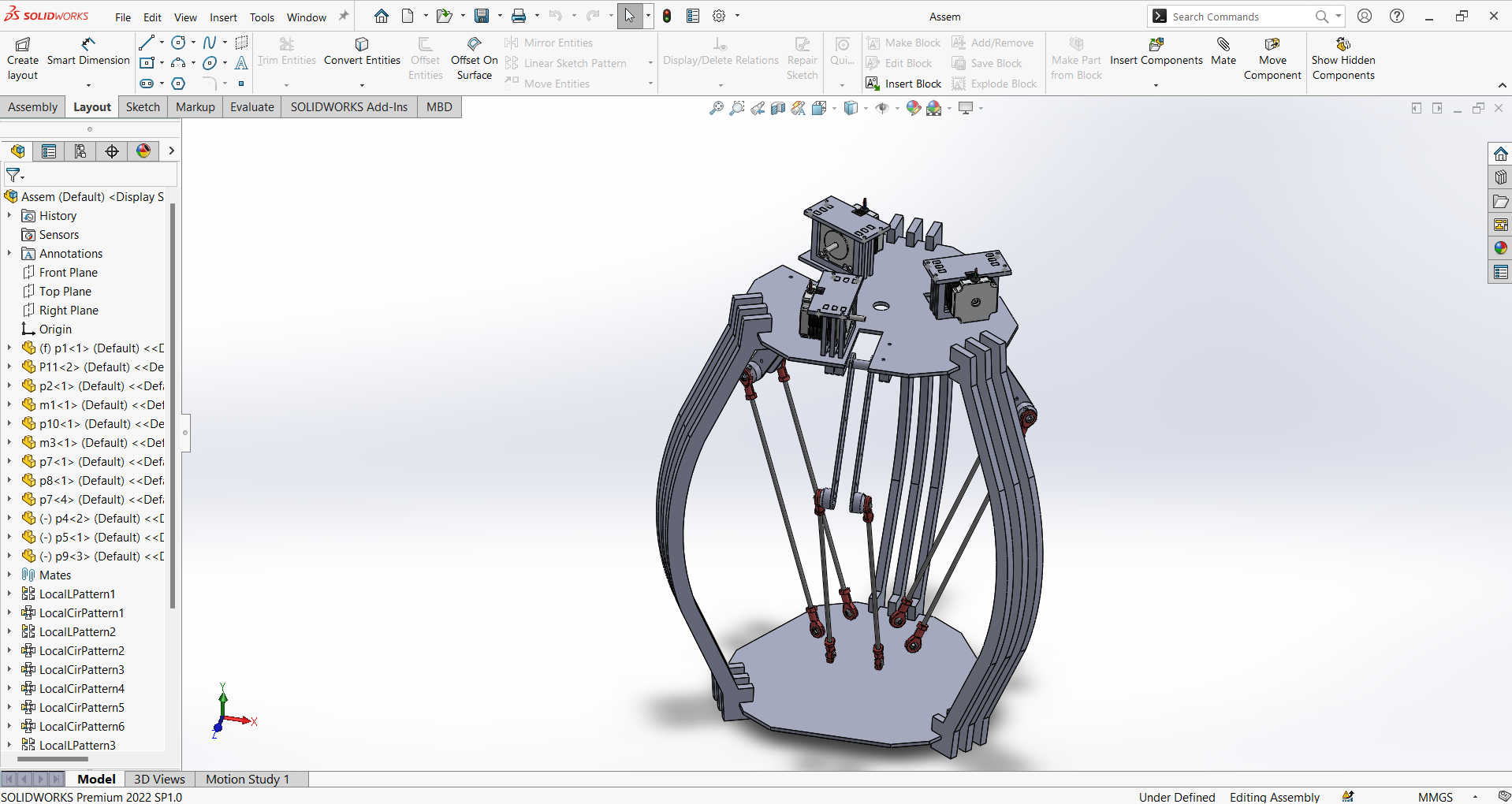

This is the 3D Model of Delta Robot

This is the complete assembled 3d model of delta robot

Delta Robot All Parts.

Delta Robot Assembly.