7. Computer-Controlled Machining

Individual assignment

1. Desing

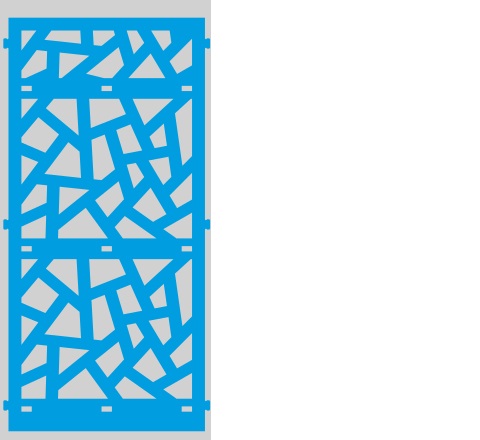

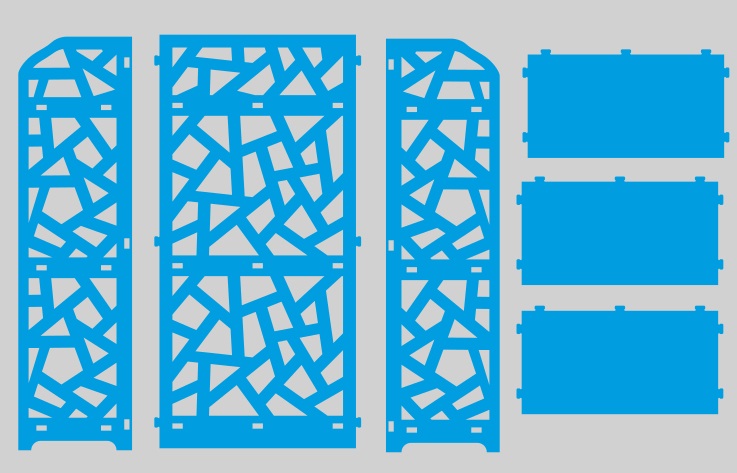

This week, we are tasked with designing a substantial object for CNC cutting. I had the concept of crafting some large shelving units that could accommodate a variety of items, such as books or ornaments. To bring this idea to life, I opted to create two distinct pieces of furniture. In the initial phase, I focused on the side panels of the furniture, incorporating a visually dynamic element by introducing triangular perforations. This not only adds an aesthetic flair but also ensures that the design doesn't appear overly flat or mundane. The deliberate use of these geometric shapes contributes to a more engaging and contemporary look.

Moving on to the central section, I maintained the same design language to create a cohesive and harmonious overall appearance. Consistency in the design elements ensures that the entire piece feels integrated and thoughtfully crafted. The triangular perforations are continued here, providing a thematic link between the different components of the furniture. Finally, in the last phase of the project, I dedicated attention to constructing the supports that would bear the weight of the objects placed on the shelves. These supports are strategically positioned to not only provide stability but also to enhance the visual appeal of the overall structure. The end result is a set of furniture pieces that not only serve a functional purpose but also stand out as visually striking and well-designed elements in any space.

I opted to streamline the process by copying and mirroring the side panel, effectively creating the counterpart for the opposite side of the furniture piece. This not only ensures uniformity in the overall aesthetic but also simplifies the manufacturing process by leveraging the same design elements.

I decided to duplicate the supports, resulting in a total of three sturdy supports for the entire furniture ensemble. This strategic replication of supports not only reinforces the stability of the shelving units but also introduces a sense of visual rhythm and repetition, contributing to the overall cohesion of the design.

With the design finalized, the next crucial step in the creative process was the actual fabrication. To bring the envisioned furniture pieces to life, I employed the precision capabilities of the Asia Robotica shop-1325 , a powerful CNC cutting tool. This advanced machinery ensures accuracy and efficiency in translating the intricate design into tangible components. The chosen material for this project was a robust 20mm plywood. This choice not only imparts durability to the furniture but also offers a versatile canvas for intricate detailing during the CNC cutting process. The thickness of the triplay provides structural integrity, ensuring that the final pieces are not only aesthetically pleasing but also robust and long-lasting.

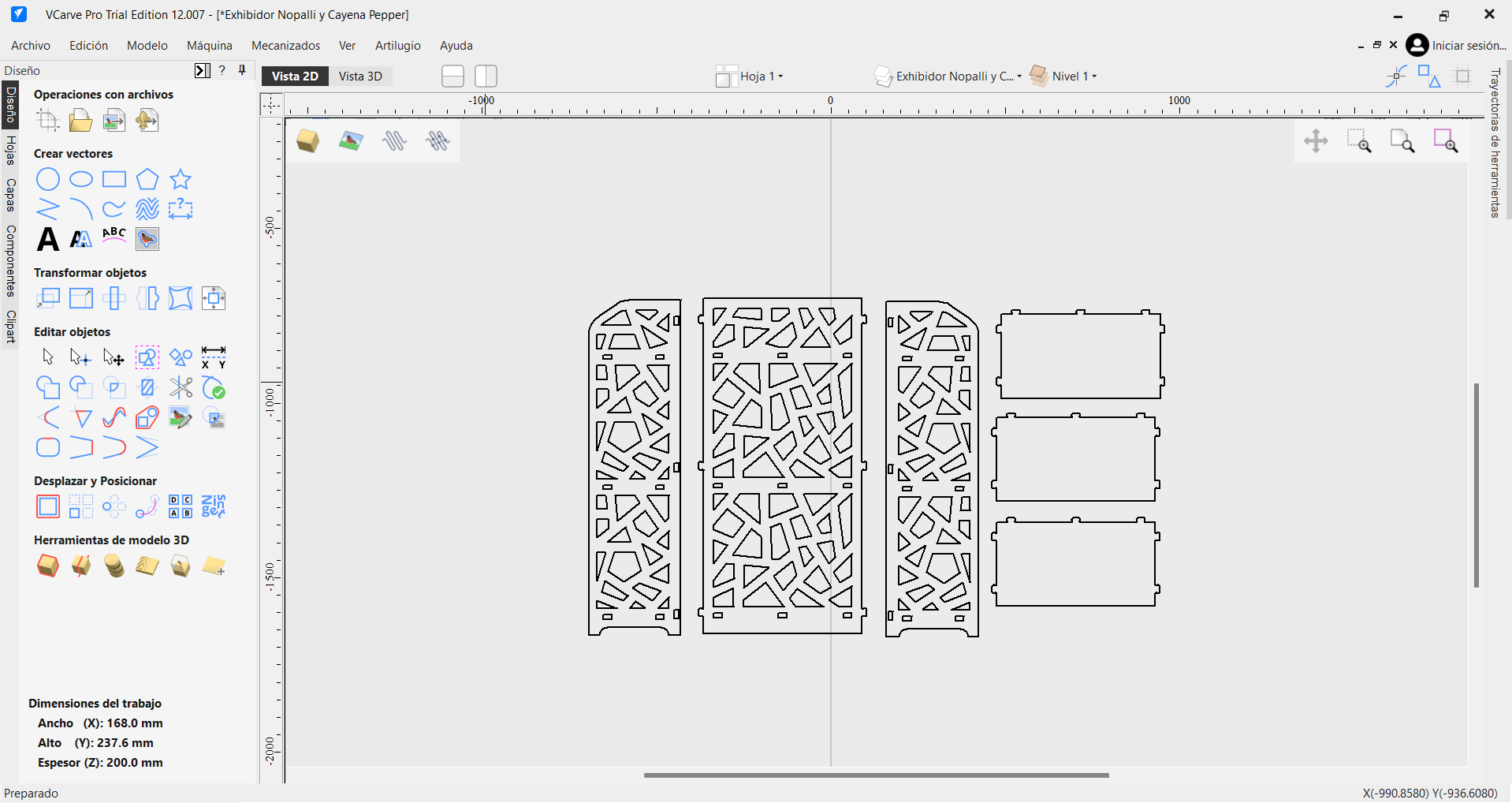

The program i used to set the parameters to the CNC was Vcarve. I import the svg and set the cutting parameters.

-

This were the parameters I used:

- I set the CNC to use de 4mm tool.

- CNC cut a deep of 20mm.

- The spindle speed was 10,000rpm.

- I used taps in the inner cut so the wood can stay in place while the outside is getting cut.

Here is a video of the cutting process.

The final step in bringing the envisioned furniture to fruition was the assembly process, culminating in a completed and functional piece. The carefully cut components from the CNC machine were meticulously aligned and joined together, showcasing the seamless integration of design and craftsmanship.