17. Project Development

Electrospinning machine

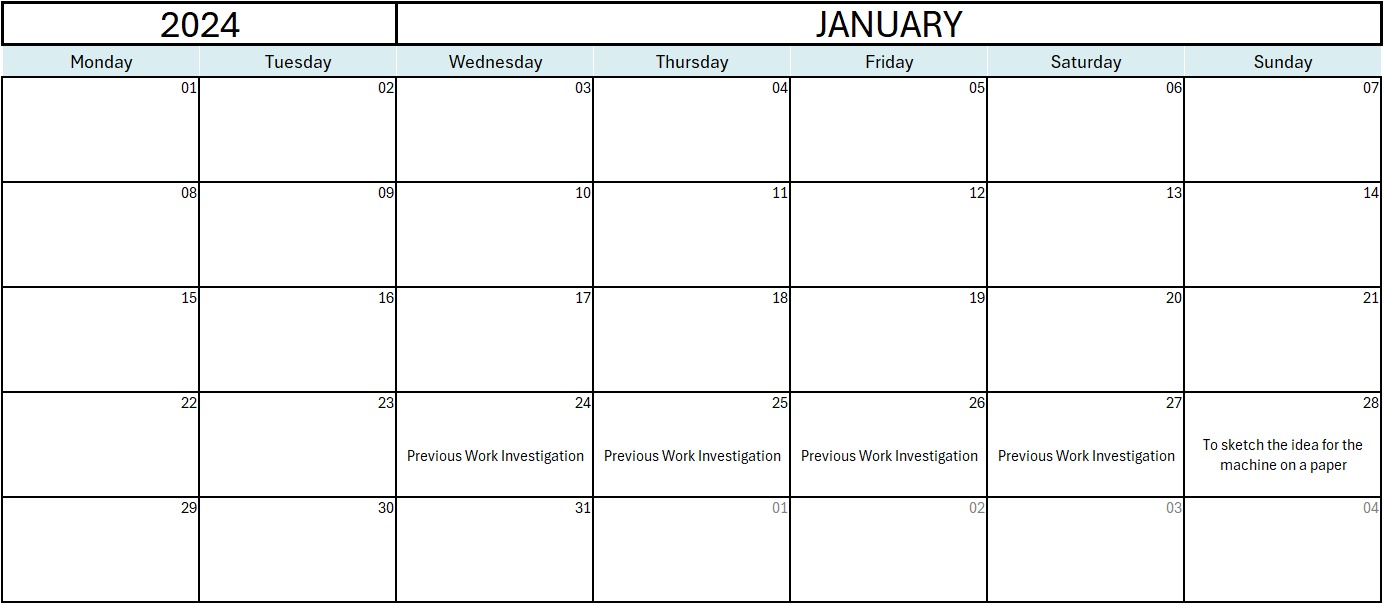

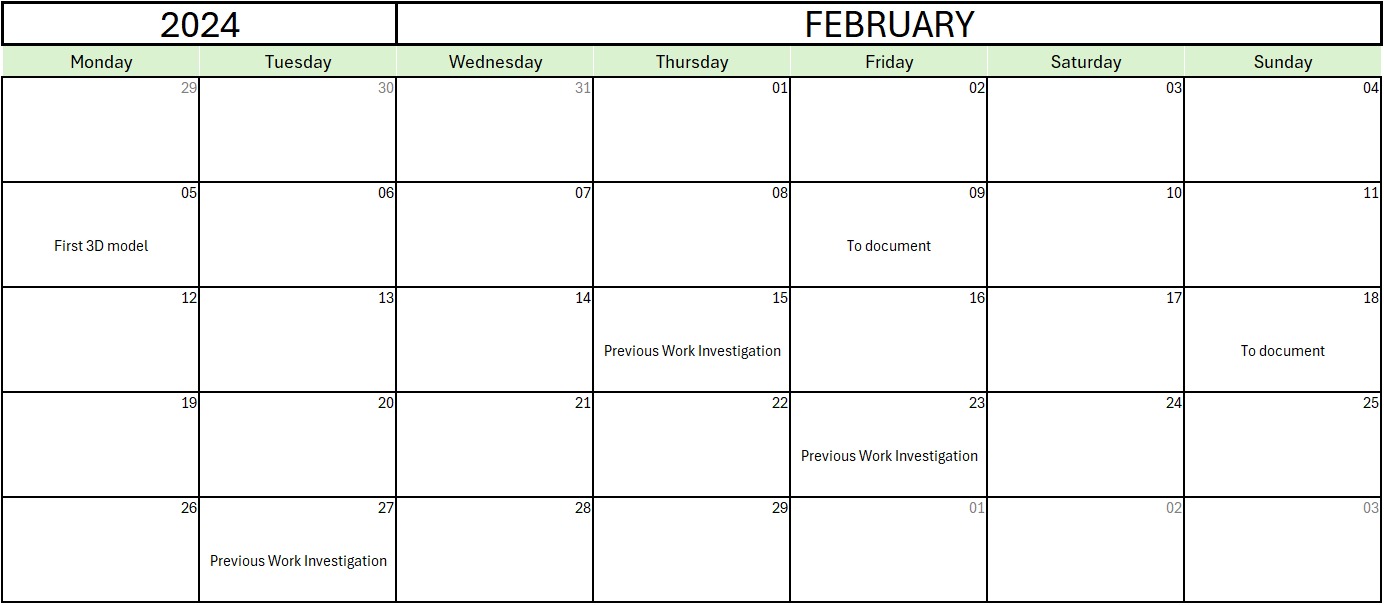

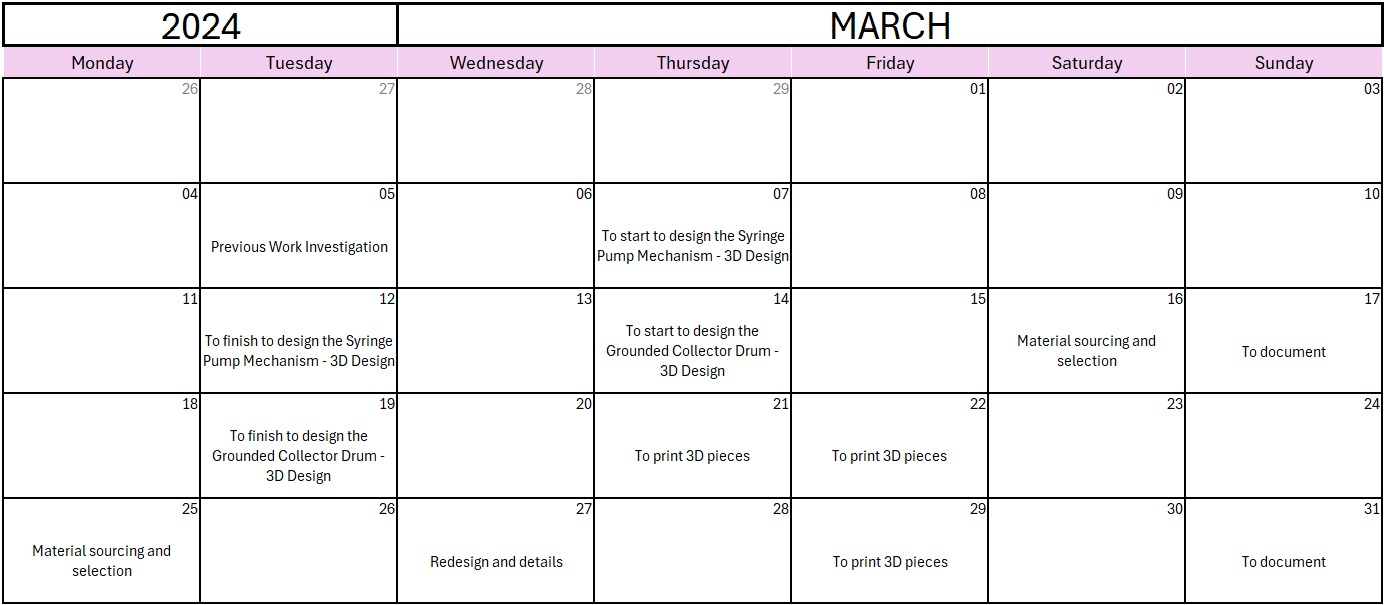

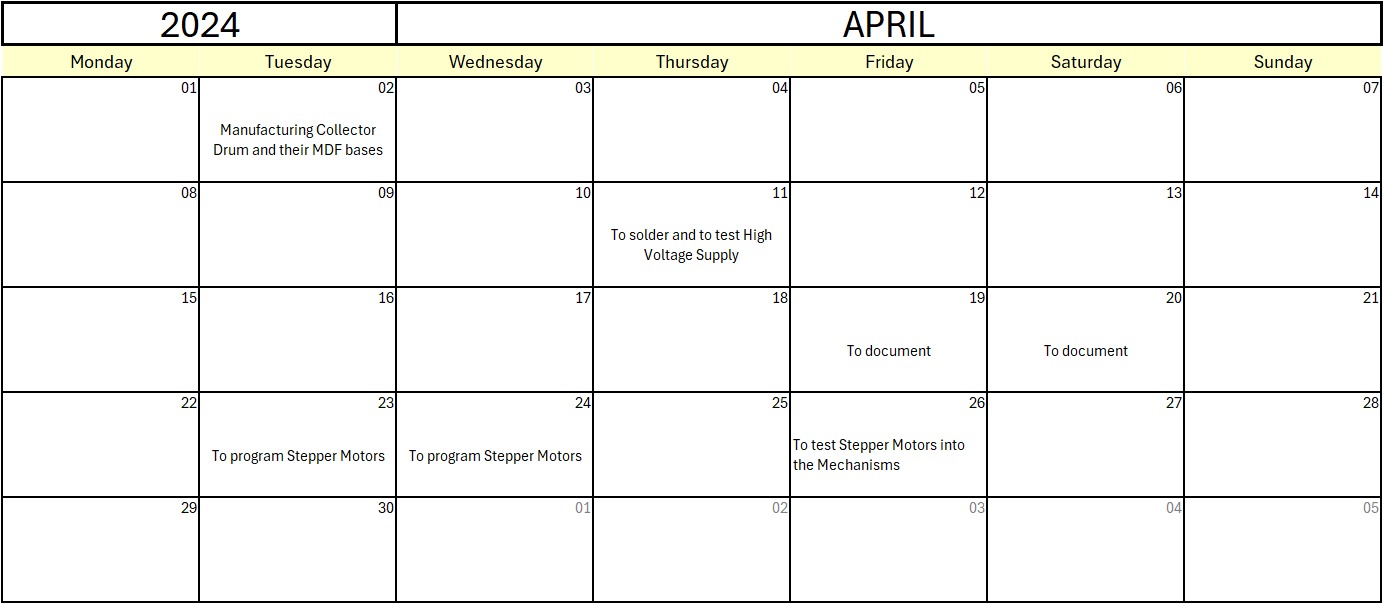

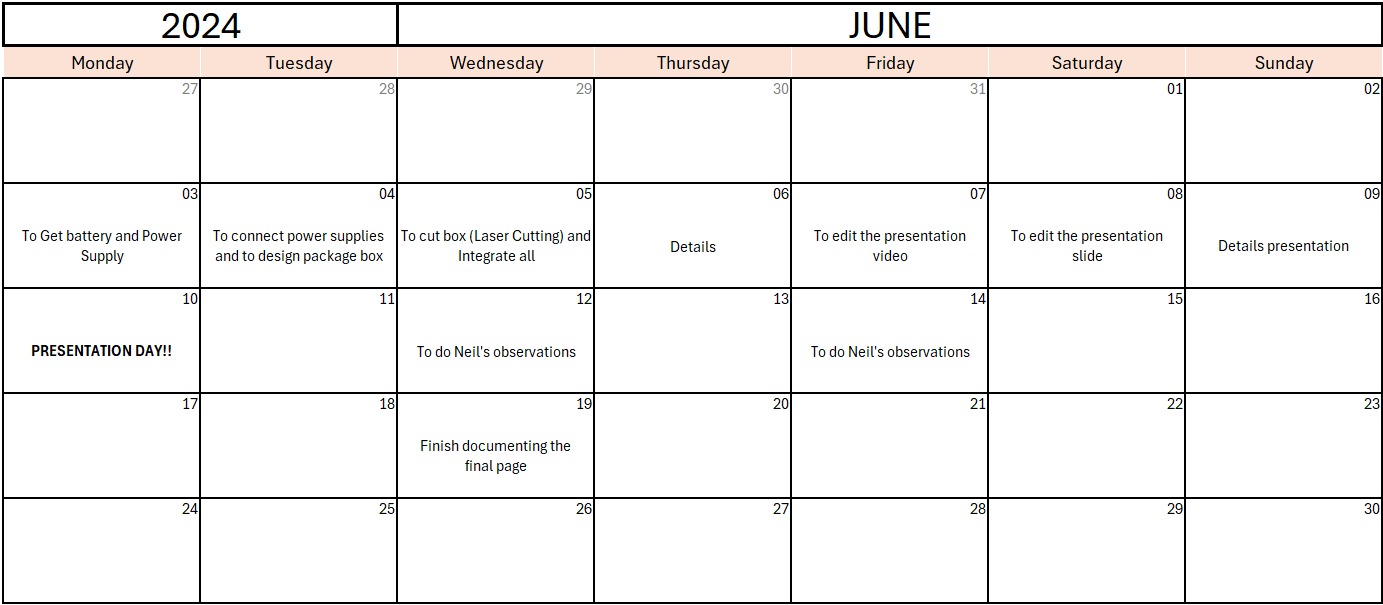

To manage my time, I usually use notes on my phone where I jot down what I'm going to do day by day, organized by hours. However, because the FAB academy required a more rigorous time management approach, I created a calendar in Excel. Honestly, my experience with managing my schedule was quite challenging because sometimes things didn't go as expected, and some semester subjects took more time than I intended to allocate. In fact, I would have liked to have had plenty of time to rest in the end and not be under pressure from deadlines. Nevertheless, I acknowledge that without Excel and my daily phone notes, I wouldn't have been able to manage my time well, and I likely wouldn't have delivered satisfactory results.

Each day's satisfaction came from deleting and updating the calendar at night, realizing I was getting closer to achieving my goal. I appreciate being taught how to better manage my time.

What tasks have been completed?

The syringe pump and the grounded collector drum are working well. The stepper motors are programmed with the XIAO RP2040 microcontroller, and they respond to all three buttons: one button returns the syringe to its home position (running the pump in reverse), one button makes the syringe pump extrude while the collector drum rotates, and one button stops the machine. Plus, the electric arc from the high-voltage source is visible.

What tasks remain?

We need to integrate everything into a box. A 3.7-volt Lipo battery will power the XIAO, and a 12v power supply connected to household electricity will run the motors. It might be a good idea to use bigger buttons for easier interaction with the machine.

What has worked? What hasn't?

Overall, the mechanism is working well, but we need to be careful with the stepper motor drivers. If the potentiometer isn't calibrated correctly, they can get damaged. Update: the high-voltage source got damaged after running continuously for about 30 minutes without a break.

What questions need to be resolved?

Will an old TV flyback transformer be a good replacement for the high-voltage source? Which polymer will work best, and what's the right formulation (proportion of solvent to polymer)?

what will happen when?

When we have a reliable high-voltage source, the polymer will extrude properly. If the 10% ratio mentioned in the literature is correct, then the machine should work without any issues.

what have you learned?

Handle the potentiometers on the motor drivers carefully because they are fragile. If they break, the current can burn out the other components. Likewise, don't force the high voltage supply to avoid issues or burning.