Week 7

Computer Controlled Machining

- Do your lab's safety training

- Test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

Computer Controlled Machining

- Lab´s safety training -

The use of CNC machines carries various hazards because, for its operation, high-speed rotational tools with sharp edges, high-voltage and heavy parts are used.

Proper attire:

- Impact-proof safety goggles, as the chips can be projected because of the operations.

- Noise protection headset, as the noise can get up to 70dBA near the machine.

- 100% cotton Lab coat/overalls.

- No hanging accessories like jewelry or garments.

- NO Shorts.

- Safety boots/shoes that have toe protection from falling heavy parts.

- Breathing mask, as the operations can project fine dust depending on the material being processed.

When the machine is operational:

- The operator must remain attentive and close to the machine when it is working.

- Do not wear gloves during the operation of the machine.

- The closet door must remain closed while the machine is on.

- The machine must be operated exclusively by trained staff.

- Do not put your hands near the cutting area while the machine is working.

During Operation to prevent dust inhalation. The vacuum extractor is used for picking up all the dust and chips after the process has ended. For turning it On/Off a switch is used.

It is important to not touch the green round button next to it, as it disables the X-axis for using the rotary add-on. During the vacuuming one must be careful to not touch any grounded surface as the dust generates a great amount of static electricity. Before starting the operation, a thorough inspection of the machine must be done, taking into consideration the next basic knowledge.

- The floor must be clean and free of any chips or residues from material to avoid falls or slippery floors.

- Keep distance from the machine as it can move very fast in any direction.

- Remember all automated machines can start suddenly, as long as the emergency stop is not activated.

- There are high-voltage components at use in this machine.

- Make sure the cutting tool is tight and centered.

- Make sure the material is well positioned, fixed and there are no obstacles in the trajectory of the cut, like clamps, nails or even heavy knots.

- Machine -

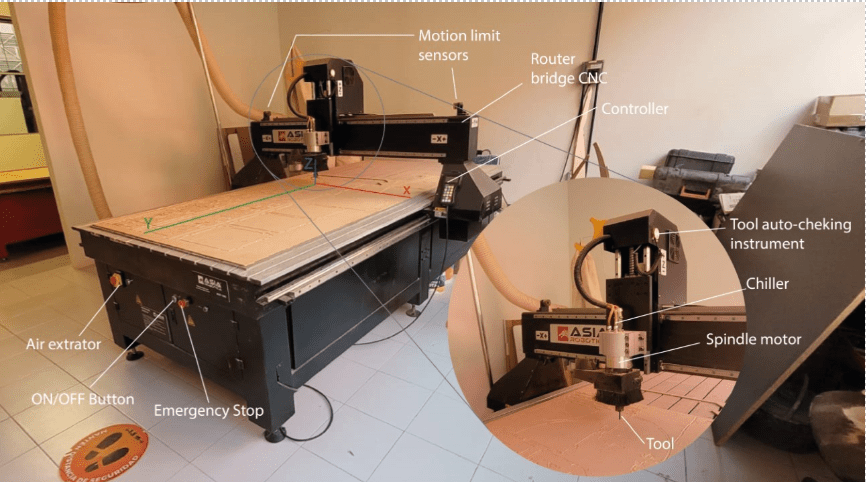

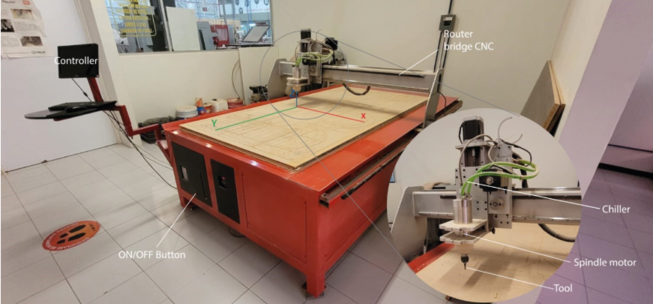

Here in Fab Lab Puebla we have two big CNC routers.

| Attribute | Details |

|---|---|

| URL | https://www.asiarobotica.com/router-cnc-shop-pro |

| Machine | Asia Robotica shop-1325 |

| Dimensions | 3x1.8x1.7mts |

| Motor Power | 4 HP at 24000 rpm´s |

| Power Supply | 220v/2F/3.5KW |

| Material Fixtures | Clamps |

| Attribute | Details |

|---|---|

| URL | Not Given |

| Machine | Generic Made by University |

| Dimensions | 3x1.8x1.7mts |

| Motor Power | 4 HP at 24000 rpm´s |

| Power Supply | 220v/2F/3.5KW |

| Material Fixtures | Nails |

- Materials -

| Material | Description | Machining Recommendations |

|---|---|---|

| ABS | Durable, strong plastic used widely across industries. | Use sharp, single-flute tools for a smooth finish. |

| Acrylic | Clear, plastic material with excellent clarity and weather resistance. | Use carbide tools and coolant to prevent melting or cracking. |

| ALUCOBOND / DIBOND ® | A composite panel with two aluminum sheets bonded to a non-aluminum core. | Use sharp tools with high cutting speed for clean edges. |

| Aluminum | Lightweight, corrosion-resistant metal used in various applications. | Use sharp, multi-flute cutters and a coolant to prevent buildup. |

| Copper | Highly conductive metal used in electrical components. | Use sharp, single or double-flute cutters for clean cuts. |

| Estirene | A brittle, transparent plastic used in model making and prototypes. | Ensure proper clamping and use sharp tools to avoid chipping. |

| Tin | Soft, malleable metal often used as a coating for other metals. | Use lower feed rates to prevent galling on the cutter. |

| Solid Wood | Natural wood, used for its aesthetic and structural properties. | Use sharp, two-flute spiral bits for efficient material removal. |

| Softwoods | Lighter, less dense wood types like pine or cedar. | Use upcut spirals for chip removal and to prevent fraying. |

| Hardwoods | Denser woods like oak or maple, known for durability. | Use downcut spirals for a smoother surface finish. |

| Plywood | Engineered wood made from thin layers of wood veneer. | Use compression cutters to prevent delamination. |

| MDF | Engineered wood product made by breaking down hardwood or softwood residuals. | Use high-speed steel (HSS) or carbide bits to reduce dust. |

| Veneered MDF | MDF covered with a thin layer of real wood veneer. | Use downcut spirals for a clean cut that won't tear the veneer. |

| MDF Laminate | MDF with a plastic laminate coating on one or both sides. | Use carbide-tipped bits for smooth cuts through the laminate layer. |

| Melamine over agglomerate | A composite material of wood chips bonded together, covered with a melamine layer. | Use a triple-chip grind (TCG) blade for clean cuts without chipping. |

| Nylon | Durable, synthetic polymer with high strength and flexibility. | Use single or double flute end mills at high speeds to prevent melting. |

| OSB | Oriented strand board, a type of engineered wood similar to particle board. | Use carbide-tipped blades for durability and to avoid wear. |

| Non-ferrous metals | Metals that do not contain iron in appreciable amounts, like aluminum and brass. | Use lubrication and specific non-ferrous geometry cutters. |

| Solid polycarbonate | Durable, transparent plastic with high impact resistance. | Use sharp tools and coolants to prevent overheating and melting. |

| Polyethylene | Flexible, durable plastic used in a wide range of products. | Use sharp, single-flute end mills for clean cuts. |

| PVC (solid/foamed) | Durable plastic used in construction and piping. | Use a low flute count bit and cooling techniques to prevent melting. |

| Bakelite | An early plastic made from phenol and formaldehyde, known for its heat resistance. | Use carbide tools at moderate speeds to avoid chipping. |

| Resins | Synthetic or natural compounds often used in composites and coatings. | Use sharp, high-speed tools for a smooth finish. |

- Runout Test -

For this test, a Starrett gauge was used for measuring the concentricity of the spindle/cutting tool, first with the spindle off, then turned on. This measuring gauge has a range of 0.01mm and after the tests, no variation was found.

For the characterization process, the chart from Shopbot: Feeds and Speeds was consulted:

| Name | SB# | Onsrud Series | Cut | Chip Load per leading edge | Flutes | Feed Rate (ips) | Feed rate (ipm) | RPM | Max Cut |

|---|---|---|---|---|---|---|---|---|---|

| 1" 60 degree Carbide V cutter | 13648 | 37-82 | 1 x D | .004-.006 | 2 | 2.4-3.6 | 90-126 | 18,000 | |

| 1/4" Straight V Carbide Tipped End Mill | 13642 | 48-005 | 1 x D | .005-.007 | 1 | 1.5-2.1 | 90-126 | 18,000 | |

| 1/2" Straight V Carbide Tipped End Mill | 13564 | 48-072 | 1 x D | .005-.007 | 2 | 3.0-4.2 | 180-252 | 18,000 | |

| 1/4" Upcut Carbide End Mill | 13528 | 52-910 | 1 x D | .005-.008 | 2 | 3.6-4.8 | 180-252 | 18,000 | |

| 1/4" Downcut Carbide End Mill | 13507 | 57-910 | 1 x D | .005-.008 | 2 | 3.6-4.8 | 180-252 | 18,000 | |

| 1/4" Upcut Carbide End Mill | 1108 | 65-025 | 1 x D | .004-.006 | 1 | 1.2-1.8 | 18,000 | ||

| 1/8" Tapered Carbide Upcut Ball End Mill | 13636 | 77-102 | 1 x D | .003-.005 | 2 | 1.8-3.0 | 18,000 | ||

| 1-1/4" Carbide Tipped Surfacing Cutter | 13555 | 91-000 | 1/2-3/4 x D | 2 | 200-600 | 12,000-16,000 | 1/8" |

Amana Tool offers a ChipLoad per tooth properties for calculating the Feed Rate of the tool setup. Amana Tools

- Design Rules -

As the tools an only create a rounded hole when they cut/plunge, it is necessary to add “dogbones" or “T-bones” which are a slight modification of the mortise, the hole where the assembly is tight and well adjusted.

This kind of assembly is called “finger joint” and its done using both t-bones and dog-bones. There are also different operations involved:

- Pocketing. This operation removes the whole area inside of a closed form up to a certain depth.

- Cutting. This operation moves the cutting tool over a trajectory up to a certain depth. These kind of cuts can be done inside of the form, outside of the form or over the line, so the software calculates the proper distance between the cutting tool and the vector.

Another interesting element included in the cut are “tabs” which hold the piece in place when the cut is done so it doesn’t get projected.

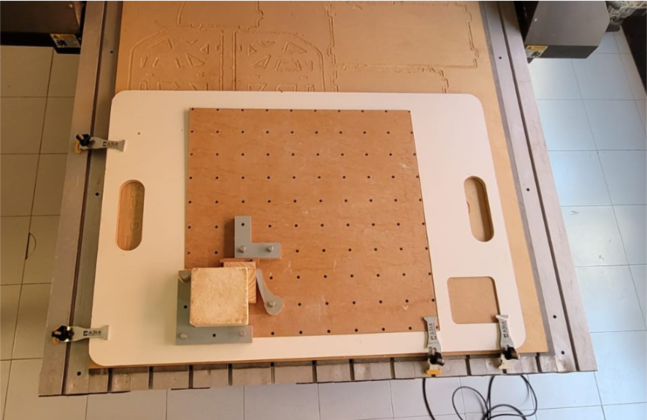

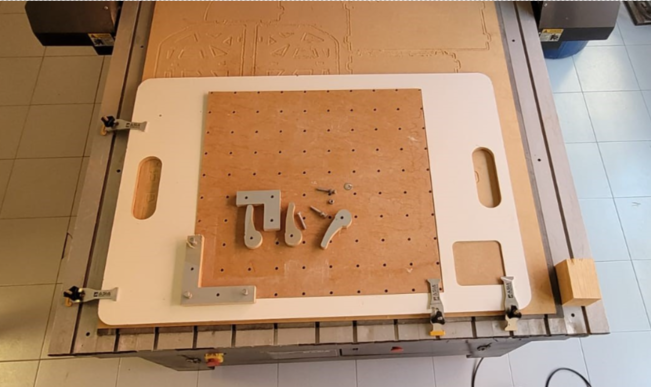

- Fixture -

The material is fixed with a clamp that passes through the different canals in the machine bed.

There is also a different kind of fixture system with threaded holes for versatility.

This table allows for double-sided cutting as the x, y and z reference points can remain still, and for securing difficult geometries.